Method for modifying membrane material in membrane bioreactor

A membrane bioreactor and membrane material technology, applied in chemical instruments and methods, biological water/sewage treatment, membrane technology, etc., can solve the problem of graft or block copolymer detachment, affecting membrane pore structure and membrane performance, stability Improve the hydrophilicity, improve the membrane fouling problem, and reduce the roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] First use the hexamic acid that accounts for 20% by weight of polyvinylidene fluoride, 3% of polyvinylpyrrolidone, 77% of N-methylpyrrolidone, and 1% by weight of polyvinylidene fluoride. Sodium and deionized water at 25°C were used to prepare the membrane solution, heated to 50°C, stirred vigorously for 24 hours, and then degassed for 30 minutes under a vacuum of -50kPa to form a uniform casting solution. Then, the organic-inorganic hybrid film was prepared by the L-S phase inversion method. During the preparation process, the nano-TiO with a weight percentage of 3% of polyvinylidene fluoride was evenly added to the casting film solution by blending. 2 Particles, and finally organic-inorganic hybrid membranes are made into hollow fiber membranes for use in membrane bioreactors.

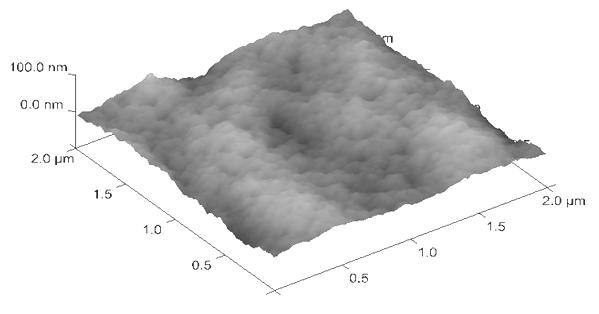

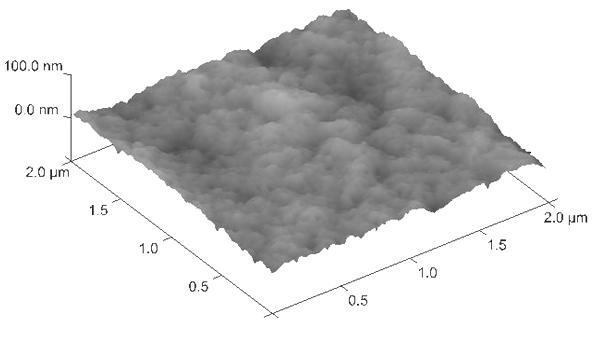

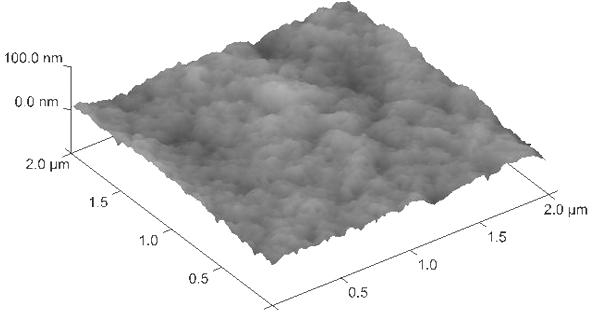

[0017] figure 1 is the three-dimensional image of the original non-modified membrane under the atomic force microscope, figure 2 It is a three-dimensional image of the hollow fiber membran...

Embodiment 2

[0019] The difference between embodiment 2 and embodiment 1 is that the nano-TiO that accounts for 4% by weight of polyvinylidene fluoride is evenly added in the casting solution by blending method 2 particle. All the other steps are the same as in Example 1.

Embodiment 3

[0021] The difference between embodiment 3 and embodiment 1 is that the nano-TiO that accounts for 4% by weight of polyvinylidene fluoride is evenly added in the casting solution by blending. 2 Particles, and finally the organic-inorganic hybrid film is made into a flat film. All the other steps are the same as in Example 1.

[0022] The modified hollow fiber membranes and flat membranes obtained in Example 2-3 and the membranes of non-modified membrane bioreactors are all placed in the membrane bioreactor under the same working condition for sewage treatment, and the treatment results are: The modified hollow fiber membrane and flat membrane have better hydrophilicity, and their anti-pollution and membrane flux are improved. After 90 days of operation, no sludge was discharged during the operation. Under different membrane suction pressures and different aeration intensities, the membrane flux and membrane filtration resistance were measured respectively. The result is that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com