Iron ore pellet additive and preparation thereof

A technology of additives and pellets, which is applied in the field of metallurgy, can solve the problems affecting the energy consumption and output of blast furnace ironmaking, the high pulverization rate of green pellets, and the slow drying speed. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

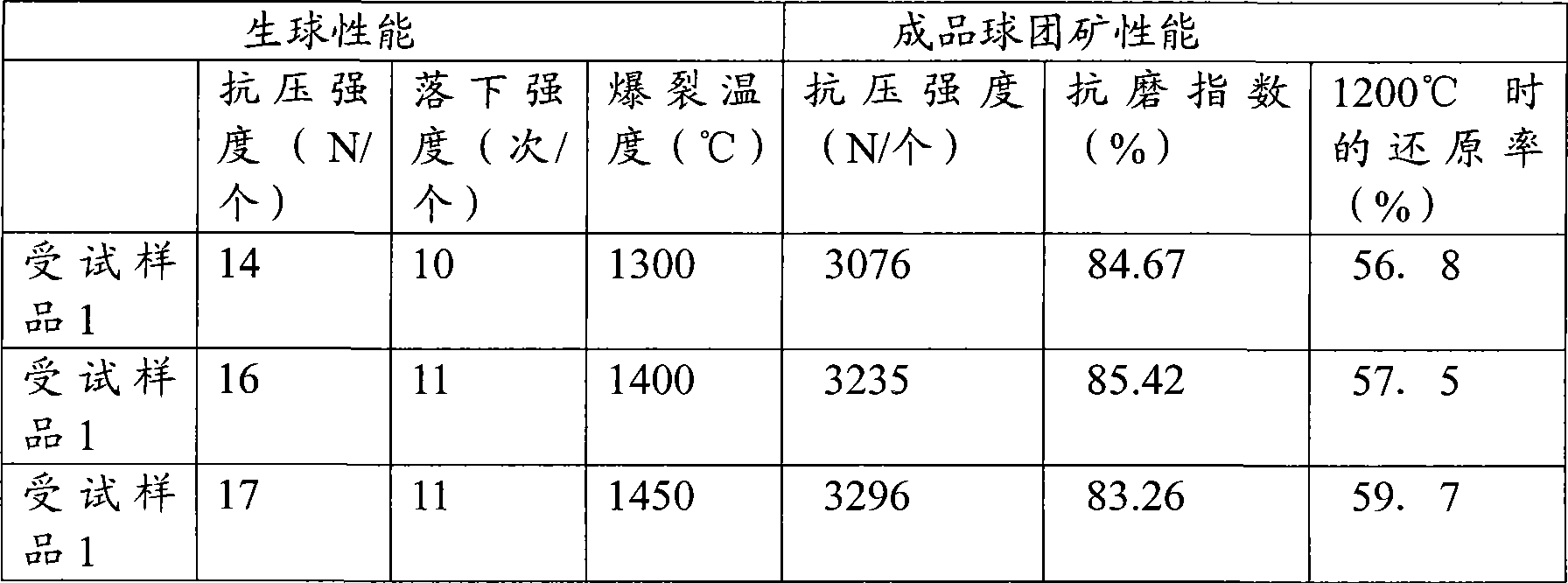

Examples

Embodiment 1

[0021] Embodiment 1 Preparation of Iron Ore Pellet Additive

[0022] (1) Take each component by the following weight (unit: Kg): bentonite 90, industrial sodium carbonate 3, superfine building material high-efficiency additive (according to the authorized announcement number: the disclosed method of CN 1268574C prepares the ultrafine building material high-efficiency additive )1;

[0023] (2) After mixing the above components together, add water to make the mixture into a paste or porridge, stir evenly, let it stand for 3-6 days, dry, and use a high-pressure jet mill (manufactured by Qingdao Micron Powder Technology Equipment Co., Ltd.) , whose model is MQL) is crushed into 1200-1500 mesh particles, that is, too.

Embodiment 2

[0024] Embodiment 2 Preparation of Iron Ore Pellet Additive

[0025] (1) Take each component (unit: Kg) by the following weight: bentonite 110, sodium hydroxide 5 for industrial use and ultrafine building material high-efficiency additive (according to the method disclosed by the authorized announcement number: CN 1268574C to prepare the ultrafine building material high-efficiency Additive) 4;

[0026] (2) After mixing the above components together, add water to make the mixture into a paste or porridge, stir evenly, let it stand for 3-6 days, dry, and use a high-pressure jet mill (manufactured by Qingdao Micron Powder Technology Equipment Co., Ltd.) , whose model is MQL) is crushed into 1200-1500 mesh particles, that is, too.

Embodiment 3

[0027] Embodiment 3 Preparation of Iron Ore Pellet Additive

[0028] (1) Take each component by the following weight (unit: Kg): bentonite 100, industrial sodium hydroxide 4, cellulose ether 3;

[0029] (2) After mixing the above components together, add water to make the mixture into a paste or porridge, stir evenly, let it stand for 3-6 days, dry, and use a high-pressure jet mill (manufactured by Qingdao Micron Powder Technology Equipment Co., Ltd.) , whose model is MQL) is crushed into 1200-1500 mesh particles, that is, too.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com