Composite material safety toe cap and manufacturing method thereof

A composite material and composite material technology are applied in the field of composite safety toe caps and their production to achieve the effects of beautiful appearance, easy implementation and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

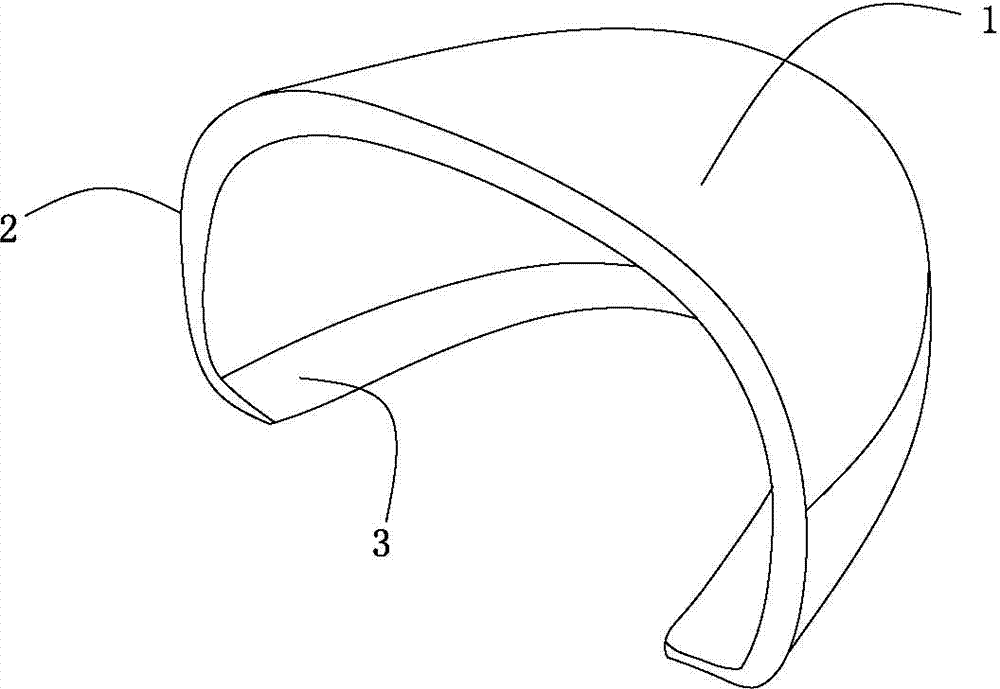

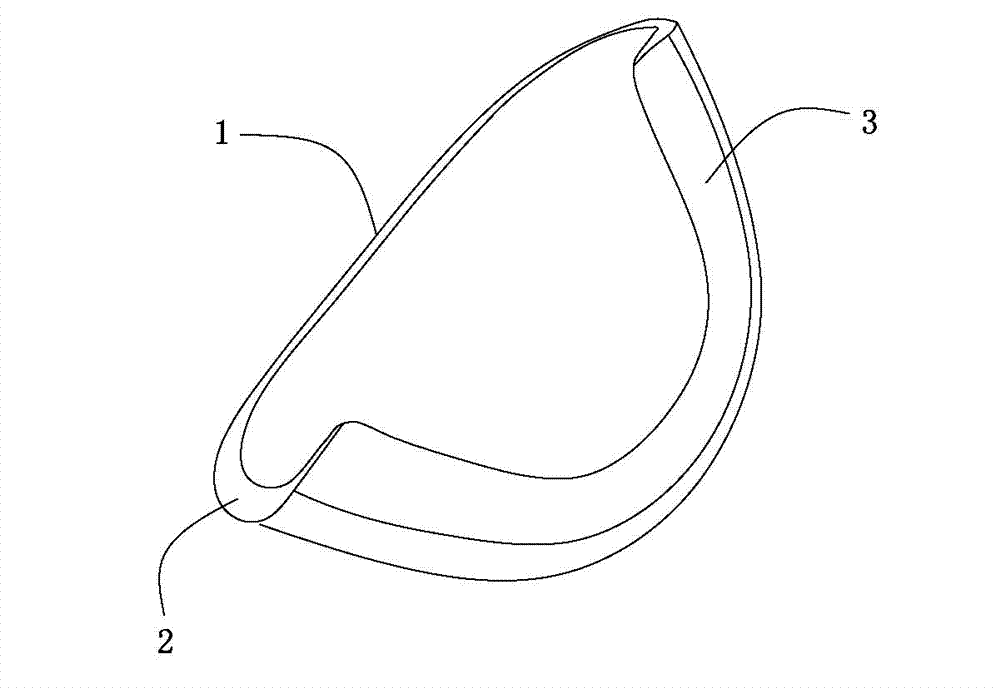

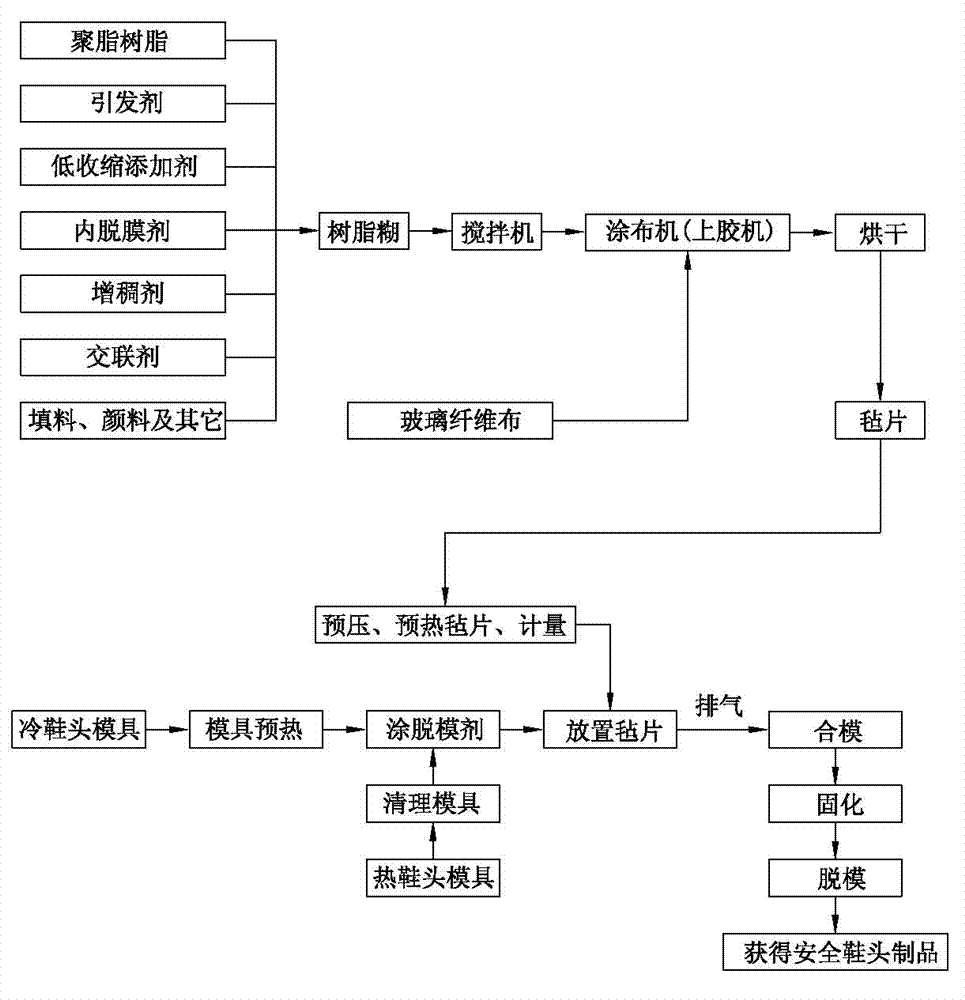

[0024] Embodiment 1: see figure 1 , figure 2 and image 3 , a composite material safety toe cap provided in this embodiment, the toe cap is formed by bonding and pressing multiple layers of glass fiber cloth coated with resin paste, the toe cap is hooked by the top surface 1, the side surface 2 and the bottom edge Composed of feet 3, the mass percentages of the resin paste and glass fiber cloth are: 65% to 80% of resin paste, 20% to 35% of glass fiber cloth; wherein the components and mass percentages of the resin paste are as follows: polyester resin 65-80%, initiator 0.2-2%, low-shrinkage additive 10-30%, internal release agent 1-2%, thickener 1-5%, cross-linking agent 1-2%.

[0025] In this embodiment, the polyester resin is preferably vinyl ester resin, the initiator is tert-butyl peroxy-2-ethyl acetate, the low-shrinkage additive is preferably a thermoplastic polymer, and the internal release film The agent is preferably zinc stearate, the thickener is preferably MgO,...

Embodiment 2

[0031] Embodiment 2: The difference between it and Embodiment 1 lies in the components in the composite material safety toe cap and their mass percentages. The components and their mass percentages are as follows: resin paste 65%, glass fiber cloth 35%; wherein the resin paste components and their mass percentages are as follows: polyester resin 75%, initiator 0.2%, low shrinkage Additive 20.3%, internal release agent 1.5%, thickener 1.2%, crosslinking agent 1.8%.

Embodiment 3

[0032] Embodiment 3: The difference between it and Embodiment 1 lies in that the components in the composite material safety toe cap and their mass percentages are different. The components and their mass percentages are as follows: resin paste 80%, glass fiber cloth 20%; wherein the resin paste components and their mass percentages are as follows: polyester resin 65%, initiator 2%, low shrinkage Additive 30%, internal release agent 1%, thickener 1%, crosslinking agent 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com