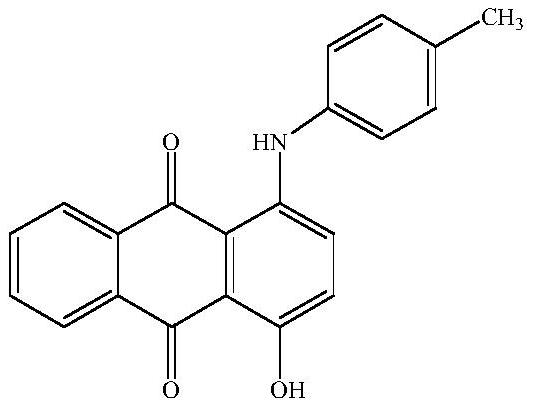

Method for preparing solvent violet 13

A solvent violet and synthesis method technology, applied in chemical instruments and methods, preparation of organic compounds, organic dyes, etc., can solve problems such as high requirements for production equipment, low degree of industrialization, and high by-products, and achieve cost-free and environmental protection Problems, reduction in the amount of solid waste, effects of avoiding addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In a 500ml autoclave, 120ml of water, 10g of solid sodium hydroxide, 30g of 1,4-dihydroxyanthraquinone, 4.6g of leuco 1,4-dihydroxyanthraquinone, 7.2g of p-toluidine, 2g of boric acid, and Transfer 0.5g of catalyst, after stirring for 0.5h, seal and slowly heat up to 115°C, take a sample for follow-up detection after holding for 3h, and stop heating after holding for 6.5h. The content is 53.8%, lower the temperature to 80°C, release the pressure, filter at this temperature, then add 20ml of 70°C hot water to wash, collect the mother liquor and the washing water after the completion, continue to wash the filter cake until it is neutral, and then dry it to obtain Solvent Violet 13 The finished product is 24.1g, and the main content is 97.83%.

[0029] In a 500ml autoclave, put the mother liquor of the previous batch + the first washing water, 14g of 1,4-dihydroxyanthraquinone, 4.6g of leuco 1,4-dihydroxyanthraquinone, 2g of caustic soda, and 7.2g of p-toluidine. 0.2g of ...

Embodiment 2

[0032] Put 165ml of water, 15g of caustic soda, 60g of 1,4-dihydroxyanthraquinone, 7.2g of leuco 1,4-dihydroxyanthraquinone, 15g of p-toluidine, 7.2g of boric acid, and phase transfer catalyst in a 1000ml autoclave. 0.6g, after stirring for 0.5h, seal and slowly heat up to 100°C, take a sample for follow-up detection after holding for 3h, and stop heating after holding for 7h. %, lower the temperature to 80°C, release the pressure, filter at this temperature, then add 40ml of 80°C hot water to wash, collect the mother liquor and the washing water, continue to wash the filter cake until it is neutral, and then dry it to obtain the finished product of Solvent Violet 13 49.6 g, main content 96.44%.

[0033] In a 1000ml autoclave, put the previous batch of mother liquor + first washing water, 30.1g of 1,4-dihydroxyanthraquinone, 7.2g of leuco 1,4-dihydroxyanthraquinone, 3g of caustic soda, and 15g of p-toluidine. 0.22g of boric acid, 0.06g of phase transfer catalyst, after stirri...

Embodiment 3

[0036] In a 500ml autoclave, 150ml of water, 12g of caustic soda, 30g of 1,4-dihydroxyanthraquinone, 9g of leuco 1,4-dihydroxyanthraquinone, 10g of p-toluidine, 1g of boric acid, 1g of phase transfer catalyst, After stirring for 0.5 hours, seal and slowly heat up to 120°C. After holding for 3 hours, take samples for follow-up detection, and stop heating after holding for 6 hours. to 80°C, release the pressure, filter at this temperature, then add 20ml of 90°C hot water to wash, collect the mother liquor and the washing water, continue to wash the filter cake until neutral, and then dry to obtain 27.9g of the finished product of Solvent Violet 13. The content is 97.83%.

[0037]In a 500ml autoclave, put the previous batch of mother liquor + the first washing water, 12.5g of 1,4-dihydroxyanthraquinone, 9g of 1,4-dihydroxyanthraquinone leuco, 2.4g of caustic soda, 10g of p-toluidine, boric acid 0.2g, 0.1g of phase transfer catalyst, after stirring for 0.5h, seal and slowly heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com