Method for preparing SIPE from SIPA by direct esterification method

A technology of diethylene glycol isophthalate and isophthalic acid, which is applied in the field of preparing diethylene glycol isophthalate-5-sulfonate, can solve the problems of high methanol recovery cost, large equipment investment, Unfavorable environmental protection and other problems, to achieve the effect of eliminating large equipment investment, high purity and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

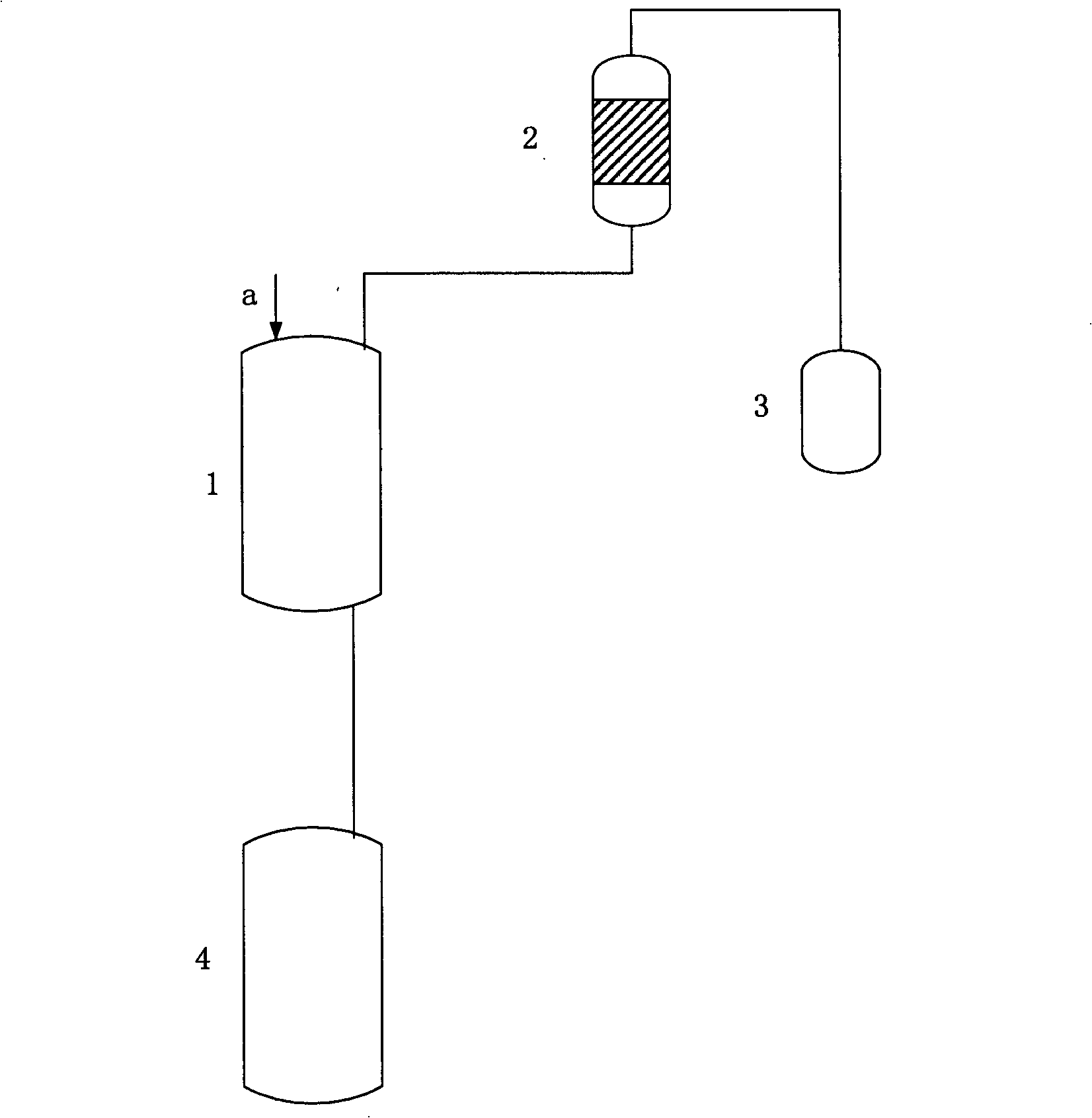

[0034] Embodiment one, a kind of isophthalic acid-5-sulfonate (SIPA) direct esterification method of the present invention prepares the method for diethylene glycol isophthalate-5-sulfonate (SIPE), comprising:

[0035] a. Ingredients stage:

[0036] Put 9000g of ethylene glycol (EG) into the esterification reactor 1. Ethylene glycol is put into the esterification reactor 1 from the feeding port a, and the temperature is raised to 80°C. Then, press isophthalic acid-5-sulfonic acid Add the isophthalic acid-5-sulfonate (SIPA) into the molar ratio of salt (SIPA) and ethylene glycol (EG) at a ratio of 1:10, then start the agitator, put in the anti-ether agent and catalyst, the anti-ether agent It is sodium acetate, the input amount of sodium acetate is 2g, the catalyst is tetraisopropyl titanate, and the input amount of tetraisopropyl titanate is 4g; isophthalic acid-5-sulfonate (SIPA), sodium acetate, titanic acid Tetraisopropyl ester all is dropped in the esterification reaction...

Embodiment 2

[0045] Embodiment two, a kind of isophthalic acid-5-sulfonate (SIPA) direct esterification method of the present invention prepares the method for diethylene glycol isophthalate-5-sulfonate (SIPE), comprising:

[0046] a. Ingredients stage:

[0047] Put 9000g of ethylene glycol (EG) into the esterification reactor 1. Ethylene glycol is put into the esterification reactor 1 from the feeding port a, and the temperature is raised to 80°C. Then, press isophthalic acid-5-sulfonic acid Add the isophthalic acid-5-sulfonate (SIPA) into the molar ratio of salt (SIPA) to ethylene glycol (EG) at a ratio of 1:10, then start the agitator, put in the anti-ether agent and catalyst, the anti-ether agent It is sodium acetate, the input amount of sodium acetate is 2g, the catalyst is tetraisopropyl titanate, and the input amount of tetraisopropyl titanate is 4g; isophthalic acid-5-sulfonate (SIPA), sodium acetate, titanic acid Tetraisopropyl ester all is dropped in the esterification reaction ...

Embodiment 3

[0055] Embodiment three, a kind of isophthalic acid-5-sulfonate (SIPA) direct esterification method of the present invention prepares the method for diethylene glycol isophthalate-5-sulfonate (SIPE), comprising:

[0056] a. Ingredients stage:

[0057] Put 9000g of ethylene glycol (EG) into the esterification reactor 1. Ethylene glycol is put into the esterification reactor 1 from the feeding port a, and the temperature is raised to 80°C. Then, press isophthalic acid-5-sulfonic acid Add the isophthalic acid-5-sulfonate (SIPA) into the molar ratio of salt (SIPA) to ethylene glycol (EG) at a ratio of 1:10, then start the agitator, put in the anti-ether agent and catalyst, the anti-ether agent It is lithium acetate, the input amount of lithium acetate is 2g, the catalyst is n-tetrabutyl titanate, and the input amount of n-butyl titanate is 4g; isophthalic acid-5-sulfonate (SIPA), lithium acetate, n-tetrabutyl titanate The esters are all dropped into the esterification reaction ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com