Patents

Literature

136results about How to "Improve roasting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting vanadium from vanadium-containing raw material

ActiveCN104388679AImprove roasting effectPromote leachingProcess efficiency improvementFiltrationSlag

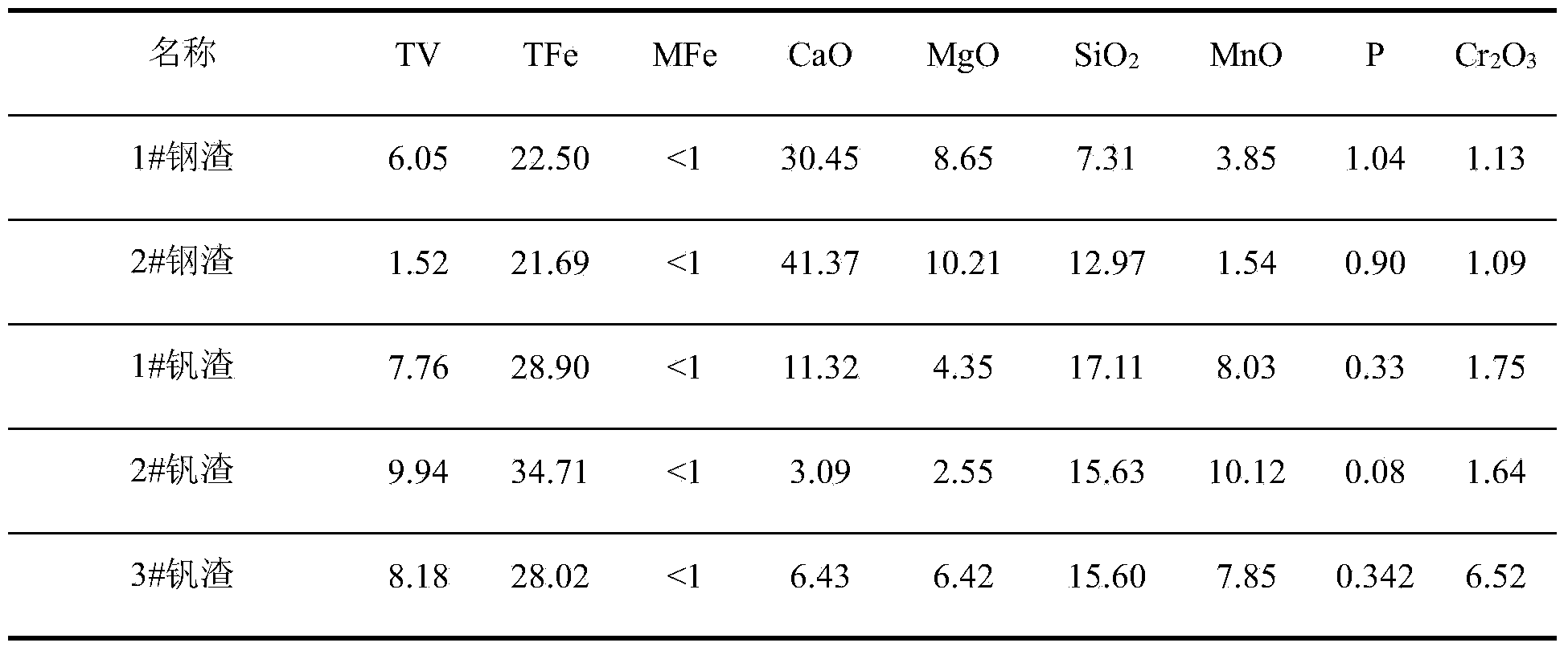

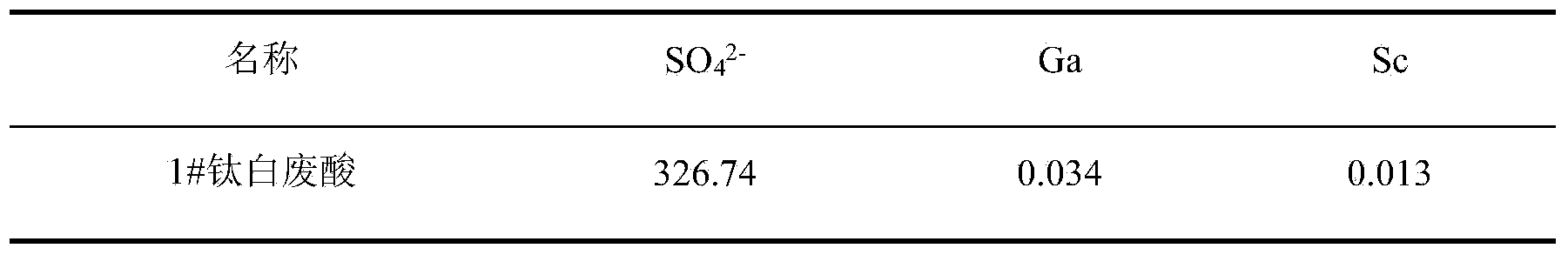

The invention discloses a method for extracting vanadium from a vanadium-containing raw material. The method comprises the following steps: a, uniformly mixing the vanadium-containing raw material, sulfuric acid and / or a sulfate, and water, so as to obtain a mixed material; b, performing aerobic roasting on the mixed material, so as to obtain a roasted clinker; c, performing leaching on the roasted clinker by using a leaching agent, so as to obtain a leaching slurry; and d, performing filtration separation on the leaching slurry, so as to obtain tails and a vanadium-containing solution. The method has relatively strong adaptability on composition variation of the vanadium-containing raw material, and helps to realize economic feasible industrial production and extraction of vanadium by using steel slag, vanadium slag and other vanadium-containing raw materials with relatively high calcium and magnesium content. The method is simple, practicable, low in equipment requirement, convenient to operate, low in material consumption and energy consumption, and easy for industrialization, and has extremely good economic benefit and social benefit.

Owner:边悟

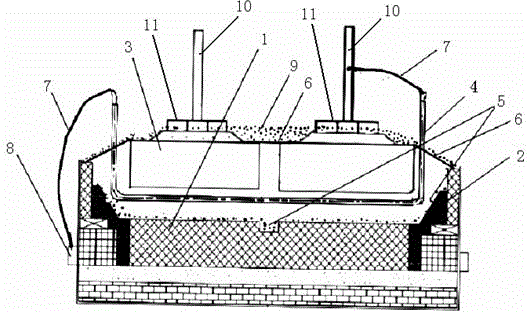

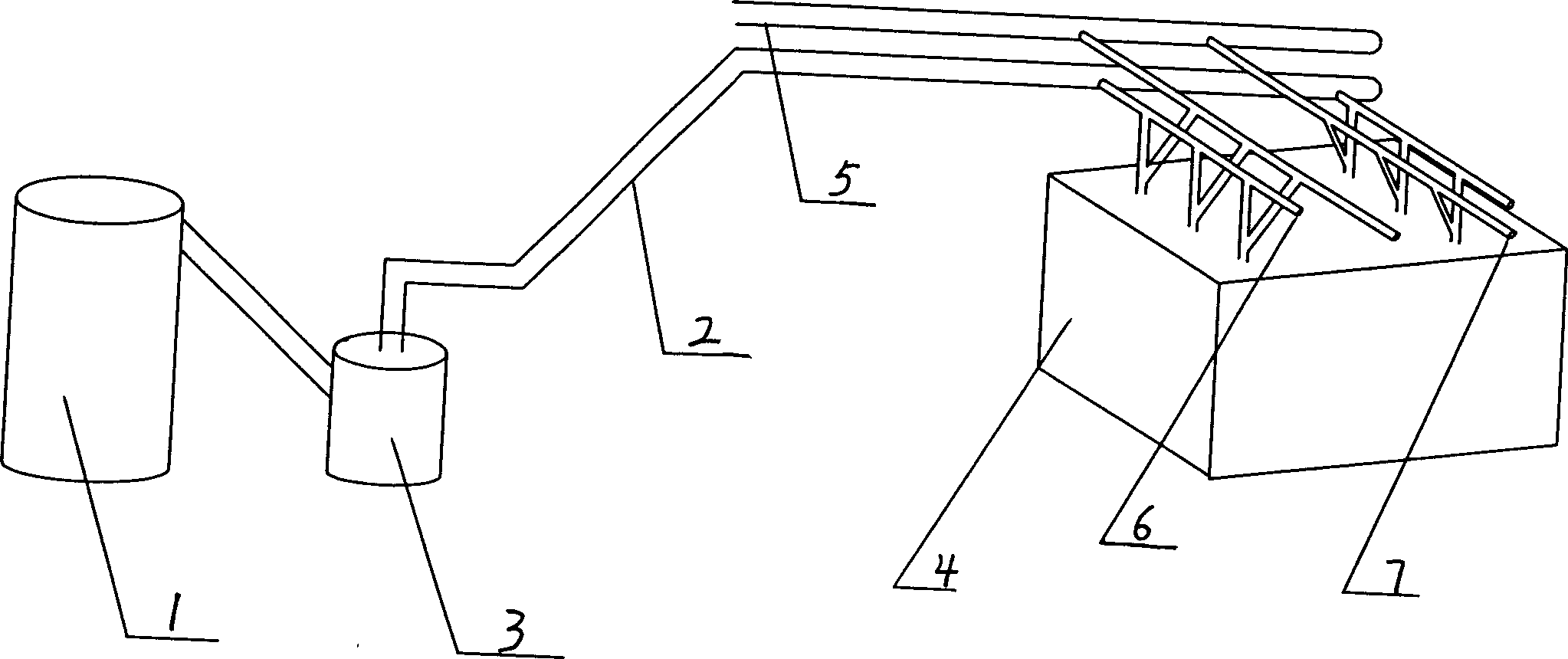

Electrolyzer circumfluence calcination method

The present invention provides electrolyzer circumfluence calcination method, when installing the electrolyzer, between the anode seam, center seam and inside edge cavity are provided with no materials, installing the electrolyzer in full cavity mode, then using the medium generated heat to calcine cathode lining of the electrolyzer in multiple heat transferring modes of radiation, convection and heat transmission etc, smoke generated by pressure difference during calcination circumfluence in the electrolyzer to make sure calcination temperature of all the sections is uniform, and avoids problem of heat stress centralization and sodium enriching in part effectively; a high-temperature insulation thermal insulating layer is lay in anode seam cavity, center seam cavity and top of edge cavity in the electrolyzer for reducing heat loss effectively, improving warming speed, shorting calcination time, saving energy sources and helpful for earlier regular production of the electrolyzer, meanwhile can reduce calcination energy consumption effectively and improve affect of radiation on operation environment; and the most important is that, using full electrolytes powder to instead of cryolite can reduce calcination startup cost greatly.

Owner:YUNNAN RUNXIN ALUMINUM

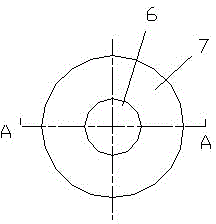

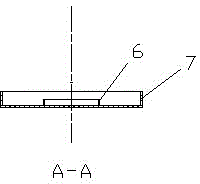

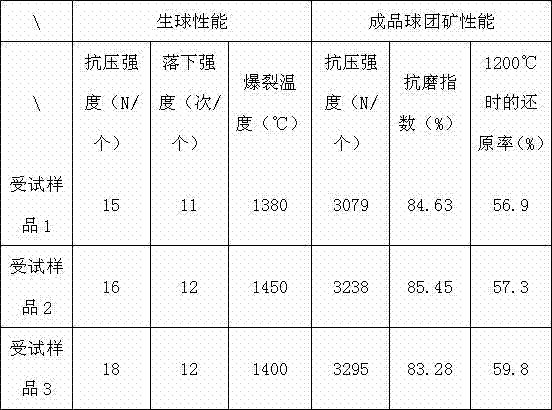

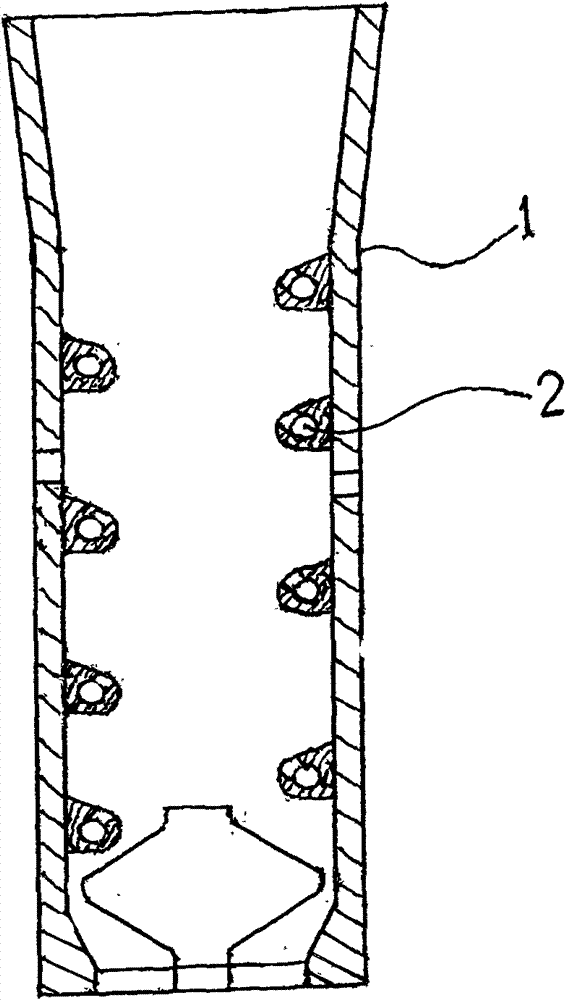

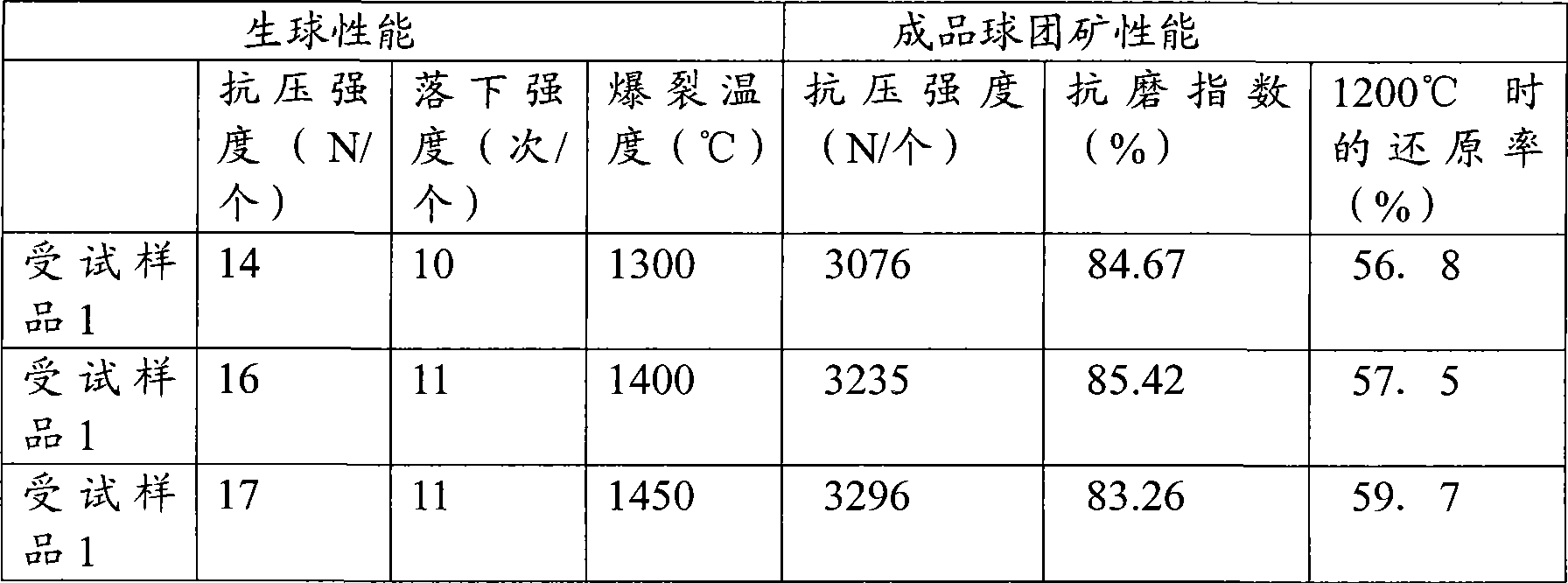

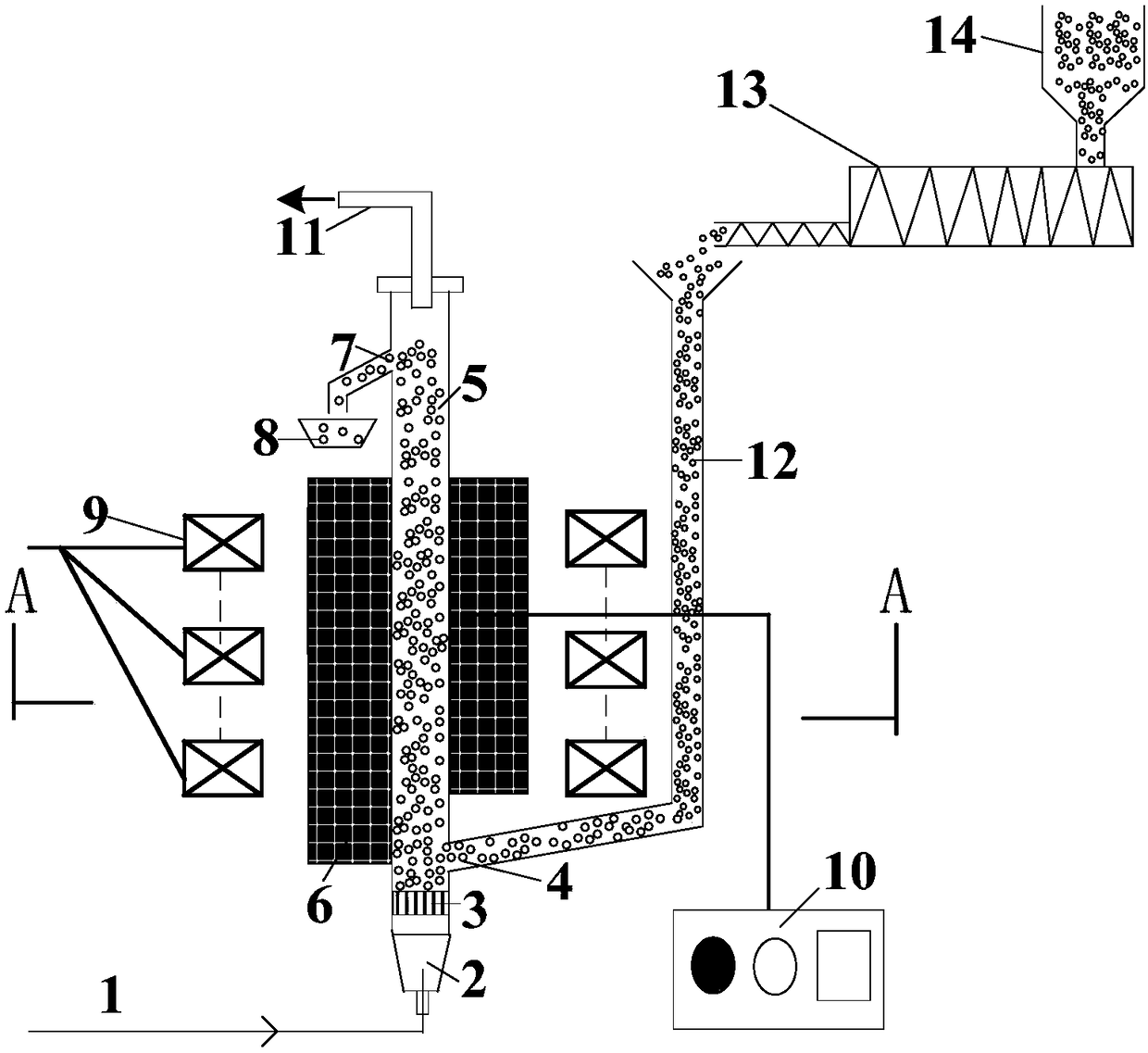

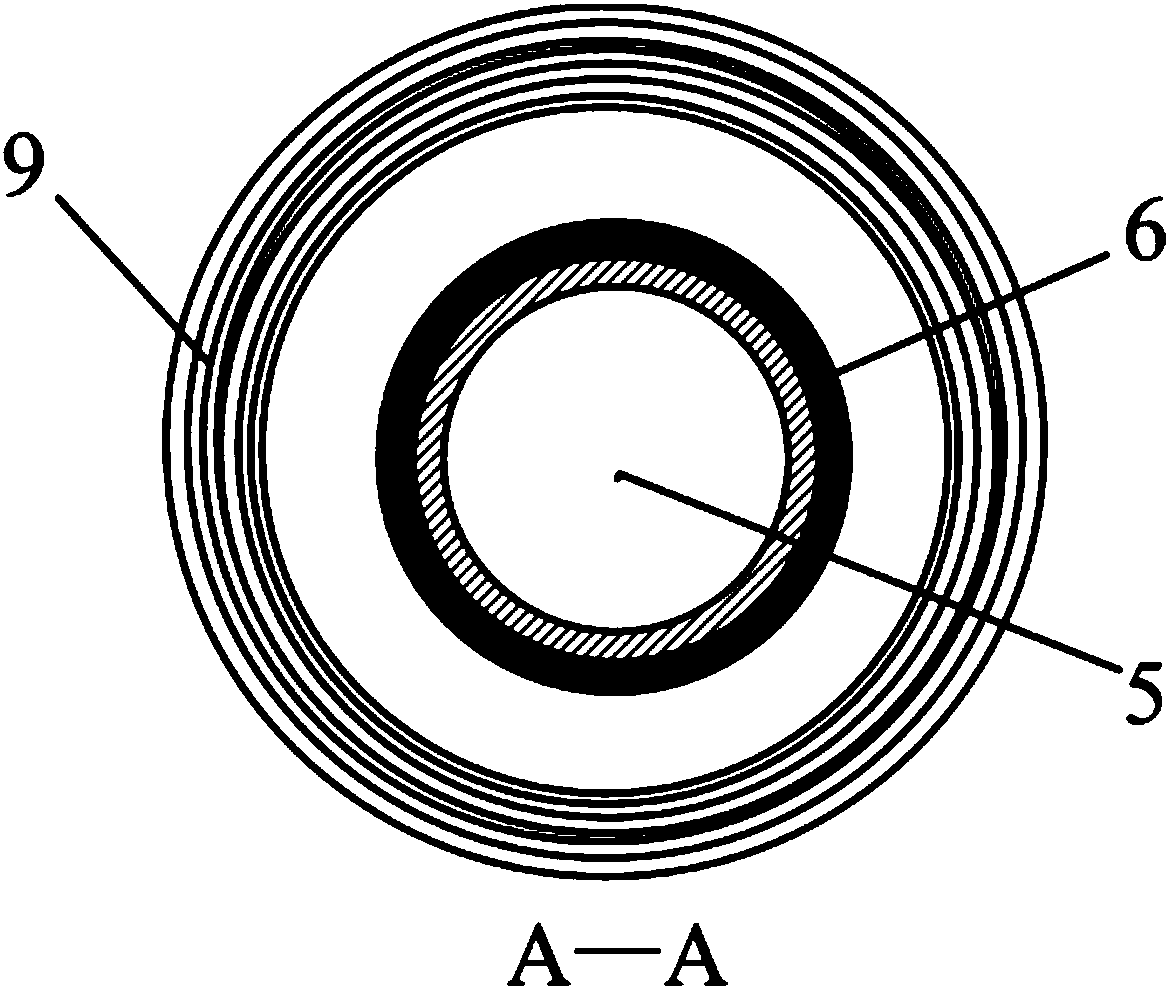

Production method of bilayer structure pellet and production equipment thereof

The invention discloses a production method of a bilayer structure pellet and production equipment thereof, belongs to the technical field of pellet production methods and equipment, and is used for producing a pellet having an inner-layer structure and an outer-layer structure. The technical scheme is that a mineral aggregate easy to generate an adverse effect on the pelletizing process and the roasting process is put in an inner-layer pelletizing disk to serve as a pellet core, and a mineral aggregate with good pelletizing performance and in favor of roasting is put in an outer-layer pelletizing disk to grow to a pellet, so that the pellet with the inner-layer structure and the outer-layer structure is formed, and the influence on the pellet by the adverse effect of the mineral aggregate is prevented. The method and the production equipment are simple in operation, are flexible in parameter adjustment, and can be adapted to a diversified raw material structure; under the condition of shortage of a high-quality iron ore resource at present, the novel production method and the novel production equipment are provided to realize reasonable resource utilization, to improve pellet quality and to guarantee smooth production; and the production method and the production equipment have positive and prominent effects on the sustainable development and the economic benefit improvement of iron and steel enterprises, and have strong promotion and application values.

Owner:邯郸钢铁集团设计院有限公司

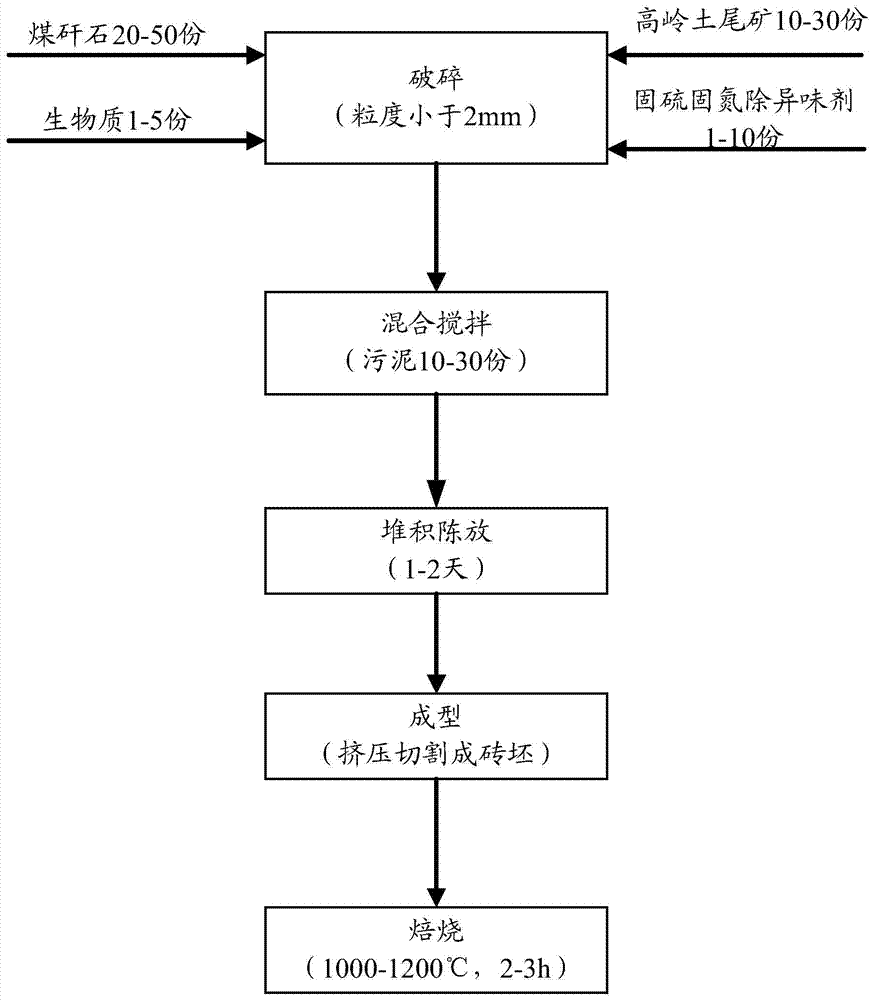

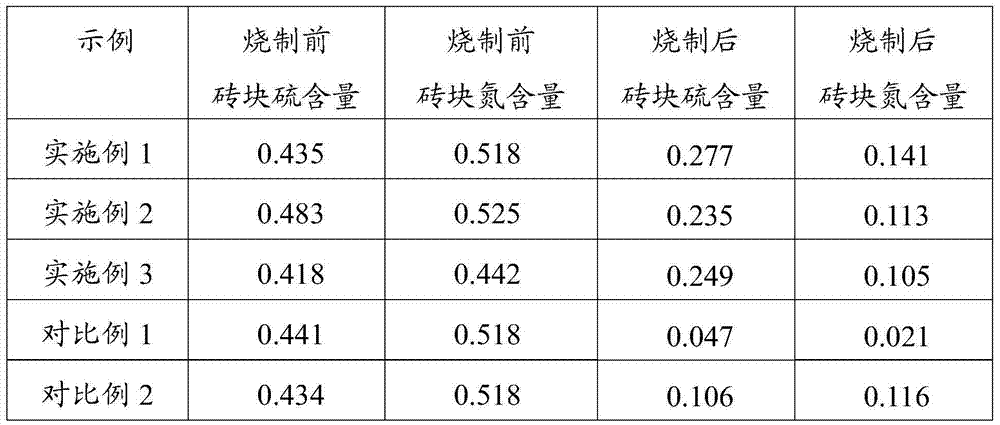

Light brick and preparation method thereof

ActiveCN103613362AWill not polluteGood sulfur and nitrogen fixationCeramic materials productionCeramicwareCooking & bakingBrick

The invention discloses a light brick and a preparation method thereof. The light brick is mainly prepared from the following raw materials in parts by weight: 10-30 parts of sludge, 20-50 parts of coal gangue, 10-30 parts of kaolin tailing, 1-5 parts of biomass and 1-10 parts of sulfur and nitrogen fixation deodorant, wherein the sulfur and nitrogen fixation deodorant consists of 90-99wt% of calcium oxide and 1-10wt% of potassium carbonate. The preparation method comprises the steps of weighing various raw materials in parts by weight, uniformly mixing, aging, pre-forming and molding, and baking the materials. The light brick is light in weight, good in heat preserving and sound insulating effects, and excellent in sulfur and nitrogen fixation effect, and effectively solves a problem of a conventional high-temperature baking process which ignores Sox and NOx discharge for a long time; and the preparation method is simple and easy in process.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Grading technology for cold-pressed pelletizing and shaft furnace magnetization roasting of powdery refractory iron oxide ore

ActiveCN102747217ARaise the gradeHigh recovery rateProcess efficiency improvementShaft furnaceShaft furnaceRoasting

A grading technology for cold-pressed pelletizing and shaft furnace magnetization roasting of powdery refractory iron oxide ore comprises the following steps: 1, preparing a combined binder through using clay or bentonite, and industrial magnesium chloride; 2, fragmenting the powdery refractory iron oxide ore, mixing with the combined binder to prepare cold-pressed balls, and sieving; or grinding the powdery refractory iron oxide ore, grading through a strong magnetic process, dehydrating, mixing with the combined binder to prepare the cold-pressed balls, and sieving; or carrying out strong magnetic selection to produce ore tailings, enriching through an ore selection process, dehydrating, mixing with the combined binder to prepare the cold-pressed balls, and sieving; 3, drying materials which cannot pass through a sieve, sieving the dried materials, returning materials which pass through the sieve to a pelletizing operation, sending balls which cannot pass through the sieve to a double combustion chamber shaft furnace to undergo a reduction reaction, cooling, and completing ore grinding and weak magnetic grading through an ore grinding and grading system. According to the technology, a large amount of idle or abandoned low-grade powdery iron oxide ore is recycled, the particle size range of ore roasted in the shaft furnace is enlarged, the shaft furnace magnetization roasting of the powdery refractory iron oxide ore is realized, and the shaft furnace is maximally utilized to complete the ore roasting.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

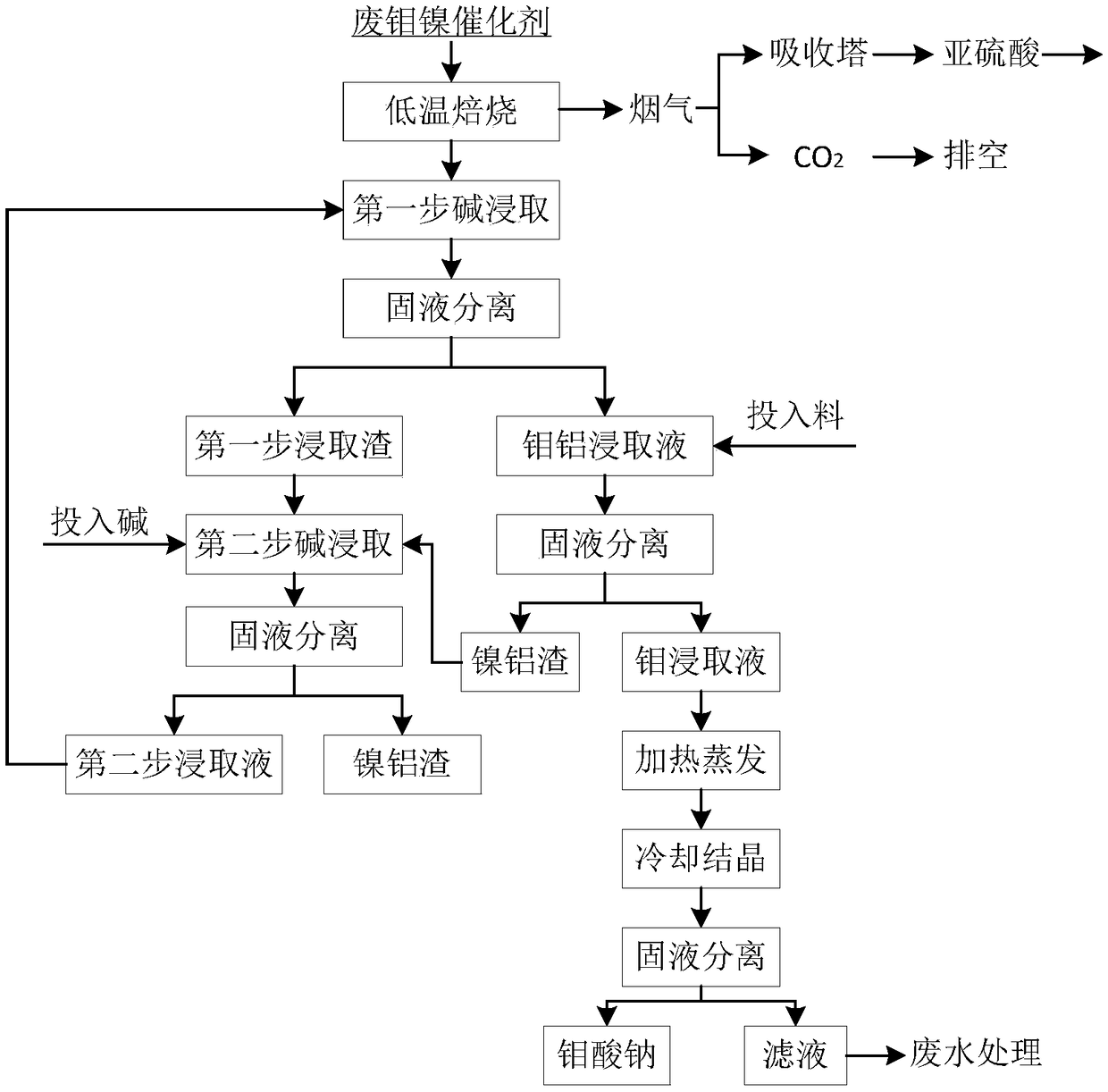

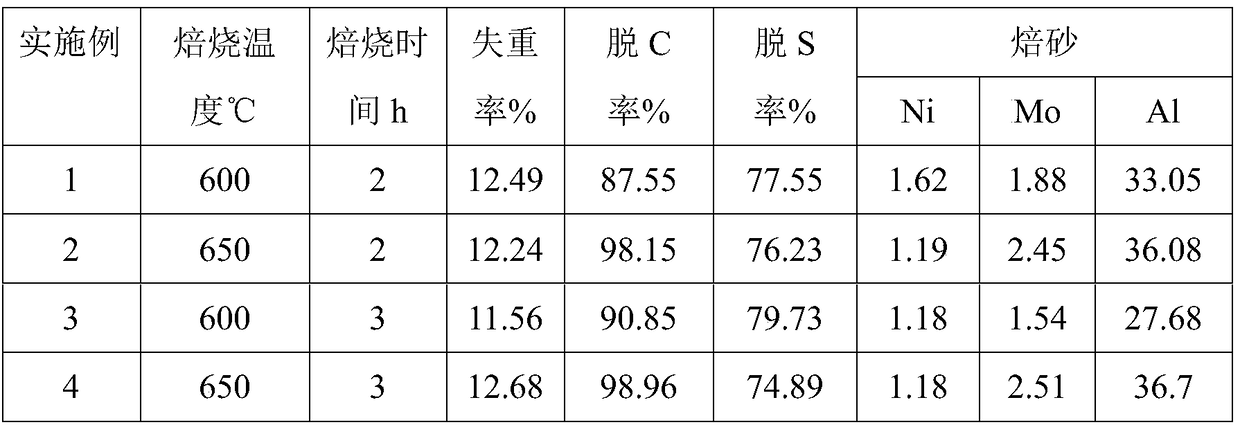

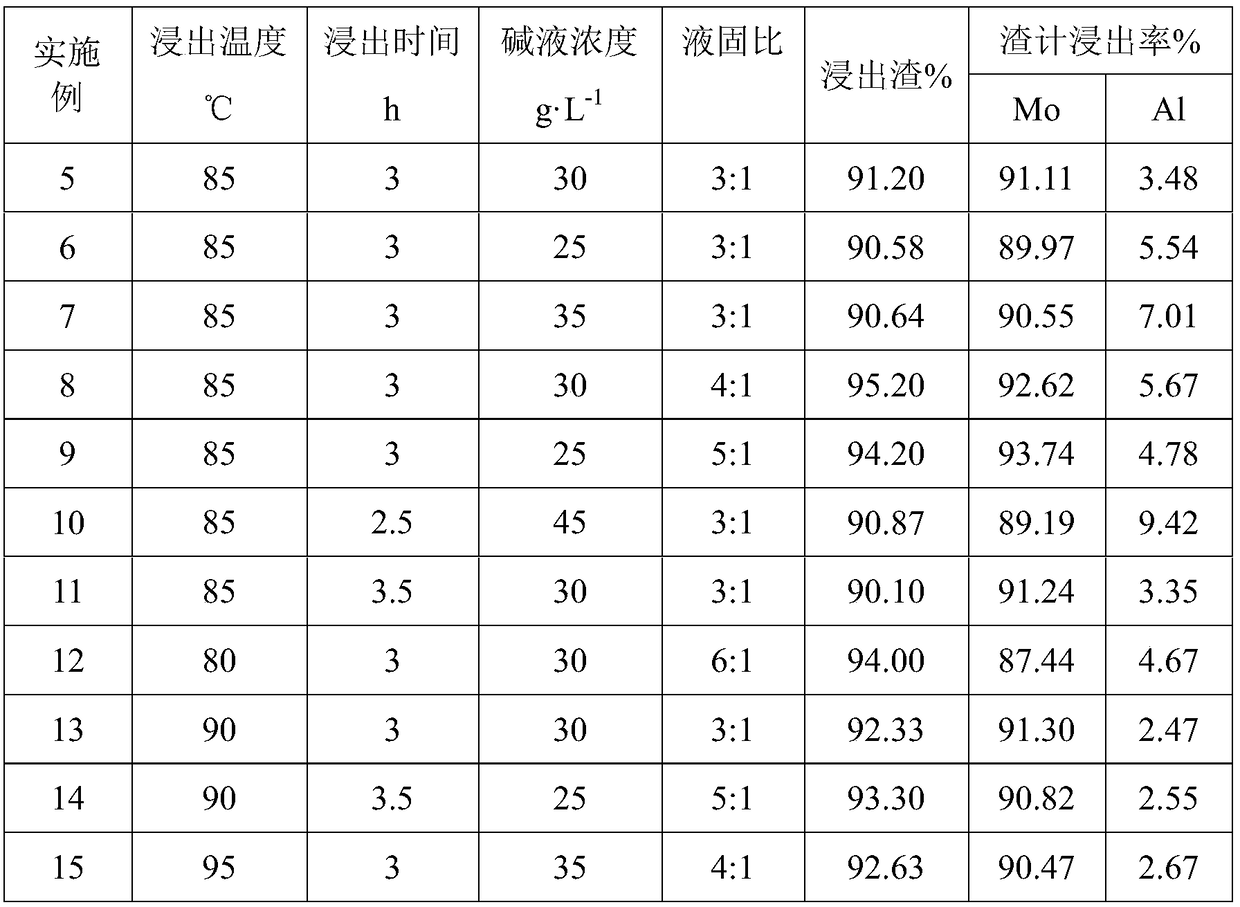

Method for extracting molybdenum from waste nickel-molybdenum catalyst

The invention discloses a method for extracting molybdenum from a waste nickel-molybdenum catalyst. The method comprises the specific steps that organic matter, sulphur, heavy metal arsenic and the like which are attached to the catalyst are removed through oxidation volatilization by means of low temperature roasting, then circulation two-stage ordinary pressure alkali leaching is adopted for achieving separation of nickel from molybdenum aluminum, sodium molybdate crude liquid is obtained and is subjected to heating, evaporation and concentration, cooling crystallization is carried out, andfiltering and separating are carried out to obtain a sodium molybdate product. According to the method, no reagent needs to be added in the roasting process, corrosion to roasting equipment is small,the operation condition is mild, the environmental pollution is small, comprehensive recovering and using of valuable metal in the catalyst are achieved, the sodium molybdate product is obtained, therecovering rate of the valuable metal is high, the product additional value is high, and a certain application value is achieved.

Owner:XUZHOU GUOMAO VALUABLE & RARE METAL COMPREHENSIVE UTILIZATION INST +1

Method for roasting and preheating aluminum electrolysis cell using direct currents

The invention relates to a method for roasting and preheating an aluminum electrolysis cell using direct currents and is characterized in that radiation heating tubes are used for replacing scorched particles to serve as heating media, and currents of an electrolytic cell series are connected, so that heat produced by the radiation heating tubes in a electrolysis cell cavity is transferred to the surrounding to heat, warm and roast linings and anodes in an electrolysis cell cathode continuously in radiation, convection and heat conduction modes, a heating device is detached after the temperature reaches or approaches a roasting start temperature of the electrolysis cell, and electrolyte is infused to start the heating device. Compared with traditional roasting methods, the method for roasting and preheating the aluminum electrolysis cell using direct currents has the advantages that the roasting effect is good, the energy consumption is low, the environment benefit is good, the labor intensity is low and the like.

Owner:YUNNAN RUNXIN ALUMINUM

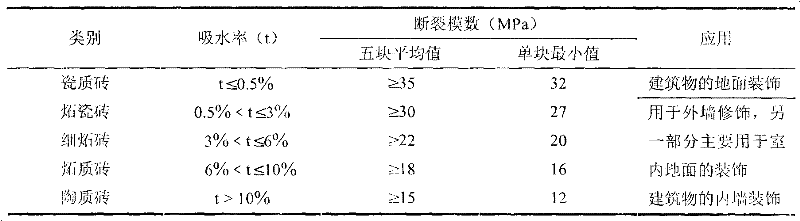

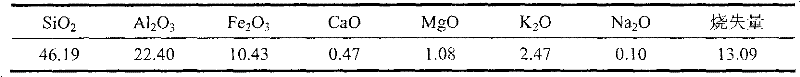

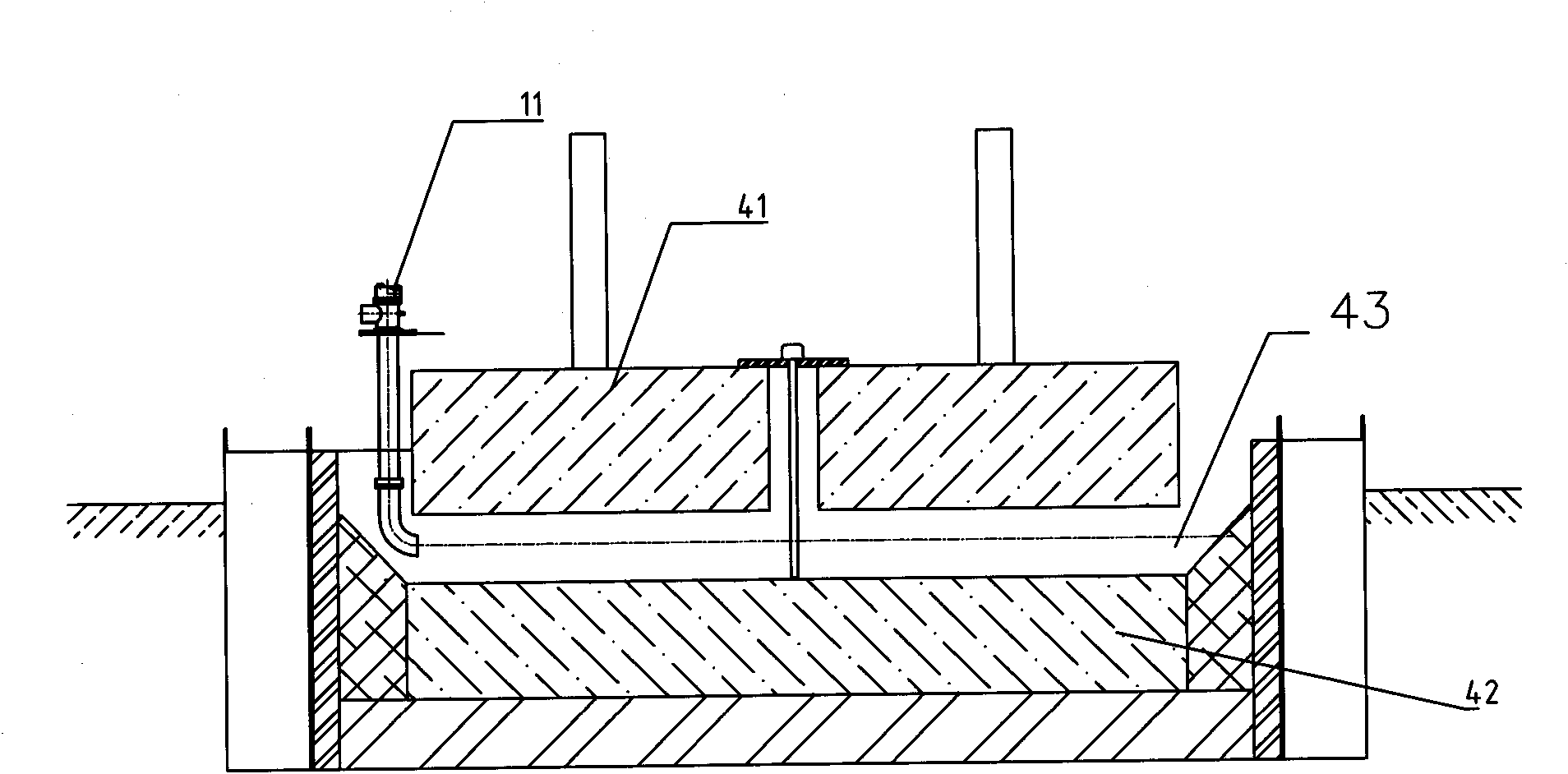

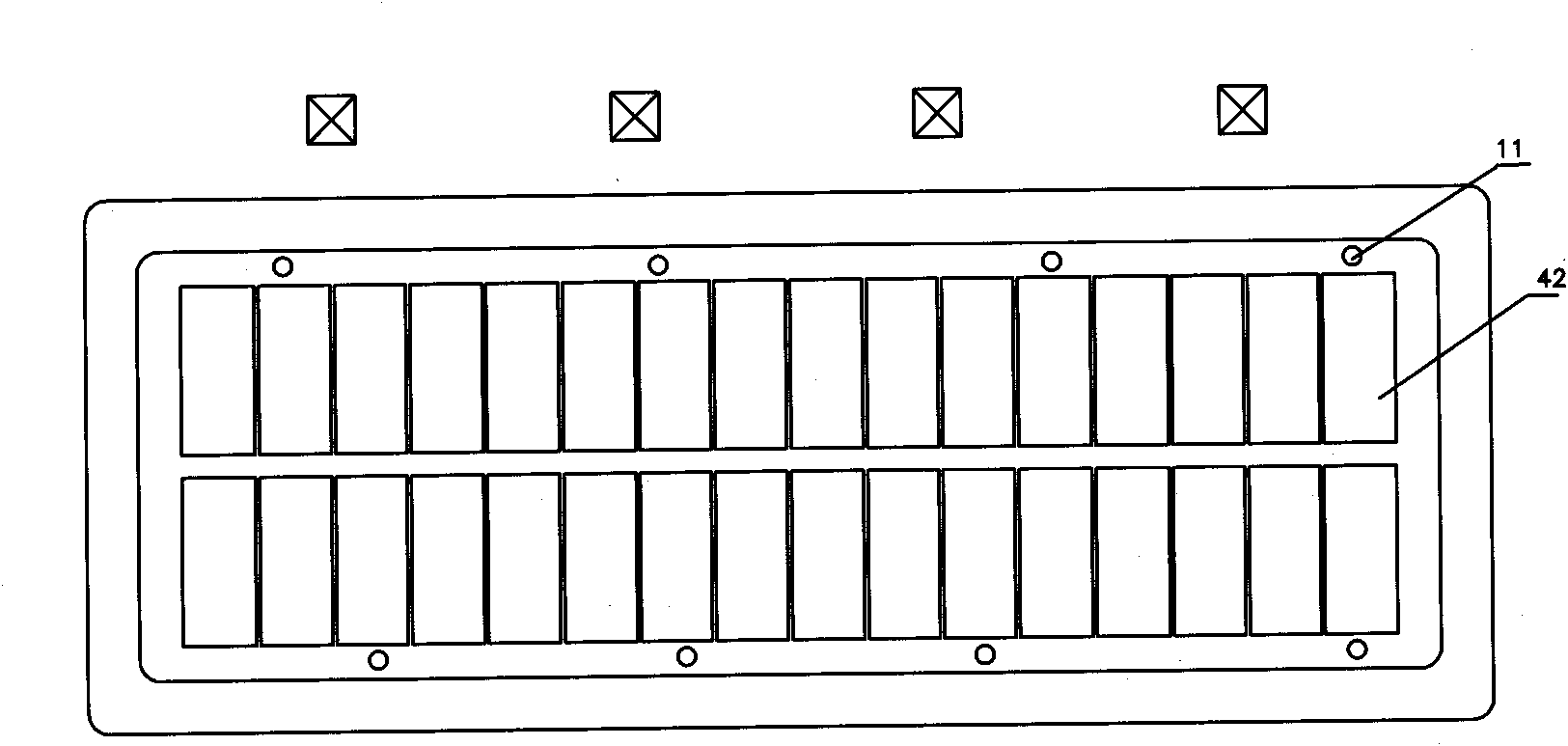

Technology for preparing ceramic tile from high-volume municipal water supply plant sludge

InactiveCN102173749AEfficient curingEasy to leachCeramic materials productionClaywaresBrickDry weight

The invention discloses a technology for preparing a ceramic tile from high-volume municipal water supply plant sludge, and belongs to the field of solid waste recycling and building material production in environmental engineering. The technology comprises the following steps of: uniformly mixing 38 to 42 mass percent of municipal water supply plant dewatering sludge powder (dry weight) with a certain grain size, 38 to 42 mass percent of kaolin and 16 to 24 mass percent of potassium feldspar powder, adding water which is about 20 percent based on the dry weight of the total material, uniformly mixing, and storing for certain time in a constant-temperature environment; and performing compression molding under certain pressure, raising the temperature from room temperature to 1,200 DEG C by a certain method and keeping temperature for one hour, and naturally cooling to the room temperature to obtain the finished product. Through detection, the main technical indexes meet the related national standard. By the technology, the water supply plant sludge is effectively utilized, and other brick production raw materials are substituted; and the technology has good environmental benefit and certain economic benefit.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Fluidization roasting separation method of siderite-containing mixed iron ores

The invention discloses a fluidization roasting separation method of siderite-containing mixed iron ores. The fluidization roasting separation method comprises the following steps: carrying out multi-stage fluidization preheating on the siderite-containing mixed iron ores with the particle size of -0.5mm in an oxidizing atmosphere until the temperature of the mixed iron ores is 600-800 DEG C; roasting the preheated materials in a reducing atmosphere under the fluidized state condition, further carrying out fluidization cooling in air until reaching the room temperature, and carrying out ore grinding and magnetic separation, so as to obtain the siderite-containing mixed iron ores. The fluidization roasting separation method is applicable to the separation of multiple siderite-containing mixed ores, high in reaction speed and efficiency, low in energy consumption, good in separation effect and very suitable for being industrially popularized, and side products which are adverse to separation are few.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

Roasting method for extracting vanadium from vanadium-containing shale

InactiveCN102230072AImprove conversion rateAdd lessVanadium compoundsProcess efficiency improvementLeaching rateRise rate

The invention relates to a roasting method for extracting vanadium from vanadium-containing shale. According to the technical scheme of the invention, the method comprises the following steps of: uniformly mixing vanadium-containing shale raw ore with a vanadium-containing shale extraction roasting additive in a ratio of 1:(0.06 to 0.1), feeding the mixture to a roasting furnace, heating to 850 to 1000 DEG C at a temperature rise rate of 400 to 500 DEG C / h, maintaining the temperature for 1 to 2 hours, then adding the roasted product to dilute sulfuric acid with volume fraction of 4 to 10% in a solid-liquid mass ratio of 1:2, and leaching at 90 to 100 DEG C for 0.5 to 1 hour under the condition of stirring. The preparation method of the vanadium-containing shale extraction roasting additive comprises the steps of: preparing Mg compounds, namely NaClO3, Na2CO3 and CaCO3 and mixing uniformly, wherein the mass ratio of NaClO3:Na2CO3:CaCO3 is 1:1:(4 to 8):(6 to 10); and grinding until the particle size is not more than 0.15 mm. The method provided by the invention increases the leaching rate up to 86% to 87% and has the characteristics of high recovery rate, short roasting period, high leaching speed and little roasting pollution.

Owner:WUHAN UNIV OF SCI & TECH

Sintering prevention vanadium-containing stone coal microwave roasting method

The invention relates to a sintering prevention vanadium-containing stone coal microwave roasting method. According to the technical scheme, the method includes: crushing vanadium-containing stone coal into coarse-grained vanadium-containing stone coal with the grain size less than 6mm and greater than 1mm and fine-grained vanadium-containing stone coal with the grain size less than 1mm; adding water to the fine-grained vanadium-containing stone coal to be mixed according to the mass ratio of the fine-grained vanadium-containing stone coal to the water of 1:0.06-0.09 to produce small balls 3-8mm in grain size and drying the small balls; placing the dried small balls in an industrial microwave roasting device as bedding materials, placing the coarse-grained vanadium-containing stone coal on the bedding materials prior to microwave roasting, and cooling to indoor temperature to obtain vanadium-containing stone coal roasting materials, wherein the microwave roasting is characterized in that the temperature rate ranging from 25 DEG C / min to 55 DEG C / min is increased rapidly to the temperature rate ranging from 750 DEG C to 850 DEG C, 25-40 min constant-temperature microwave roasting is performed, and the industrial microwave roasting device is 2400 to 2500 MHz (megahertz) in frequency. With the method, sintering during microwave roasting of the vanadium-containing stone coal is obviously reduced, and the effect of microwave roasting is good.

Owner:WUHAN UNIV OF SCI & TECH

Flame roasting direct-on starting process of aluminum electrolysis cell

ActiveCN101851768AReduce vertical temperature gradientPrevent oxidationTemperature controlElectrolysis

The invention discloses a flame roasting direct-on starting process of an aluminum electrolysis cell, comprising the following steps in sequence: selecting an electrolysis cell, installing the electrolysis cell, installing a gas control system, determining the position of a gas burner, debugging a gas temperature control system and setting a roasting curve of aluminum electrolysis cell temperature control equipment; controlling an ignition roasting procedure; starting the gas control system of the electrolysis cell; adopting a batch injection method to inject electrolyte in the electrolysis cell; and electrifying and starting the process. The process has the advantages that a cell chamber is heated uniformly by flame formed by reasonable arrangement of controllable gas; a better roasting effect is achieved by reducing the temperature gradient of a cathode surface along the vertical direction so as to prevent heat shock damage resulted from an overlarge heating gradient and non-uniform lining temperature; and a reasonable coking process for bottom mash is realized by setting a reasonable heating curve, thus effectively getting rid of moisture and volatile substances in a lining, reducing and effectively filling in holes produced in the roasting process of the cathode and the bottom mash, and enhancing the integrality of the cathode, the bottom mash and the lining.

Owner:包头铝业有限公司

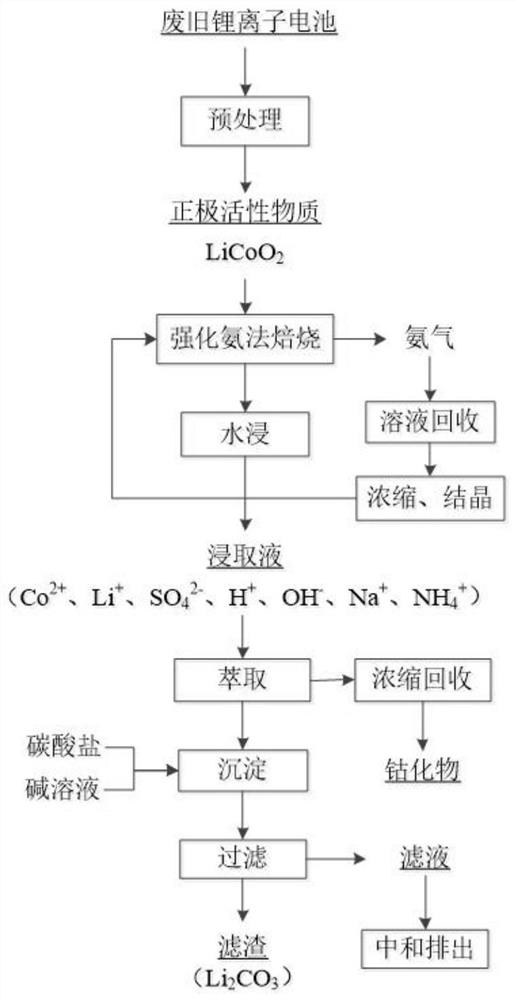

Method for recovering cobalt and lithium metals from waste lithium cobalt oxide battery

InactiveCN112095000AReduce recycling costsImprove extraction efficiencyWaste accumulators reclaimingProcess efficiency improvementAmmonium sulfateChemistry

The invention provides a method for recovering cobalt and lithium metals from a waste lithium cobalt oxide battery. The method is characterized by comprising the following steps: (1) carrying out discharge treatment on the waste lithium cobalt oxide battery, and carrying out disassembly, crushing, pyrolysis and screening to obtain black lithium cobalt oxide powder; (2) mixing the black lithium cobalt oxide powder obtained in the step (1) with ammonium salt according to a molar ratio of 1: (1.5-4), putting the mixture into a high-temperature ball mill for enhanced ammonia process roasting to convert the lithium cobalt oxide into sulfate, performing water leaching to obtain a leaching solution rich in Co < 2 + > and Li < + >, recycling ammonia gas generated in the process, and recycling andreusing the ammonia gas in the form of ammonium sulfate; and (3) selectively recovering cobalt and lithium components from the leaching solution rich in Co < 2 + > and Li < + > obtained in the step (2), recovering cobalt by using an organic extracting agent, recovering lithium in residual liquid by using a precipitation method, and recovering the lithium in the form of lithium carbonate. The method meets the requirements of environmental protection, low consumption, high efficiency and short-process recovery of valuable metals from the waste lithium ion battery.

Owner:NORTHEASTERN UNIV

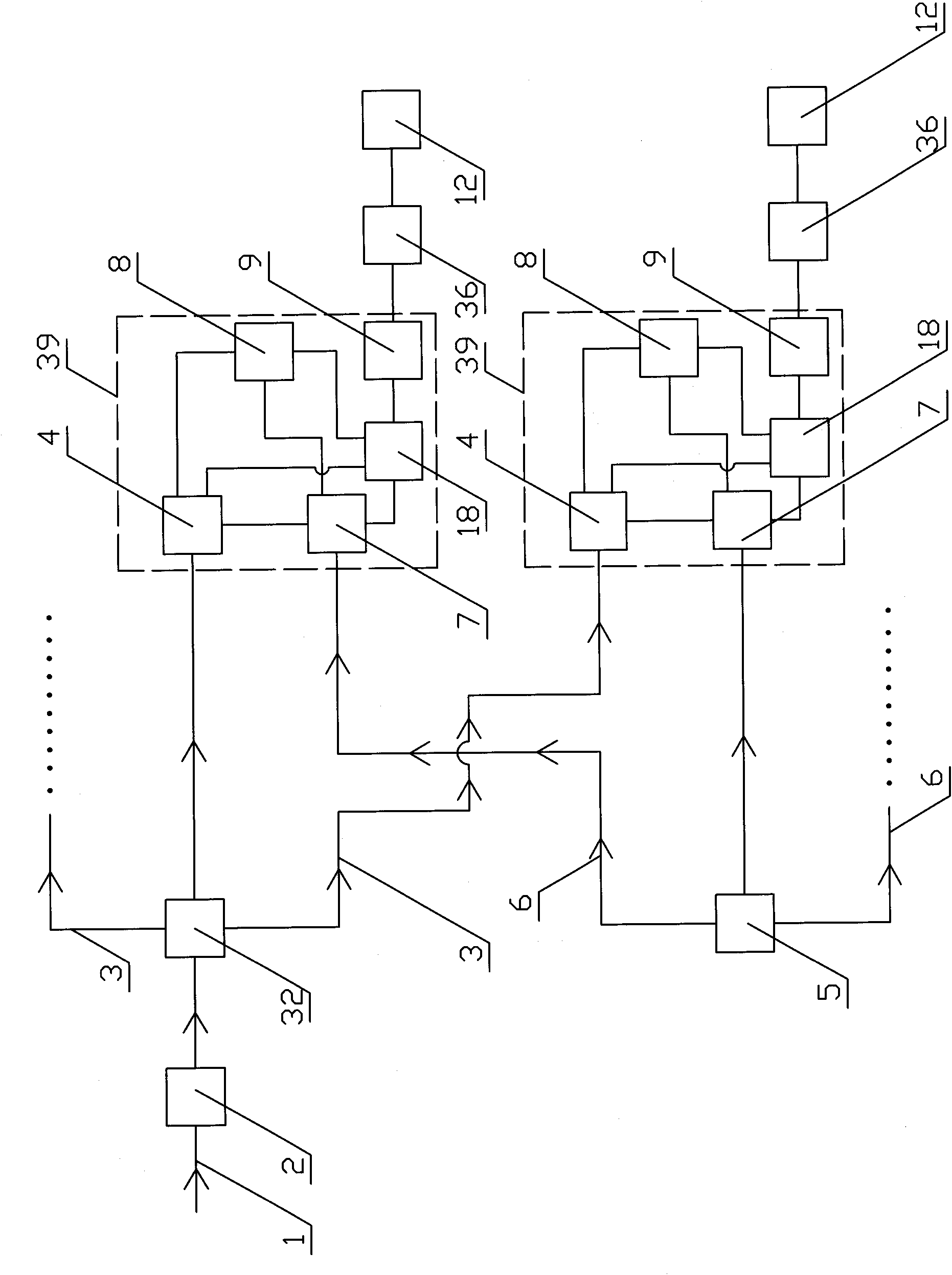

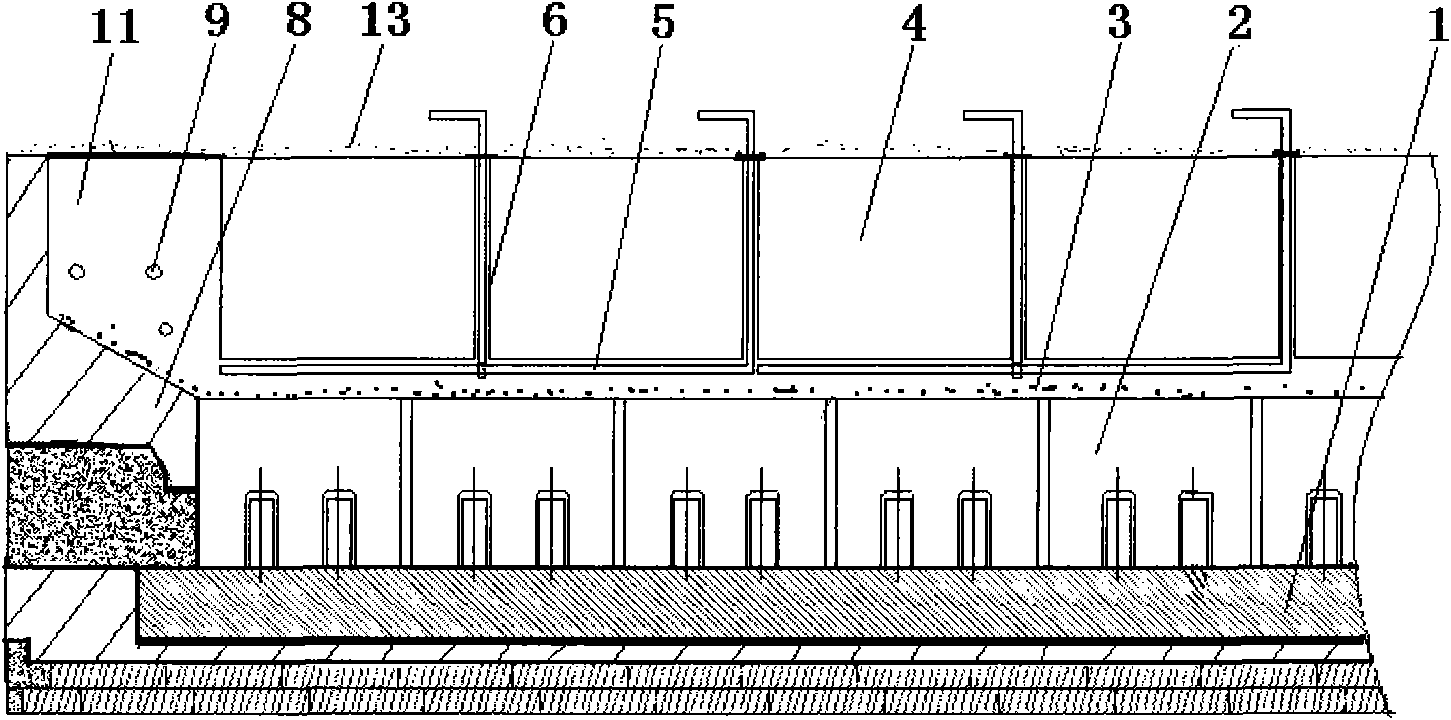

Multi-bed linkage fluidized bed roasting furnace

A multi-bed linkage fluidized bed roasting furnace comprises a feeding device, a combustion chamber, a top passing flue arranged at the top of the combustion chamber, a cold slag device and a cyclone separator connected behind the top passing flue. Roasting beds at two or more levels are arranged under the combustion chamber, each roasting bed at the previous level and the corresponding roasting bed at the next level are arranged in a stepped mode, each roasting bed comprises an air chamber, an air distributing plate, air caps arranged on the air distributing plate and a slag discharging pipe on the bed, and an additive opening for adding calcium-based additives or combustion-supporting coal is formed in the upper portion of each roasting bed; the cold slag device is arranged behind the roasting bed at the last level. The height difference h between each roasting bed at the previous level and the corresponding roasting bed at the next level is 100-300 mm, wherein the roasting beds are arranged in the stepped mode. The multi-bed linkage fluidized bed roasting furnace has the advantages of being high in roasting efficiency and treating roasting flue gas well.

Owner:BEIJING SIWEI TIANTUO TECH CO LTD

Bentonite used for pellets, and preparation method thereof

The invention discloses bentonite used for pellets, and a preparation method thereof. The bentonite is composed of the components of, by weight: 90-100 parts of bentonite, 3-5 parts of industrial alkali, and 1-3 parts of cellulose ethers or cellulose sodium. When the pellet-use bentonite provided by the invention is used for coating obtained iron ore pellets, pellet bursting is reduced. The iron ore pellets can be prevented from bursting under more than 3000 Newton and 10 times of drops. Silicon content of the pellets is greatly reduced. As a result of furnace casting experiments, when the pellets are added at a temperature of 1200 DEG C, the pellets do not burst. Also, an iron tapping speed is substantially improved. Compared with a traditional method that only bentonite is used as an additive, the pellet-use bentonite provided by the invention is advantaged in high adhesive force, high pellet degree, reduced roasting time, good roasting performance, improved pellet ore grade, and reduced energy consumption.

Owner:绵阳堃山矿业有限公司

Method for producing ceramic die core

The invention provides a method for producing a ceramic die core. The method comprises the following steps of (1) producing a ceramic die core blank; (2) pre-treating a filler for the shaping of the ceramic die core, specifically adding the filler to be treated into a nonmetal material hopper with de-ionized water, continuously stirring slurry obtained by mixing powder and de-ionized water, continuously dropwise adding analytically pure hydrochloric acid to adjust the pH value of the slurry to 4 to 6, stopping adding analytically pure hydrochloric acid when the pH value is changed by less than or equal to 0.2 within 5 minutes, continuing stirring the slurry for 10 to 60 minutes, standing and settling the slurry for 4 to 12 hours, pouring an upper-layer solution, washing settled powder for 1 to 3 times by using de-ionized water until the pH value of an obtained solution is 6 to 8, drying the powder finally sinking to the bottom at 100 to 140 DEG C, calcining the powder for 4 to 6 hours at 1200 to 1500 DEG C, and crushing and sieving the powder; (3) performing shaping calcination; (4) performing reinforcement reconditioning. The method is simple, economical and low in time consumption, manpower is saved, energy consumption is eliminated, the production efficiency of the ceramic die core is greatly improved, and the quality of the ceramic die core is improved.

Owner:DONGFANG TURBINE CO LTD

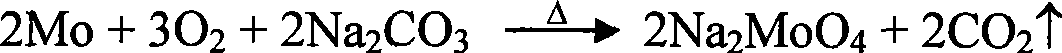

Method for extracting molybdenum by roasting high impurity sodium carbonate nickel-ferro-molybdenum

InactiveCN101386922AFast responseGood roasting effectProcess efficiency improvementSodium carbonateNickel

The invention relates to a method for extracting molybdenum by roasting nickel-molybdenum iron alloy sodium carbonate with high impurities. The process comprising three main steps of preparation, roasting and leaching is as follows: firstly adding sodium carbonate and lime into nickel-molybdenum iron alloy powder with high impurities to evenly mix and mill to roast the sodium carbonate and the lime; and leaching calcine obtained from roasting in a dilute alkali solution into molybdenum and vanadium. The method has the advantages of a small amount of sodium carbonate, high extraction rate of molybdenum and vanadium, low production cost and environment protection and so on.

Owner:CENT SOUTH UNIV

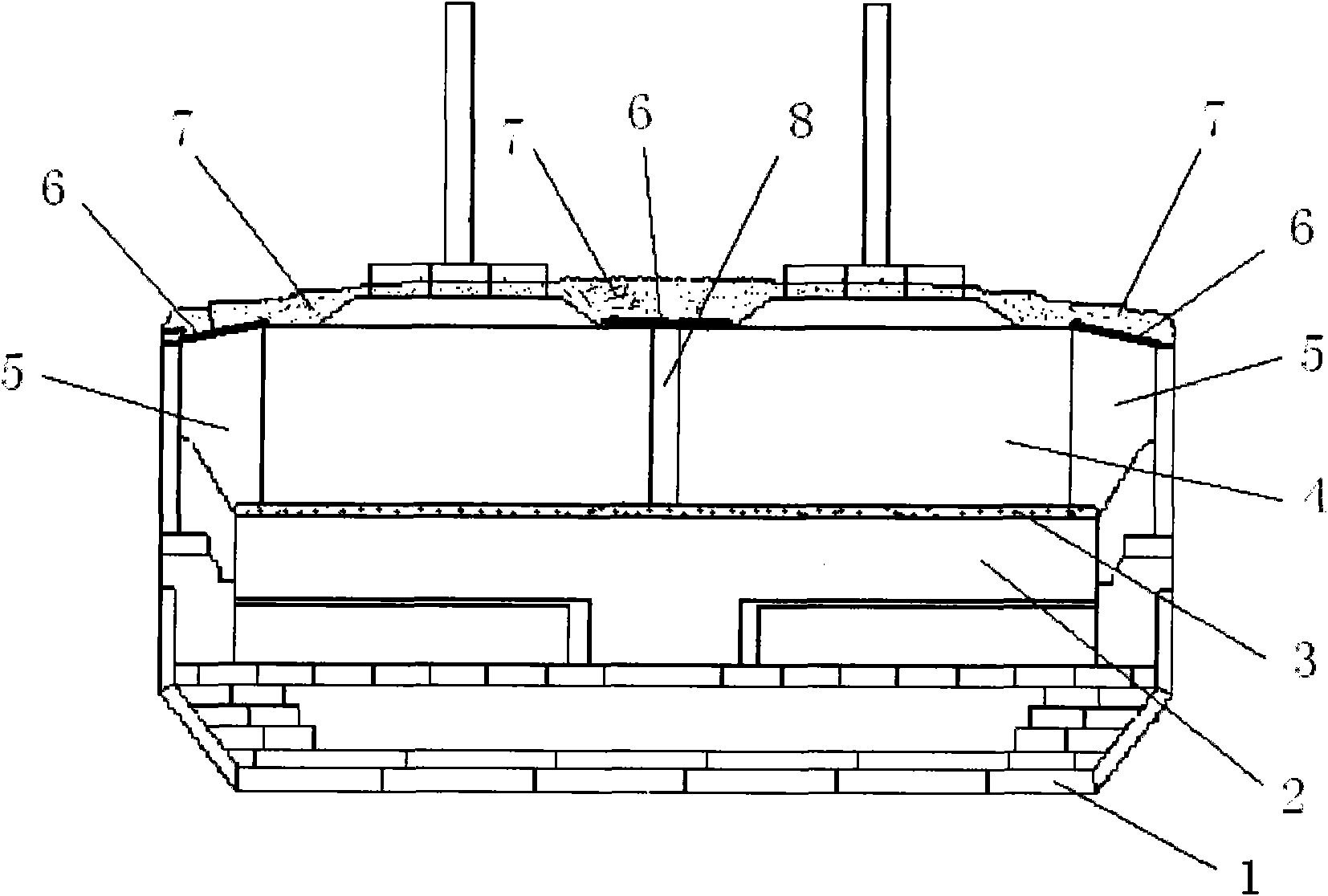

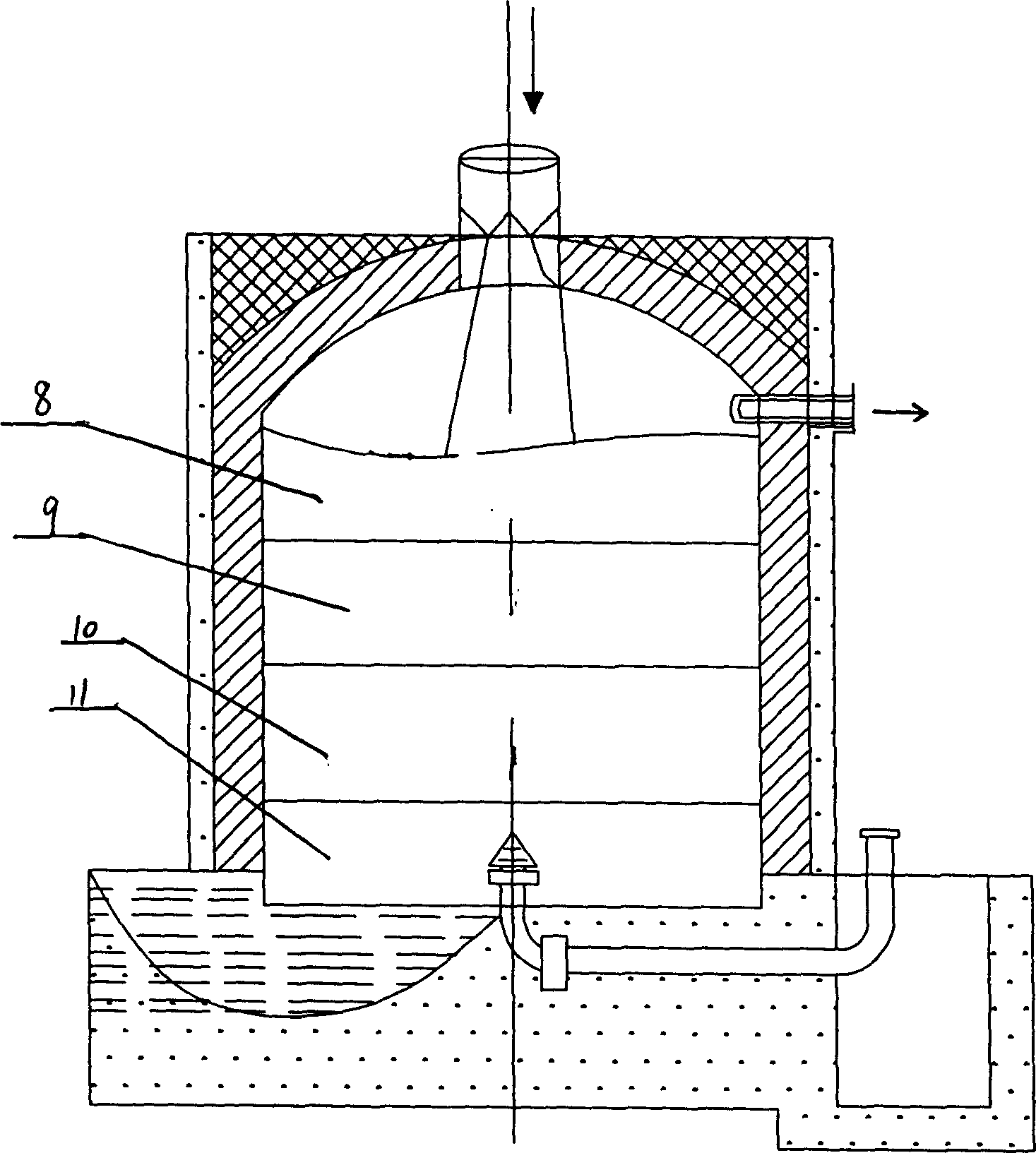

Electric heating roasting preheating electrolytic bath and cleaning and roasting method

ActiveCN101886274ARealize low-carbon roastingImprove the operating environmentElectricityAutomatic control

The invention provides an electric heating roasting preheating electrolytic bath and a cleaning and roasting method. The electric heating roasting preheating electrolytic bath comprises a bath body, a cathode carbon block fixed at the bottom of the bath body, artificial extending legs arranged on the periphery of the cathode carbon block and an anode for lifting in the bath body. The electric heating roasting preheating electrolytic bath is characterized in that electric heating elements are movably arranged below the anode, an intermediate clearance cavity between anodes and a side part cavity between the anode and the bath body and are used for finishing the roasting and the heating of the electrolytic bath. The invention not only has uniform roasting temperature, high energy utilization rate and low electric consumption, but also can realize the automatic control of temperature raising speed, greatly improve the roasting effect, reduce the labor intensity and the roasting cost, simplify the operation and realize the low-carbon roasting. In addition, the invention can reduce the carbon content of electrolyte, avoid a starting bath from generating carbon-containing accidents, enable a roasting bath to be turned into normal production and generate relatively profound effect on improving the roasting method of the electrolytic bath in the further and improving the utilization rate of energy sources and resources, and has broad popularization and application potentials.

Owner:YUNNAN RUNXIN ALUMINUM

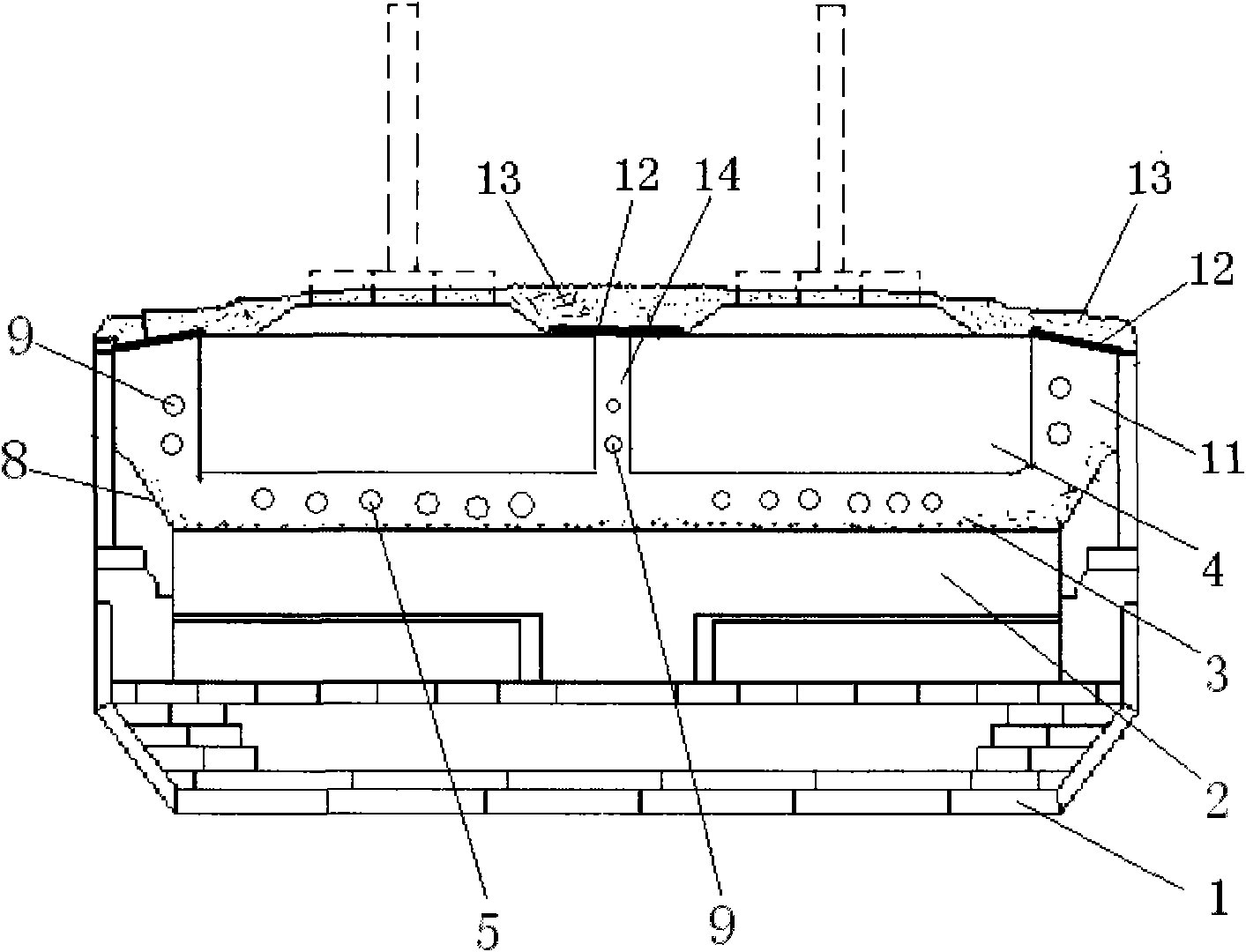

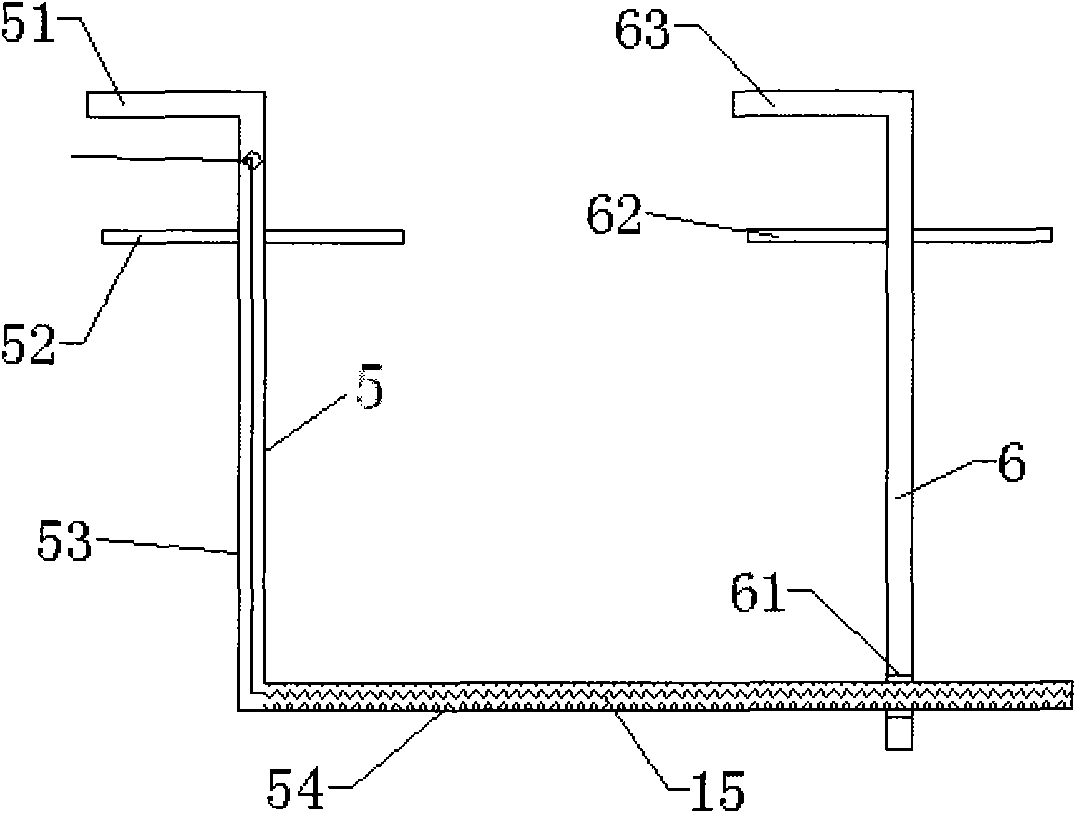

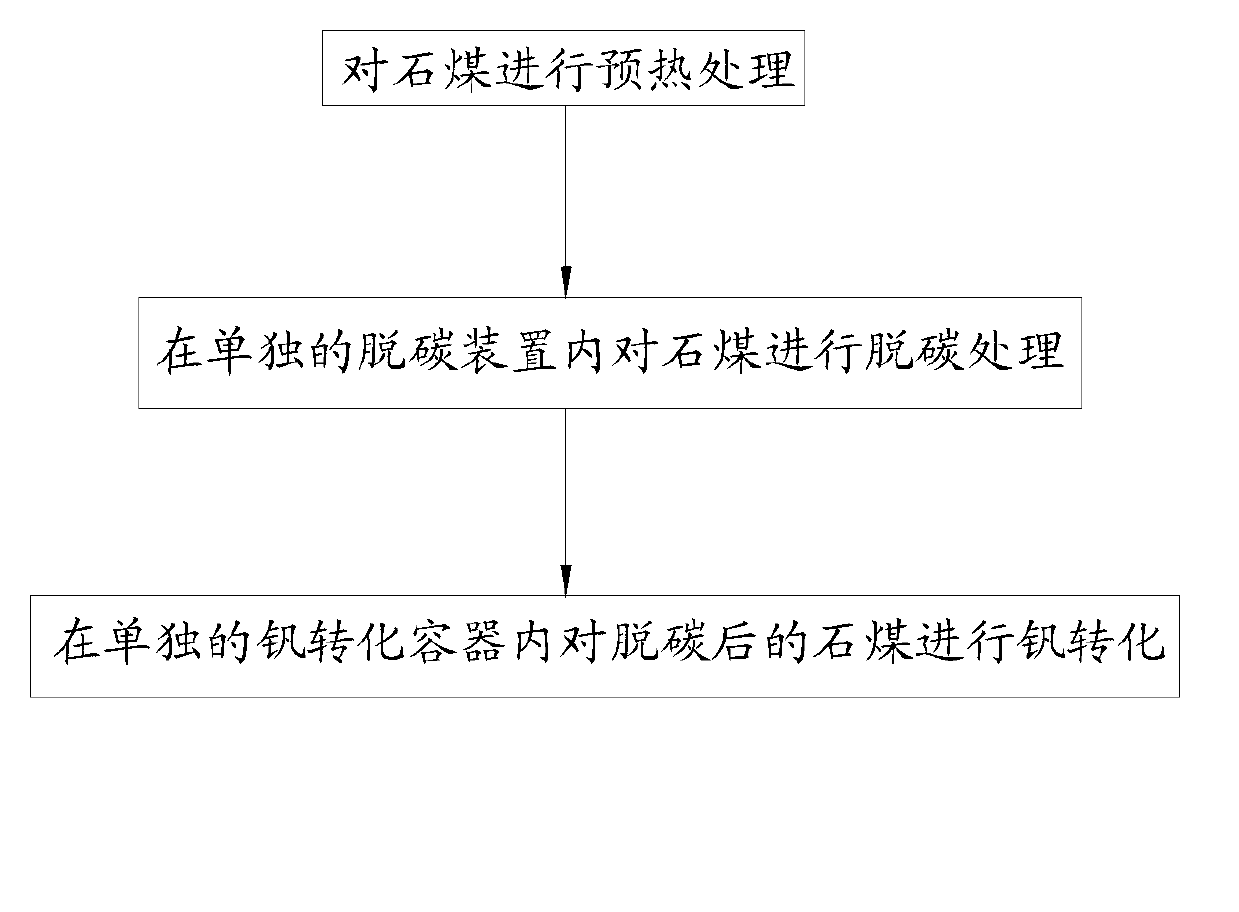

Roasting process for extracting vanadium from stone coal

ActiveCN102766762AAvoid conversion mutual constraintsEasy to control individuallySmall footprintCoal

The invention discloses a roasting process for extracting vanadium from stone coal. The process comprises the following steps of: decarburizing the stone coal in an independent decarburization device; and performing vanadium transformation on the decarburized stone coal in an independent vanadium transformation container. According to the roasting process for extracting the vanadium from the stone coal, the independent decarburization device and the independent vanadium transformation container are used for the decarburization of the stone coal and the vanadium transformation respectively, so that the mutual restriction of the decarburization and the vanadium transformation is avoided, conditions in the decarburization device and the vanadium transformation container can be respectively and independently controlled conveniently, the process has a roasting effect, and the immersion ratio of products is high. In addition, the whole equipment is low in cost and small in floor area, and the investment is reduced.

Owner:CHINA ENFI ENGINEERING CORPORATION

Calcining method for belt sintering machine

InactiveCN1776337ALow costIncreased sintering throughputFurnace typesGaseous fuel burnerSmall footprintEngineering

Under stable supply, coal gas is fired to burn materiel on lead sinter machine. Through gas pipe, coal gas generated from gas generator is entered to cyclone dust collector. Through gas pipe, dust removed coal gas is entered to branch pipe. Through air pipe, comburant air enters into branch pipe. After branch pipe for coal gas and branch pipe for comburant air are connected to each other, and led to burner, where gas and air are mixed fully in volume ration being about 1:1. Through the burner, mixed gas burns in firebox of ignition furnace. Advantages are: lowering cost by using gas to replace heavy oil, better controlling fire behavior, and good effect for baking materiel.

Owner:HENAN YUGUANG GOLD & LEAD

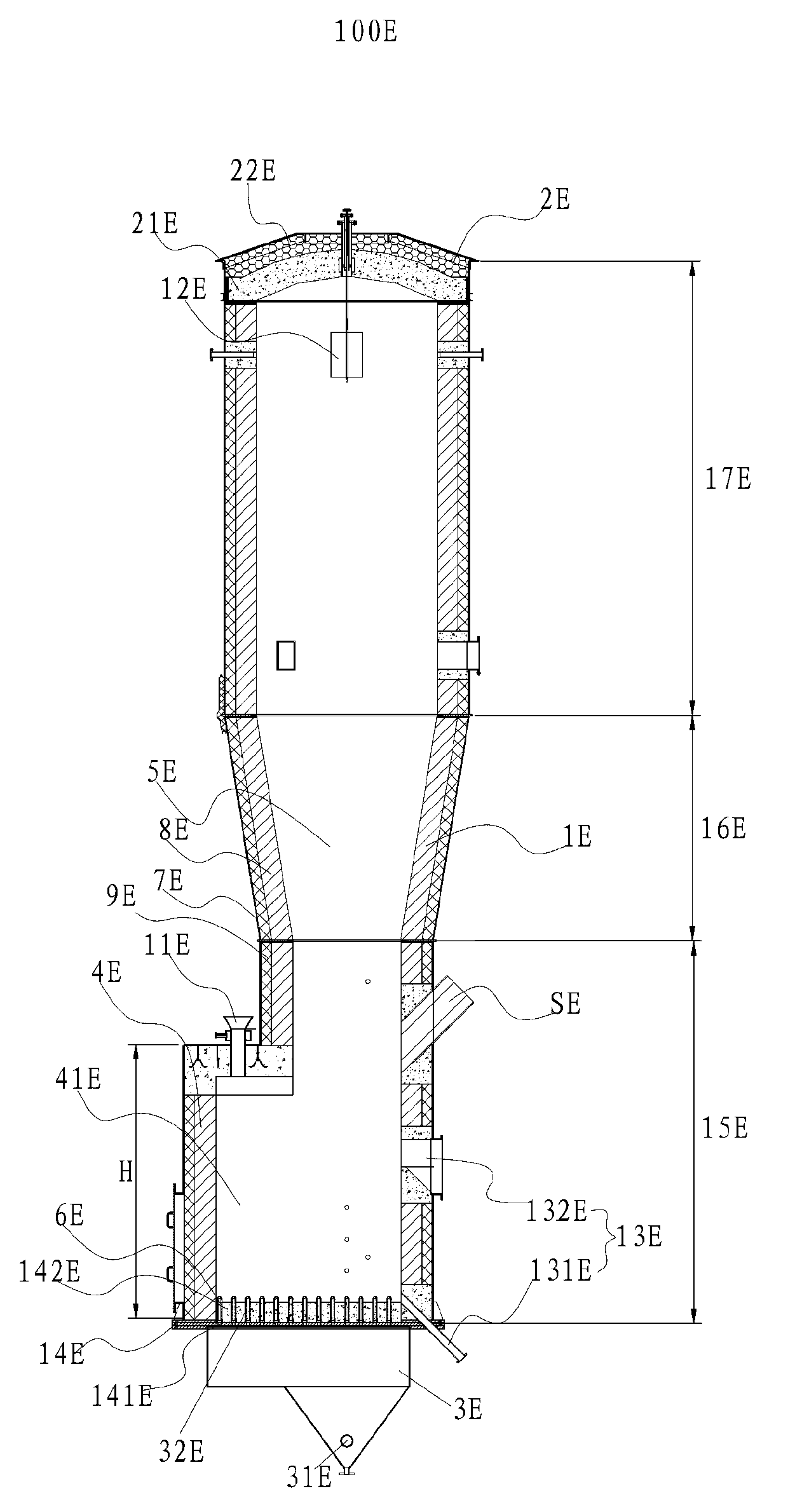

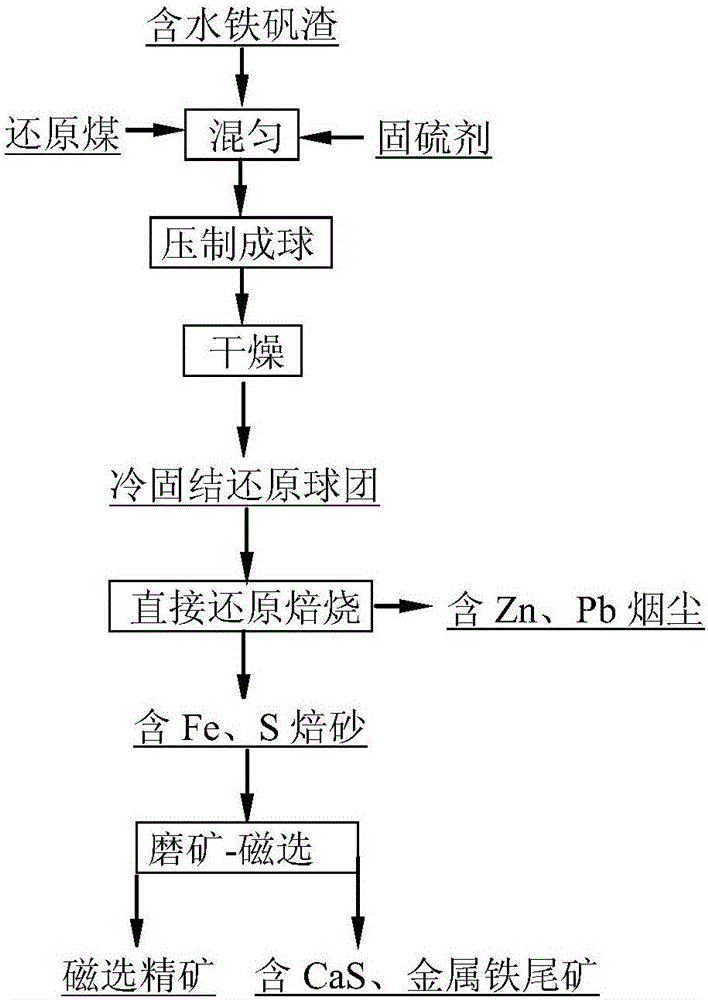

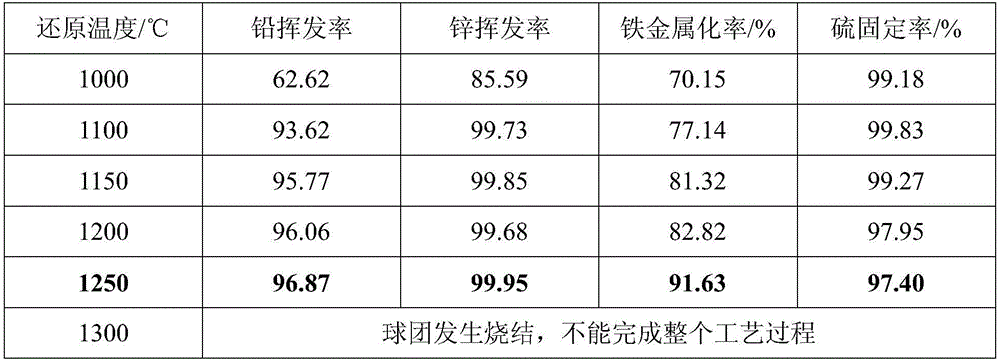

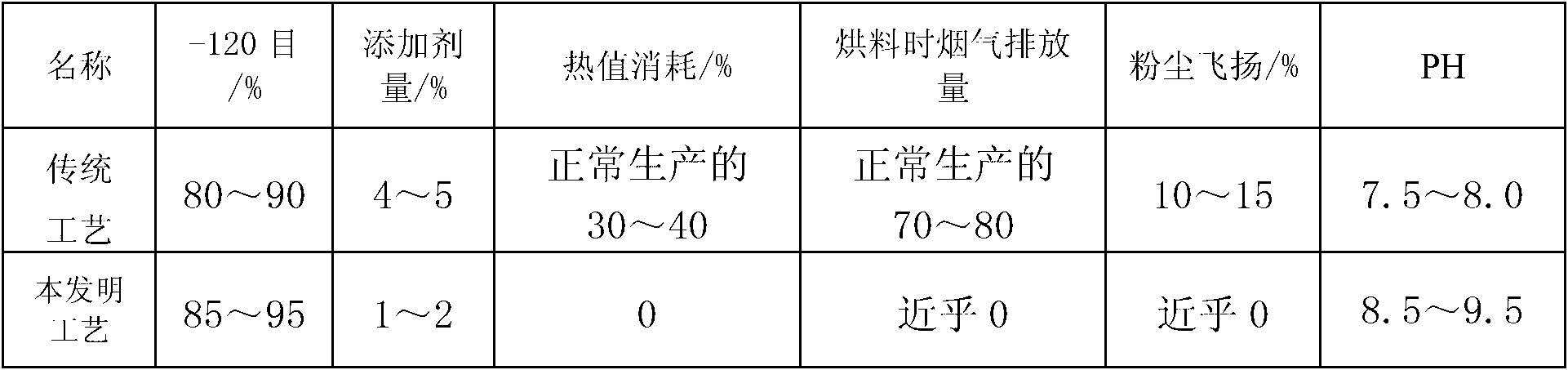

Ferroalumen slag cold-bonded and reduced pellet preparation and recycled lead, zinc and iron synchronous sulfur fixation process method

ActiveCN106755974AAvoid the problem of dehydrationEfficient and clean utilizationProcess efficiency improvementGrain treatmentsSulfurSlag

The invention relates to a ferroalumen slag cold-bonded and reduced pellet preparation and recycled lead, zinc and iron synchronous sulfur fixation process method. Firstly, ferroalumen slags, reducing coal and sulfur fixing agents are mixed and pressed into green ferroalumen slag cold-bonded and reduced pellets; the green ferroalumen slag cold-bonded and reduced pellets are dried, and preparation of ferroalumen slag cold-bonded and reduced pellets is finished; and the ferroalumen slag cold-bonded and reduced pellets are directly reduced and roasted at the temperature of 1100-1250 DEG C, smoke containing lead and zinc and roasted ore containing iron and sulfur are obtained, and ferroalumen slag cold-bonded and reduced pellet recycled lead, zinc and iron synchronous sulfur fixation is finished. The water-containing ferroalumen slags, the reducing coal and the sulfur fixing agents are made into the cold-bonded and reduced pellets, then a lead, zinc and iron chemical compound in the ferroalumen slags is directly reduced and subjected to synchronous sulfur fixation through high-temperature roasting, valuable metals including lead and zinc are recycled from the smoke, iron is recycled from the roasted ore, water difficult to remove in the ferroalumen slags is directly used, sulfur in the ferroalumen slags is fixed, and efficient and clean utilization of the valuable metals in the ferroalumen slags can also be achieved.

Owner:HANZHONG ZINC IND +1

Raw material pretreatment process for extracting vanadium from vanadium slag

The invention discloses a raw material pretreatment process for extracting vanadium from vanadium slag. The process comprises the following steps of: a, performing wet ball milling on the vanadium slag, and filtering the vanadium slag; b, drying the vanadium slag filtered in the step a in a drying kiln, and controlling the drying temperature to be between 150 and 300 DEG C; and c, adding a sodium salt adjuvant into the vanadium slag dried in the step b, and performing sodium roasting on the vanadium slag. By adopting the process, the vanadium slag is high in alkalinity, so that an alkali is not needed, the total amount of an additive during material blending is reduced, the used amount of a sodium salt is less than one half of that of the conventional process additive, and then the production cost is reduced. According to the process, a rotary kiln is not independently used for drying the vanadium slag, a vertical drying kiln is directly used, and the vanadium slag can be dried by using the waste heat generated in the sodium roasting process, so that the cost is reduced to the maximum extent and the space occupied by equipment is reduced.

Owner:攀枝花卓越钒业科技股份有限公司

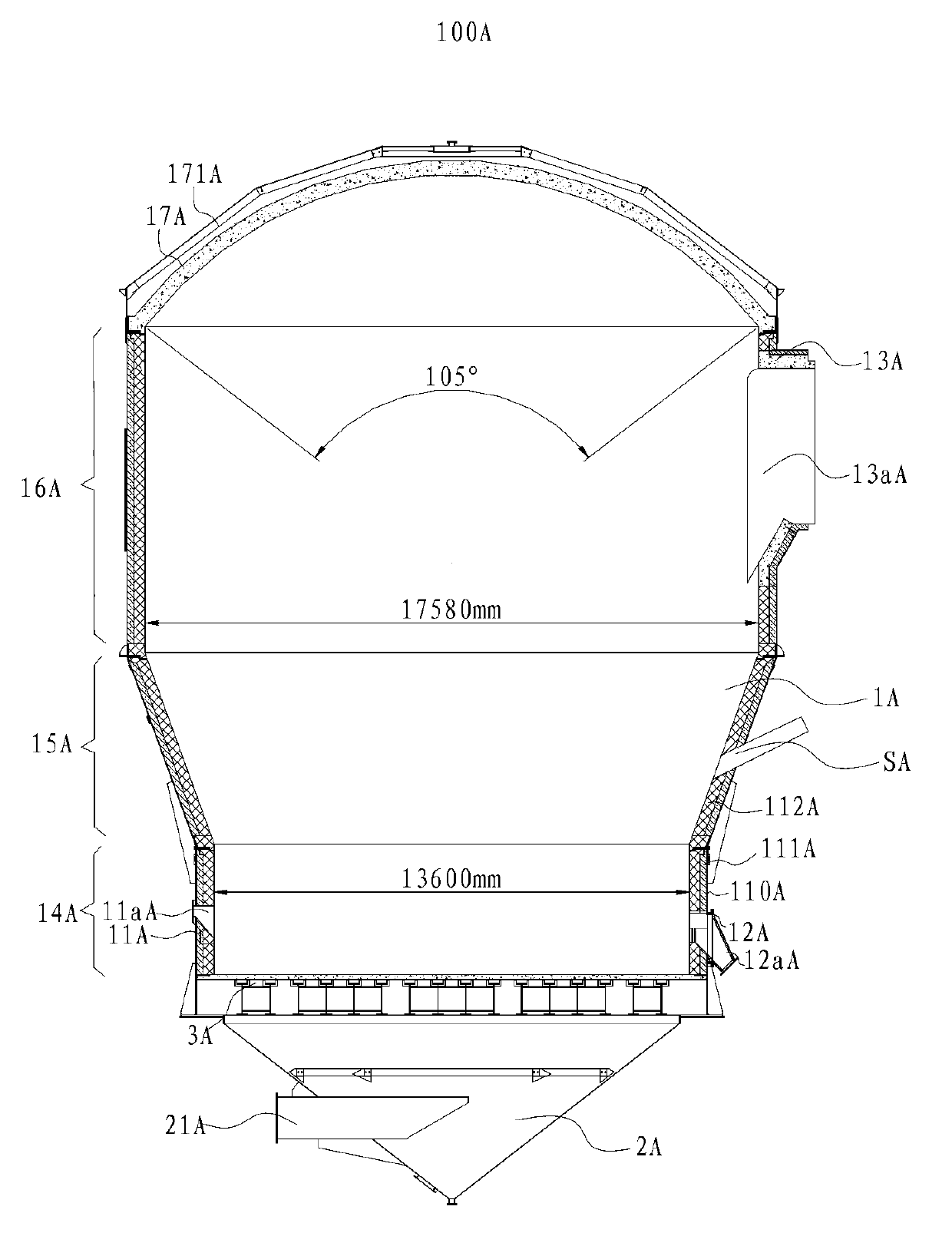

High-efficiency roasting shaft kiln for stone coal

InactiveCN102778121AMedium temperature is natural and evenMedium temperature completelyVertical furnacesSpontaneous combustionFlue gas

The invention discloses a high-efficiency roasting shaft kiln for stone coal and aims at overcoming the defects that a flat kiln and a rotary kiln adopted in the prior art for extracting vanadium by roasting the stone coal are low in degree of automation, high in operation cost, high in dust content and serious in pollution, air distribution in a shaft kiln cannot completely meet the requirement of intermediate temperature spontaneous combustion of the stone coal and the like. According to the high-efficiency roasting shaft kiln disclosed by the invention, an air channel communicated with an air inlet is arranged in an inner cavity of a shaft kiln body and is provided with an air feeding port; and the air channel is spirally arranged on the inner cavity wall from bottom to top. The high-efficiency roasting shaft kiln disclosed by the invention is mainly used for roasting the stone coal and is uniform, complete and sufficient in combustion and favorable in roasting effect; the cost of roasting each ton of vanadium in the rotary kiln by using 5 tons of standard coal is saved; 1000 tons of stone coals are roasted each day by 24 persons; the output of the shaft kiln is equivalent to over two times that of the flat kiln; the roasting conversion rate of the shaft kiln is 10-15 percent higher than the flat kiln; during roasting, the dust discharge capacity is only one tenth of the rotary kiln; and in addition, dust and flue gas of the shaft kiln can be centrally treated and remarkable economic and environment-friendly benefits are obtained.

Owner:台泥(怀化)水泥有限公司

Iron ore pellet additive and preparation thereof

The invention discloses an iron ore pellet additive and a preparation method thereof. The iron ore pellet additive consists of constituents by the following weight portion: 90 to 110 portions of bentonite, 3 to 5 portions of industrial alkali, and 1 to 4 portions of cellulose ether or ultramicro building material high-efficiency additives; and the constituents are mixed together, added with water to form paste or porridge, stirred evenly, placed for 3 to 6 days, dried, and crushed into particles with 1200-1500 meshes to obtain the iron ore pellet additive. An iron ore pellet obtained by wrapping the iron ore pellet additive has reduced burst, can reach more than 3000N, does not produce cracks after falling for 10 times, and greatly reduces silicon content; a furnace casting experiment proves that the iron ore pellet can not explode when entering a furnace at a temperature of 1200 DEG C, and can remarkably improve the tapping rate; compared with the prior additive which is simply the bentonite, the additive has the characteristics of strong adhesion force, high pelletization degree, short roasting time, good roasting performance, improved grade of pellet ore, energy consumption reduction, and so on.

Owner:刘贵堂 +2

Technology for processing and making edible rice flour

InactiveCN107912686AQuality improvementSimple processing technologyFood thermal treatmentFood mechanical treatmentFlavorBiology

The invention discloses a technology for processing and making edible rice flour. The technology for processing and making edible rice flour, disclosed by the invention, comprises the following eightsteps: selecting materials, airing, shelling, removing dust, roasting, grinding, screening and packaging. The technology disclosed by the invention has the beneficial effects that attention is paid todetails when raw materials are selected, so that high quality of the raw materials can be ensured, and a guarantee is provided for the quality of the made rice flour. Meanwhile, the processing technology is simple and practical, and is suitable for mass factory production and home cooking, the process is simple, the operation is convenient, and rice flour with fragrant taste can be achieved by using simple materials. In the processing technology, hot air blowing is adopting during roasting, so that the stir-fried rice is difficult to be in long-term contact with heating machinery, the heatingis uniform, the roasting effect is excellent, the rice can emit a burnt flavor, and a fragrance guarantee is provided for making the rice flour. Meanwhile, the rice flour is easily ground, the made rice flour is excellent in shape, and the processing efficiency is high.

Owner:防城港市绿华源农林科技有限公司

Wear-resistant and high-toughness material for 3D printing ceramic

InactiveCN110002848AImprove function and effectPromote redox reactionsAdditive manufacturing apparatusCeramic materials productionDispersityKerosene

The invention discloses a wear-resistant and high-toughness material for 3D printing ceramic, belongs to the field of ceramic materials, and solves the problem of poor wear resistance and toughness ofcommon ceramic materials at present. The ball milling efficiency can be improved by adding kerosene and absolute ethyl alcohol as ball milling media, and combustion of the kerosene can promote unoxidized metal components in a ball milling material to have a redox reaction. Aluminum oxide contained in fly ash and an Mg<2+> component in palygorskite can produce a magnesia-alumina spinel component with erosion resistance and abrasion resistance at high temperature. A boron oxide component contained in boric sludge added to aids is acid anhydride of boric acid, the acid anhydride can produce boric acid and metaboric acid with water and emit a lot of heat, a boehmite component is embedded in a hard roasted product to improve dispersity and binding force among structures, external friction canbe well scattered, quick wear can be avoided, adsorption can be formed in combination with acrylic resin, the structure compactness of a material system can be improved, and tensile strength and wearresistance can be improved.

Owner:何治伟

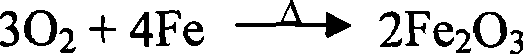

Fluidization roasting technology for processing iron ores

The invention relates to a fluidization roasting technology for processing iron ores and belongs to the technical field of mineral processing. The fluidization roasting technology for processing the iron ores is characterized in that iron ore particles are continuously fed into a reduction reactor from the lower portion of the reduction reactor, reductive mixed gas flow entering the reduction reactor from the bottom of the reduction reactor is used for carrying the iron ore particles to move upward, and roasting is conducted on the iron ore particles at 500-600 DEG C; after roasting, the obtained solid material is continuously discharged out of the reactor via a material outlet on the upper portion of the reactor, a magnetic field is exerted to the reduction reactor at the same time, the intensity of the magnetic field is 40-60 kA / m, and the direction of the magnetic field is vertically upward. According to the fluidization roasting technology for processing the iron ores, the stable magnetic field is exerted around the reduction reactor, the flowing behavior of magnetic particles in the reactor is reasonably controlled, the gaseous-solid two-phase flow in the reactor is more stable, the gas is fully reacted with the iron ores, and the roasting efficiency is improved.

Owner:NORTHEASTERN UNIV

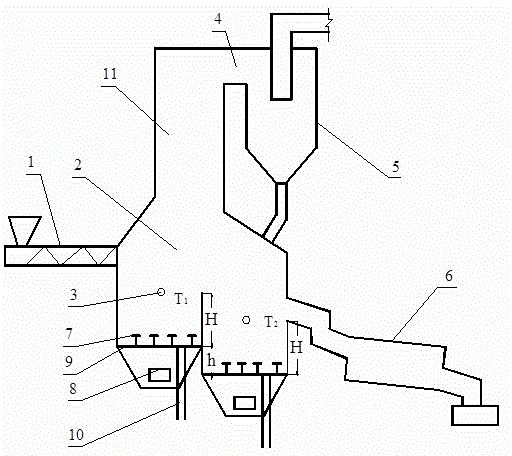

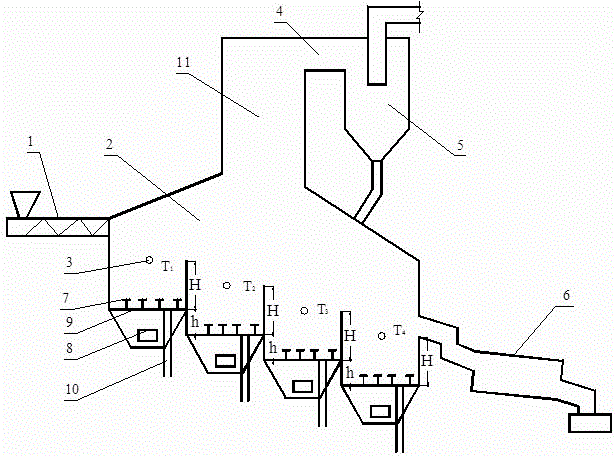

Rotary kiln roasting structure and roasting process thereof

InactiveCN112113419AGood roasting effectReduce roasting energy consumptionRotary drum furnacesEngineeringRotary kiln

The invention discloses a rotary kiln roasting structure and a roasting process thereof. The rotary kiln roasting structure comprises a bottom plate, wherein a rotary kiln body which is obliquely arranged is arranged above the bottom plate; a first motor is arranged at one side below the rotary kiln body; the output end of the first motor is fixedly connected with a drive gear; the middle part ofthe rotary kiln body is fixedly connected with a driven gear; one end of the rotary kiln body is connected with a coal injection mechanism; the coal injection mechanism comprises a combustor; one endof the rotary kiln body is rotatably connected with the middle part of the combustor; one end, far away from the rotary kiln body, of the combustor is fixedly connected with a connecting tube; the drive gear is engaged with the driven gear, the driven gear rotates, and the rotary kiln body fixedly connected with the driven gear rotates; the rotary kiln body is obliquely arranged, and the rotary kiln body rotates, so that materials move from the head end of the rotary kiln body to one end of the combustor while rotating; the closer the materials are to the combustor, the higher the temperatureis; and the materials are gradually roasted by flame sprayed out from a burner uniformly, so that the roasting effect is better, and roasting energy consumption is reduced.

Owner:JIANGSU HUIRAN IND CO LTD

Charging method for aluminum electrolysis cell during roasting start

InactiveCN102808195AUniform firing temperatureImprove roasting effectStress concentrationElectrolysis

The invention discloses a charging method for an aluminum electrolysis cell during roasting start, and relates to improvement on an aluminum electrolysis cell charging roasting start method in an aluminum electrolysis production process. A scorched particle roasting method is adopted in the roasting start process. The method is characterized in that calcined scorched particles with high and low resistance rates are charged in the charging process. The charging method for the aluminum electrolysis cell during roasting start is applied to charging operation; and after a conductive medium is selected and laid, in the roasting process, the roasting temperature of a cathode is distributed uniformly, thermal stress of the cathode is reasonably absorbed, and thermal stress concentration is avoided.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

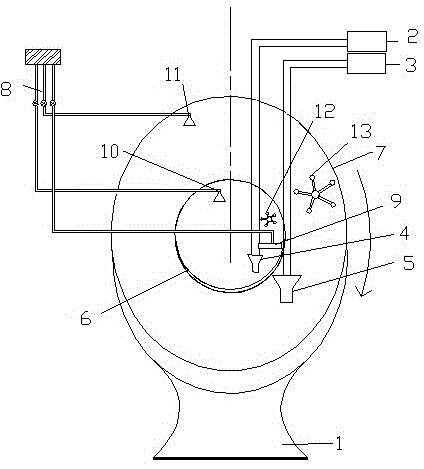

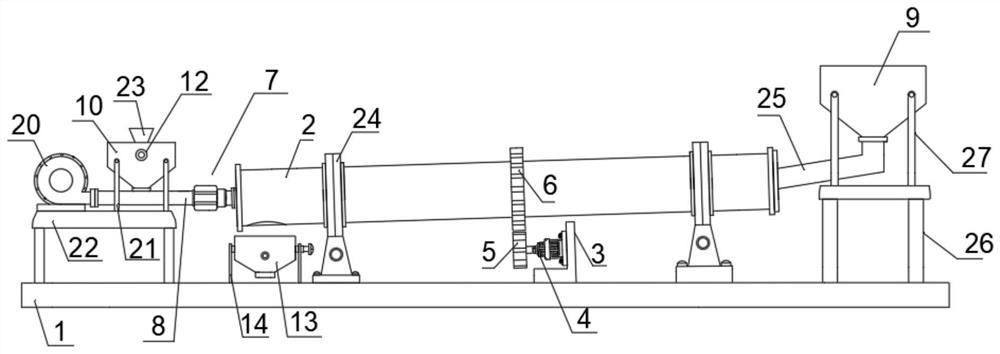

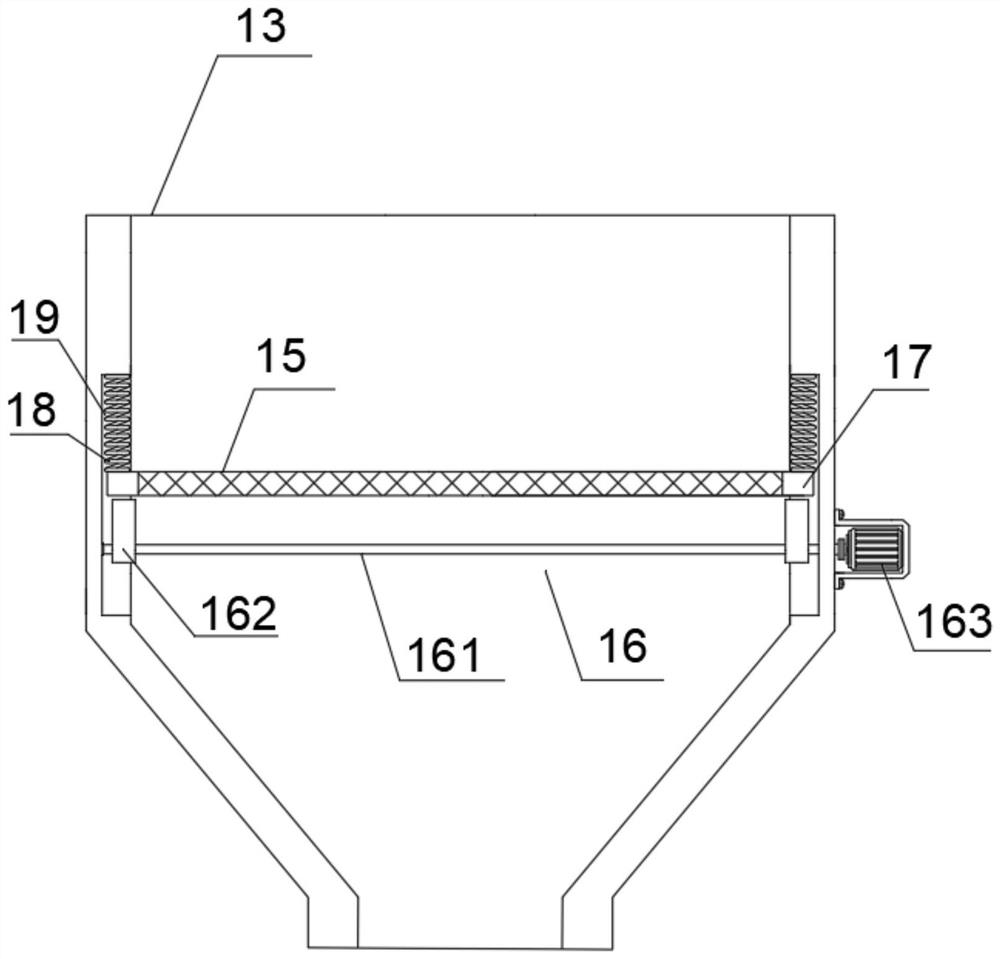

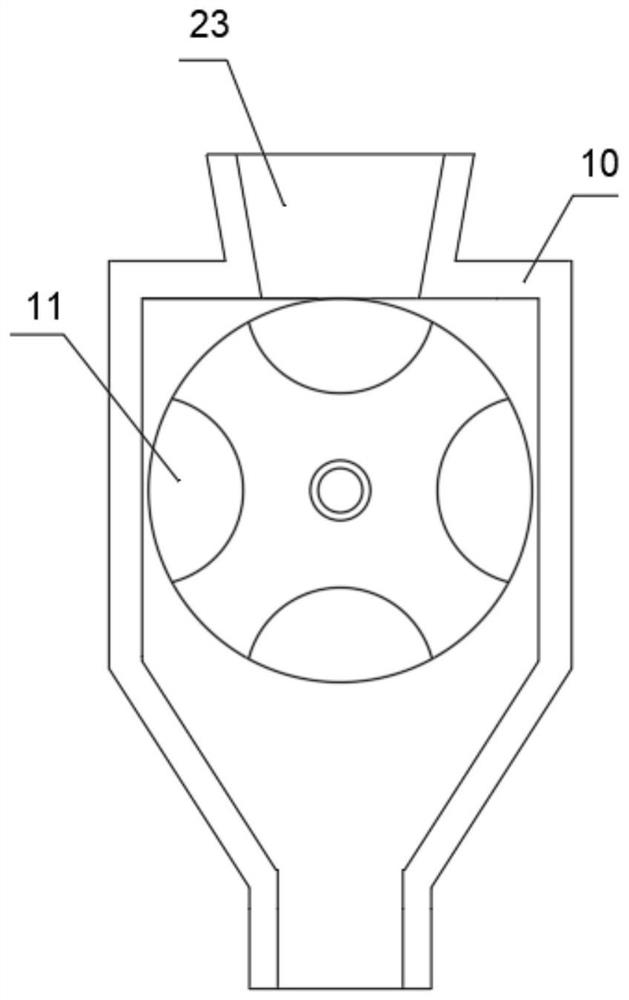

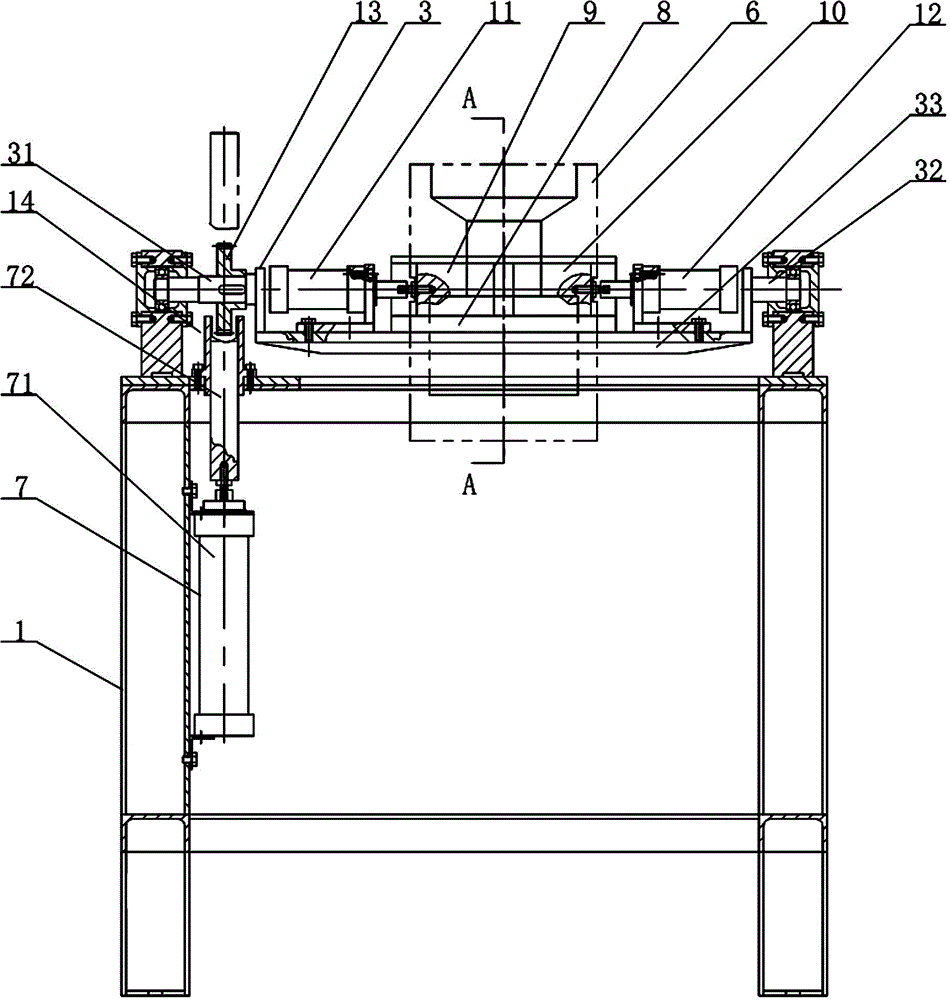

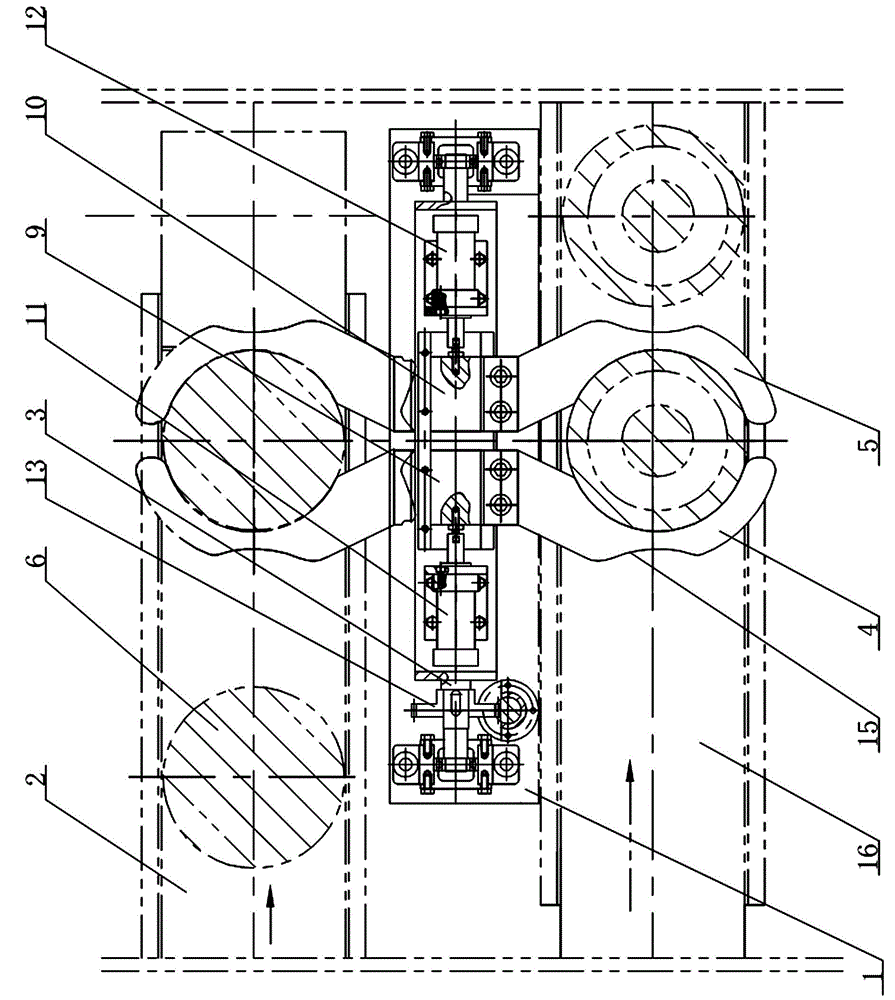

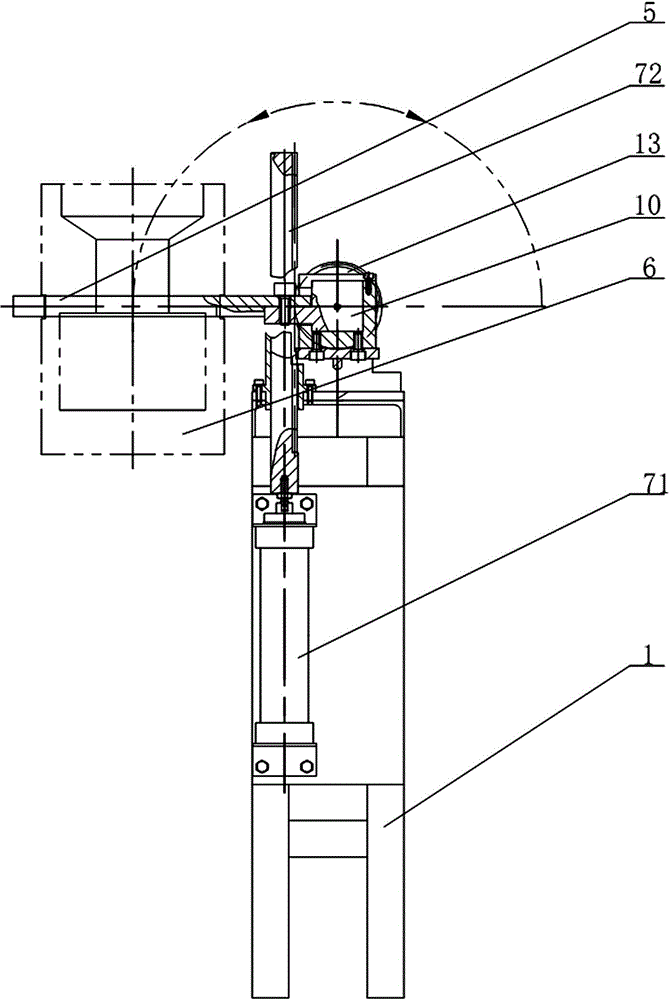

Dewaxing mold shell overturning and conveying device

ActiveCN104826996AEvenly placedImprove roasting effectFoundry mouldsFoundry coresMaterials sciencePrecision casting

The invention relates to a dewaxing mold shell overturning and conveying device. The problems that in a fired mold precision casting process, mold shells are conveyed manually, the labor intensity is high, the work efficiency is low, and automatic and continuous production cannot be implemented are solved. The dewaxing mold shell overturning and conveying device is characterized in that a rotating central shaft (3) is arranged on a support (1); a left jaw (4) and a right jaw (5) which can slide relatively are arranged on the rotating central shaft (3); after the left jaw (4) and the right jaw (5) are combined, a mold shell (6) can be clamped; the rotating central shaft (3) is driven to rotate in a reciprocating manner at an angle of 180 degrees by a driving device (7); and the left jaw (4) and the right jaw (5) are driven by the rotating central shaft (3) to overturn at an angle of 180 degrees. The mold shell is clamped by the left jaw and the right jaw which overturn in a reciprocating manner at an angle of 180 degrees, mold shell dewaxing and mold shell roasting are sequentially carried out automatically, the labor intensity of workers is reduced, the work efficiency is improved, the mold shells are uniformly placed on a roasting conveying belt, and a roasting effect is high.

Owner:台山市鼎富金属制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com