Method for mixing electrolytic aluminum waste cathode particles and coke particles for electrolytic cell roasting

A waste cathode and electrolytic cell technology, which is applied in the field of treatment and utilization of waste cathode carbon blocks of electrolytic aluminum, can solve the problems of occupying large land, ecological environment pollution, hidden dangers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method of mixing electrolytic aluminum waste cathode particles and coke particles for electrolytic cell roasting. This method forms a heating medium by mixing aluminum electrolysis waste cathode particles with coke particles, laying them between the anode carbon block and cathode carbon block of the electrolytic cell, and then electrifying Roasting, forming a new method of starting the heating medium for aluminum electrolytic cell firing. The specific method steps are as follows:

[0019] A. Sorting the slag from the overhaul of the electrolytic cell, selecting qualified waste cathode carbon blocks and cleaning the surface, crushing and screening the cleaned waste cathode carbon blocks, and selecting particles with a particle size of 2-5mm. The screened spent cathode particles and coke particles are mixed according to the mass ratio of 1:1, and mixed and stirred at a slow speed by a mixer to obtain a heating medium;

[0020] B. Tanking. In the electrolytic cell, the...

Embodiment 2

[0024] The method for mixing electrolytic aluminum waste cathode particles and coke particles for electrolytic cell roasting, the specific method steps are as follows:

[0025] A. Sorting the slag from the overhaul of the electrolytic cell, selecting the qualified waste cathode carbon blocks and cleaning the surface, crushing and screening the waste cathode carbon blocks, selecting waste cathode particles with a particle size of 2-5mm, and screening The spent cathode particles and coke particles are mixed according to the mass ratio of 1:2, and mixed and stirred at a slow speed by a mixer to obtain a heating medium;

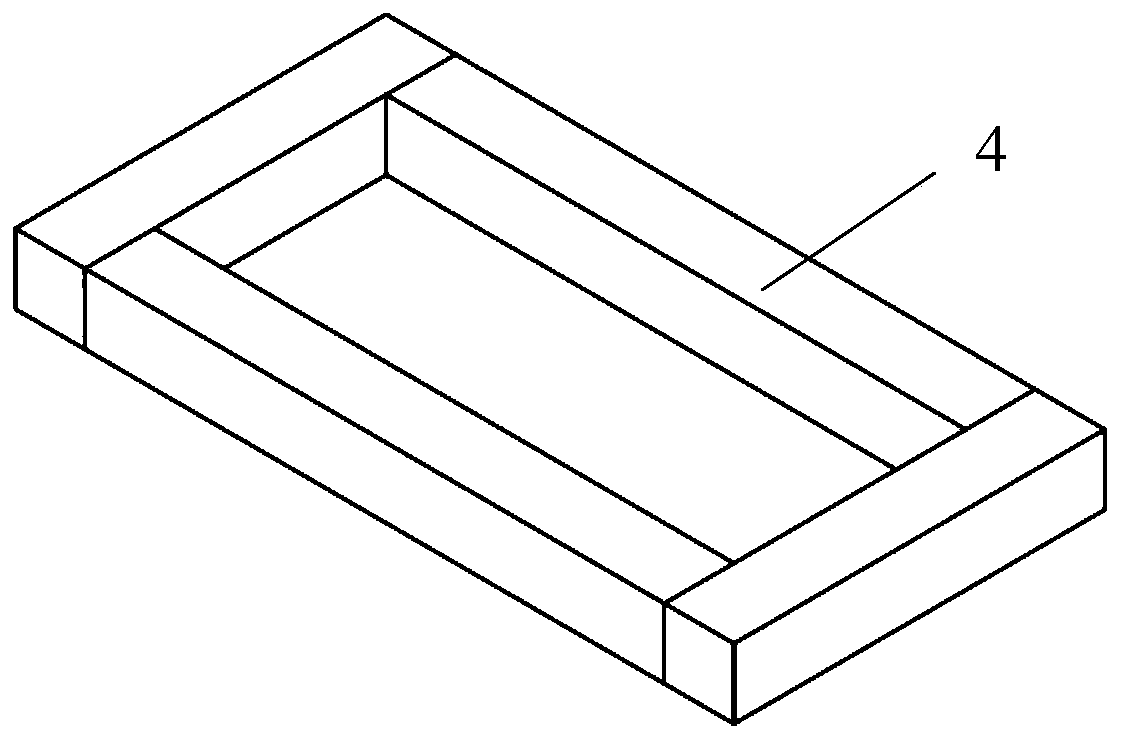

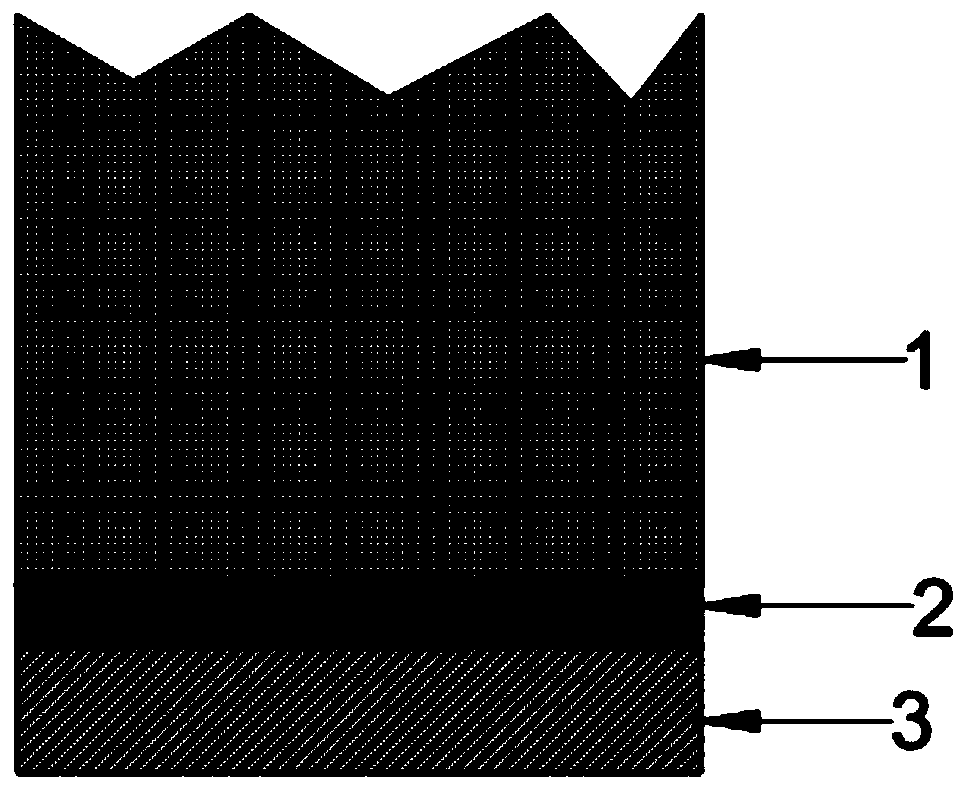

[0026] B. Install the tank, place the frame 4 horizontally on the surface of the cathode carbon block 3 in the electrolytic cell, then lay the heating medium 2 in the frame, and scrape the heating medium with a level to ensure that the laying thickness is uniform. The thickness of the single groove is uniformly laid, and the laying height of the 300kA groove is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com