Coke pit exhaust gas collecting and purifying system

A waste gas collection and purification system technology, applied in gas treatment, chemical instruments and methods, steam/steam condensers, etc., can solve the problems of foggy coke pits, affecting the surrounding environment, coke powder, water vapor fugitive emissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

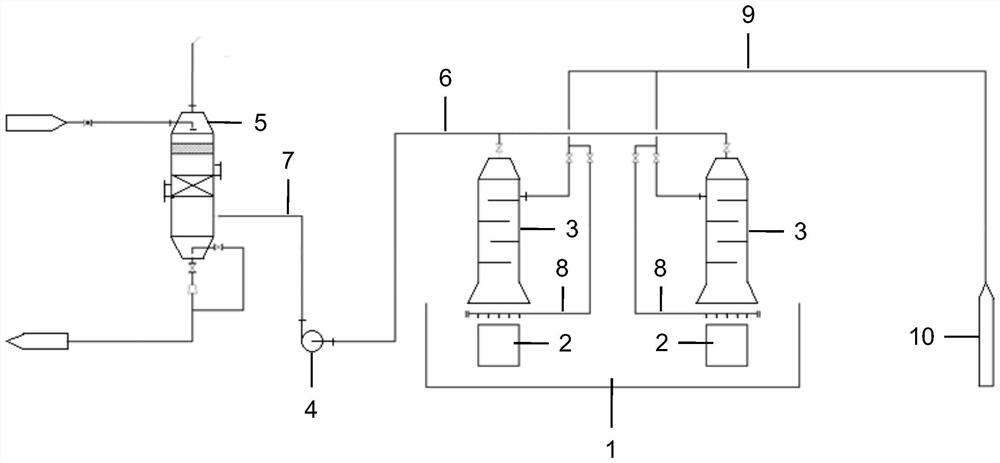

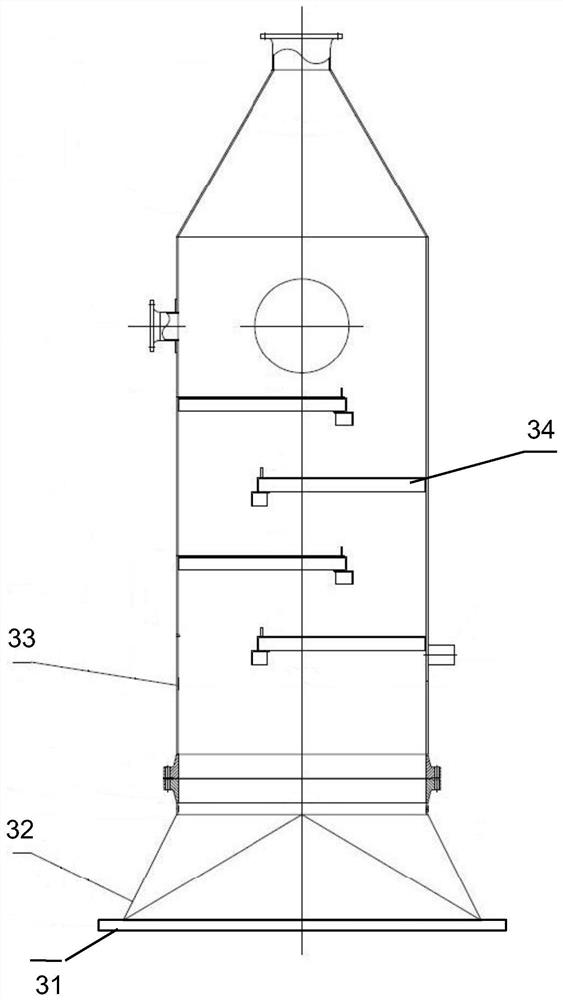

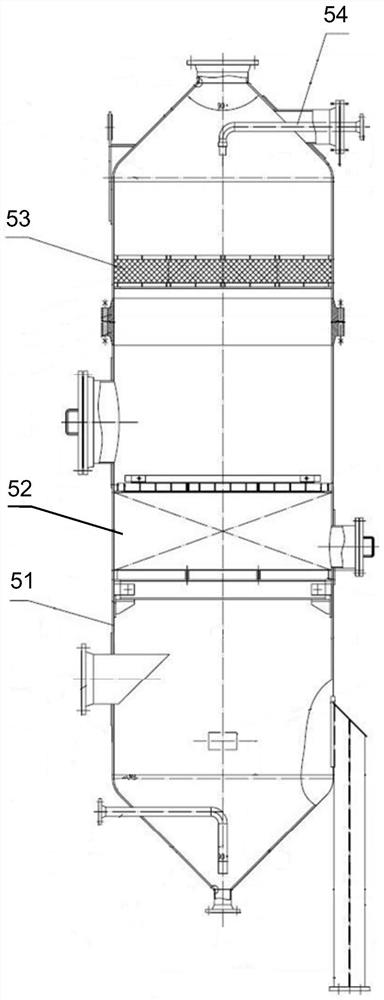

[0023] The technical solutions of the present invention are further described below with reference to the accompanying drawings and embodiments.

[0024] please combine Figure 1 to Figure 3 As shown in the figure, a coke pit waste gas collection and purification system provided by the present invention is installed at the coke outlet 2 position of the coke pit 1, and includes a gas collecting hood 3, a gas collecting fan 4 and a coke adsorption tower 5. At the coke outlet 2 On the top, two gas collecting hoods 3 are added at the positions where coke powder and water vapor are relatively concentrated. The two gas collecting hoods 3 are connected with the gas collecting fan 4 through the connecting pipe 6, and the gas collecting fan 4 is connected with the coke adsorption tower 5 through the connecting pipe 7. Connected, more than 90% of the coke powder and water vapor at the position of the coke outlet 2 are pumped to the coke adsorption tower 5 through the gas collecting fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com