Method for extracting vanadium from vanadium-containing raw material

A technology for raw materials and slurry, applied in the field of vanadium extraction from new vanadium-containing raw materials, can solve the problems of poor adaptability of vanadium raw materials, difficult to realize industrialized production, difficult solid-liquid separation, etc., and achieves improved roasting effect and low equipment requirements. , the effect of low safety management requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

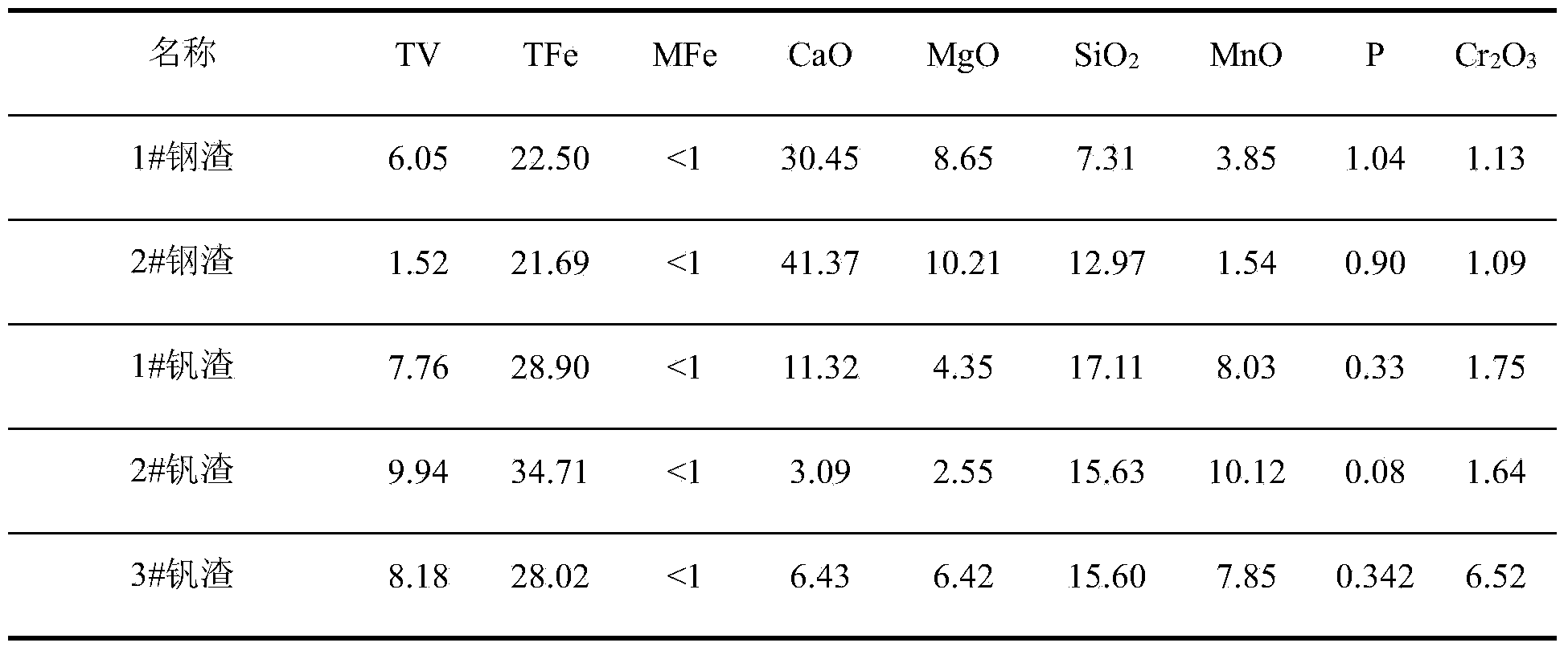

Embodiment 1

[0055] Weigh 2350g of -200 mesh 1# steel slag and 4700g of ferrous sulfate heptahydrate, mix well, and then spray 700mL of water for granulation. The particle size is not controlled, and the diameter is basically between 1mm and 20mm. In the furnace, heat up to 910°C in 50 minutes, keep it warm for 100 minutes, take it out of the furnace to cool, and get 4503.6g of clinker a (this clinker will be used in some examples later), take 500g of clinker and grind it to -100 mesh, add it to 1500mL In water, add 50wt% sulfuric acid dropwise to carry out stirring and leaching at room temperature for 1 hour. During the leaching process, the pH value is controlled between 1.7 and 2.0, and 89.3mL of 50wt% sulfuric acid is consumed. The slurry is filtered and washed (washed four times with 1000mL water), and the TV is 5.90g. / L vanadium liquid 2342mL, the obtained TV is 0.35% residue 501.0g, the vanadium transfer leaching rate is 92.92% according to the liquid, and the vanadium transfer leac...

Embodiment 2

[0057] Weigh 500g of clinker a, with a diameter between 4mm and 20mm, without grinding, add it to 1500mL of water, add 50wt% sulfuric acid dropwise and carry out stirring and leaching at room temperature for 1 hour. During the leaching process, control the pH value between 1.7 and 2.0 and consume 50wt% sulfuric acid 611.8mL was filtered and washed (washed four times with 160mL of water), and 2920mL of vanadium liquid with a TV of 2.91g / L was obtained, and 487.0g of a residue with a TV of 1.48% was obtained. The leaching rate is 77.17%. The vanadium liquid was extracted with 15% N235 extractant (TBP5%, sulfonated kerosene 80%), the O / A ratio was 1:3, and the pH value was 1.96. After primary extraction of vanadium (artificial shaking for 5 minutes, static for 5 minutes), The raffinate contains TV0.11g / L. Before stripping, wash the organic phase with 20mL of 7% sulfuric acid, and carry out stripping with 200mL of 5% ammonia water. Adjust the pH of the stripping solution to 9.5. ...

Embodiment 3

[0059] Take 50g of clinker a and grind it to -100 mesh, add it to 100mL water, add 50wt% sulfuric acid dropwise to carry out stirring and leaching at room temperature for 1h, control the pH value between 2.5 and 3.5 during the leaching process, and filter and wash the slurry (wash four times with 100mL water ), to obtain residue and leaching solution, vanadium-containing leaching solution, the French domestic Rohm and Haas IRA96RF resin is used to adsorb the vanadium solution, and the remaining adsorption solution is used as the next leaching water (concentration of vanadium is lower than 1mg / L), after 10 cycles, the remaining adsorption The concentration of liquid Mn rose from 1.69g / L to 15.88g / L, and white magnesium sulfate crystals were continuously precipitated after 6 cycles. The manganese-containing 15.88g / L solution was extracted with an extractant containing 15% P204 (TBP5%, sulfonated kerosene 80%), the O / A ratio was 1:2, the pH value was 3.52, and the manganese was ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com