Dewaxing mold shell overturning and conveying device

A conveying device and mold shell technology, which is applied to mold handling equipment, casting molding equipment, casting molds, etc., can solve the problems of inability to automate continuous production, low work efficiency, and high labor intensity, so as to achieve good roasting effect and reduce Labor intensity, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

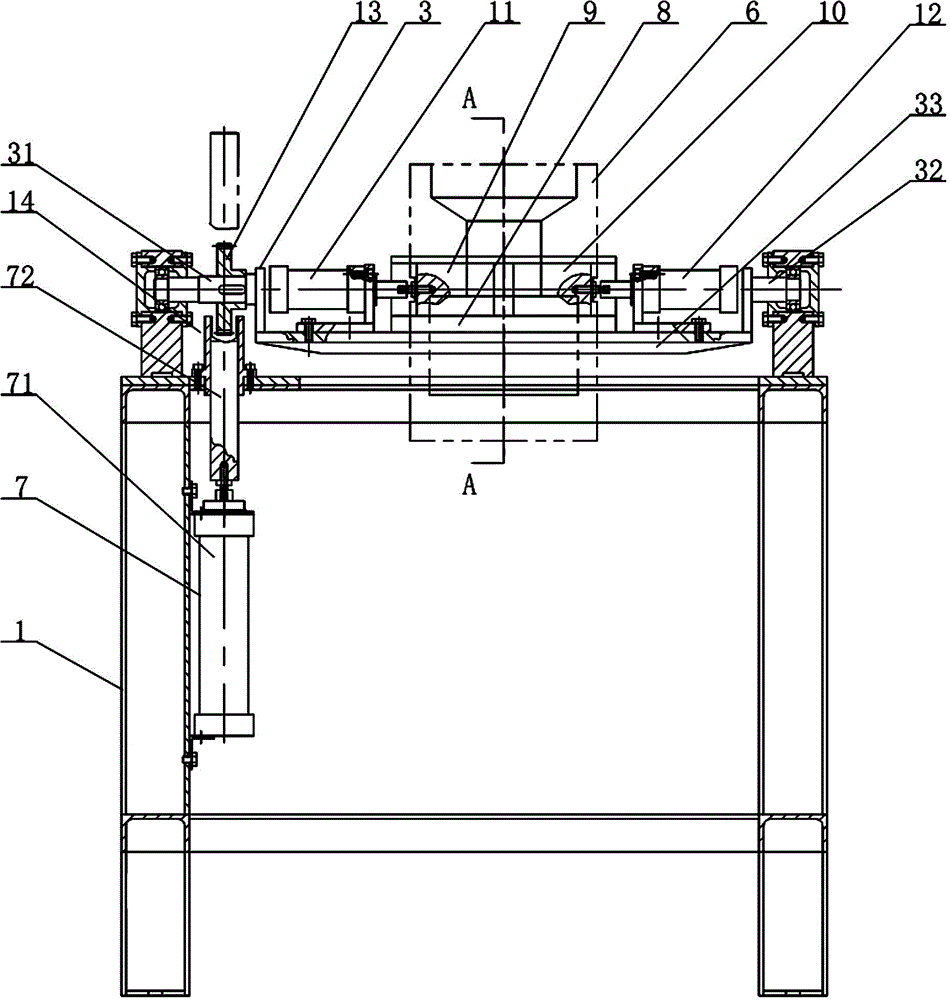

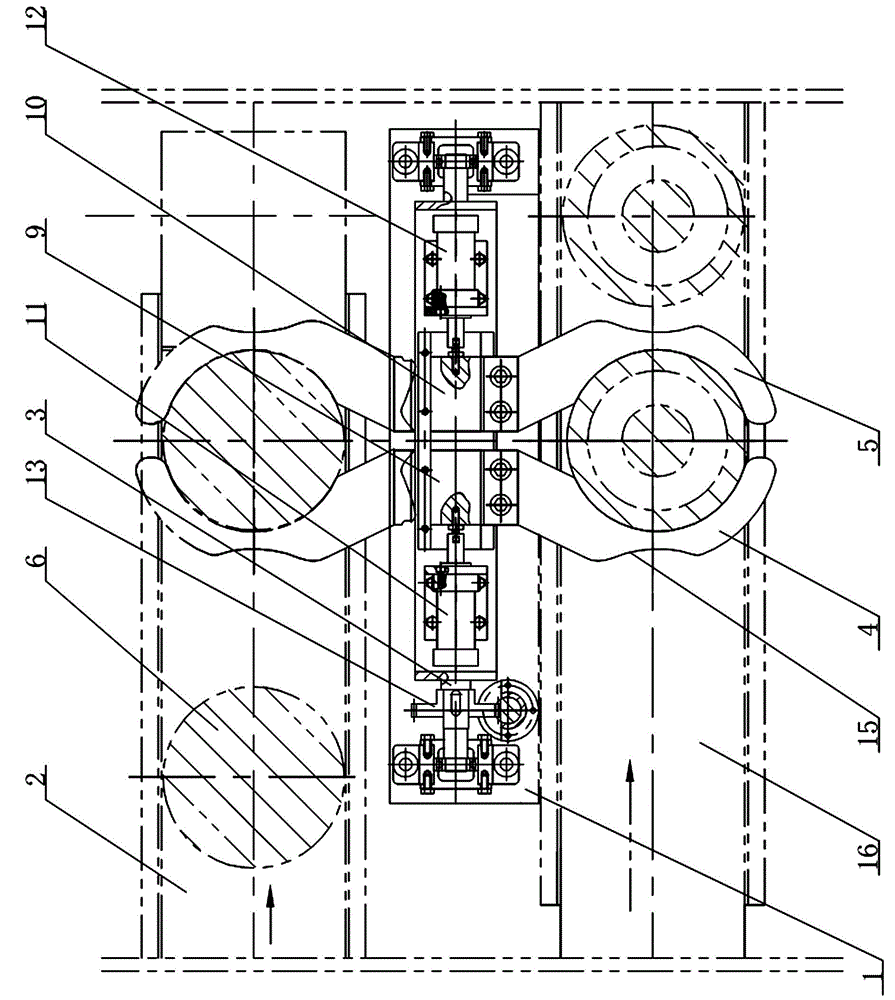

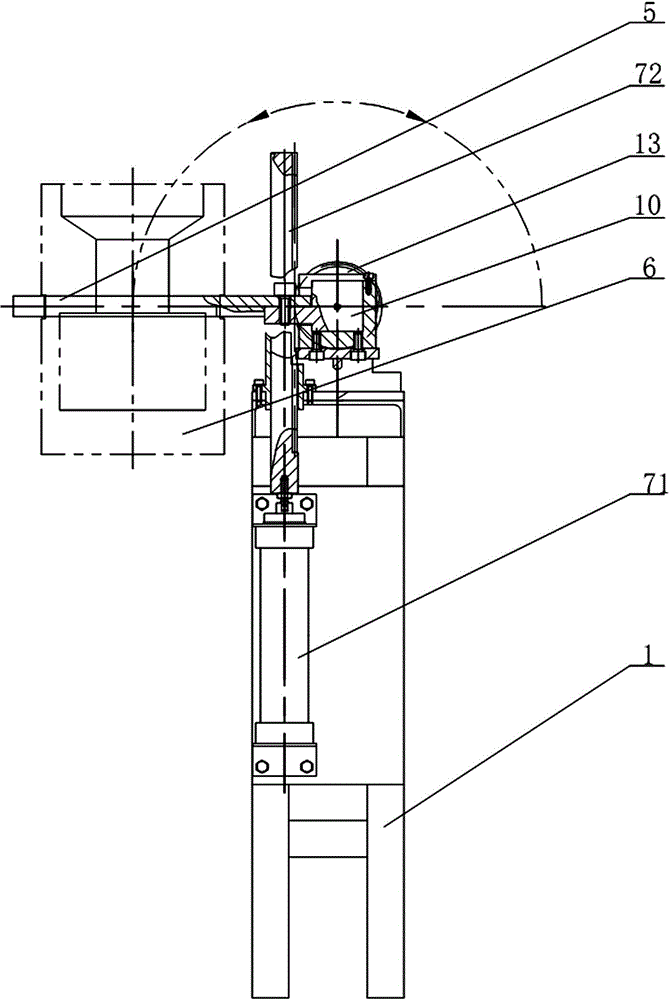

[0015] The present invention will be further described below in conjunction with accompanying drawing:

[0016] Depend on Figure 1 ~ Figure 3 As shown, the dewaxing mold shell inversion conveying device includes a support 1, the support 1 is located between the dewaxing conveyor belt 2 and the roasting conveyor belt 3, and the rotation center shaft 3 is installed on the support 1 The left jaw 4 and the right jaw 5 that can slide relatively are installed on the rotating central shaft 3, and the left jaw 4 and the right jaw 5 can clamp the mold shell 6 after being closed, and the rotating central shaft 3 is driven by the driving device 7 180 ° reciprocating rotation, the left jaw 4 and the right jaw 5 are driven by the rotating central axis 3 to turn over 180 °. Due to the adoption of the above-mentioned technical scheme, the left jaw 4 and the right jaw 5 that are reciprocated at 180° are used to clamp the mold shell 6, and the mold shell 6 is turned over and transported from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com