Flame roasting direct-on starting process of aluminum electrolysis cell

An aluminum electrolytic cell and electrolytic cell technology, applied in the field of metallurgy, can solve the problems of aluminum liquid leakage, large cathode thermal shock, excessive temperature gradient and set value deviation, etc., to prolong the production life and reduce the temperature gradient , the effect of preventing thermal shock damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: a kind of aluminum electrolyzer utilizes flame roasting to start the process directly, and it comprises the following steps successively,

[0043] (1) Select the 5046# electrolytic cell of the 240KA electrolytic series;

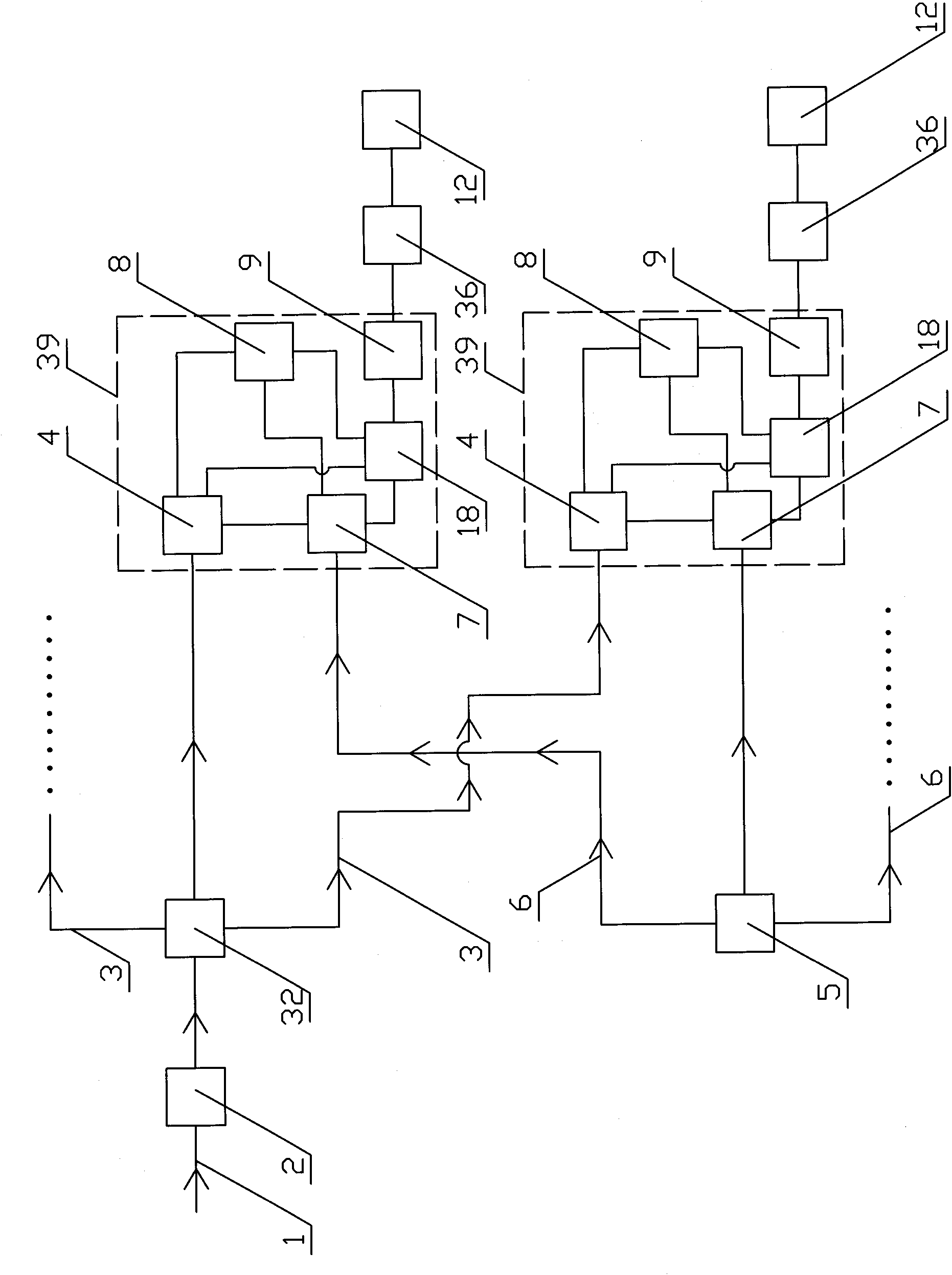

[0044] (2) Install the anode used in the electrolytic cell, connect the detection and control system, and confirm that the equipment is installed in good condition;

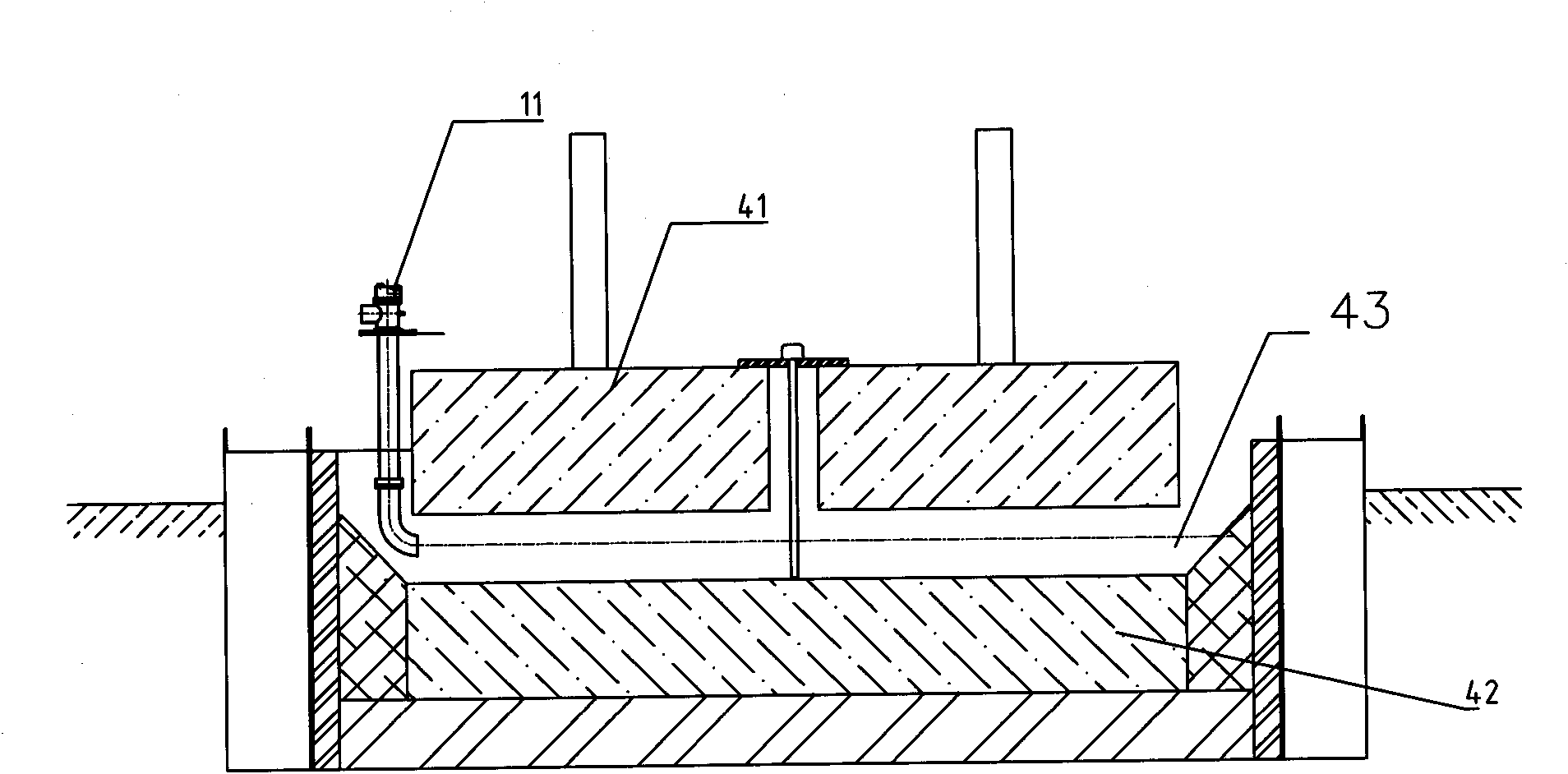

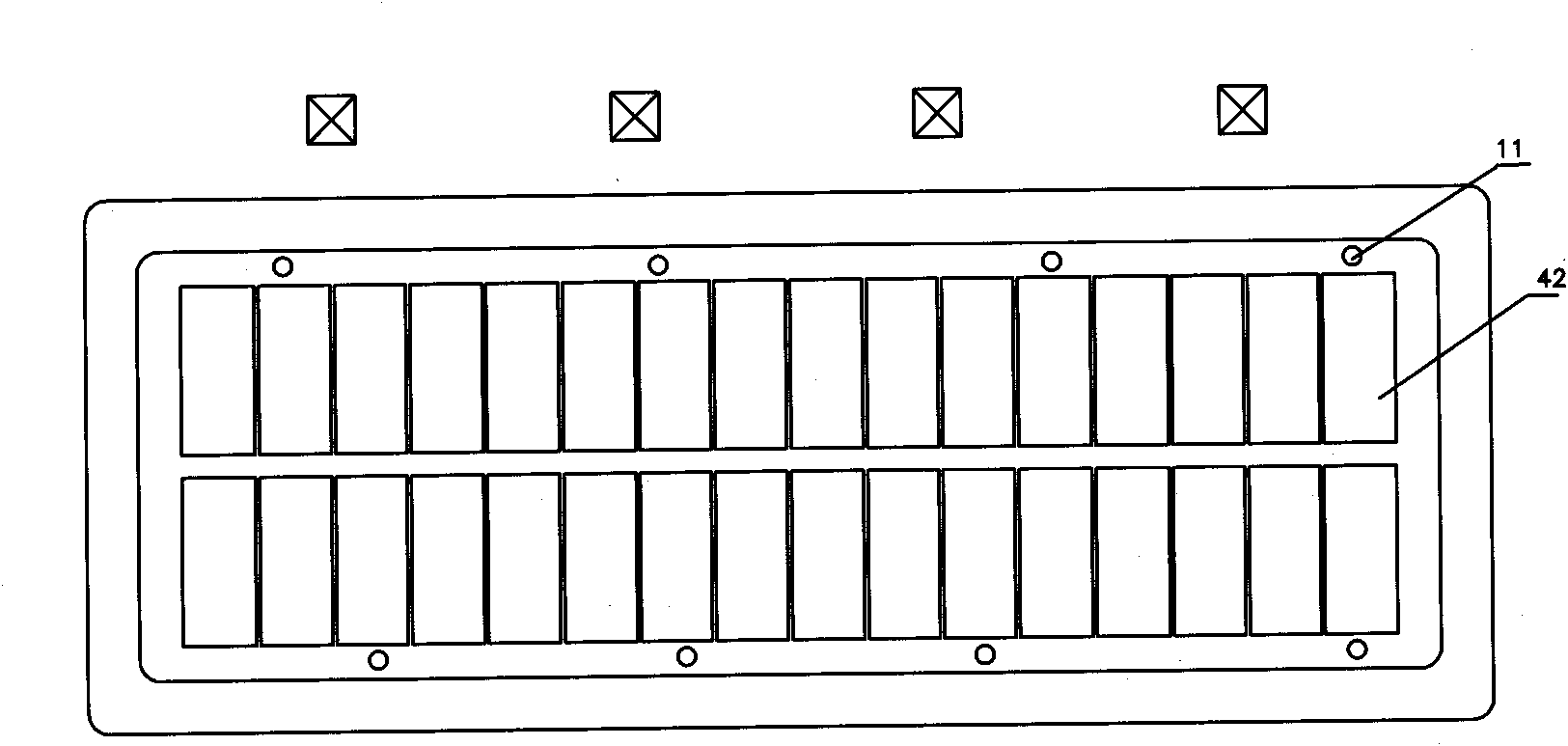

[0045] (3) Install the gas control system and determine the position of the gas burner: Before the electrolytic cell is roasted, install the gas control system in the electrolytic plant according to the site conditions; divide the electrolytic cell into four roasting areas, and place a burner in each roasting area Temperature Sensor. There are 3-4 gas burners in each roasting area, and the gas burners are reasonably and evenly installed between the bottom of the anode and the upper part of the cathode in the furnace of the electrolytic cell; preferably, the gas burners are ...

Embodiment 2

[0072] Embodiment 2: a kind of aluminum electrolyzer utilizes flame roasting to start the process directly, and it comprises the following steps successively,

[0073] (1) Select the 612# electrolytic cell of the 200KA electrolytic series;

[0074] (2) Install the anode used in the electrolytic cell, connect the detection and control system, and confirm that the equipment is installed in good condition;

[0075] (3) Install the gas control system and determine the position of the gas burner: Before the electrolytic cell is roasted, install the gas control system in the electrolytic plant according to the site conditions; divide the electrolytic cell into four roasting areas, and place a burner in each roasting area Temperature Sensor. There are 2-3 gas burners in each roasting area; the gas burners are reasonably and evenly installed in the furnace of the electrolytic cell on the bottom of the anode and the upper part of the cathode; preferably, the position of the gas burner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com