Nanometer montmorillonite-soft polyurethane foam plastic and its preparation process

A technology of flexible foam plastic and nano-montmorillonite, which is applied in the field of polymer materials, can solve the problems of environmental hazards, harm, and high production costs, and achieve the effects of eliminating environmental hazards, reducing costs, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

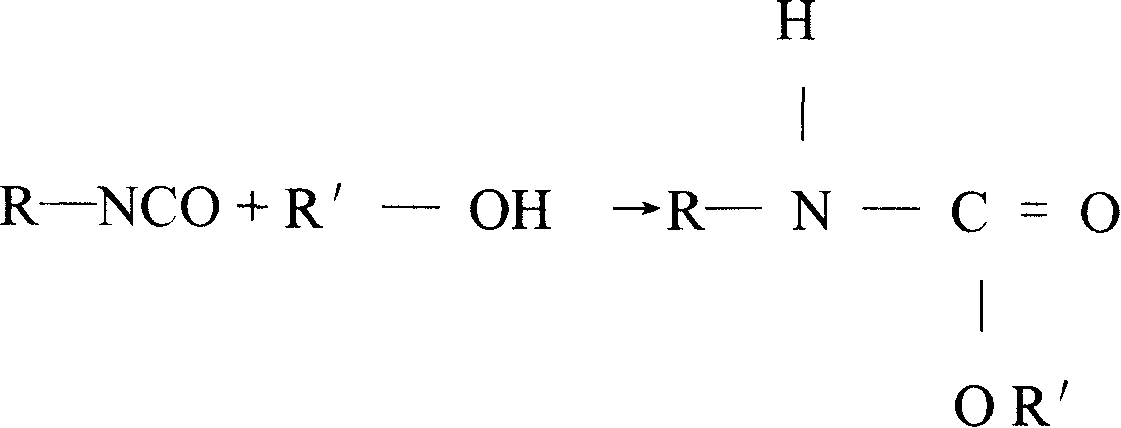

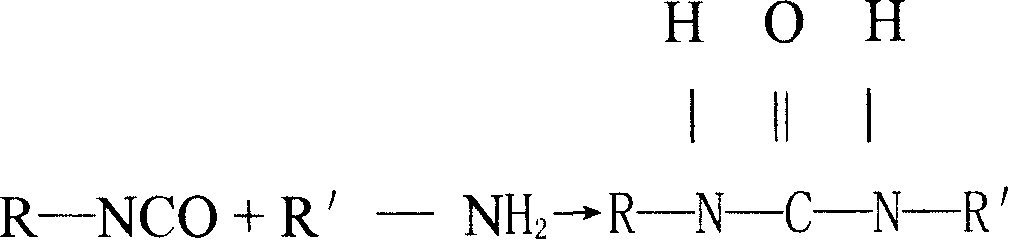

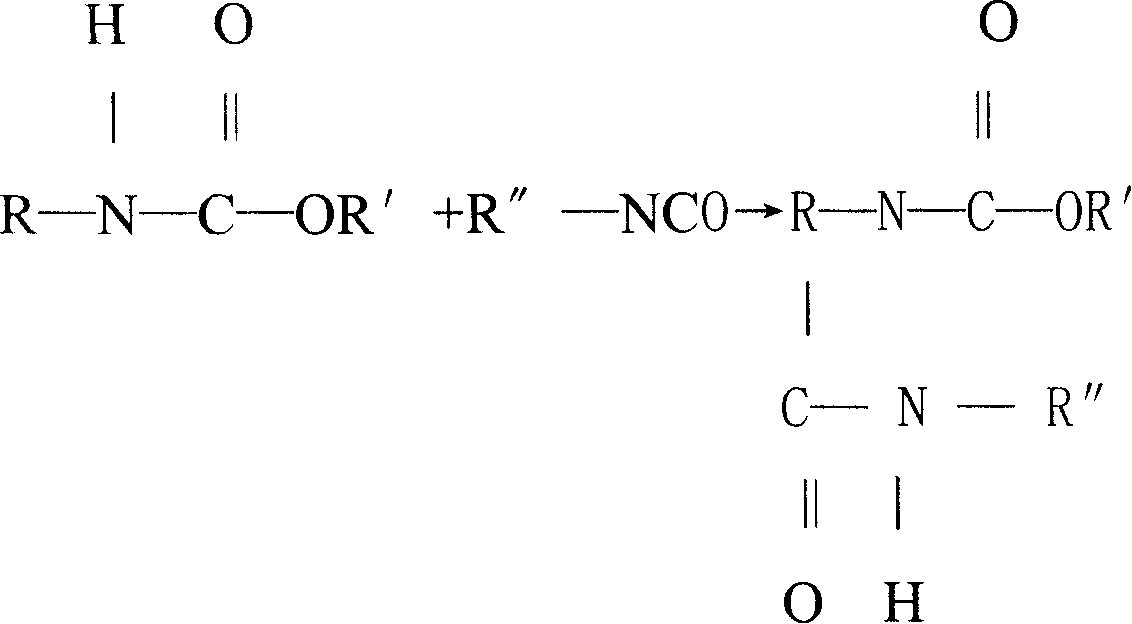

Method used

Image

Examples

Embodiment 1

[0007] Embodiment 1: To make a car seat cushion, the seat cushion mold is heated to 35° C. for subsequent use.

[0008] First, the nano-montmorillonite with 5 parts by weight and the polyether polyol with 95 parts by weight are placed in the same container and stirred and compounded; the mixed catalyst with 0-4 parts by weight is added, and then the parts by weight are added. 1-5 foaming agent-water, 1-3 parts by weight of foam stabilizer, and then fully stirred and mixed to prepare a combined polyether; finally, add isocyanate with an NCO index of 1, and stir. The stirring speed is 4000 rpm, the stirring time is 7 seconds, and then poured into the mold; the ambient temperature is 15°C, the material temperature is 22°C, the mold temperature is 35°C, the curing temperature is 70°C, and the curing time is 10 minutes. After molding, it can form a highly elastic flexible polyurethane foam.

Embodiment 2

[0009] Embodiment 2: To make a sofa seat cushion, heat the seat cushion mold to 50° C. for later use.

[0010] First, the nano-montmorillonite with 40 parts by weight and the polyether polyol with 60 parts by weight are put into the same container for stirring and compounding; the catalyst with 0-4 parts by weight is added, and the 5 foaming agent-water, 1-3 parts by weight of a foam stabilizer, and then fully stirred and mixed to prepare a combined polyether; finally, add isocyanate with an NCO index of 1.2, and stir. The stirring speed is 5000 rpm, the stirring time is 15 seconds, and then poured into the mold; the ambient temperature is 20°C, the material temperature is 25°C, the mold temperature is 50°C, the curing temperature is 120°C, and the curing time is 15 minutes. After molding, it can form a highly elastic flexible polyurethane foam.

Embodiment 3

[0011] Embodiment 3: To make a soft handrail, heat the mold to 40°C for later use.

[0012] First, put 20 parts by weight of nano-montmorillonite and polyether polyols of 80 parts by weight into the same container and stir and compound; add catalysts with parts by weight of 0-4, and then add 1 -5 foaming agent-water, foam stabilizer with a weight of 2, and then fully stirred and mixed to prepare a composite polyether; finally, add an isocyanate with an index of 1, and stir. The stirring speed is 4500 rpm, the stirring time is 10 seconds, and then poured into the mold; the ambient temperature is 18°C, the material temperature is 24°C, the mold temperature is 40°C, the curing temperature is 100°C, and the curing time is 12 minutes. After molding, it can form a highly elastic flexible polyurethane foam.

[0013] The following table is a comparison of several raw materials and their respective formulas, after foaming with the same auxiliary material and the same process parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com