Ceramic hanger for bathroom and manufacturing process of ceramic hanger

A manufacturing process and hanger technology, which is applied in the field of ceramic hangers for bathrooms and its manufacturing process, can solve the problems of bacteria breeding, easy oxidation of zinc alloy, short service life, etc. , Easy maintenance and easy effect

Inactive Publication Date: 2015-02-25

SUNLOT SHARES

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, there are many kinds of materials used in bathroom pendants on the market, such as copper, plastic, aluminum alloy, zinc alloy, etc.: (1) Hangers stamped and formed by copper materials have high cost, heavy weight, and post-production The process is complicated; (2) The hanger made of aluminum alloy, zinc alloy and other casting methods with molds has difficult processing technology, low hardness, high cost, and aluminum alloy and zinc alloy are easy to oxidize and corrode, shortening the service life. Second, the surface of the products made of these materials needs to be polished, electroplated or sprayed, and dust is generated during the polishing process, which not only pollutes the air, but also causes harm to the health of the polishing workers. The sewage generated in the production process of the spraying process is difficult to comprehensively treat, and it is easy to cause water pollution when discharged, which seriously pollutes water resources and the natural environment; (3) the hanger made of plastic is low in cost and simple in production process, but its hardness Low, placed in the bathroom for a long time, easy to get damp, breed bacteria, short service life, etc.;

[0003] Thirdly, the surface treatment color of the hanger made of the above materials is relatively single, and the quality of the surface treatment is uneven. The surface is easy to corrode during the use of the product, and it is easy to cause surface problems such as surface scratches during the maintenance process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

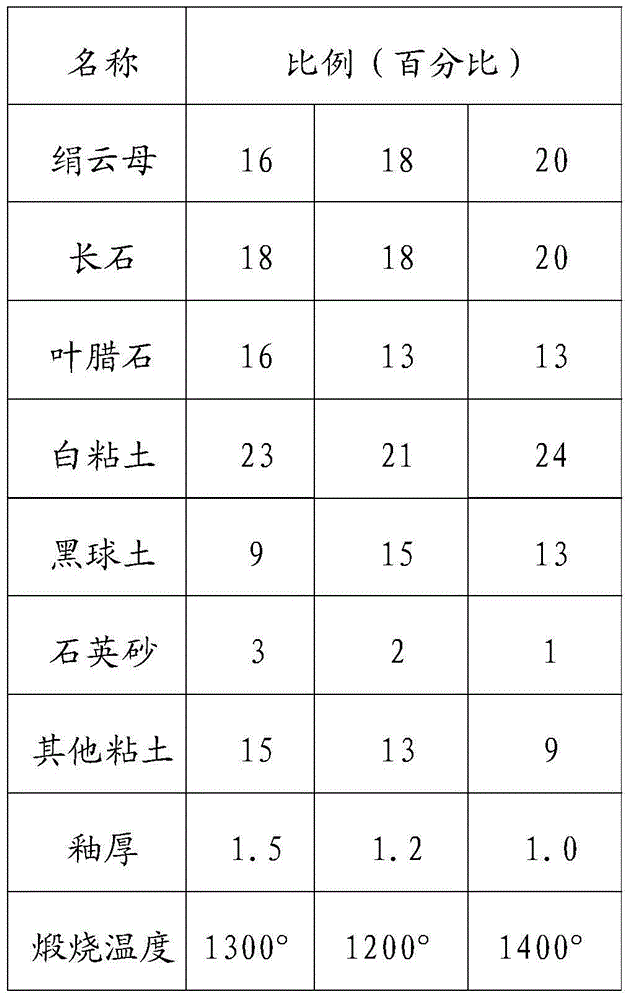

[0045] Embodiment 1 is based on the basis of specific implementation methods, and the same parts will not be repeated. The ratio of mud raw materials: 3 kinds of ratio methods (as shown in the table below)

[0046]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

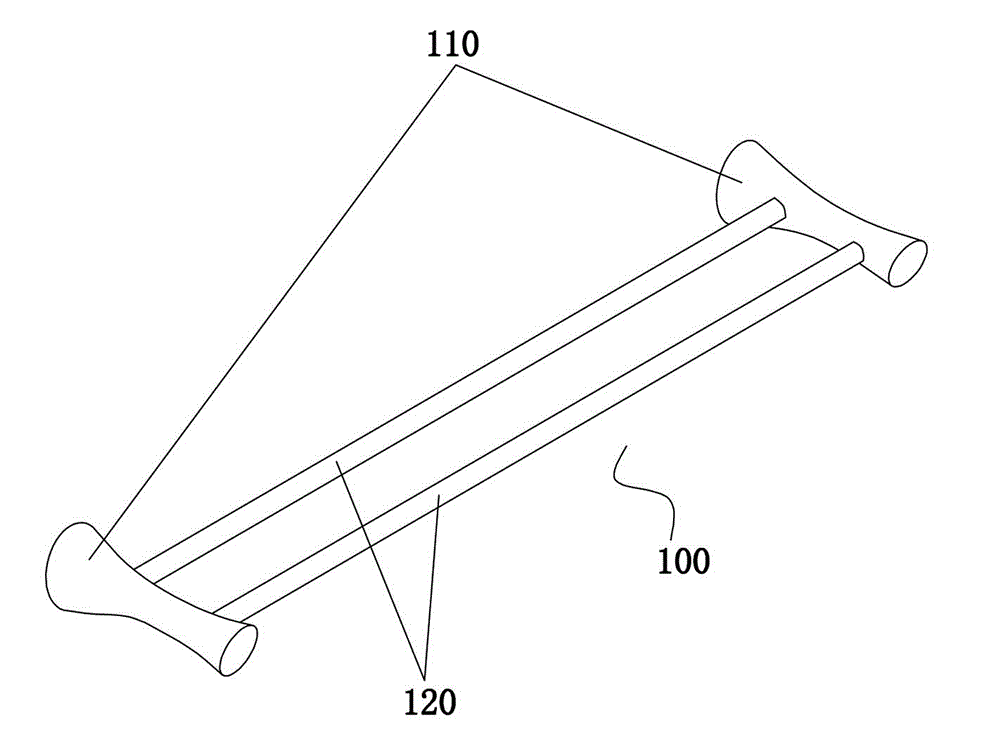

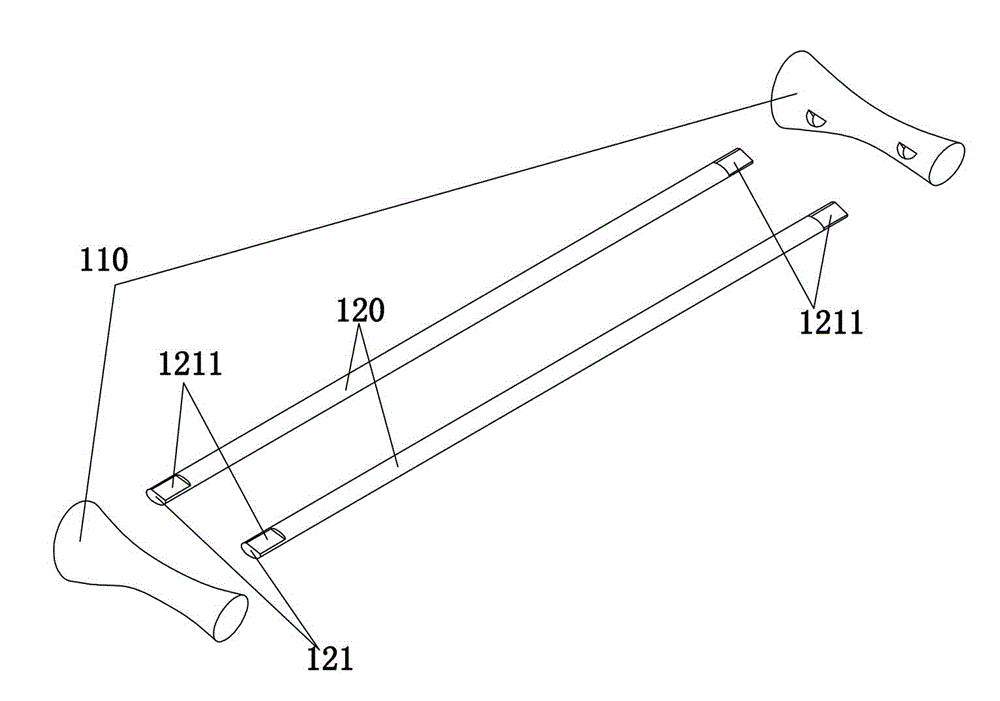

The invention discloses a ceramic hanger for a bathroom and a manufacturing process of the ceramic hanger. The ceramic hanger comprises two bases and one or more hanging rods, the bases are fixed on a wall, rotation stopping portions are formed at two ends of each hanging rod, and the bases are provided with positioning holes matched with the rotation stopping portions. Ceramic is adopted as a raw material, and the surface of the ceramic is glazed, so that the surface of the ceramic hanger formed after high-temperature sintering is round and exquisite in texture, the glazed surface is smooth and bright, and the ceramic hanger is less prone to dirt adhesion, easy to clean, less prone to corrosion and oxidization, convenient and easy to maintain and long in service life.

Description

technical field [0001] The invention relates to a bathroom hanger, in particular to a bathroom ceramic hanger and its manufacturing process. Background technique [0002] At present, there are many kinds of materials used in bathroom pendants on the market, such as copper, plastic, aluminum alloy, zinc alloy, etc.: (1) Hangers stamped and formed by copper materials have high cost, heavy weight, and post-production The process is complicated; (2) The hanger made of aluminum alloy, zinc alloy and other casting methods with molds has difficult processing technology, low hardness, high cost, and aluminum alloy and zinc alloy are easy to oxidize and corrode, shortening the service life. Second, the surface of the products made of these materials needs to be polished, electroplated or sprayed, and dust is generated during the polishing process, which not only pollutes the air, but also causes harm to the health of the polishing workers. The sewage generated in the production proc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A47K1/08A47K10/04C04B33/13C04B41/86C04B35/622

Inventor 洪建城洪跃进黄敏新

Owner SUNLOT SHARES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com