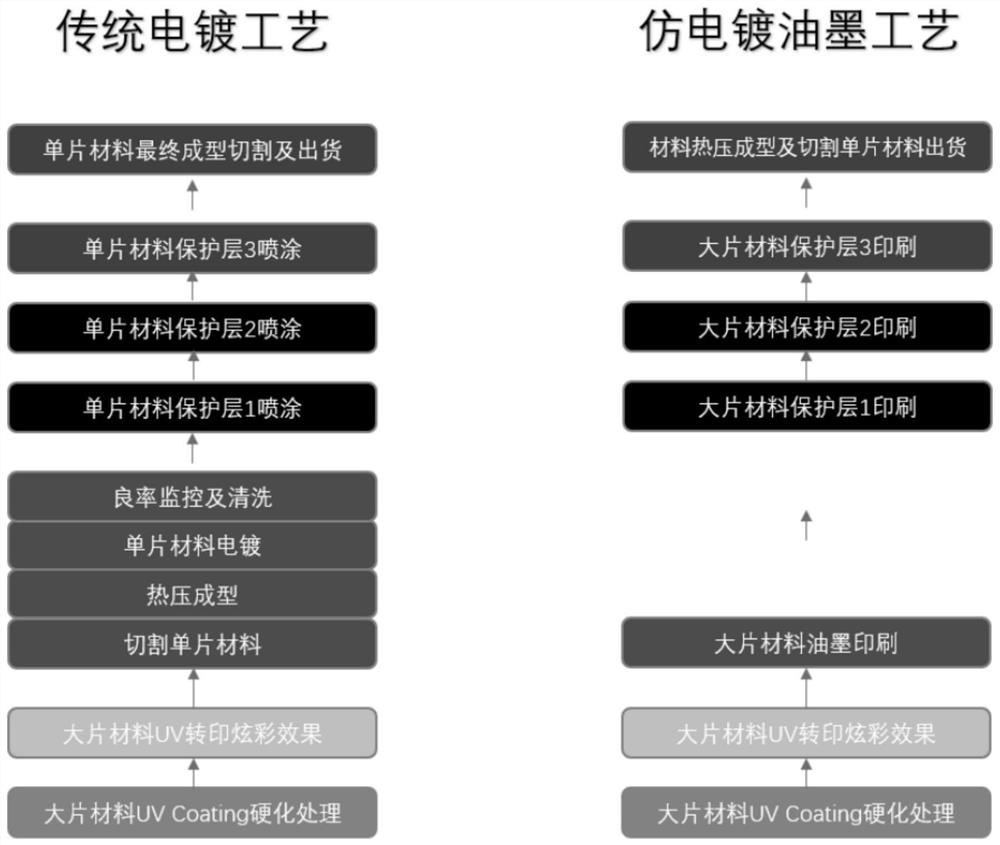

Single-component low-temperature curing imitation electroplating ink and preparation method thereof

An imitation electroplating, single-component technology, applied in the direction of ink, household utensils, applications, etc., can solve the problems of harsh storage conditions, difficulty in storage, short shelf life of ink, etc., achieve high-temperature calendering and tensile properties, reduce production costs, and store The long-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

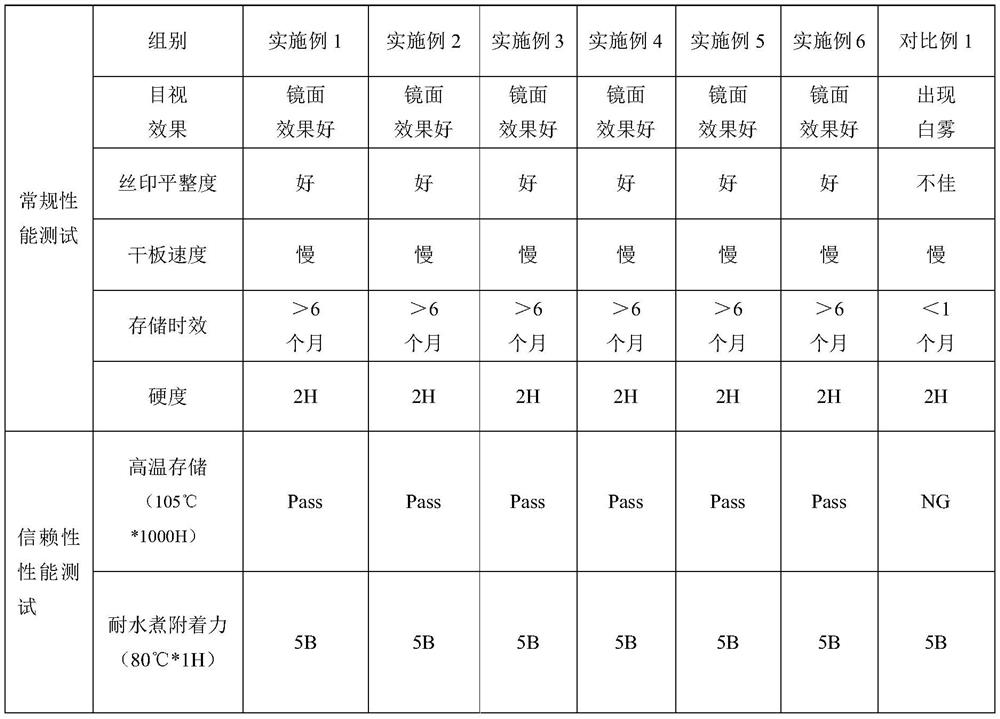

Examples

Embodiment 1

[0065] A low-temperature curing imitation electroplating ink, including the following components: 15g of multipolymer acrylic resin, 1.5g of high molecular weight phenoxy resin, 30g of spherical silver powder, 38.15ml of propylene glycol phenyl ether, 0.15ml of organic silicon leveling agent, organic 3ml of silicon defoamer, 1.5ml of epoxy coupling agent, 0.5ml of silicone wetting agent, 0.2ml of polyether modified anti-settling agent, 5ml of carboxylate dispersant, and 5ml of low-temperature deblocking isocyanate curing agent.

[0066] The preparation method of the low-temperature curing imitation electroplating ink of the present embodiment is:

[0067] S1. Mix multiple polymerized acrylic resin, high molecular weight phenoxy resin, and propylene glycol phenyl ether, and use a high-speed disperser to disperse and stir at a speed of 1500rpm to completely dissolve the multiple polymerized acrylic resin and phenoxy resin in propylene glycol phenyl ether , the mixture A was obta...

Embodiment 2

[0072] A low-temperature curing imitation electroplating ink, comprising the following components: styrene acrylic resin 15g, high molecular weight phenoxy resin 1.5g, granular silver powder 30g, diethylene glycol butyl ether 38.15ml, silicone leveling agent 0.15g ml, acrylic defoamer 3ml, aminosilane coupling agent 1.5ml, fluorocarbon modified wetting agent 0.5ml, fumed silica anti-sedimentation agent 0.2ml, oleic acid 5ml, low temperature deblocking type isocyanate curing agent 5ml.

[0073] The preparation method of the low-temperature curing imitation electroplating ink of the present embodiment is:

[0074] S1. Mix styrene acrylic resin, high molecular weight phenoxy resin, and diethylene glycol butyl ether, and use a high-speed disperser to disperse and stir at a speed of 1600rpm to completely dissolve polystyrene acrylic resin and phenoxy resin In diethylene glycol butyl ether, mixed solution A was obtained;

[0075] S2. Mix silicone leveling agent, acrylic defoamer, a...

Embodiment 3

[0079] A low-temperature curing imitation electroplating ink, comprising the following components: 15g of butyl methacrylate copolymer, 1.5g of high molecular weight phenoxy resin, 30g of spherical silver powder, 38.15ml of glycerin, 0.15ml of silicone leveling agent, Cellulose acetate defoamer 3ml, epoxy silane coupling agent 1.5ml, silicone modified wetting agent 0.5ml, polyether modified anti-settling agent 0.2ml, carboxylate 5ml, low temperature deblocking type isocyanate curing agent 5ml .

[0080] The preparation method of the low-temperature curing imitation electroplating ink of the present embodiment is:

[0081] S1. Mix butyl methacrylate copolymer, high molecular weight phenoxy resin, and glycerin, and use a high-speed disperser to disperse and stir at a speed of 2000rpm to completely dissolve the butyl methacrylate copolymer and phenoxy resin In glycerin, mixed solution A was obtained;

[0082] S2. Silicone leveling agent, cellulose acetate defoamer, epoxy silane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com