Water-based inner wall environmentally-friendly sealing compound using circulating resources and method for preparing same

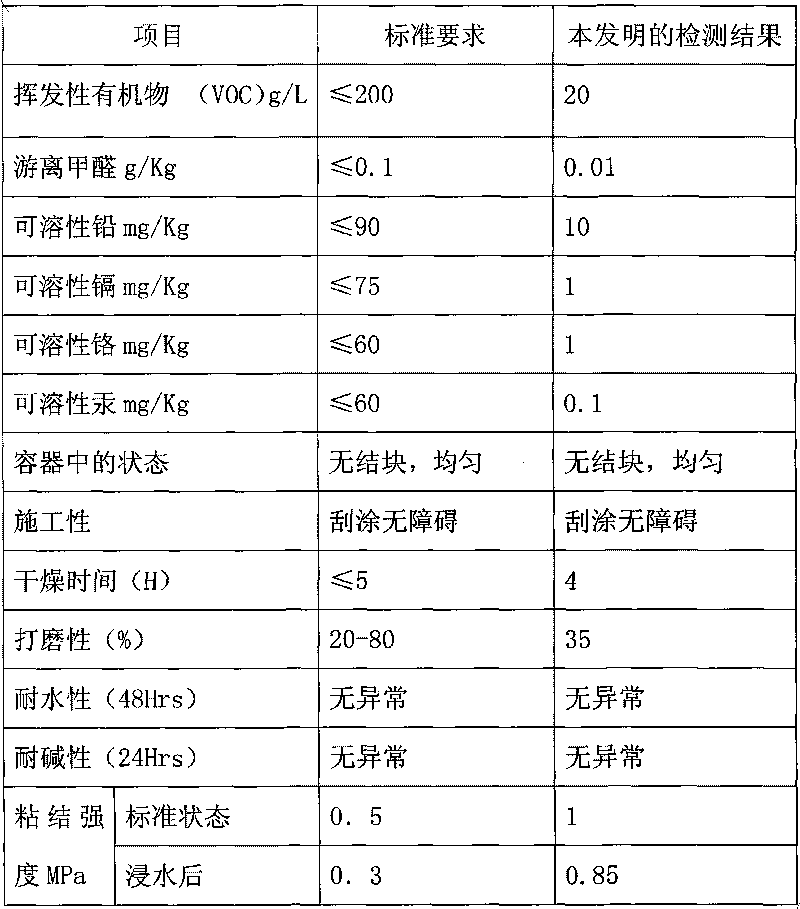

An interior wall and environmental protection technology, applied in the direction of filling slurry, etc., can solve the problems of waste of resources, putty-soluble heavy metals are not environmentally friendly, and high VOC content, and achieve the effect of easy construction, reducing serious environmental pollution problems, and removing environmental protection problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

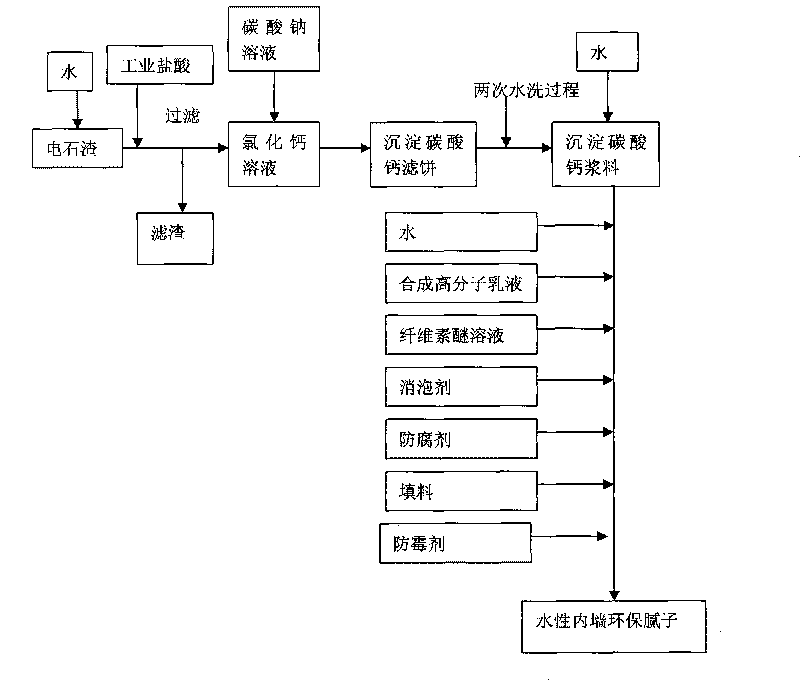

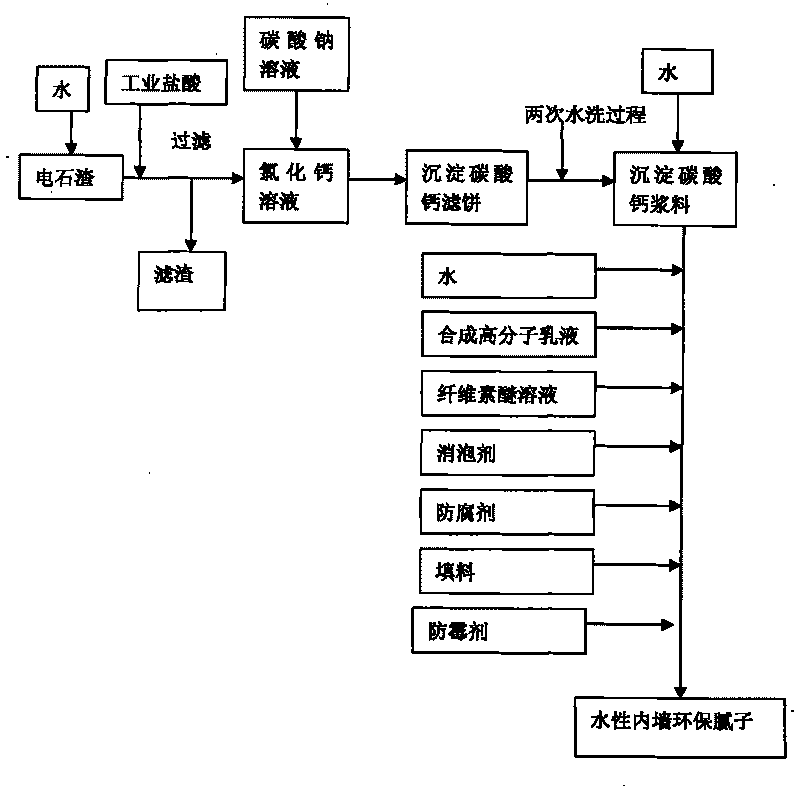

[0050] a. Prepare precipitated calcium carbonate slurry:

[0051] a1. In the beaker 1, prepare a mixed solution according to the ratio of calcium carbide slag: water (mass ratio) = 1: 15, stir under the high-speed disperser to reach a uniform suspension state, and add 4mol / L dropwise at a speed of 600 rpm The hydrochloric acid, the ratio of hydrochloric acid and the above-mentioned calcium carbide slag dispersion slurry is 1: 1, keep the rotating speed of 800r / min at room temperature and react for 3 hours and then let it stand, then filter the reaction mixture, and get the clear calcium chloride solution for subsequent use.

[0052] a2. Put the calcium chloride solution taken out into the beaker 2, stir the calcium chloride solution at a high speed of 1000-1200r / min and add a sufficient amount of 0.1mol / L sodium carbonate solution until the reaction reaches the end point. Monitor the progress of the reaction with a pH meter, and finish the reaction when the pH value of the rea...

Embodiment 2

[0066] a. Prepare precipitated calcium carbonate slurry:

[0067] a1. In the beaker 1, prepare a mixed solution in the ratio of calcium carbide slag: water (mass ratio) = 1: 10, stir under a high-speed disperser to reach a uniform suspension state, and add 4mol / L dropwise at a speed of 600 rpm The hydrochloric acid, the ratio of hydrochloric acid and the above-mentioned calcium carbide slag dispersion slurry is 1: 1, keep the rotating speed of 800r / min at room temperature and react for 5 hours and then let it stand, then filter the reaction mixture, and get the clear calcium chloride solution for subsequent use.

[0068] a2. Put the calcium chloride solution taken out into the beaker 2, stir the calcium chloride solution at a high speed of 1000-1200r / min and add a sufficient amount of 0.1mol / L sodium carbonate solution until the reaction reaches the end point. Monitor the progress of the reaction with a pH meter, and finish the reaction when the pH value of the reaction mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com