Patents

Literature

102results about How to "Realize automatic connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

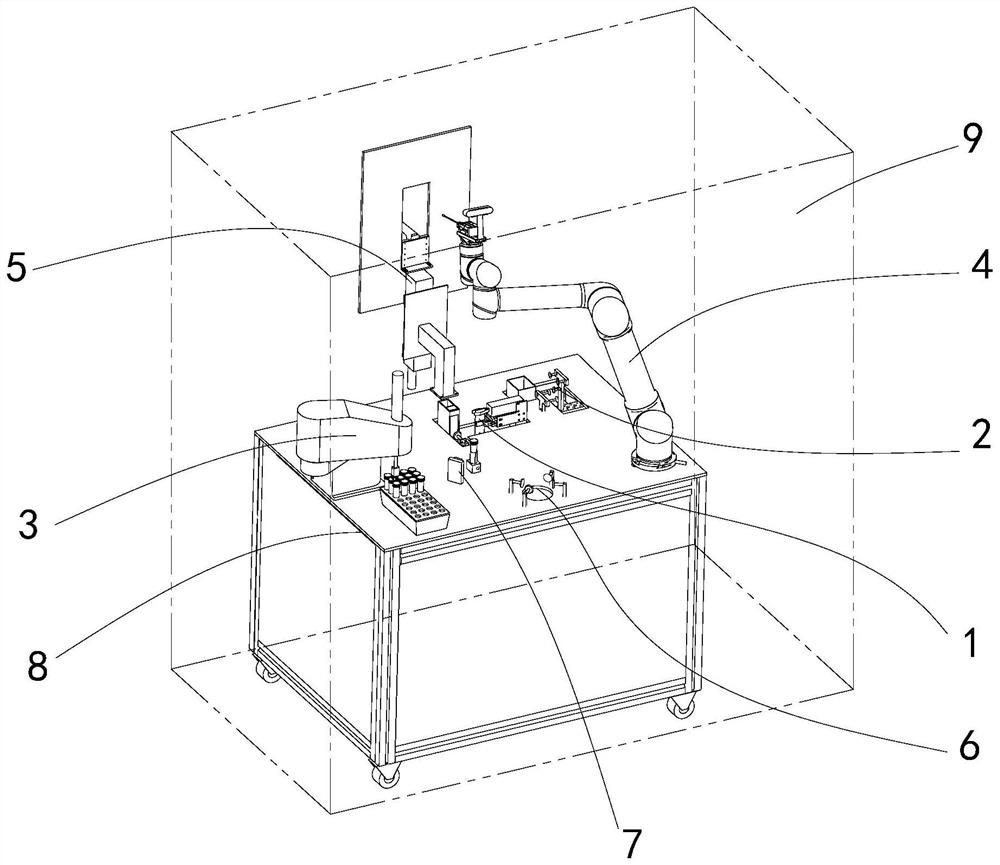

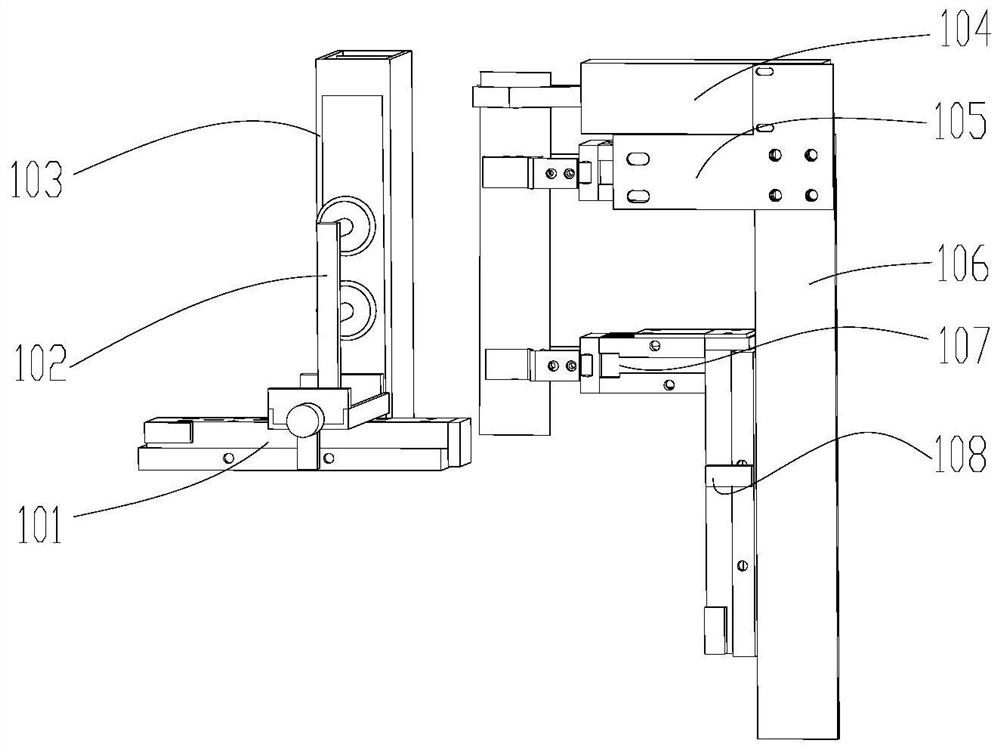

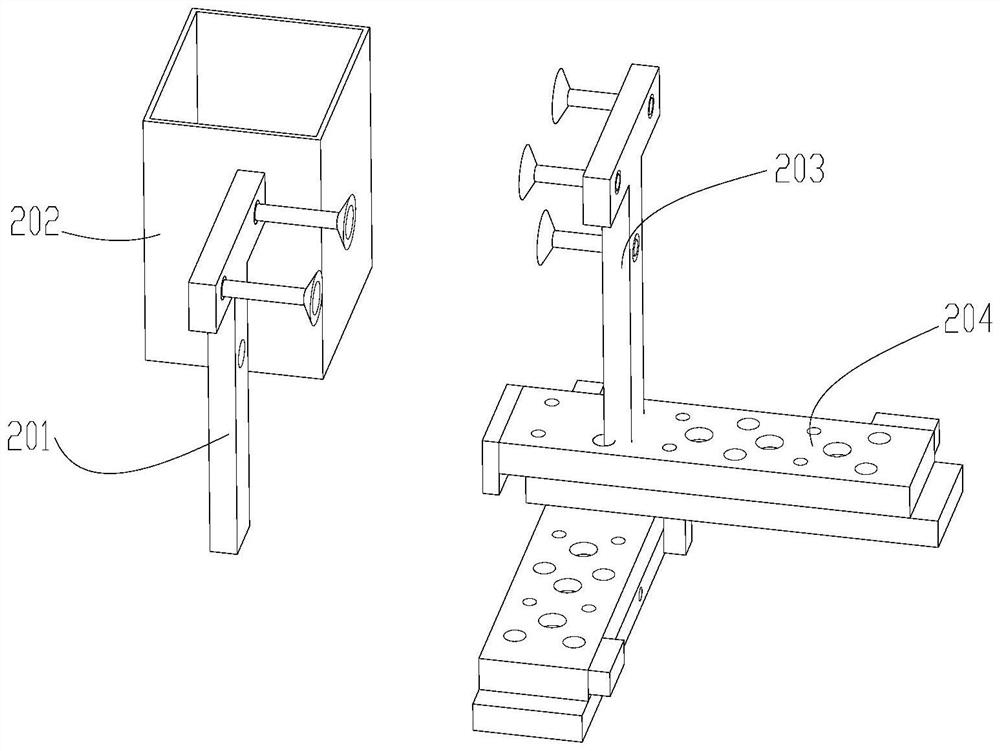

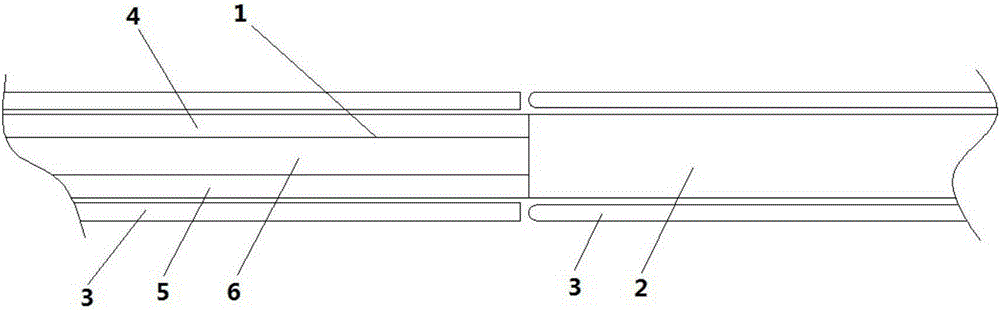

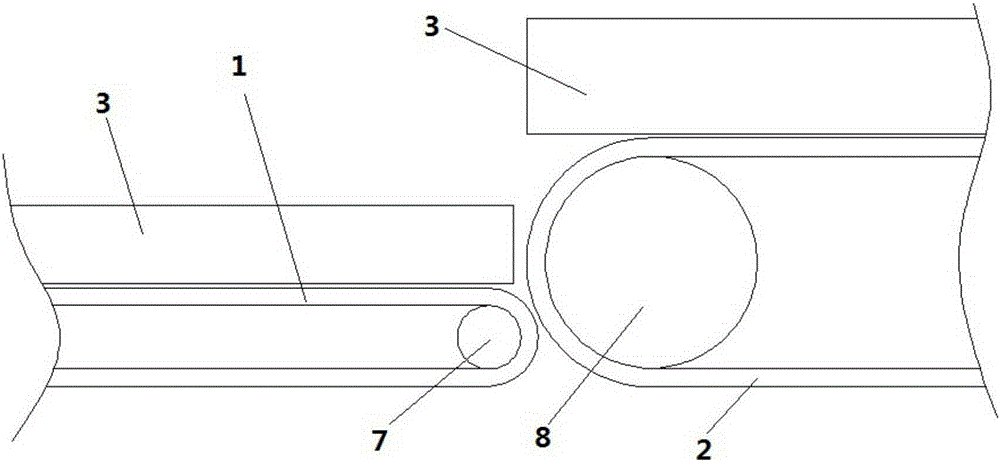

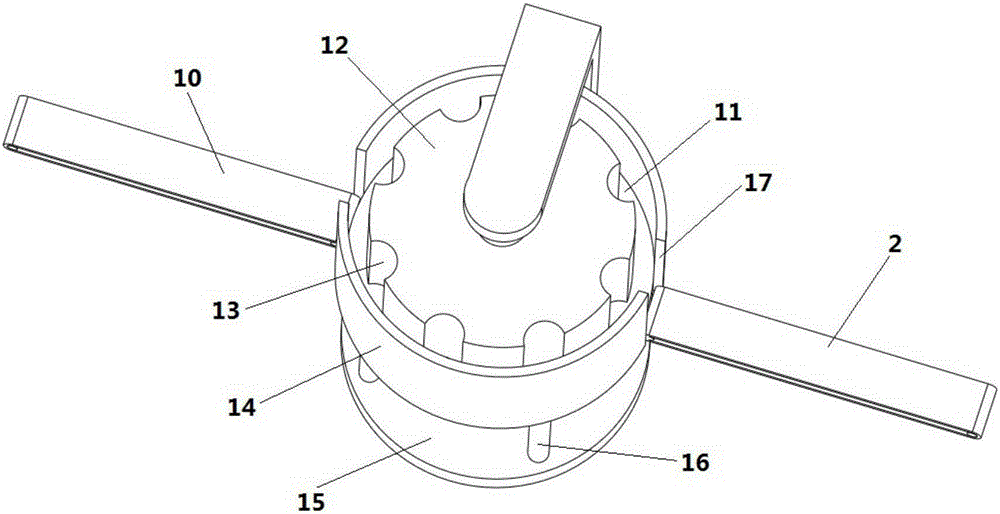

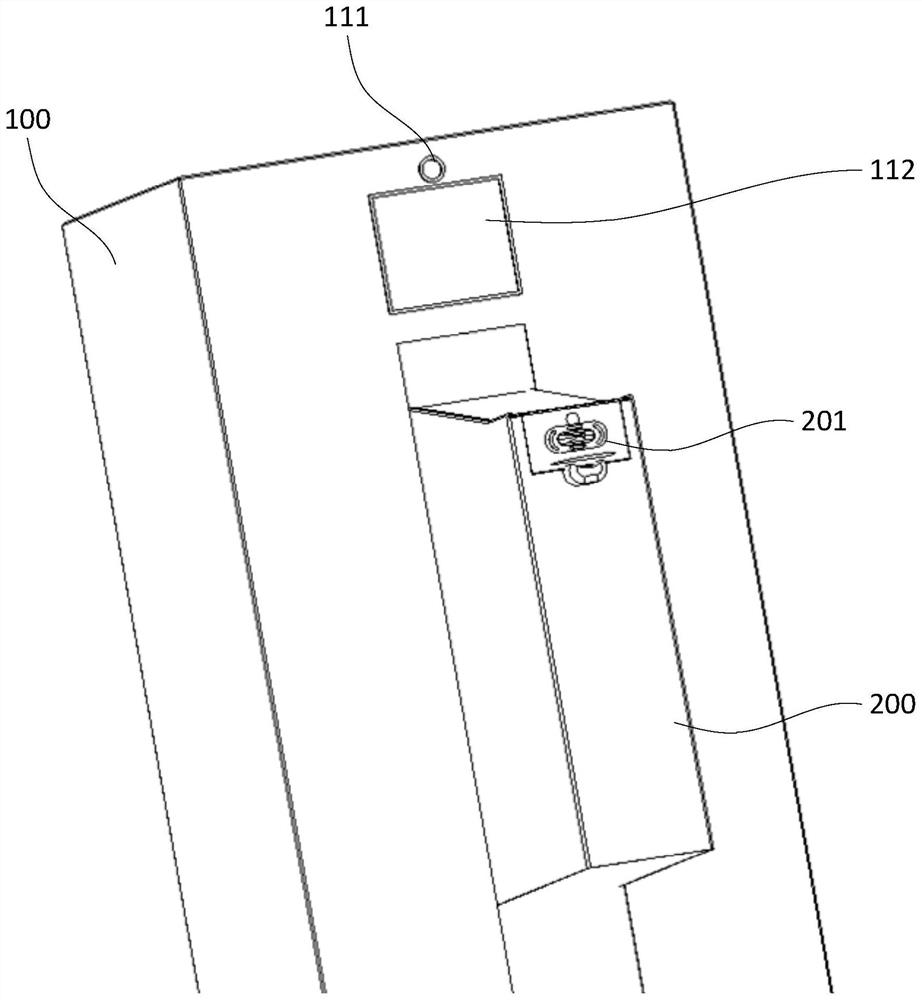

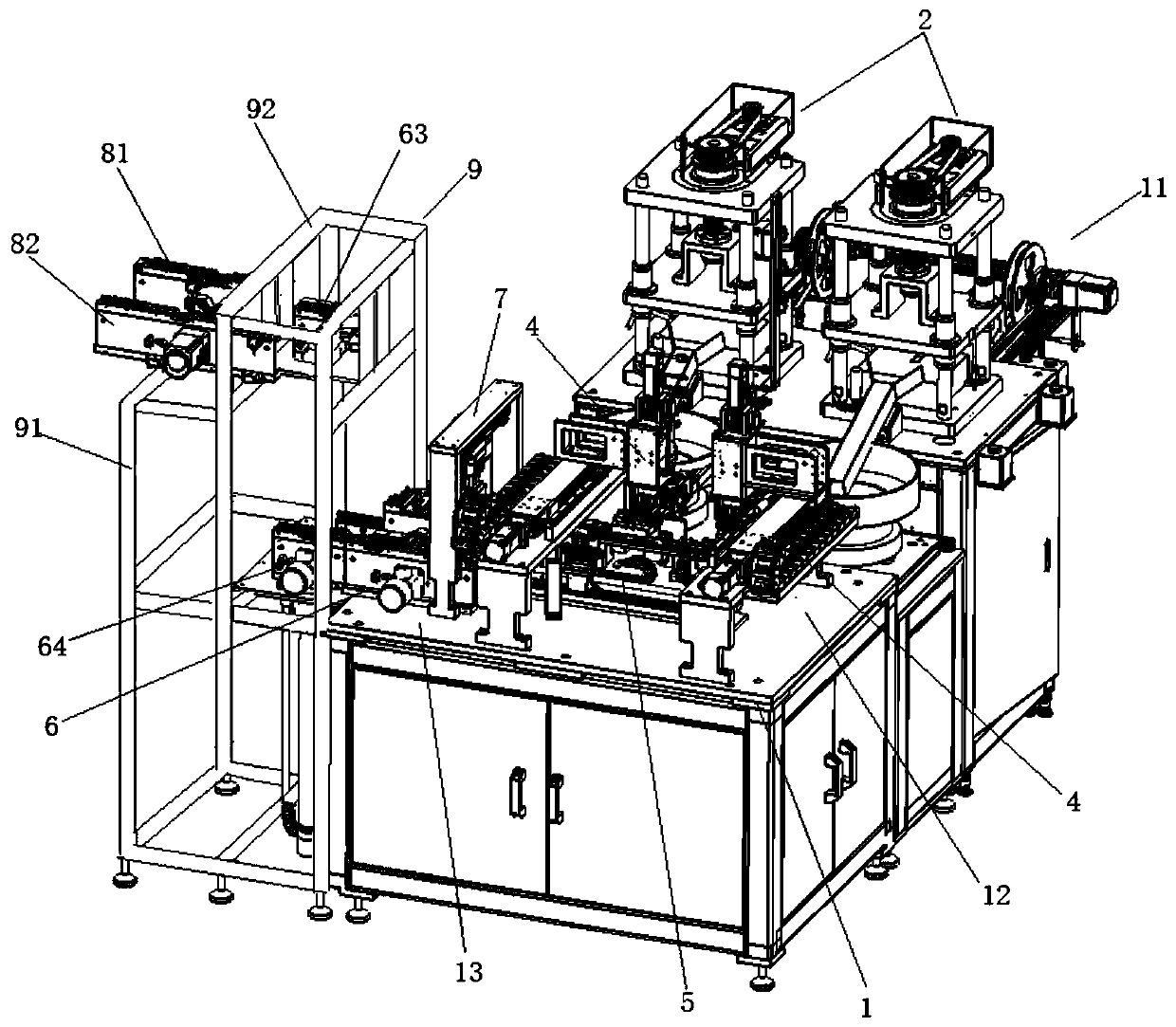

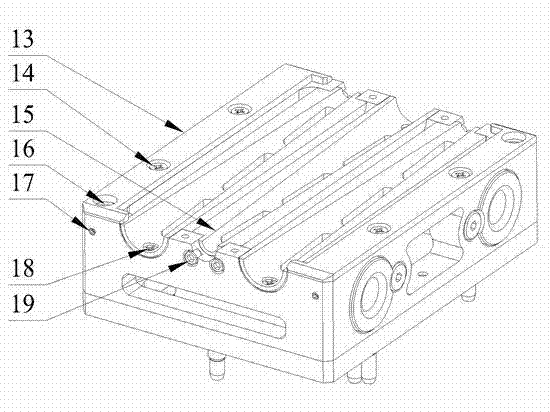

Nasopharyngeal swab sampling robot

PendingCN111975799AEffective isolationRealize automatic connectionSurgical needlesVaccination/ovulation diagnosticsPhysical medicine and rehabilitationPhysical therapy

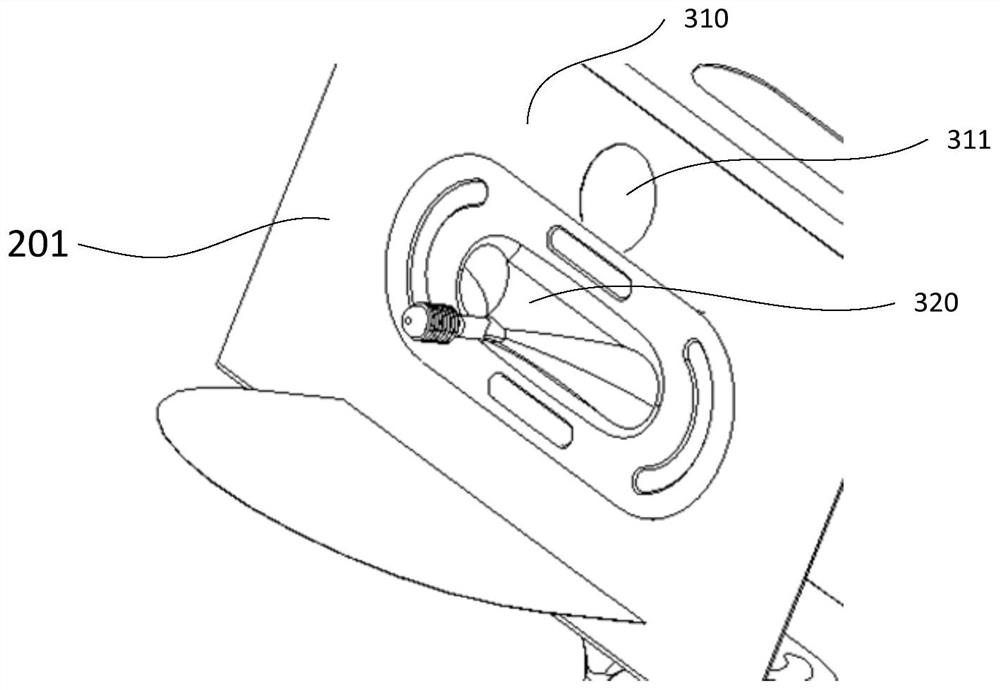

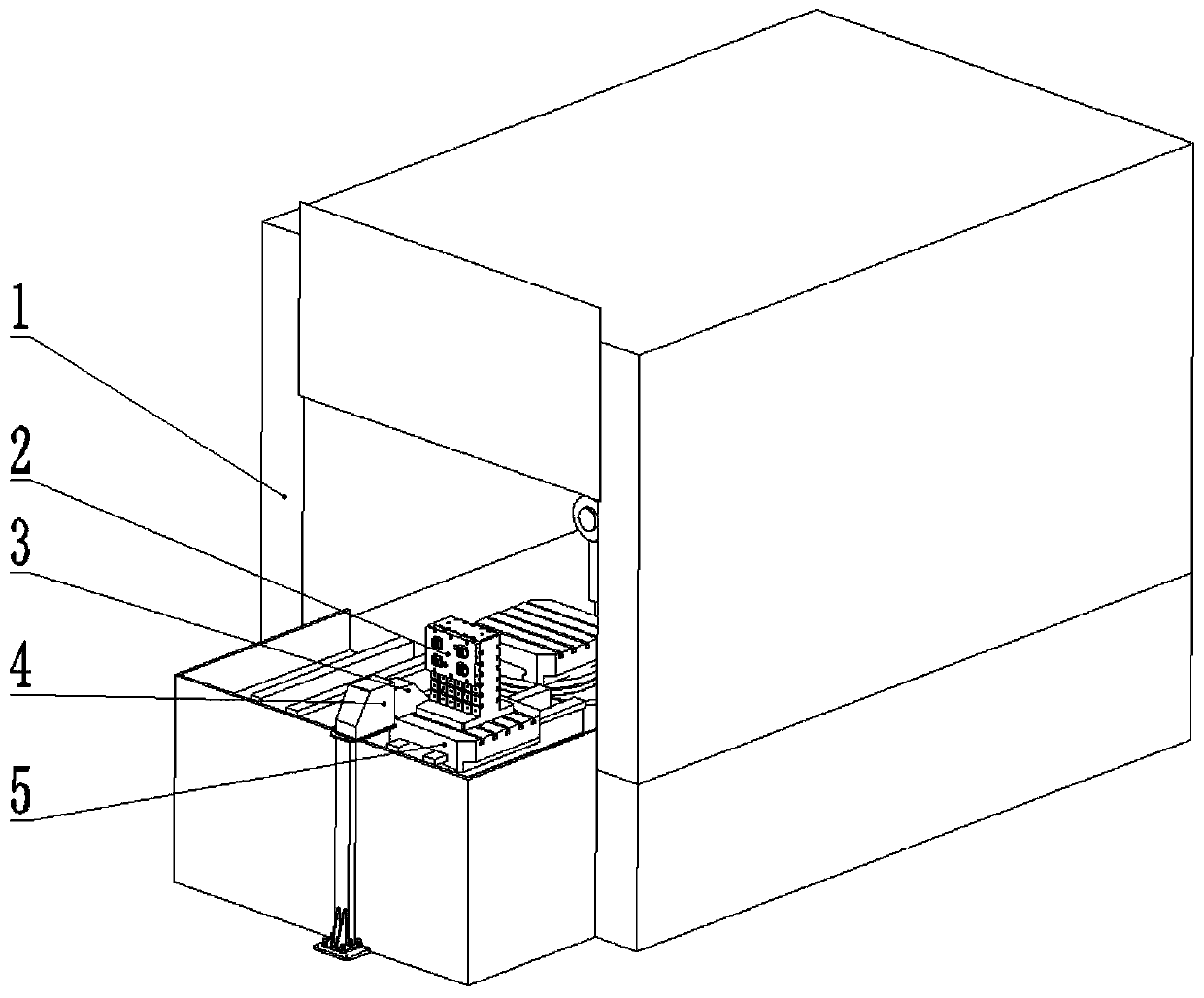

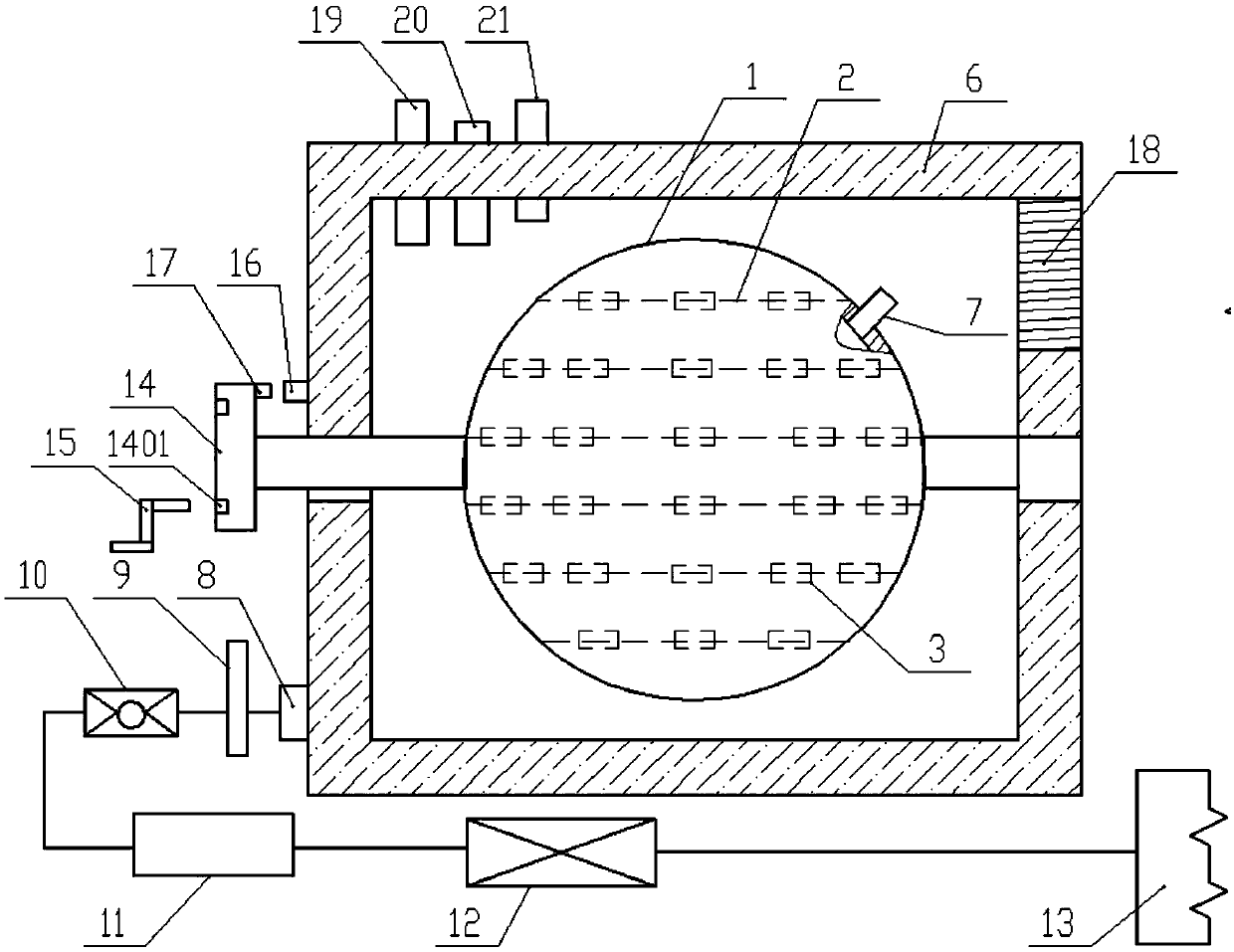

The invention belongs to the technical field of robots, and particularly relates to a nasopharyngeal swab sampling robot. The device comprises a mobile working platform, and an automatic swab stripping device, an automatic isolation sleeve wearing device, a test tube transferring and cover opening and closing device, a sampling mechanical arm, a sampling window module and an isolation sleeve removing device which are arranged on the mobile working platform; the movable working platform is arranged in an isolation hood; the automatic swab stripping device is used for stripping a swab packagingbag; the automatic isolation sleeve wearing device is used for mounting an isolation sleeve on the outer side of a sampling tail end mechanism of the sampling mechanical arm; the sampling window module is arranged at a sampling window formed in the isolation hood; the test tube transferring and cover opening and closing device is used for opening and closing test tube covers and transferring testtubes; and the isolation sleeve removing device is used for detaching the isolation sleeve outside the sampling tail end mechanism. The robot can effectively isolate medical staff from sampled staff in the whole sampling process, automatic connection of the sampling process is achieved, all functional assemblies are modularized, and disassembly, assembly and maintenance are convenient.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI +1

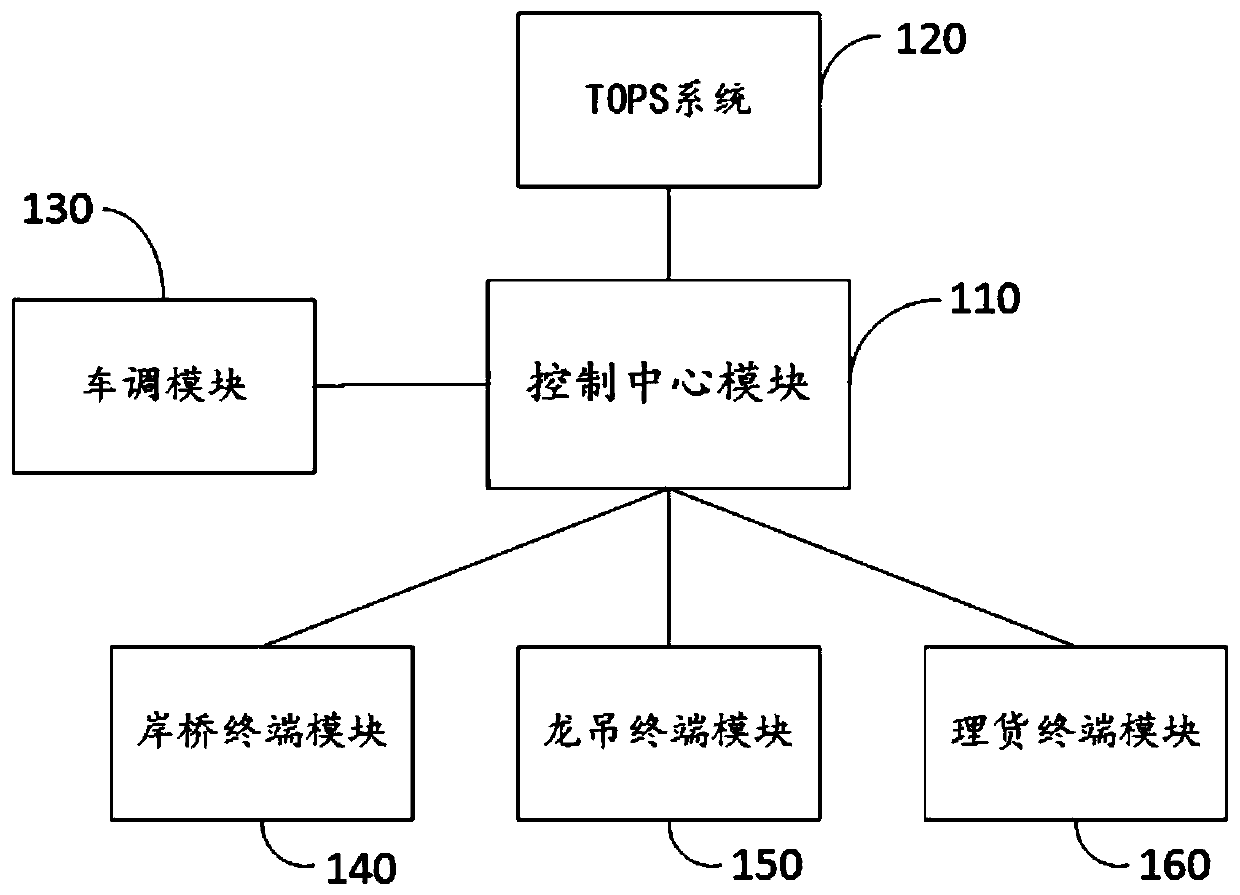

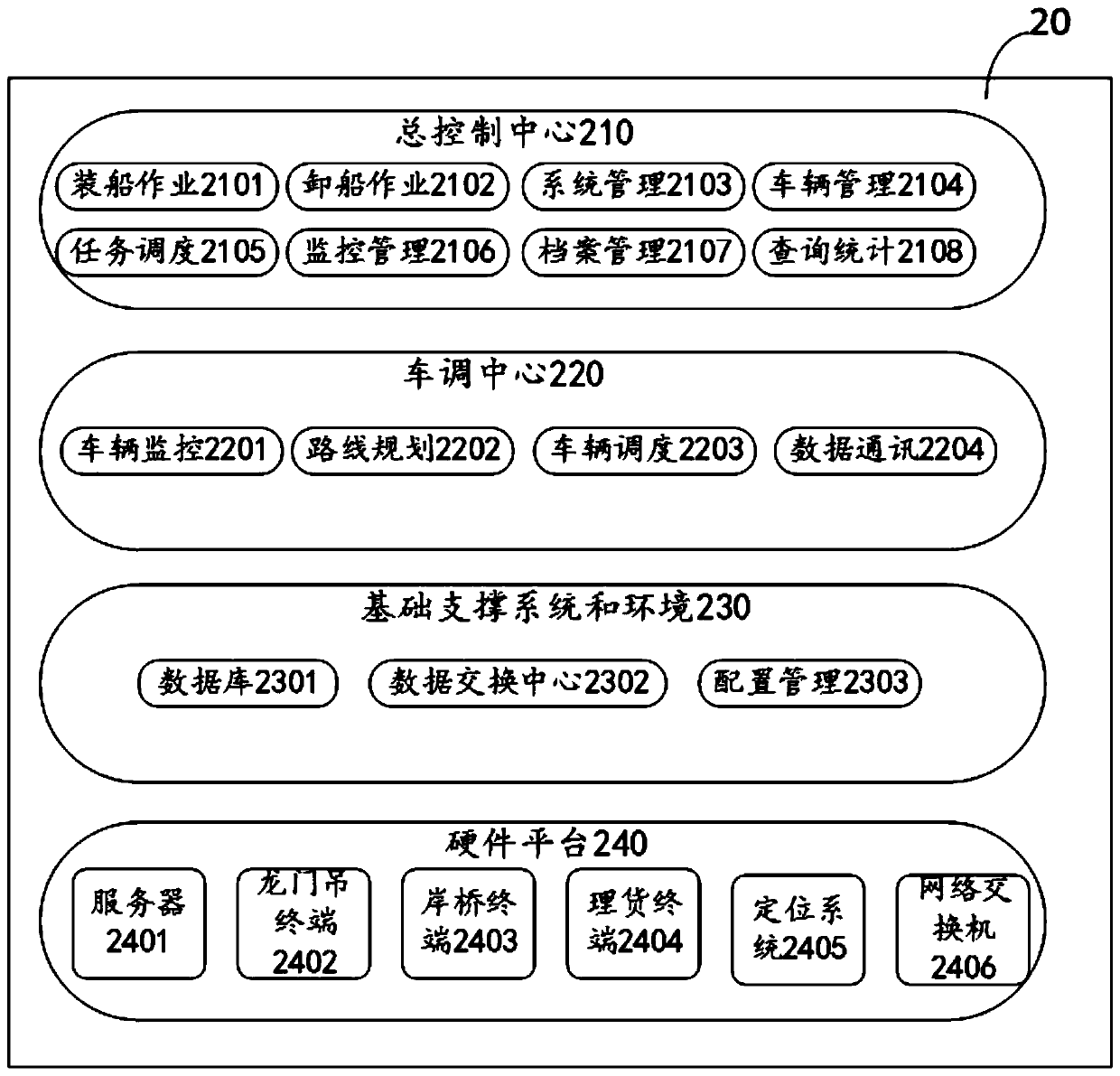

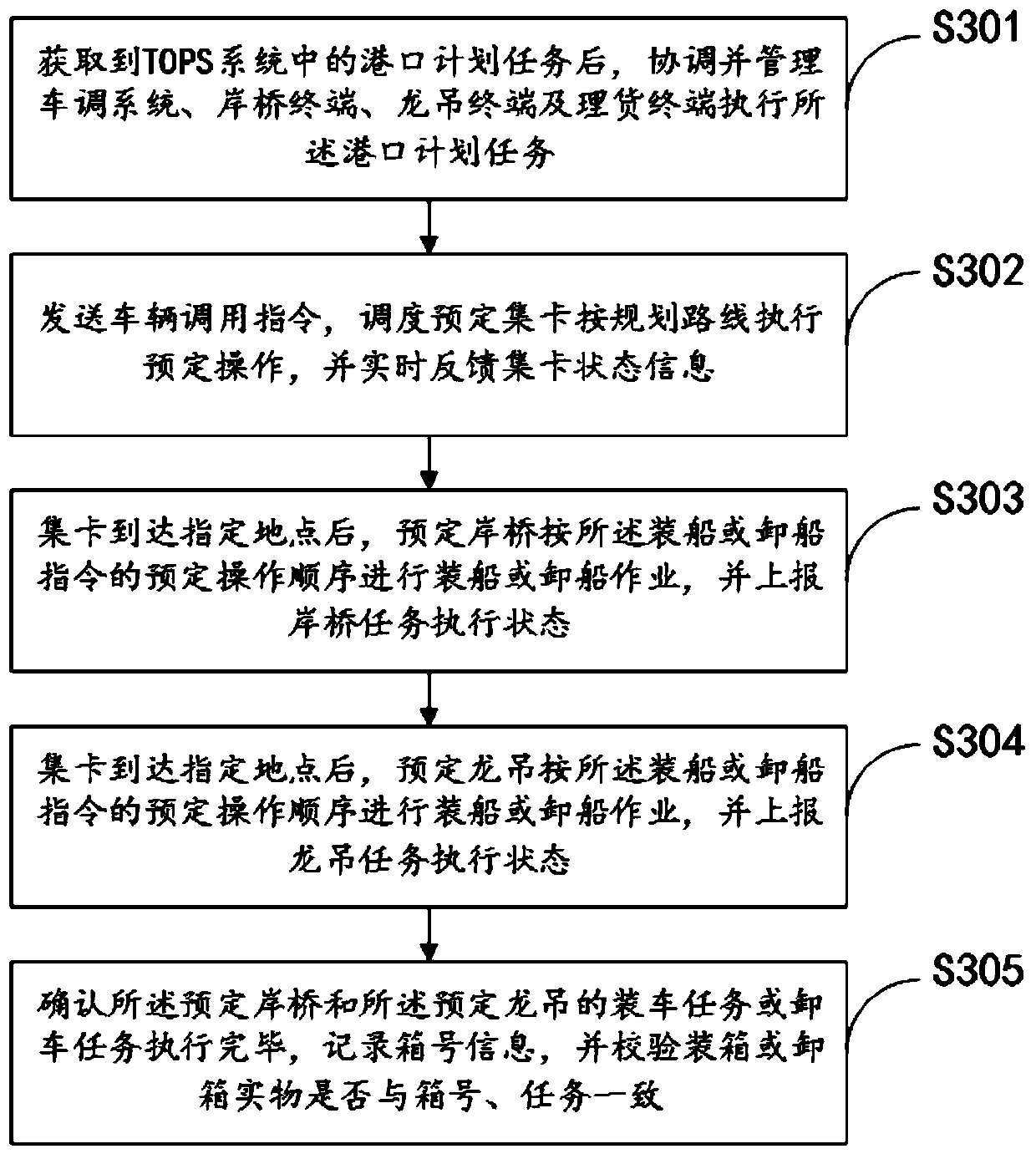

Port scheduling system and method based on unmanned driving

PendingCN110598987AGuarantee reasonable schedulingRealize automatic connectionResourcesLogisticsGantry craneQuay crane

The invention relates to a port scheduling system and method based on automatic driving, and belongs to the field of automatic driving. The port scheduling system comprises a control center module which is used for inputting a planned task, managing and coordinating a vehicle dispatching module, a quay crane terminal module, a gantry crane terminal module and a cargo handling terminal module to execute the planned task, carrying out the information interaction with the vehicle dispatching module, and obtaining the vehicle state information in real time, a vehicle dispatching module which is used for receiving the control management of the control center module, monitoring the state of the vehicle, planning a driving route and controlling the operation of the vehicle, a quay crane terminalmodule and a gantry crane terminal module which are used for receiving the shipment or unshipment instruction, carrying out shipment or unshipment operation according to a preset sequence and feedingback an execution state, and a tallying terminal module which is used for confirming that the container loading task or unloading task is executed, and recording and verifying the container loading orunloading information. Through the port scheduling system, the port operation efficiency can be improved, and the scheduling cost is reduced, and efficient and orderly operation of port operation isensured.

Owner:WUHAN ZHONGHAITING DATA TECH CO LTD

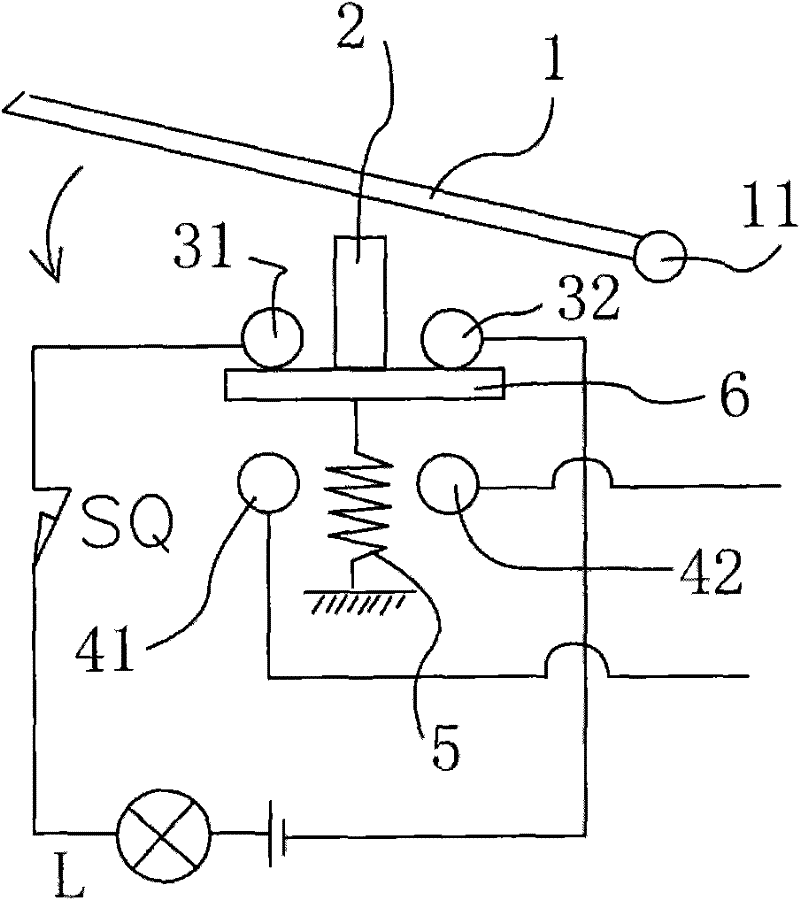

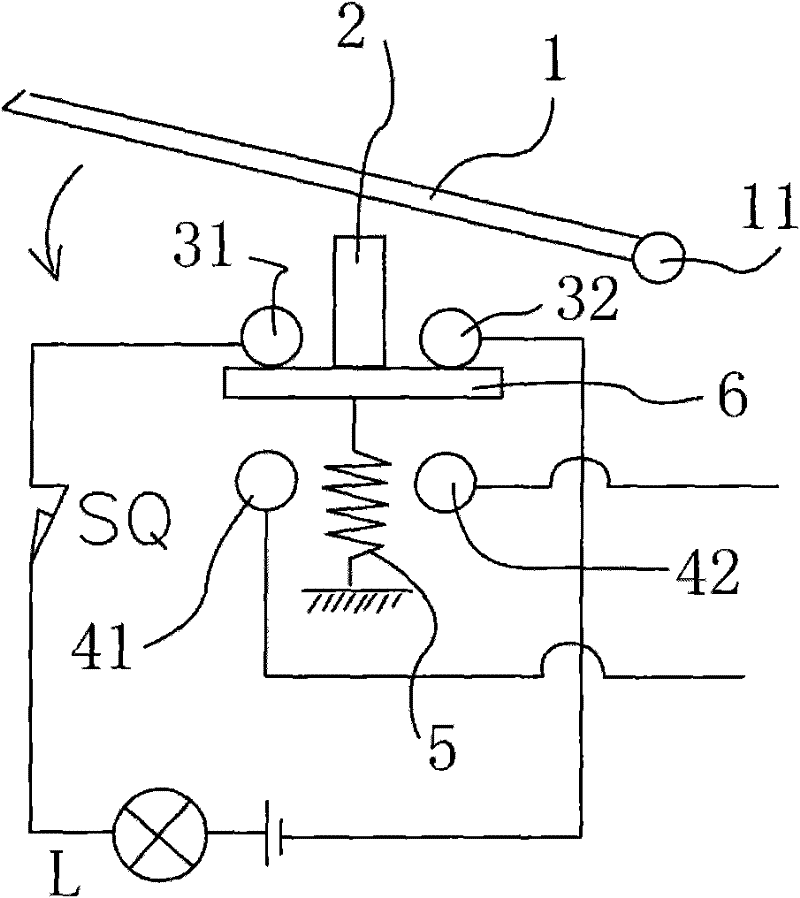

An electric cabinet door control device

InactiveCN102271477ARealize automatic connectionUse safe and energy-savingContact operating partsCasings/cabinets/drawers detailsMetalClose contact

The invention relates to a door control device for an electrical cabinet, comprising a contact button, one end of the contact button abuts on the door of the electrical cabinet, and the other end is connected to a metal contact piece supported by a return spring. , both ends of the metal contact piece are connected to a circuit connected in series with an electrical cabinet lighting lamp and a normally closed contact; when the return spring is tightened, the two ends of the metal contact piece are far away from the connection contacts of the circuit. The door control device realizes the purpose of automatically connecting the lighting circuit when the cabinet door is opened and automatically cutting off the lighting circuit when the cabinet door is closed through a spring-controlled door control button, which is energy-saving and safe to use.

Owner:SUZHOU SUZHU IND CONTROL ENG TECH RES CENT CO LTD

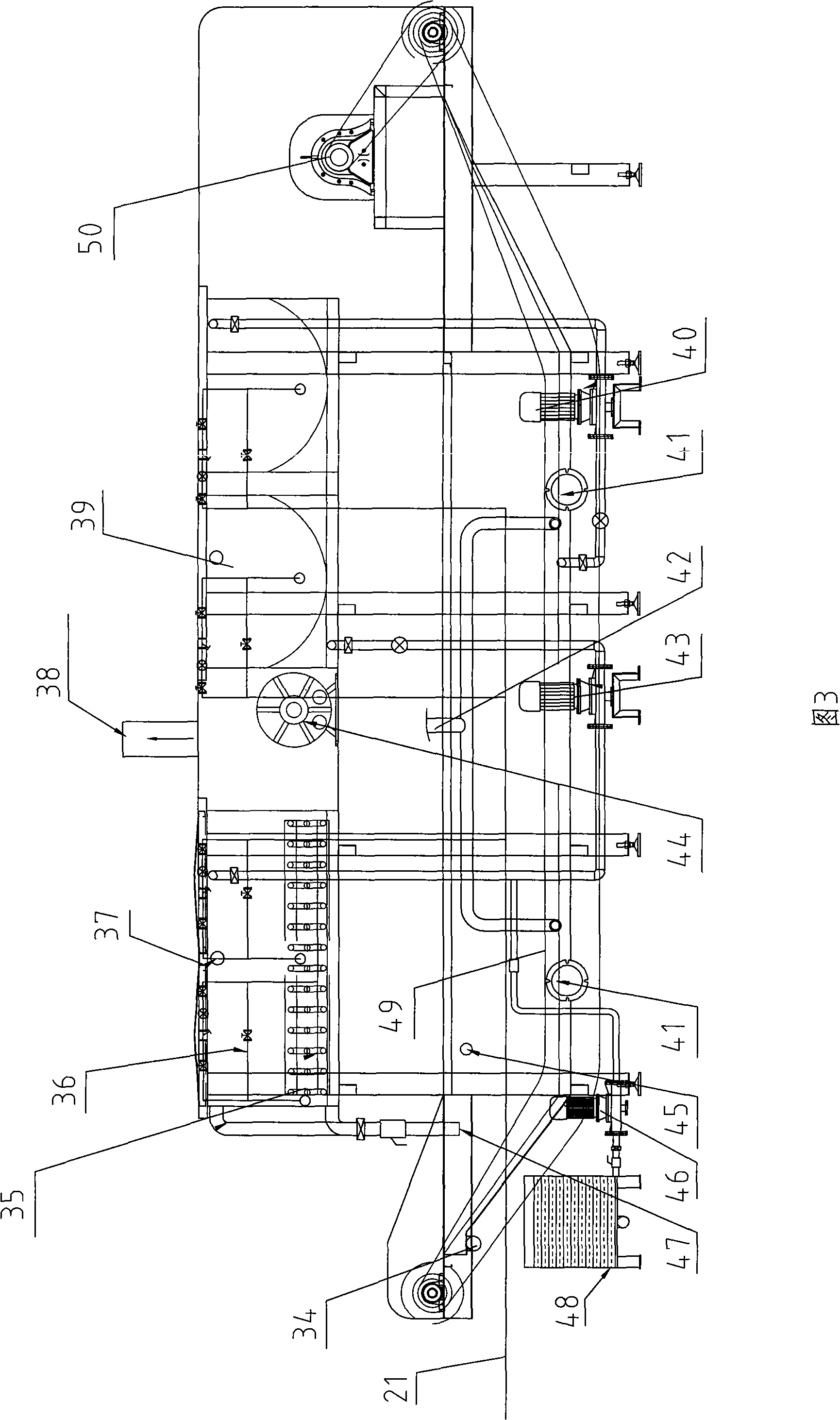

Full-automatic alkali-dipping, rinsing and marinating production line

The invention relates to a production line for fully-automatic alkali parboiling, bleaching and marinating, which belongs to foodstuff processing mechanical equipment and aims to solve the problems that the prior marinated food processing equipment has large labor coefficient, unstable product quality caused by human factors, and low production efficiency. The production line comprises an alkali-parboiling machine, a bleaching machine, a marinating machine and an automatic control device, wherein the three machines are provided with a stirring mechanism and a dewatering mechanism respectively, and the alkali-parboiling machine and the marinating machine are also provided with a technological parameter sensor and an overflow liquid reclaiming mechanism which are electrically connected with the automatic control device. The production line is applicable to processing marinated foods.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

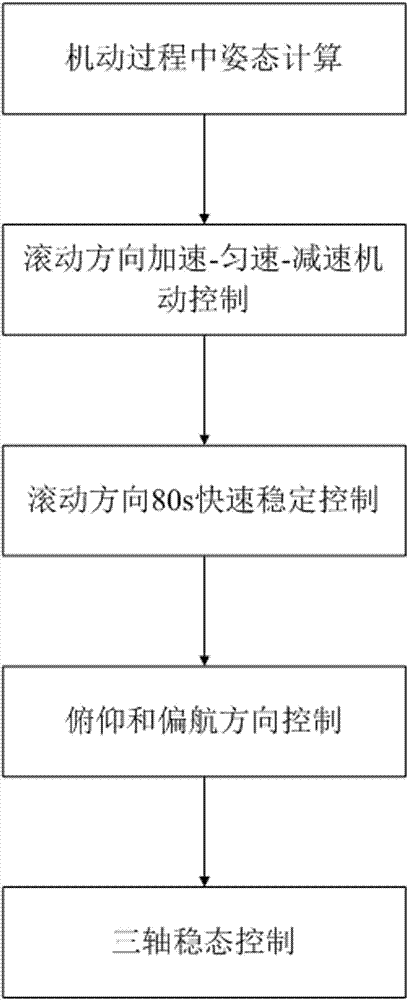

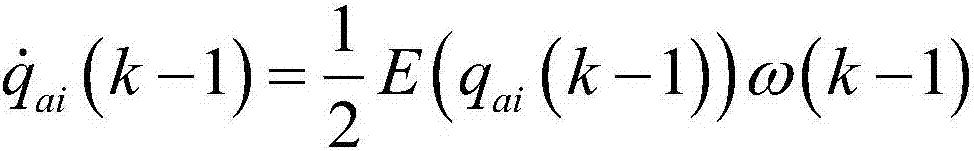

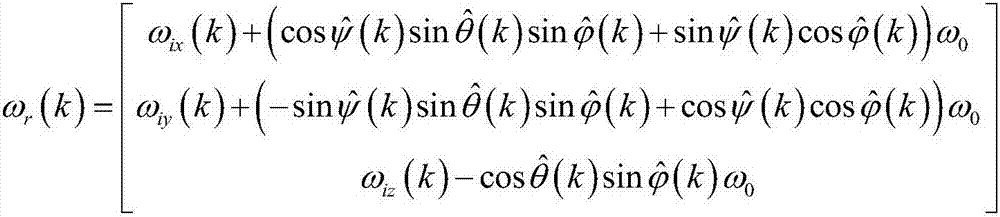

Satellite attitude maneuvering method based on subsection control

ActiveCN106945849ARealize automatic connectionHigh bandwidthArtificial satellitesSpacecraft guiding apparatusAcceleration UnitSatellite

The invention discloses a satellite attitude maneuvering method based on subsection control. The method comprises the following steps that attitudes of a satellite in the attitude maneuvering process are determined; acceleration, constant velocity and deceleration maneuvering control is conducted on the direction of a satellite rolling axis; the direction of the satellite rolling axis is stably controlled; maneuvering control is conducted on the directions of a satellite pitch axis and a satellite yaw axis; and the satellite rolling axis, the satellite pitch axis and the satellite yaw axis are switched into a homeostatic state control mode. According to the method, by means of symmetry of acceleration and deceleration of the maneuvering process, the attitude maneuvering of the satellite can be autonomously divided into the processes of acceleration, constant velocity, deceleration, fast steadiness and homeostatic control, the processes are controlled correspondingly, and the maneuvering process is automatically interlocked.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

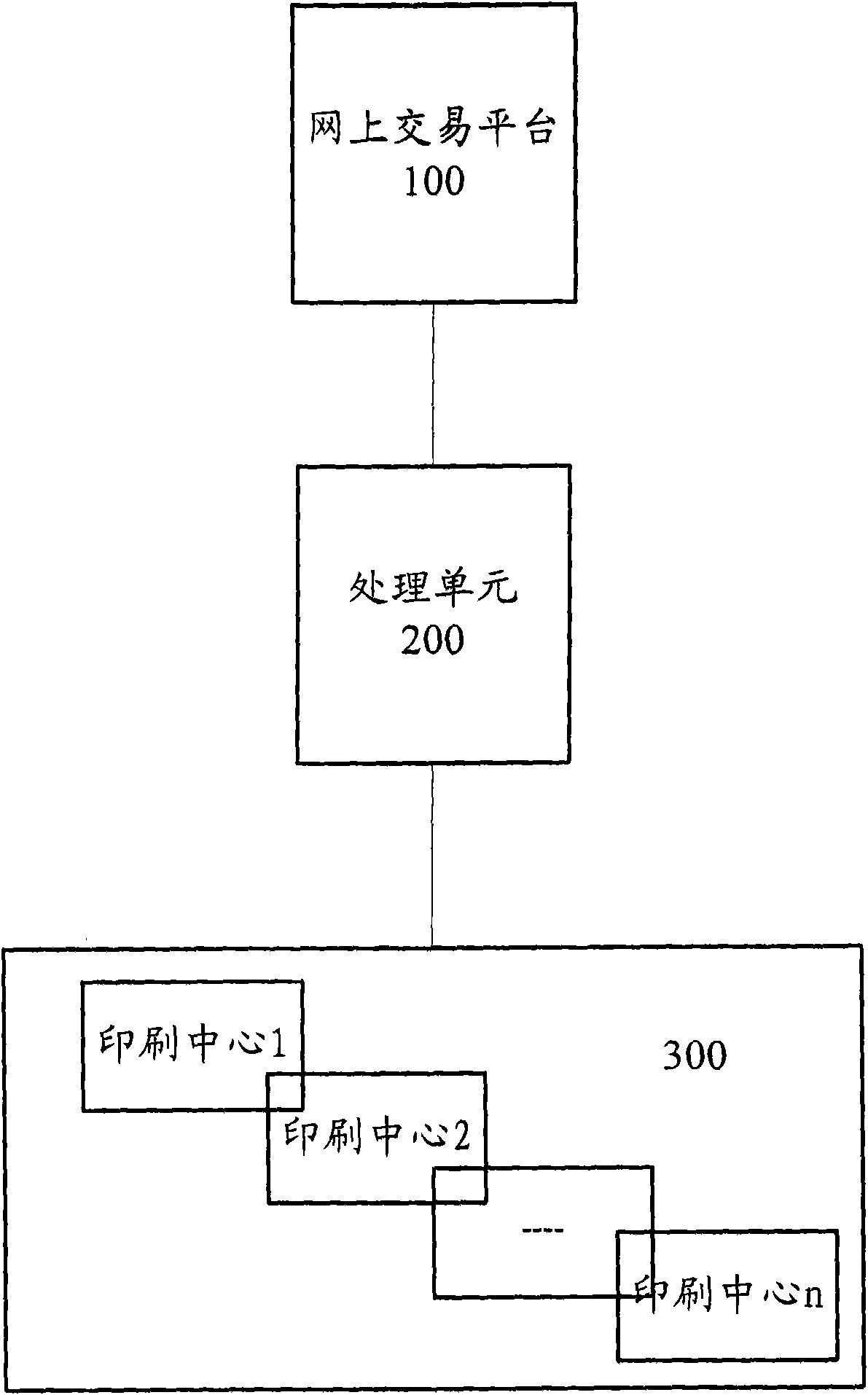

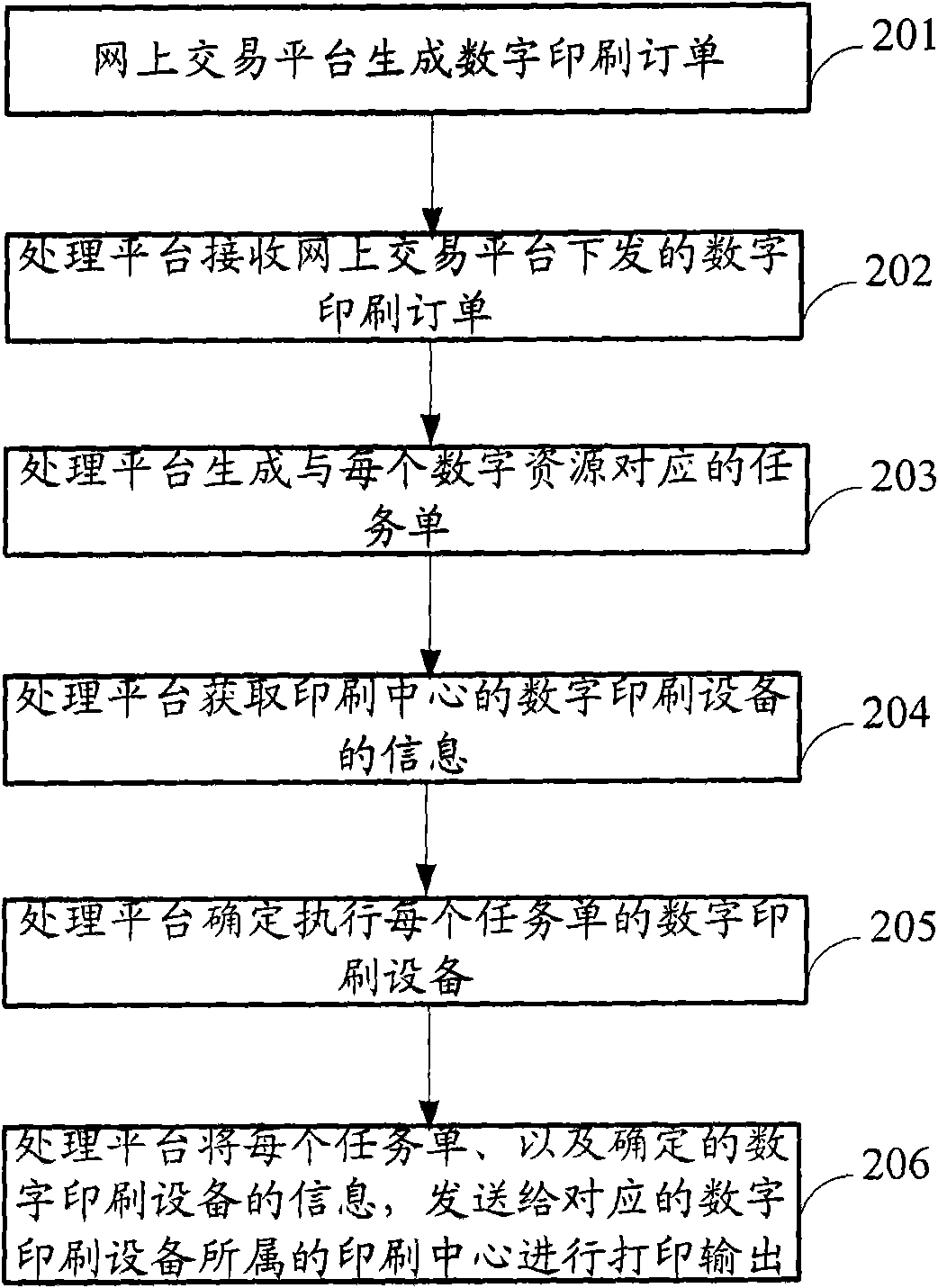

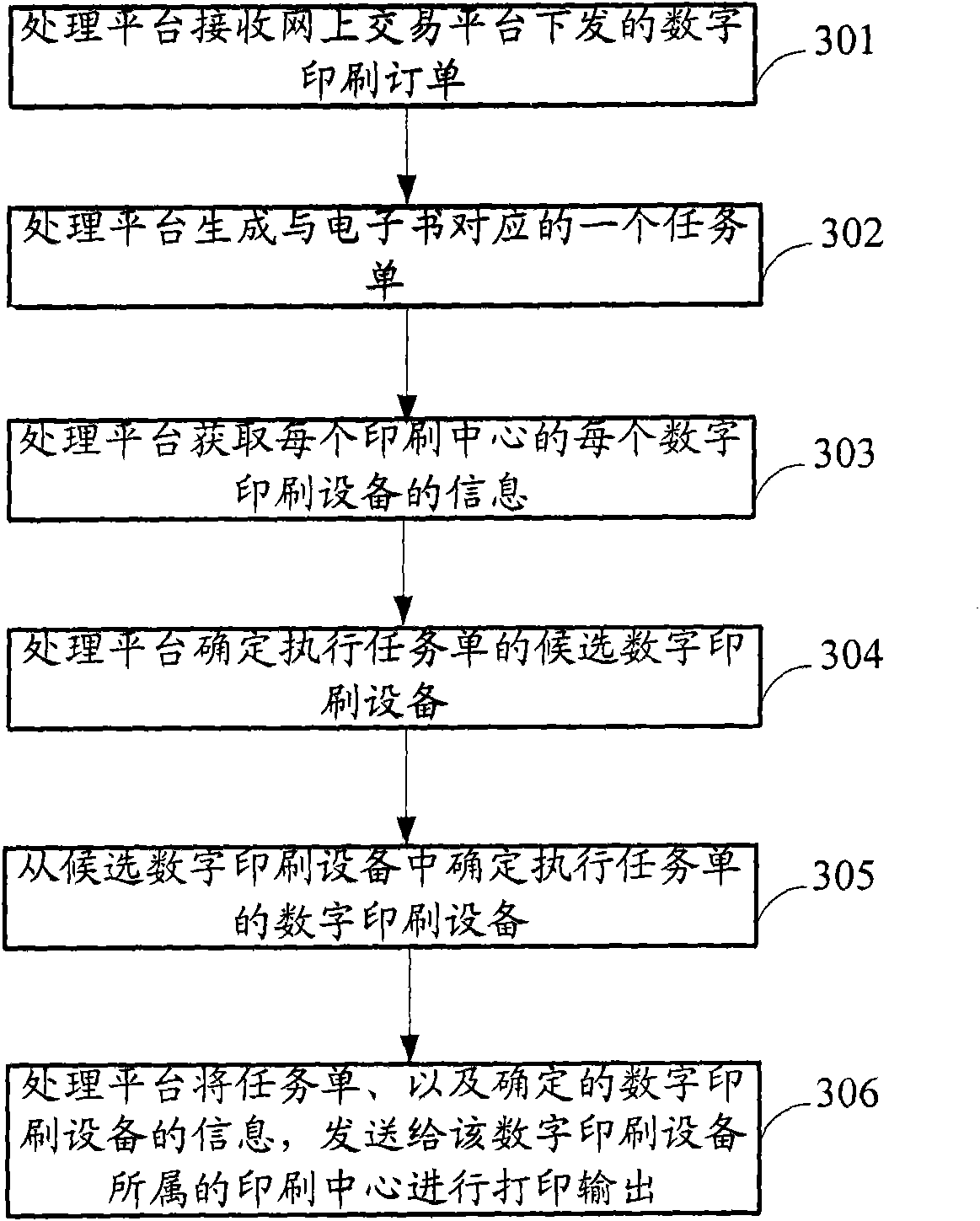

Digital printing order processing method and device

InactiveCN102117461ARealize automatic connectionAutomatic automatic schedulingCommerceDigital printingOnline trading

The invention discloses a digital printing order processing method and a digital printing order processing device, which are used for solving the problem that the automatic scheduling of a digital printing order onto digital printing equipment is not realized in the prior art. The method comprises that: a processing platform receiving the digital printing order from an online trading platform, wherein the digital printing order comprises at least one digital resource and the printing process information of each digital resource; the processing platform resolves the digital printing order, andgenerates a task list corresponding to each digital resource; the processing platform determines the digital printing equipment for executing each task list according to the printing process information of the digital resource in each task list and the acquired information of each piece of digital printing equipment of each printing center; and the processing platform transmits each task list andthe information of the determined digital printing equipment to the corresponding printing centers of the digital printing equipment for printing output.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

Full-automatic alkali-dipping, rinsing and marinating production line

ActiveCN101491309ARealize automatic controlRealize automatic connectionFood preparationAlkalinityProduction line

Te invention relates to a production method for fully-automatic alkali parboiling, bleaching and marinating, which belongs to a production method for food processing and aims to solve the problems that the prior production method for processing marinated foods has large labor coefficient, unstable product quality caused by human factors, and low production efficiency. The production method comprises three processing steps of alkali-parboiling, bleaching, and marinating, wherein in each processing step, materials are conveyed by a conveying net which is controlled by an automatic control device; the alkalinity of the alkali-parboiling is adjusted by a lye delivery valve controlled by the automatic control device after being detected by a pH value detector; in the processing steps of alkali-parboiling and bleaching, the materials are dewatered by a dewatering mechanism in the conveying process by the conveying net; in the marinating processing step, technological parameters of brine are adjusted by a charging part which is controlled by the automatic control device after being detected by a sensor; and the input end and the output end of the conveying net in the processing steps of alkali-parboiling, bleaching, and marinating are connected in series one after another to form a continuous process for conveying the materials automatically. The production method is applicable to processing marinated foods.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

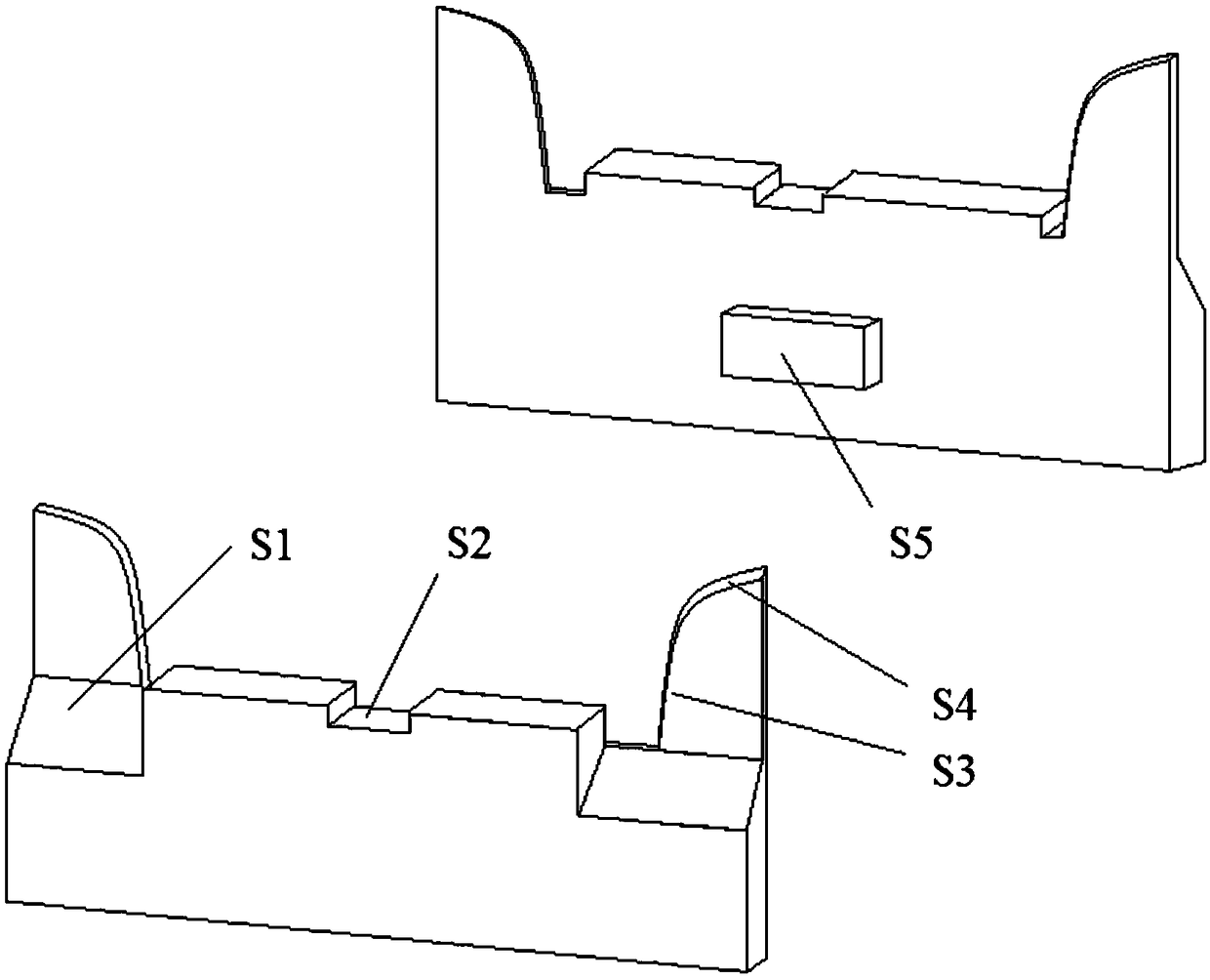

Reversing fixed-distance feeding system for cylindrical tanks

InactiveCN105253604AControl spacingImprove transmission performanceConveyor partsEngineeringMechanical engineering

The invention discloses a reversing fixed-distance feeding system for cylindrical tanks. The system comprises a feeding conveying belt and a monomer conveying belt joined together, wherein the monomer conveying belt is joined with a discharge conveying belt through a gap adjusting device; the feeding conveying belt and the monomer conveying belt are positioned on one vertical surface; the feeding conveying belt is driven through a feeding belt wheel; the monomer conveying belt is driven through a monomer belt wheel; a carrier surface at the top of the monomer conveying belt is higher than a carrier surface at the top of the feeding conveying belt; a lower bottom surface of the monomer conveying belt is lower than the carrier surface at the top of the feeding conveying belt; and the monomer conveying belt is a magnetic conveying belt. The system converts the lying transmission of the cylindrical tanks to the standing transmission by the feeding conveying belt and the monomer conveying belt with different heights; semicircular grooves peripherally and uniformly distributed on a turntable are used for accommodating the cylindrical tanks; and the turntable rotates with uniform speed, so that the cylindrical tanks ate uniformly thrown onto the discharge conveying belt.

Owner:长兴佳瑞清洁用品有限公司

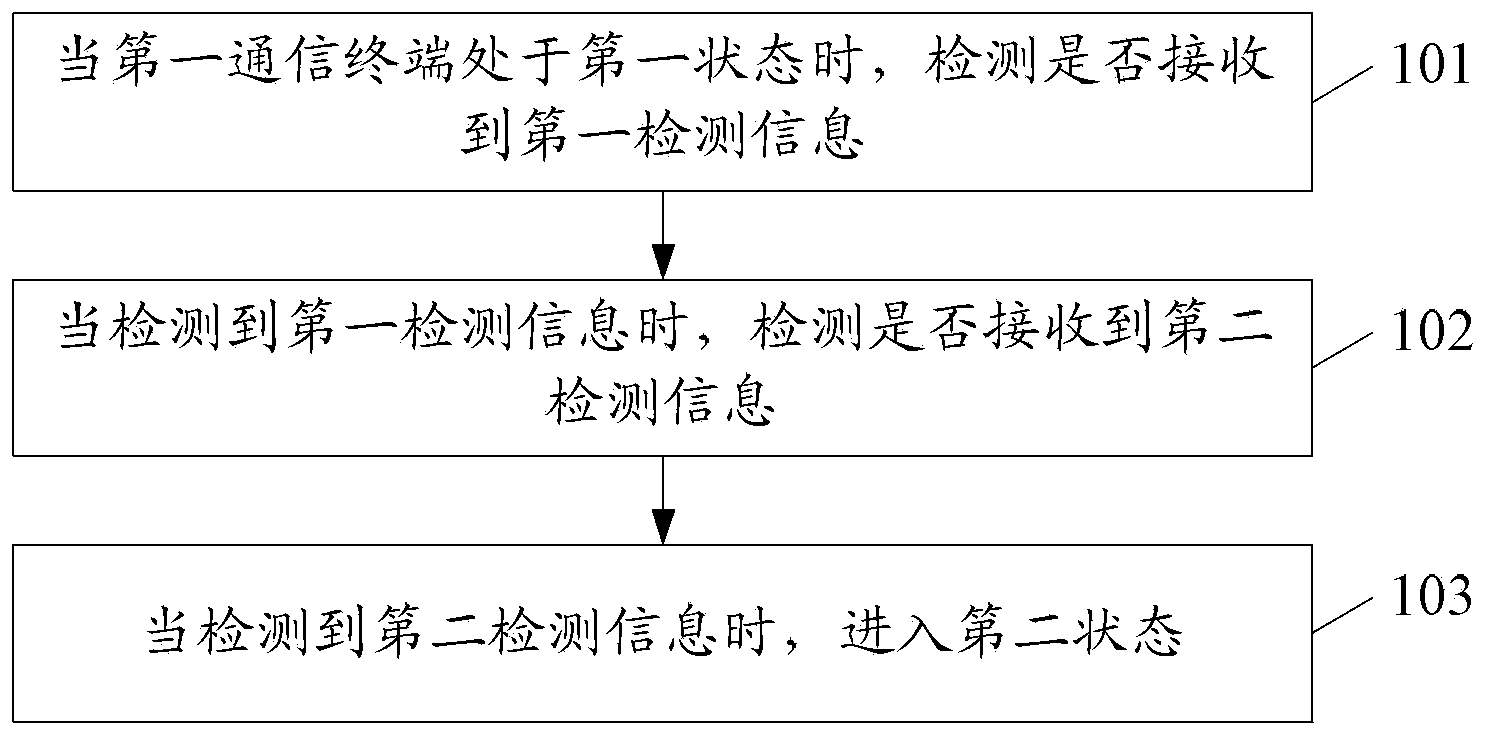

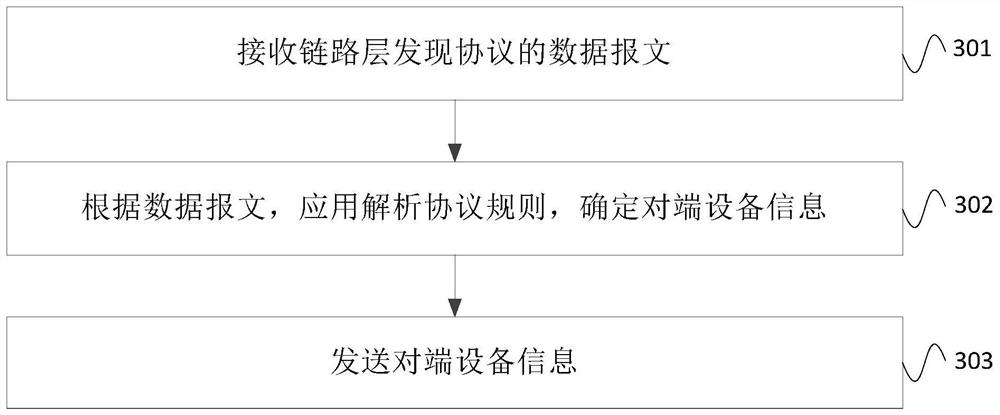

State switching method and device and first communication terminal

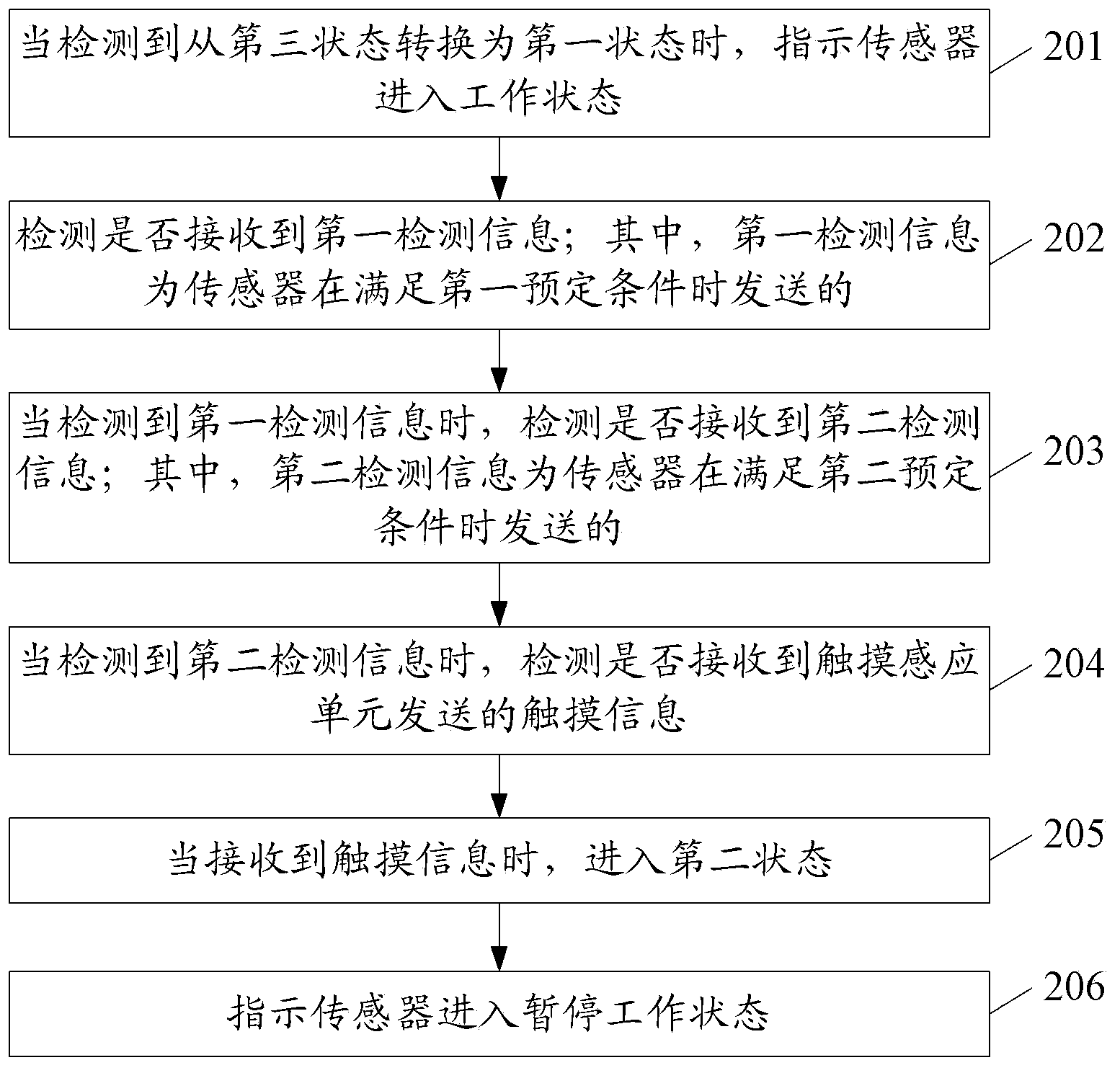

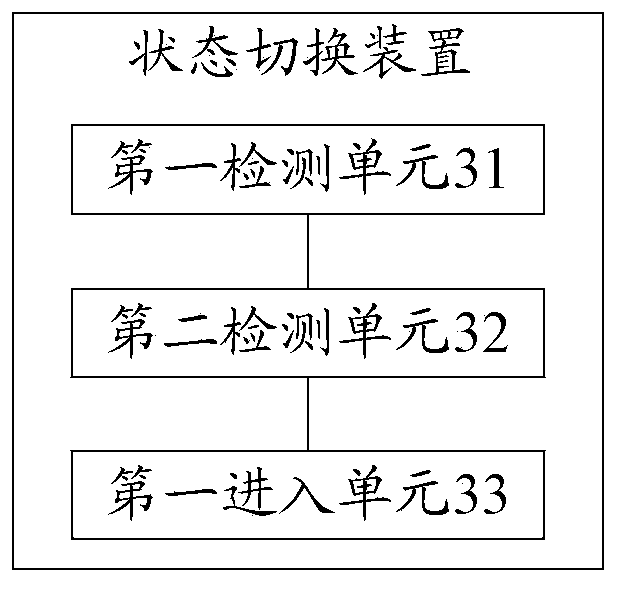

InactiveCN103856613ARealize automatic connectionImprove experienceSubstation equipmentComputer terminalState switching

The embodiment of the invention discloses a state switching method and device and a first communication terminal, and relates to the field of application of electronic devices. Through the state switching method and device and the first communication terminal, automatic receiving of communication requests is achieved, and user experience is improved. According to the specific scheme, the method includes the steps that when the first communication terminal is in a first state, whether first detection information is received or not is detected, wherein the first detection information is sent by a sensor when a first preset condition is met; when the first detection information is detected, whether second detection information is received or not is detected, wherein the second detection information is sent by the sensor when a second preset condition is met; when the second detection information is detected, the first communication terminal is in a second state. The state switching method and device are used for the state switching process of the communicated terminal.

Owner:LENOVO (BEIJING) LTD

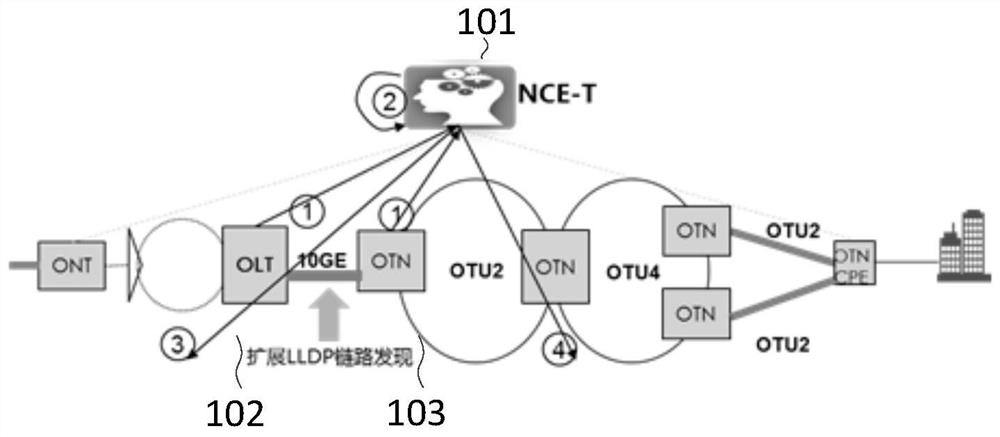

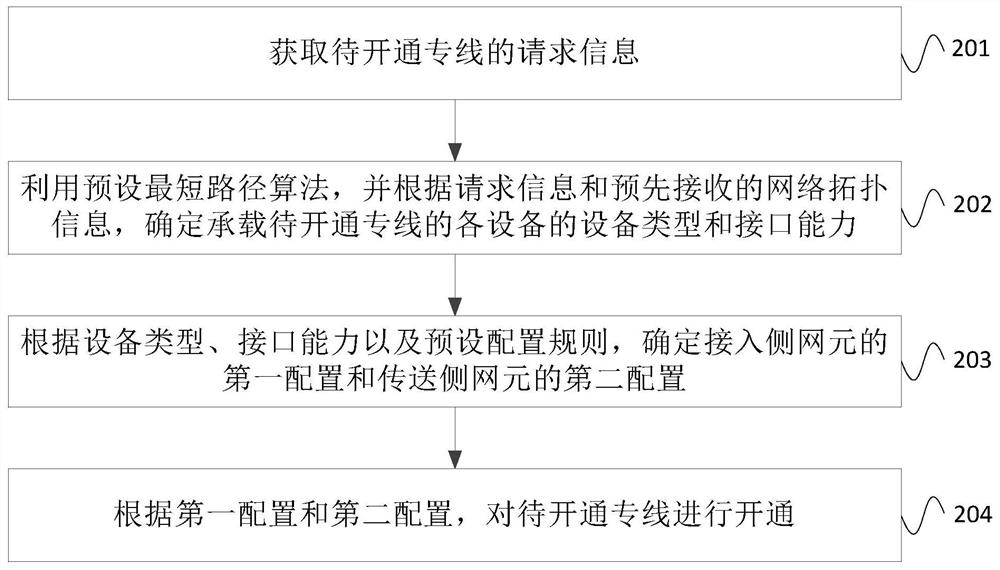

Special line opening method and device

ActiveCN112203172ARealize automatic connectionImprove activation efficiencyMultiplex system selection arrangementsPathPingDevice type

The invention provides a special line opening method and device, and the method provided by the embodiment comprises the steps: obtaining the request information of a to-be-opened special line; utilizing a preset shortest path algorithm, and according to the request information and pre-received network topology information, determining the equipment type and interface capability of each piece of equipment bearing the to-be-opened special line; determining a first configuration of an access side network element and a second configuration of a transmission side network element according to the device type, the interface capability and a preset configuration rule; and opening the special line to be opened according to the first configuration and the second configuration. According to the special line opening method provided by the embodiment of the invention, automatic opening of the service paths in the fusion special line is realized, so that the opening efficiency is improved and the labor cost is reduced.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

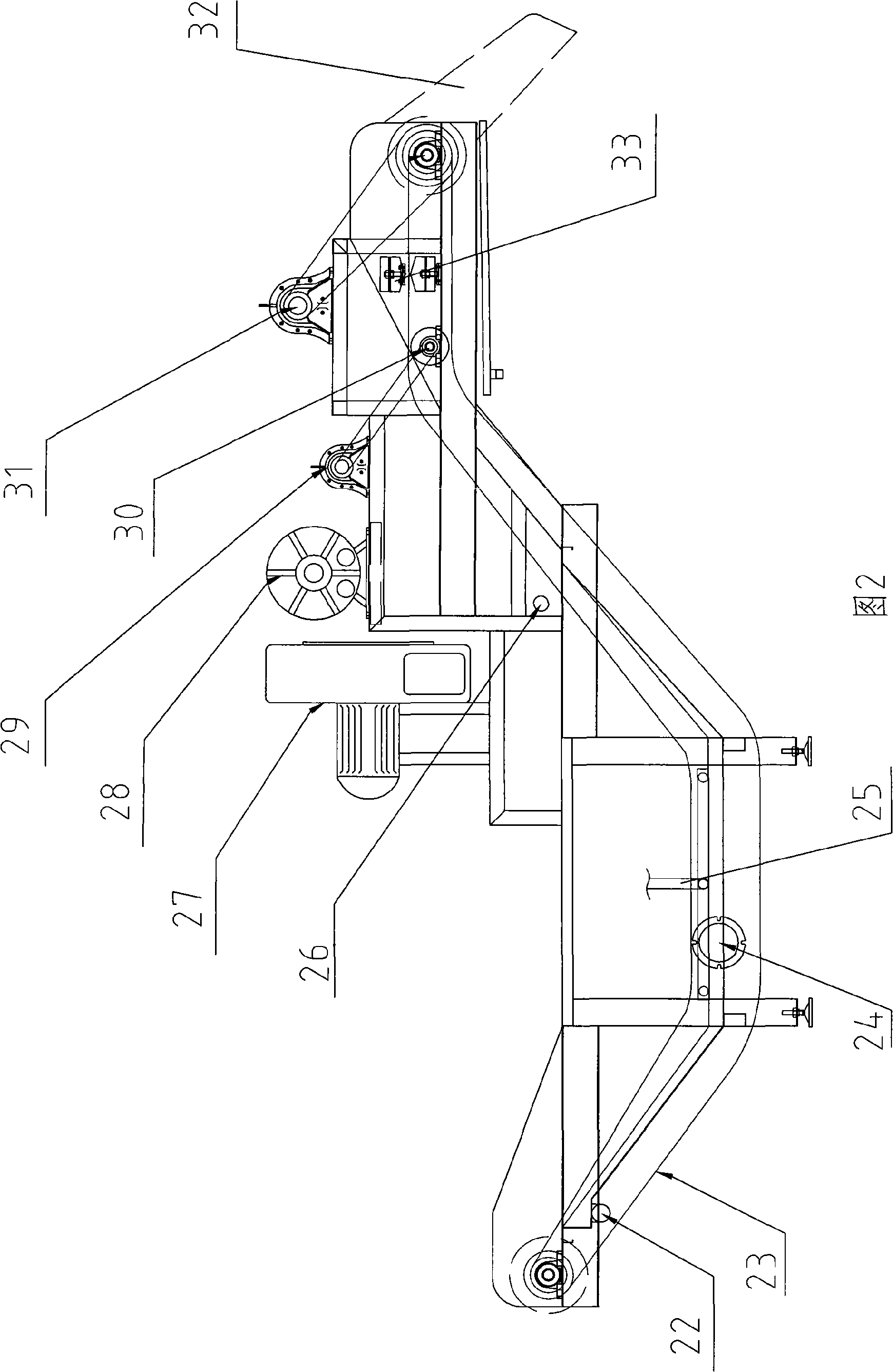

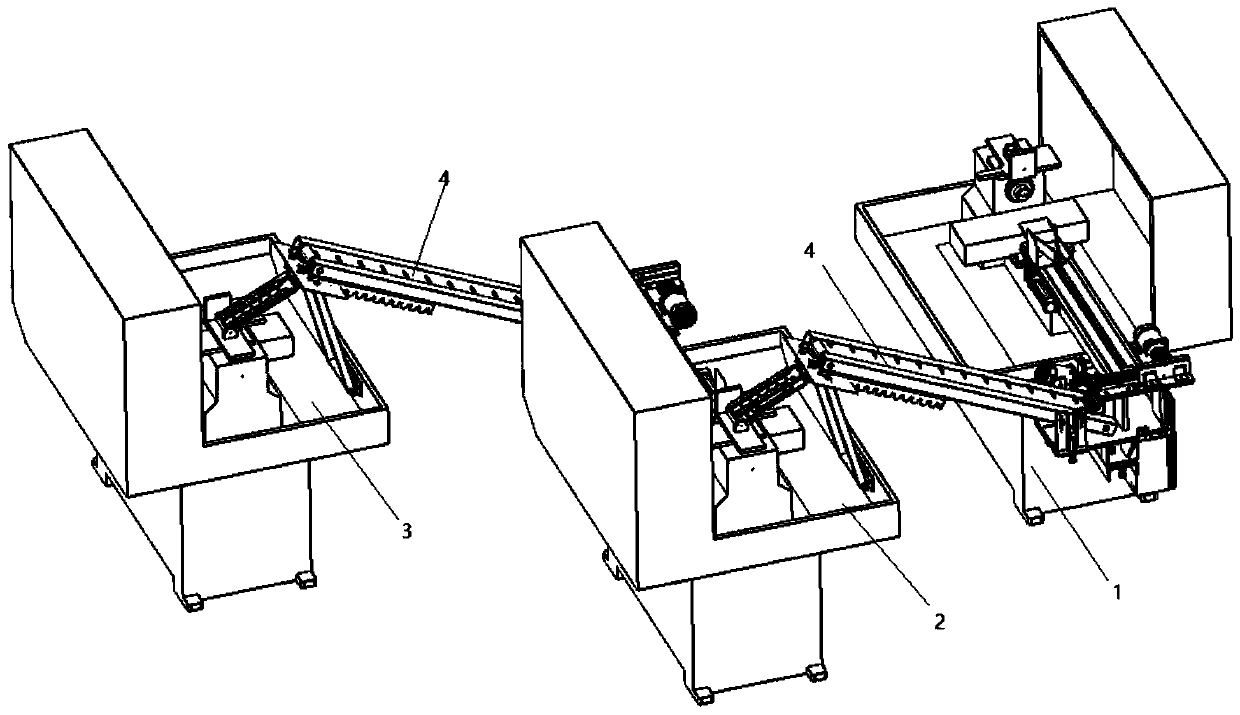

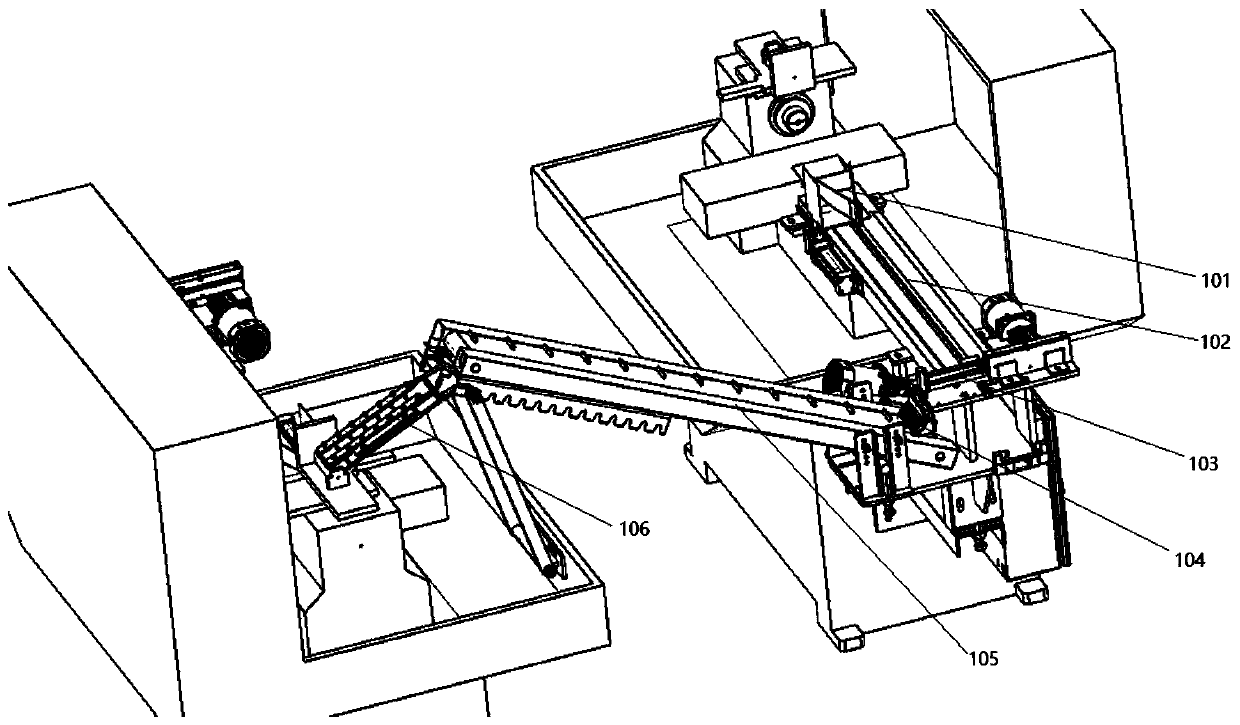

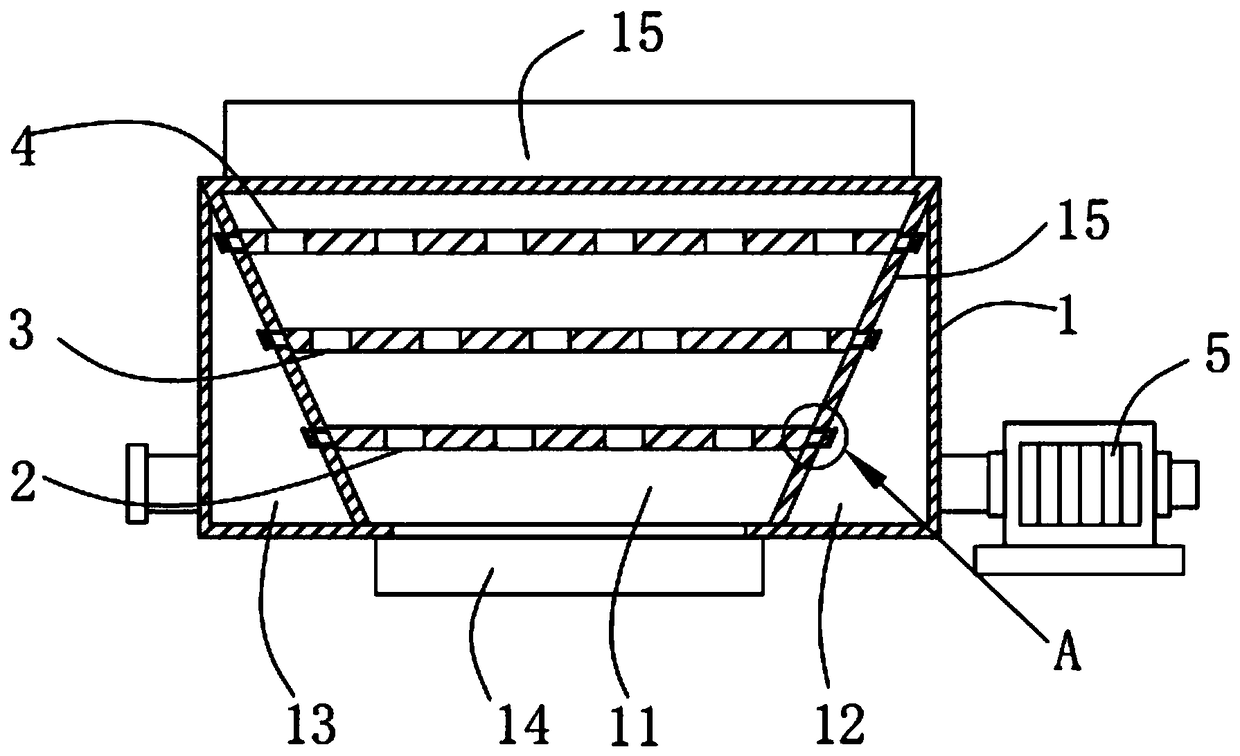

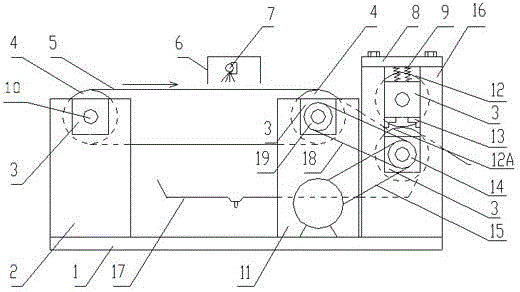

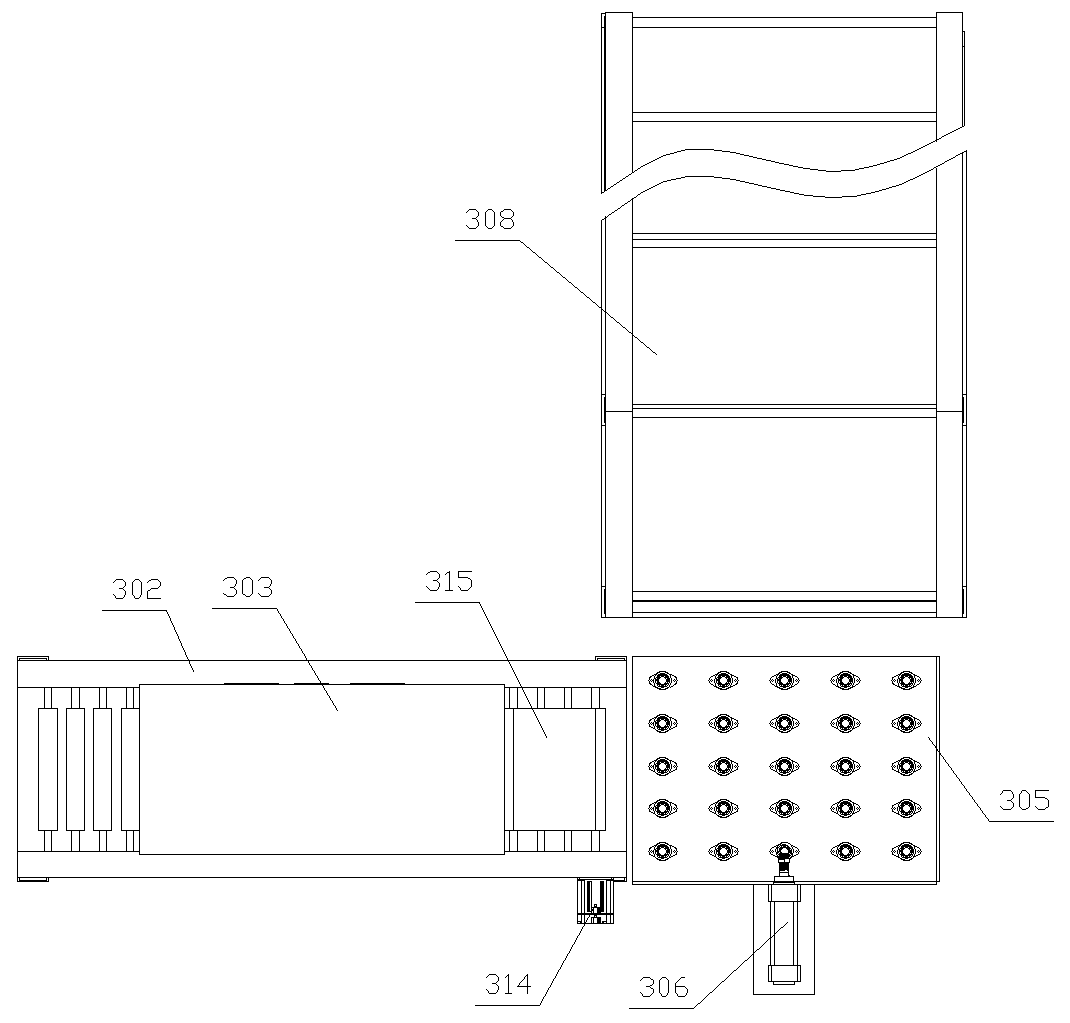

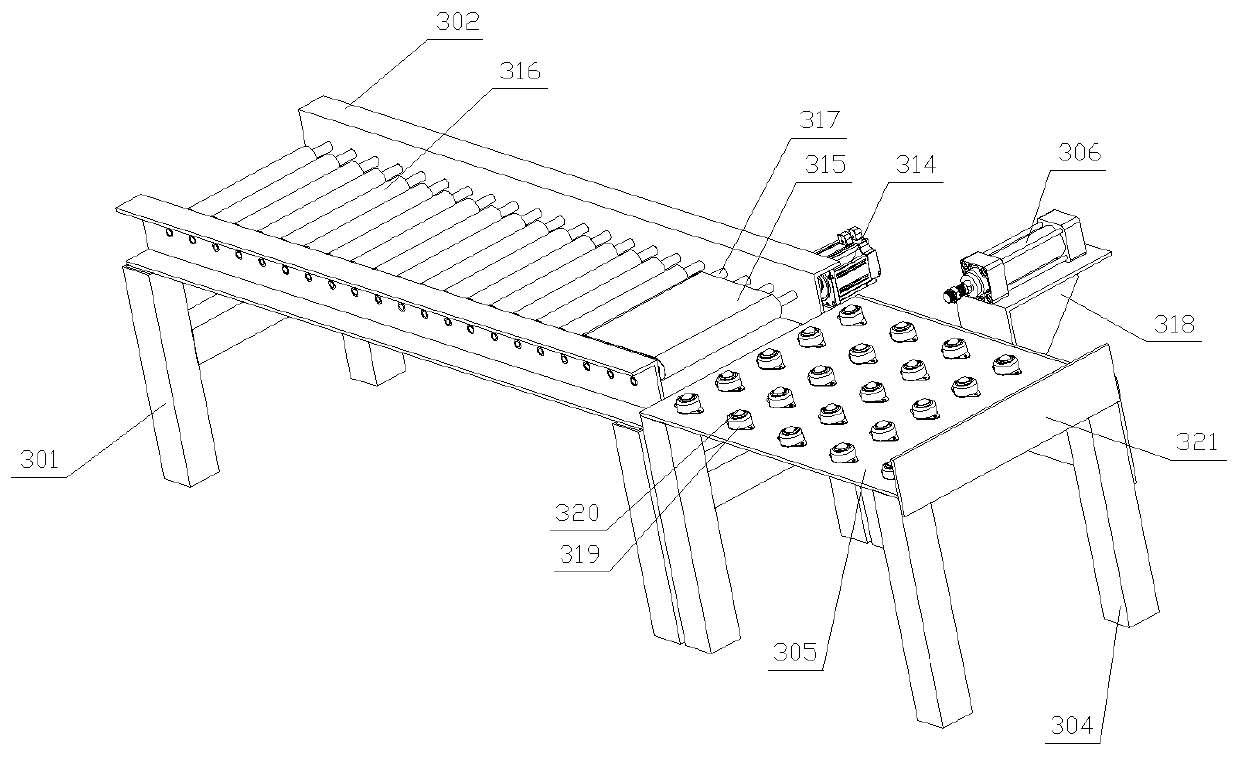

Automatic wire connecting device for numerical control lathes

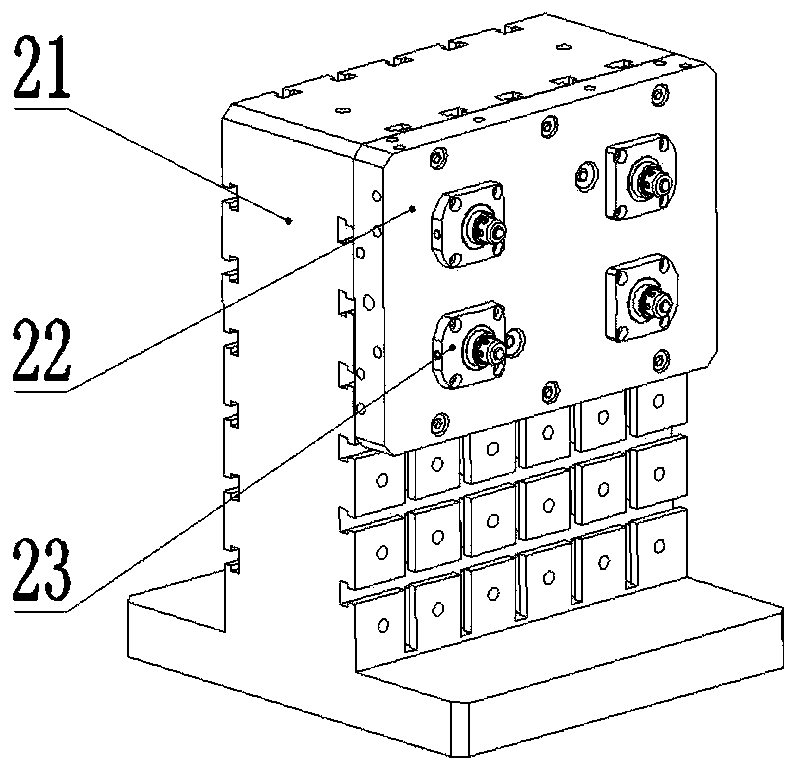

ActiveCN110202168AIncrease productivityReduce labor costsMetal working apparatusMachining processNumerical control

The invention provides an automatic wire connecting device for numerical control lathes. The automatic wire connecting device is characterized by comprising a material receiving device, a first conveying device, a pushing device, a material arranging bin, a second conveying device and a clip assembly, wherein the material receiving device, the first conveying device, the pushing device, the material arranging bin, the second conveying device and the clip assembly are sequentially connected; the material receiving device receives materials from the first numerical control lathe and transmits the materials to the pushing device along a fixed direction through the first conveying device; the pushing device pushes the materials to the material arranging bin; and the bar materials slide to thesecond conveying device through the material arranging bin; the second conveying device is arranged under the material arranging bin and used for conveying the materials to the clip assembly; and theclip assembly conveys the materials to a machining feeding inlet of the second numerical control lathe. The problem that the efficiency is reduced due to the fact that the materials are required to bemanually transferred in the existing machining process of the bar materials is solved.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

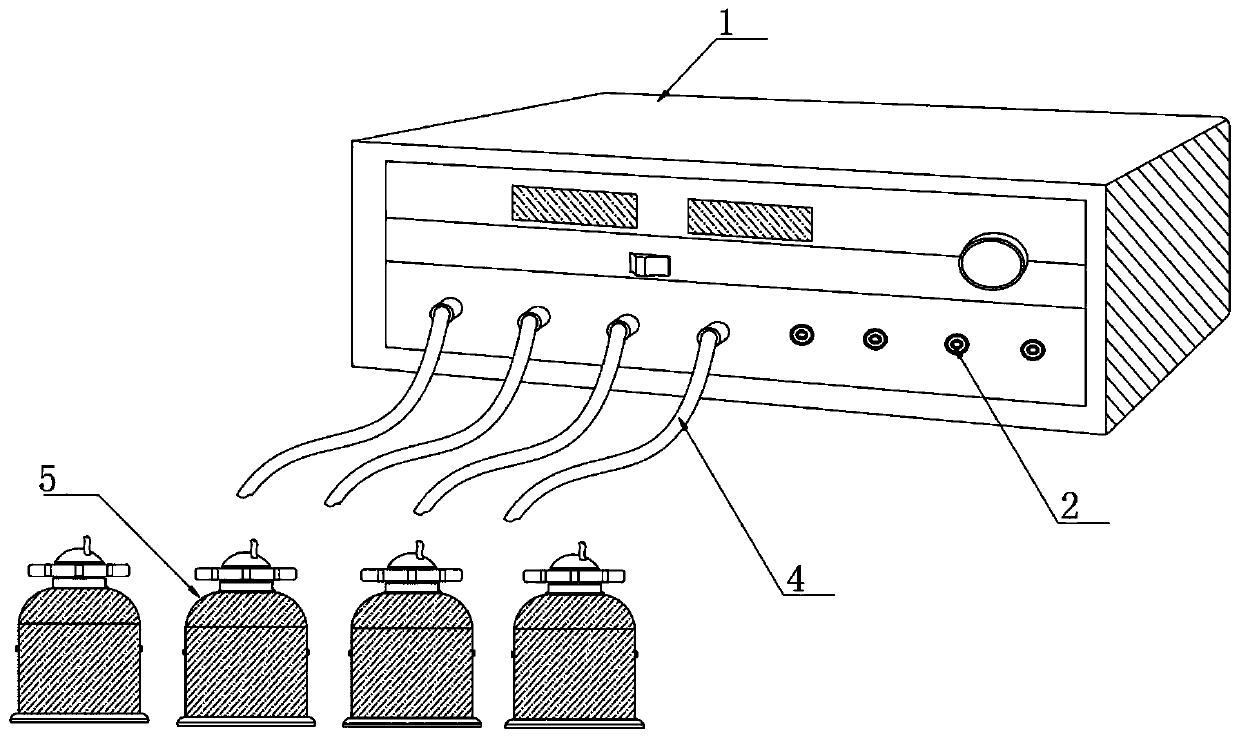

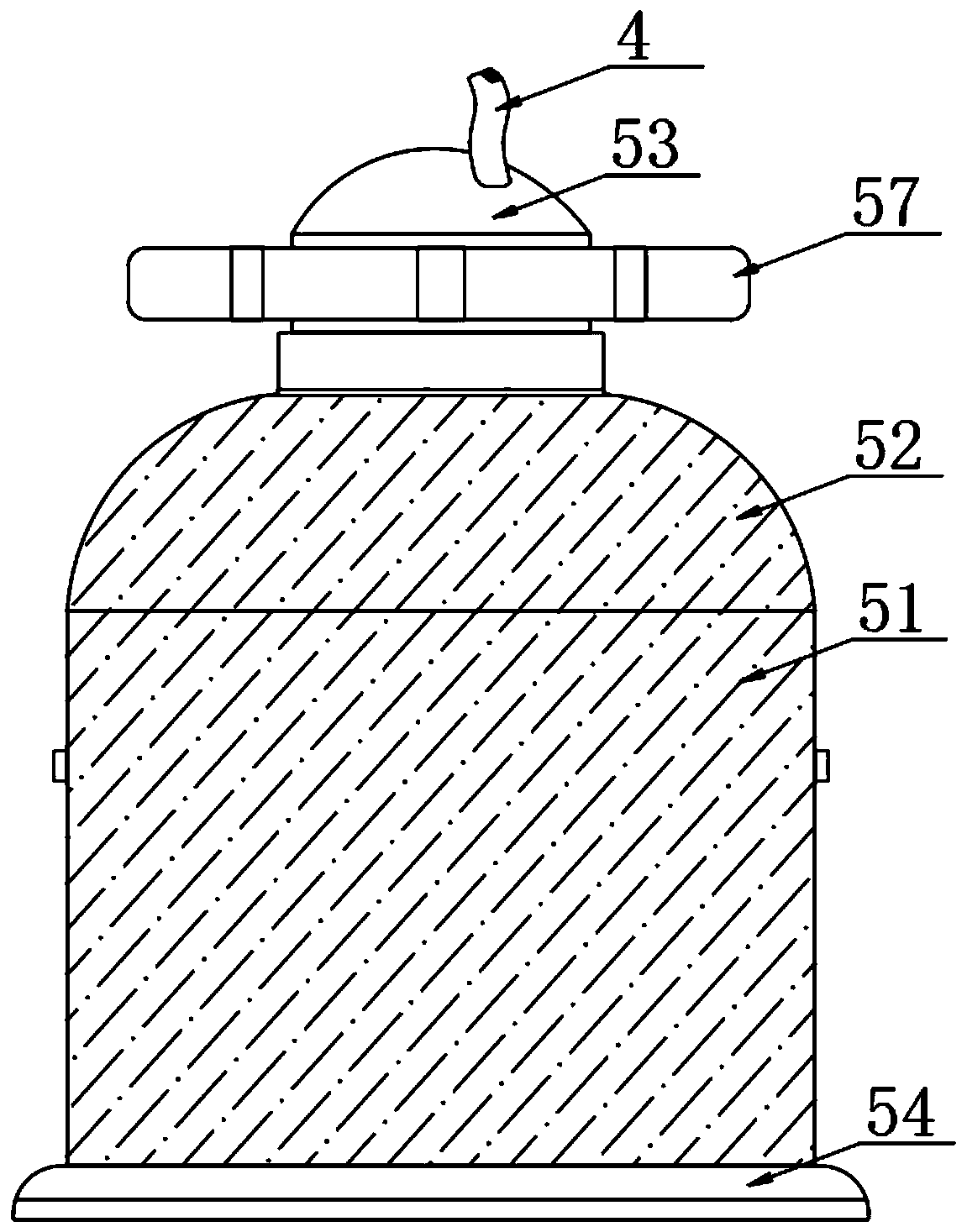

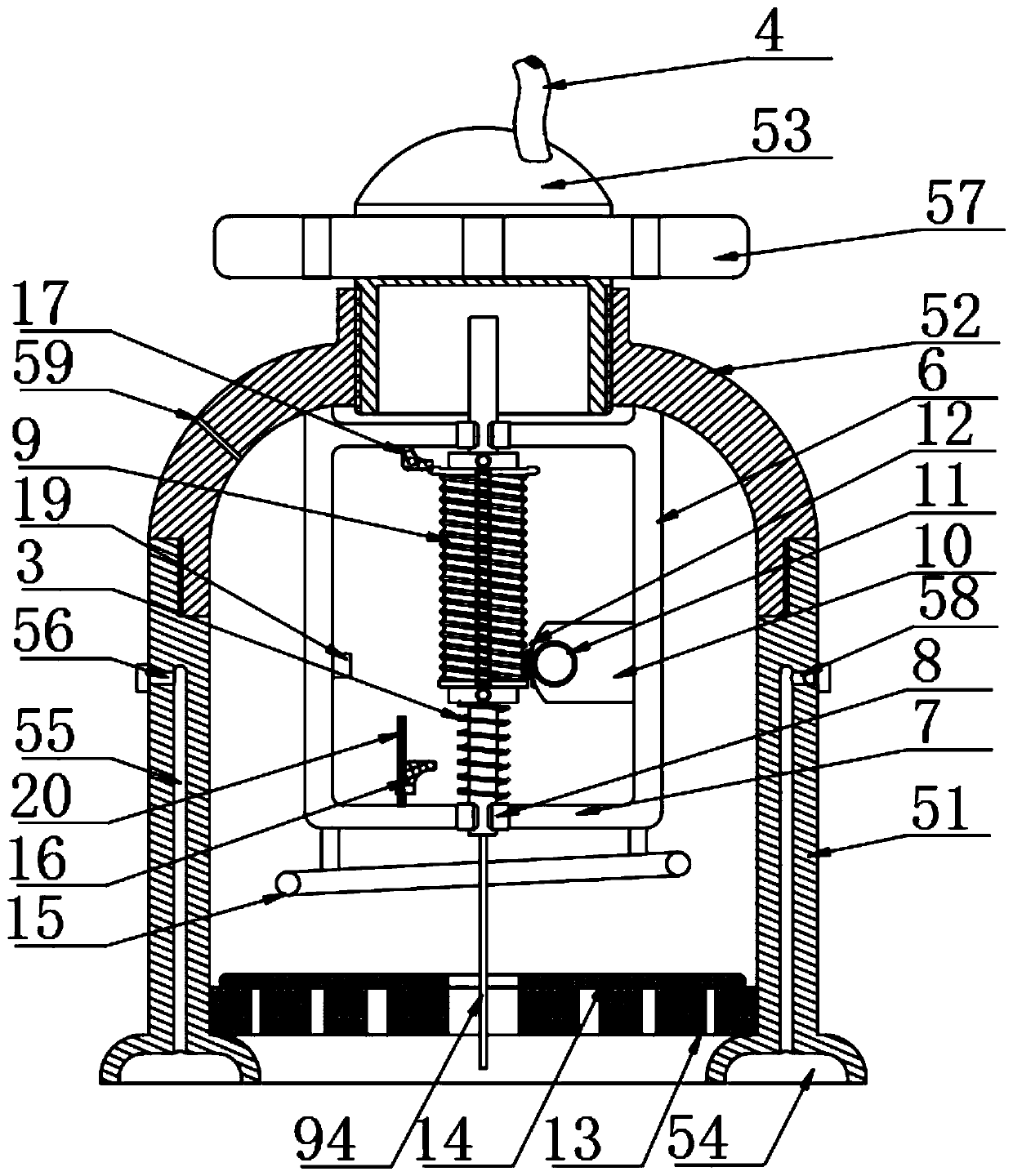

Electronic heating-type acupuncture device

ActiveCN110859747AReduced needle bendingGood combinationDevices for heating/cooling reflex pointsAcupunctureElectric heatingMicro motor

The invention discloses an electronic heating-type acupuncture device. The device comprises a control host, a control circuit is arranged in the control host, a plurality of sockets are connected to the control circuit in parallel, power lines are inserted into the sockets, and acupuncture assemblies are arranged at the other ends of the power lines. According to the invention, a plurality of acupuncture assemblies are placed at human body acupuncture positions, the interior of the air cavity is vacuumized, so that the acupuncture assemblies are adsorbed on a human body, a power supply transmission head and the socket are connected, the acupuncture assemblies are powered on, and a single-chip microcomputer electrically communicates with the control host. A micro motor is started to simulate hand twisting, so that the needle easily punctures a human body, needle bending is reduced, moxibustion is activated after acupuncture, an electric heating piece is turned on to bake a moxibustion cotton pad, so that heat and moxibustion extracting solution vapor penetrate through moxibustion holes to penetrate into a human body, veins are relieved, a good conditioning effect is achieved, the skin of the human body is prevented from being burnt by overheating, the acupuncture and moxibustion combination effect is good, downward pricking is stable, and the device is simple in structure and convenient to install and use.

Owner:SHAANXI UNIV OF CHINESE MEDICINE

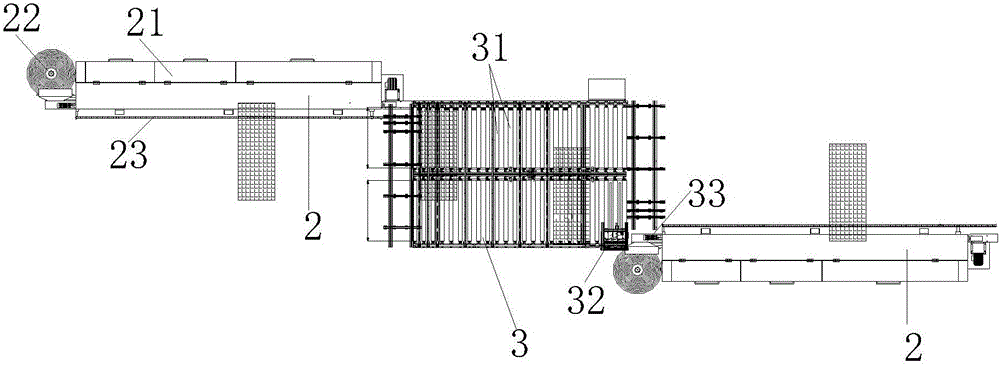

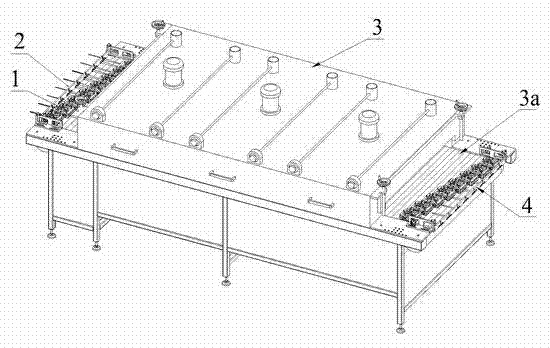

Intelligent panel type custom furniture conveying production line

InactiveCN106144469ARealize automatic connectionRelaxed and comfortable working environmentMulti-purpose machinesDomestic articlesProduction lineCarrying cost

The invention relates to the technical field of furniture production, and discloses an intelligent panel-type customized furniture conveying production line, including an automatic material preparation conveying system, an edge banding system and a double-row power translation system. The power translation system is connected; the edge banding system is arranged on both sides of the double-row power translation system, and the edge banding system can move along the side of the double-row power translation system; the present invention has the advantages of direct reduction in manual handling costs , The stacking of workpieces on the roller line is conducive to management and convenient transportation, and the advantages of realizing automatic connection of processing equipment and improving production efficiency.

Owner:广东友力智能科技有限公司

Argon-blowing butt-joint mechanism and steel ladle buggy

The invention provides an argon-blowing butt-joint mechanism. An elastic part is designed on a lower connecting plate, so that when a butt-joint device is in but-joint with a butt-joint surface of a trunnion box, the lower connecting plate can be upwards bounced all the time to press and fit to an upper butt-joint plate, and therefore, sealing and automatic communicating of a combined surface whena steel ladle argon-gas butt-joint pipeline is in automatic butt-joint are finally realized. The invention further provides a steel ladle buggy provided with the argon-blowing butt-joint mechanism.

Owner:SHANDONG IRON & STEEL CO LTD

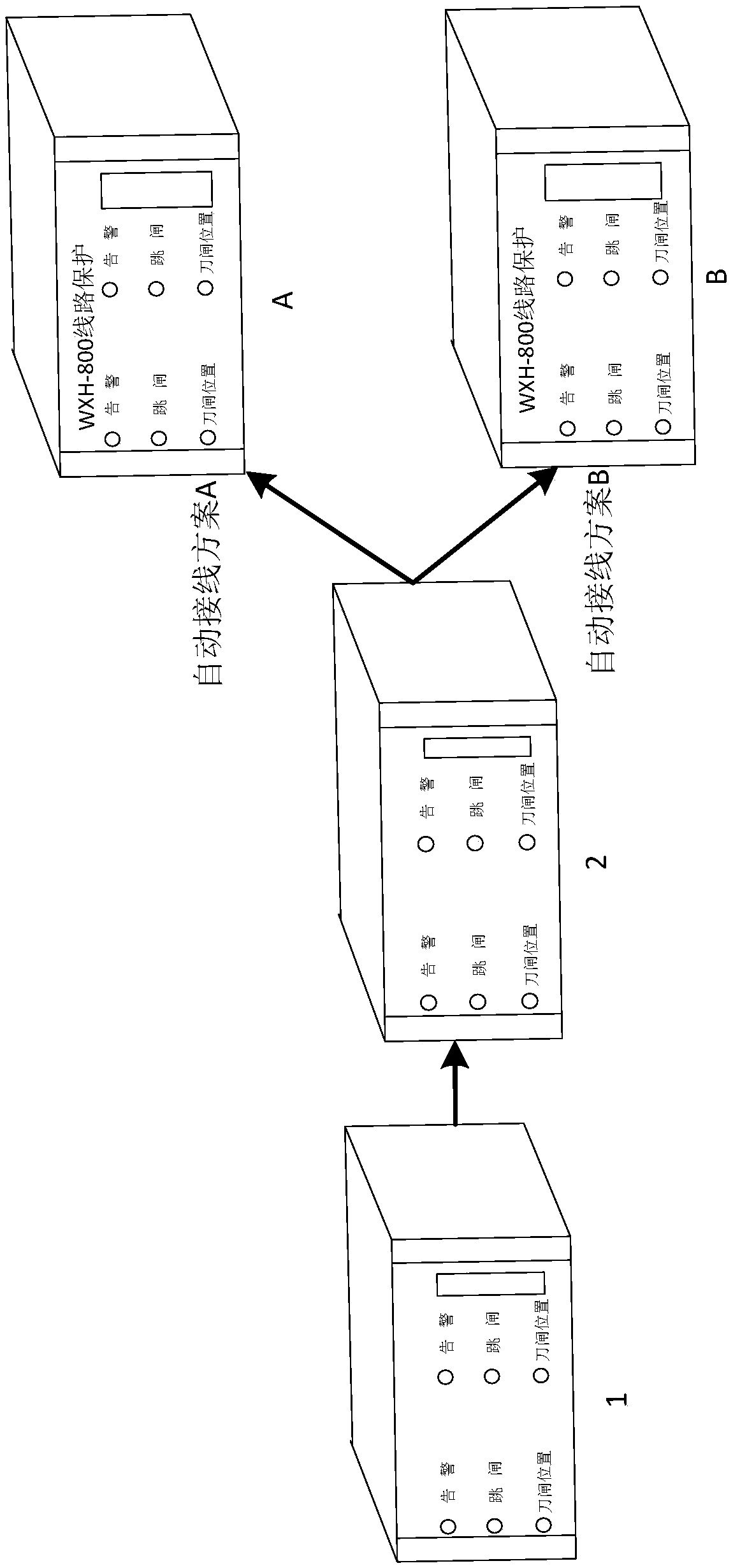

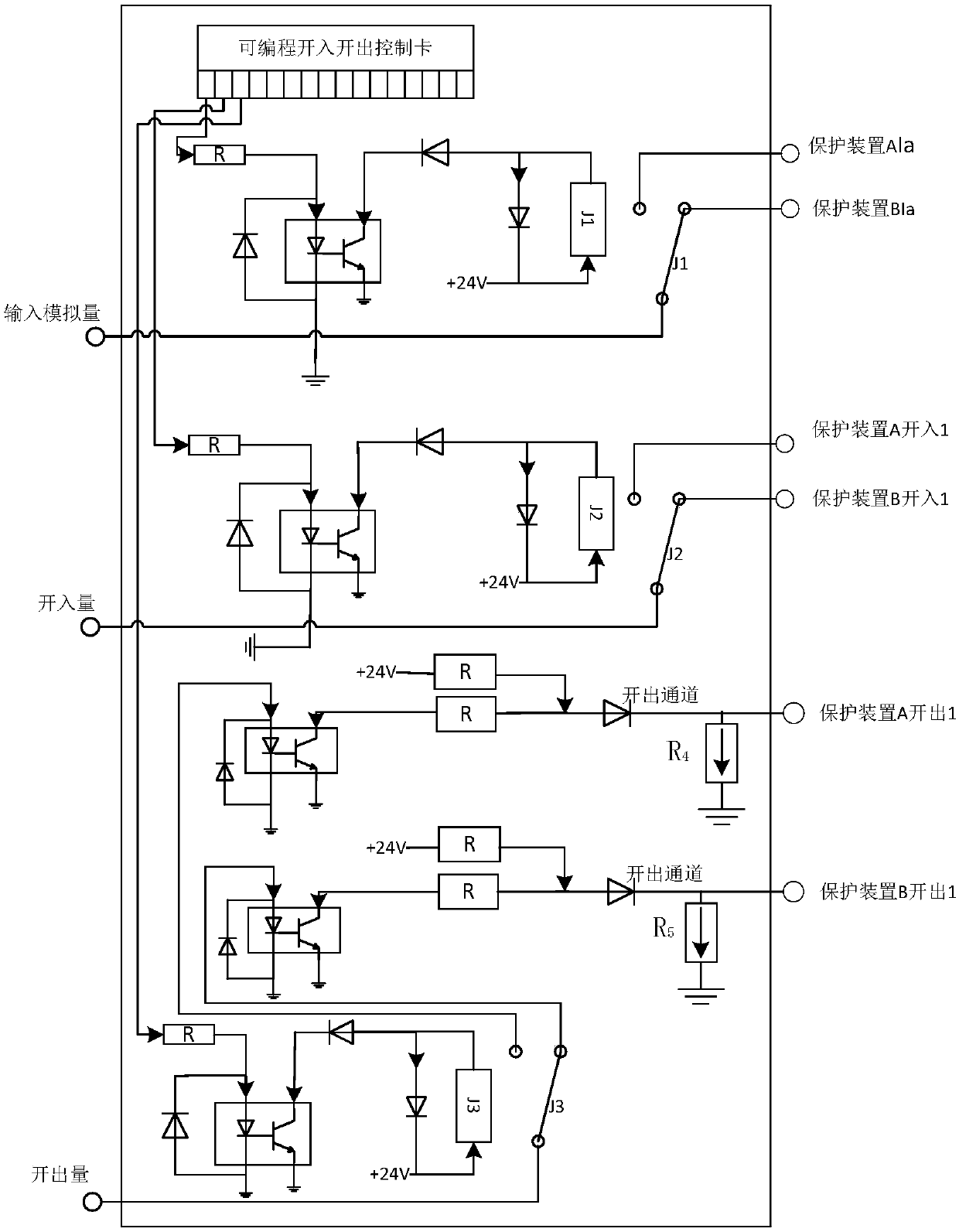

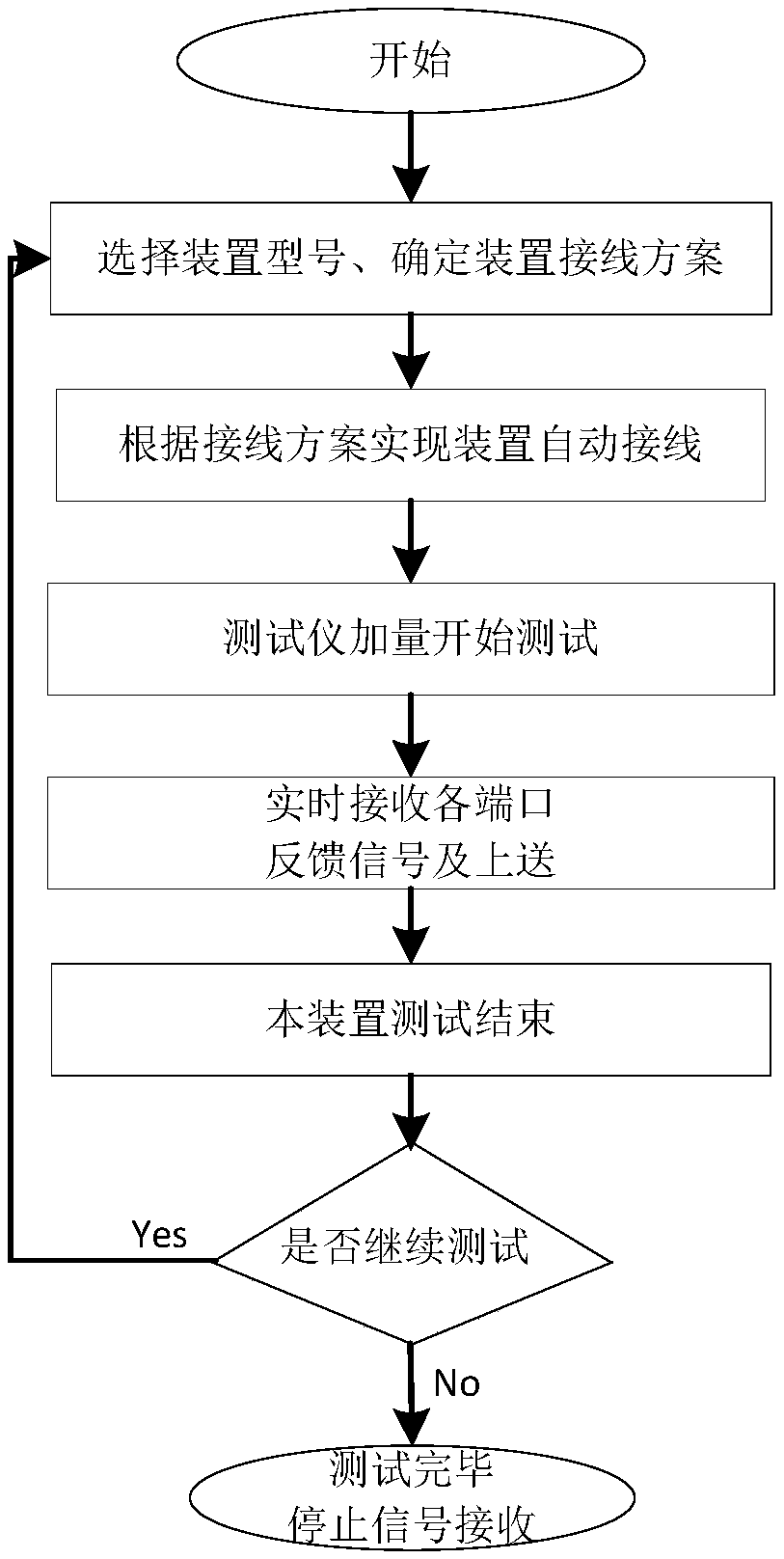

Automatic programmable wiring device for protecting simulation test

InactiveCN107748277AHigh degree of automationRealize automatic connectionMeasurement instrument housingTester deviceControl selection

The invention relates to an automatic programmable wiring device for protecting a simulation test. The device comprises a programmable control card in control connection with a simulation channel selection loop, an input channel selection loop and an output channel selection loop, wherein one end of the simulation channel selection loop is used for controlling selection connection with analog quantity wiring ends of a first to-be-detected protection device and a second to-be-detected protection device, the other end of the simulation channel selection loop is connected with an analog quantitywiring end of a tester, one end of the input channel selection loop is used for controlling selection connection with input wiring ends of the first to-be-detected protection device and the second to-be-detected protection device, the other end of the input channel selection loop is used for connecting with an input wiring end of the tester, one end of the output channel selection loop is used forcontrolling selection connection with output wiring ends of the first to-be-detected protection device and the second to-be-detected protection device, and the other end of the output channel selection loop is used for connecting with an output wiring end of the tester. The automatic programmable wiring device is advantaged in that the automatic device wiring process can be realized through the programmable control card, test wiring steps are simplified, and the automatic programmable wiring device is not easy to generate faults.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +5

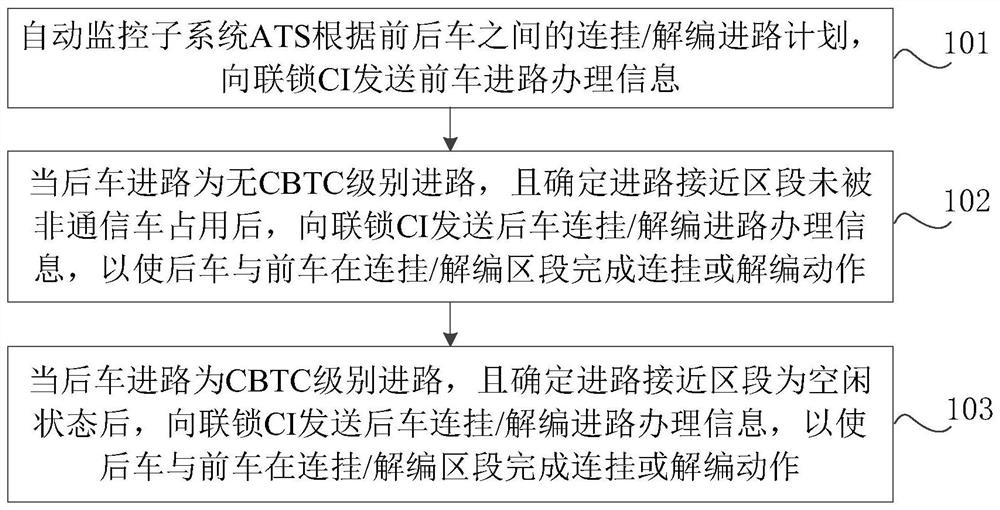

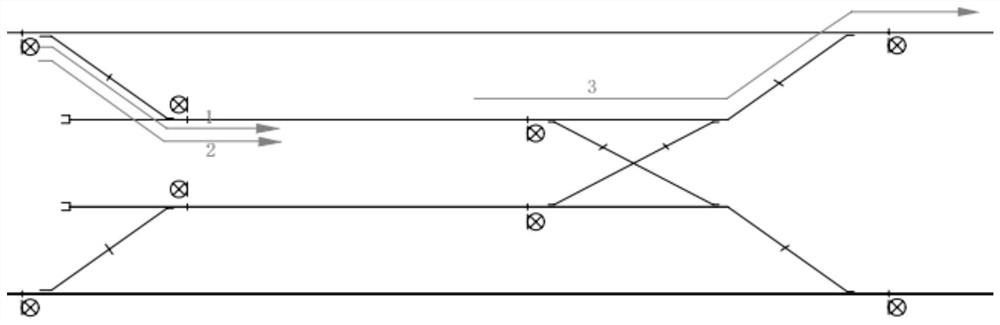

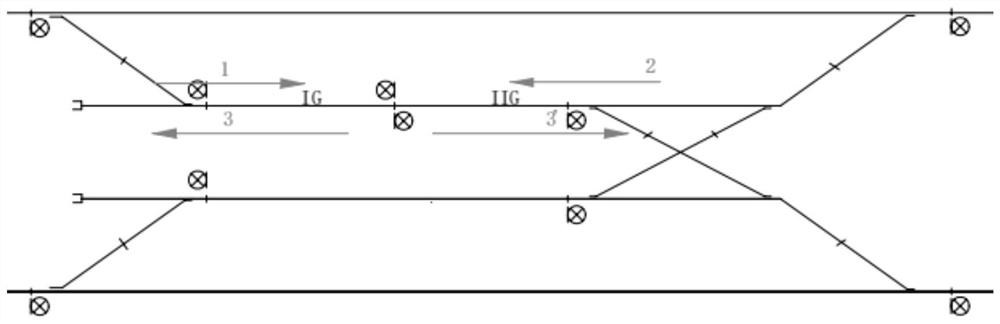

Marshaling interlocking control method, device and system based on FAO

ActiveCN113734248AInterlocking rule optimizationFlexibly change the number of groupsAutomatic systemsTotal factory controlEngineeringReal-time computing

The invention provides a marshaling interlocking control method, device and system based on FAO, and the method comprises the steps: an automatic monitoring subsystem ATS sends front vehicle route handling information to an interlocking CI according to a coupling / decompilation route plan between a front vehicle and a rear vehicle; when the rear vehicle route is the route without the CBTC level and it is determined that the route approaching section is not occupied by the non-communication vehicle, rear vehicle coupling / de-coding route handling information is sent to the interlocking CI, so that the rear vehicle and the front vehicle complete coupling or de-coding action in the coupling / de-coding section; and when the rear vehicle route is a CBTC-level route and the route approaching section is determined to be in an idle state, rear vehicle coupling / de-coding route handling information is sent to the interlocking CI, so that the rear vehicle and the front vehicle complete coupling or de-coding action in the coupling / de-coding section. By optimizing the interlocking rule of the CBTC level route and the non-CBTC level route, it can be guaranteed that the rear train and the front train can achieve automatic coupling or decoding action in the coupling / decoding section, and the train marshalling number is flexibly changed.

Owner:TRAFFIC CONTROL TECH CO LTD

Heat exchanger for chemical production

ActiveCN108981440AImprove space utilizationExpand the top areaIndirect heat exchangersHeat exchanger casingsEngineeringMicro heat exchanger

The invention relates to the technical field of chemical production equipment, in particular to a heat exchanger for chemical production. The heat exchanger comprises a box body, a first heat exchangeplate, a second heat exchange plate, a third heat exchange plate, ejection mechanisms, a reset mechanism and a blocking plate. According to the heat exchanger, the heat exchange contact area can be increased while the occupied area is reduced; the retractable ejection mechanisms are installed on both sides of the heat exchange plates, so that the heat exchange plates can be quickly and conveniently installed and disassembled, subsequent cleaning and maintenance are facilitated, and circulation of chemical liquid is ensured; the blocking plate is arranged outside a first circulating channel, when the heat exchange plates are not installed, a heat exchange chamber can further ensure the normal circulation of the chemical liquid without flowing to a drainage chamber and a water inlet chamberon both sides; and when the heat exchange plates are installed, a top plate pushes the blocking plate to be open, so that water can enter the heat exchange plates through sliding blocks, and automatic communication of the heat exchange plates with the drainage chamber and the water inlet chamber is realized.

Owner:TAIXING SMELTING PLANT

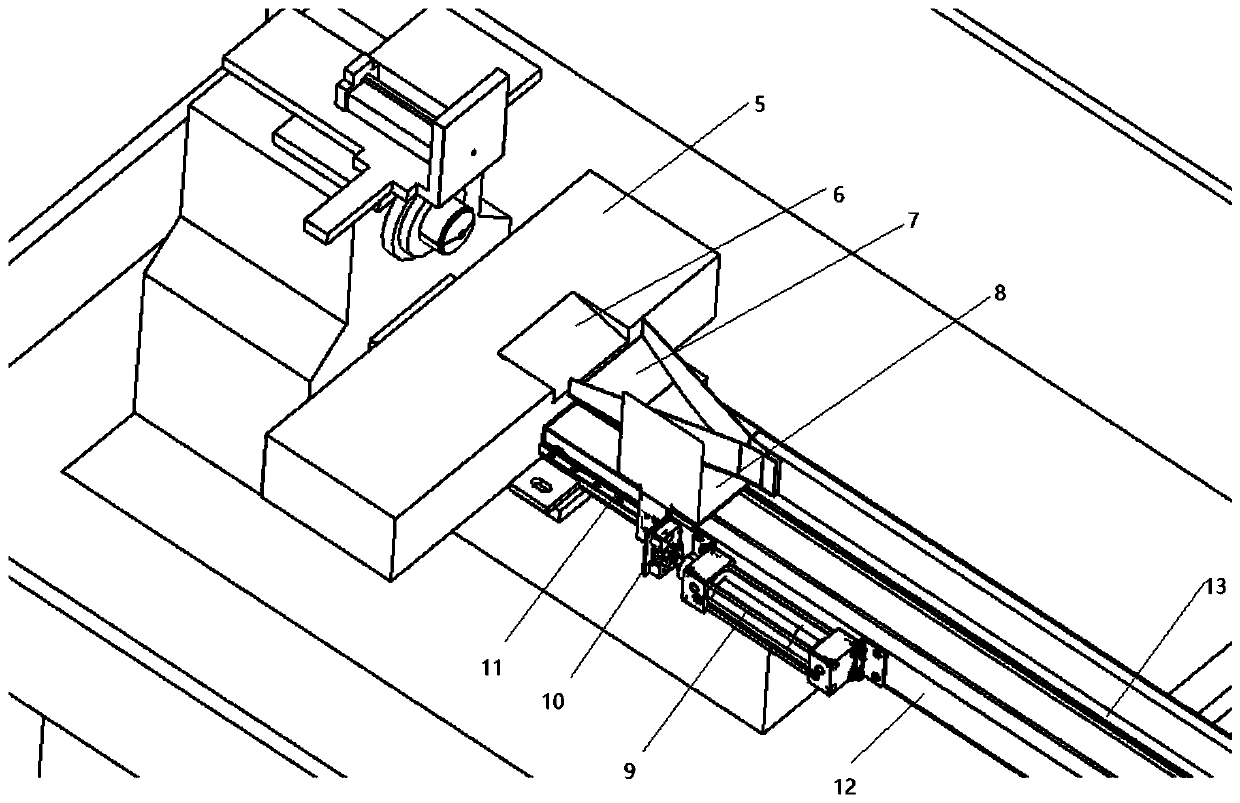

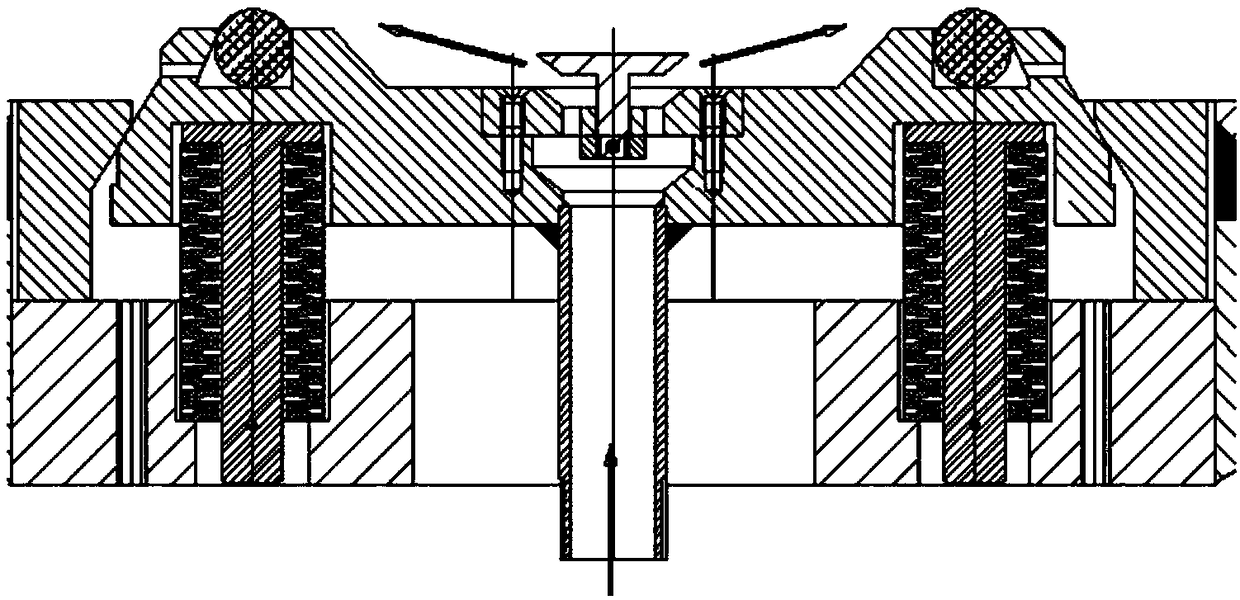

Dewaxing mold shell overturning and conveying device

ActiveCN104826996AEvenly placedImprove roasting effectFoundry mouldsFoundry coresMaterials sciencePrecision casting

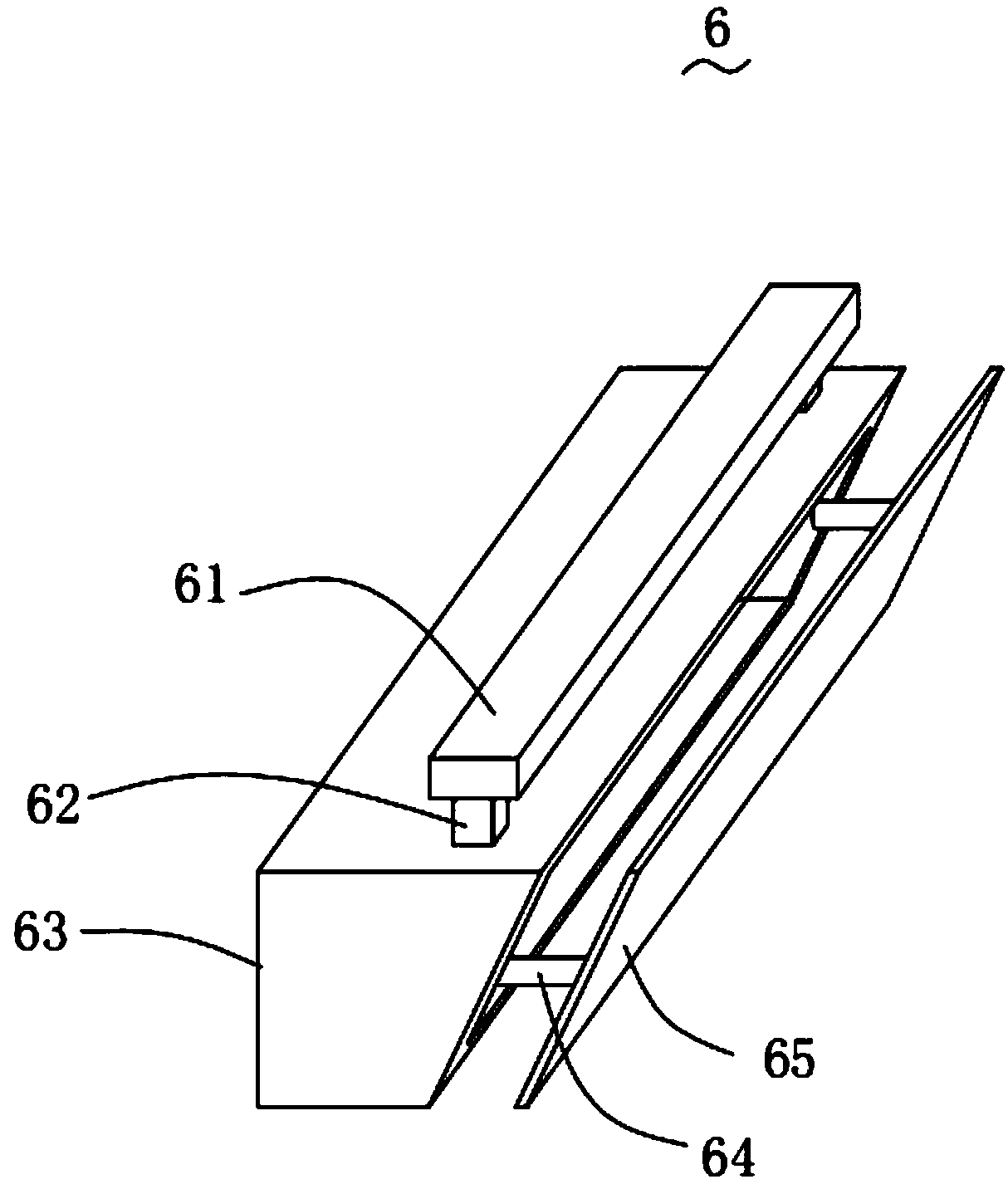

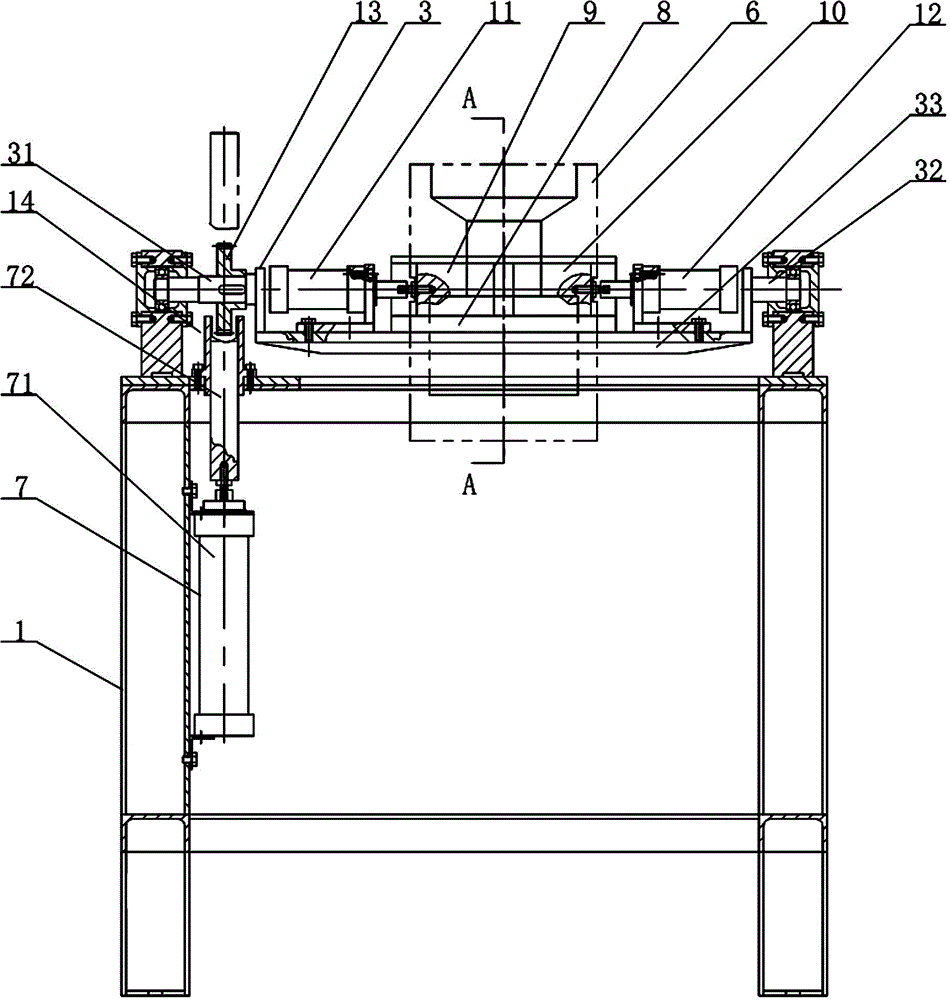

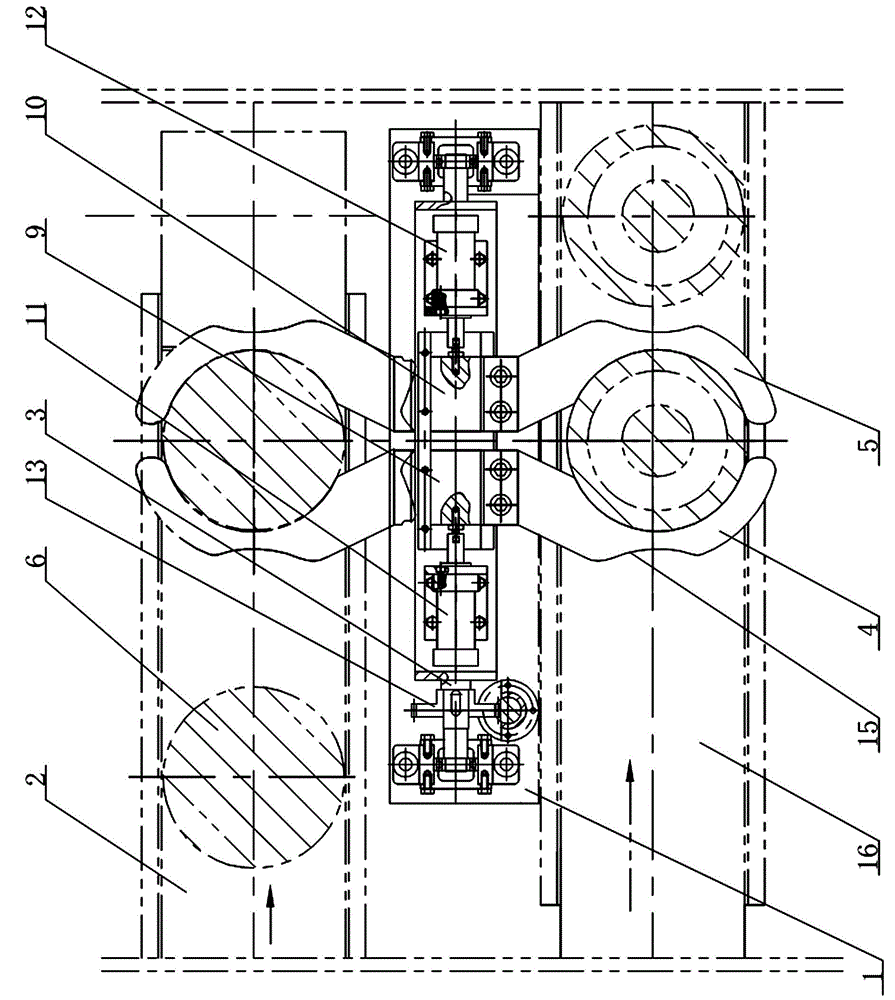

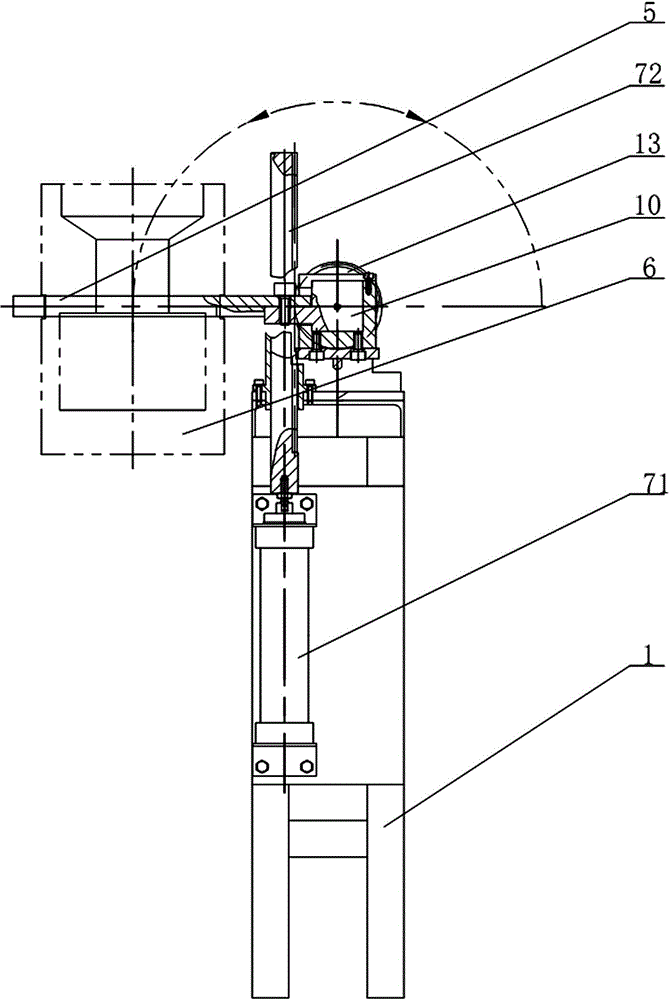

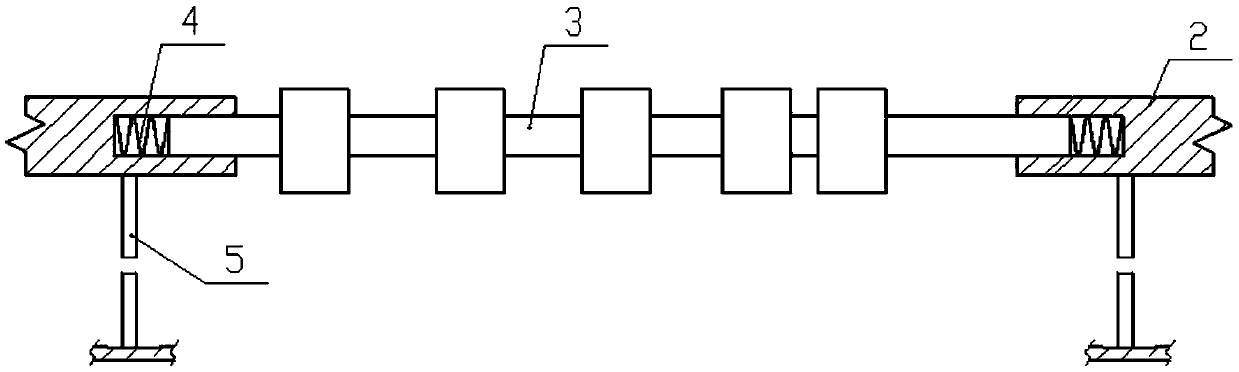

The invention relates to a dewaxing mold shell overturning and conveying device. The problems that in a fired mold precision casting process, mold shells are conveyed manually, the labor intensity is high, the work efficiency is low, and automatic and continuous production cannot be implemented are solved. The dewaxing mold shell overturning and conveying device is characterized in that a rotating central shaft (3) is arranged on a support (1); a left jaw (4) and a right jaw (5) which can slide relatively are arranged on the rotating central shaft (3); after the left jaw (4) and the right jaw (5) are combined, a mold shell (6) can be clamped; the rotating central shaft (3) is driven to rotate in a reciprocating manner at an angle of 180 degrees by a driving device (7); and the left jaw (4) and the right jaw (5) are driven by the rotating central shaft (3) to overturn at an angle of 180 degrees. The mold shell is clamped by the left jaw and the right jaw which overturn in a reciprocating manner at an angle of 180 degrees, mold shell dewaxing and mold shell roasting are sequentially carried out automatically, the labor intensity of workers is reduced, the work efficiency is improved, the mold shells are uniformly placed on a roasting conveying belt, and a roasting effect is high.

Owner:台山市鼎富金属制品有限公司

Automatic gluing and synchronous rolling all-in-one machine for bamboo bunches

ActiveCN105799034ARealize synchronous transmissionGuaranteed fluencyWood working apparatusFlat articlesDrive shaftEngineering

The invention discloses an automatic gluing and synchronous rolling all-in-one machine for bamboo bunches, and relates to the field of machining machines of bamboo based fiber composites for manufacturing artificial boards. The automatic gluing and synchronous rolling all-in-one machine comprises a gluing unit, a rolling unit and a motor for providing power, and the gluing unit, the rolling unit and the motor are mounted on a machine base. An inclined material guide frame is arranged between the gluing unit and the rolling unit. A driven shaft and a driving shaft are arranged on the gluing unit and each provided with 3-6 conveying chain wheels. The corresponding conveying chain wheels on the driving shaft and the driven shaft are sleeved with conveying chains. A glue collection disc is arranged below the conveying chains, a glue nozzle is arranged above the conveying chains, and the glue nozzle is connected with a glue bucket through a glue extraction pump. The rolling unit comprises a rear rack fixed to the machine base and a discharging frame behind the rear rack. An upper roller and a lower roller which are vertically opposite are arranged on the rear rack, one of the upper roller and the lower roller is a driving roll, and the driving roll and the driving shaft are connected through a synchronous chain.

Owner:HONGYA BAMBOO ERA SCI & TECH

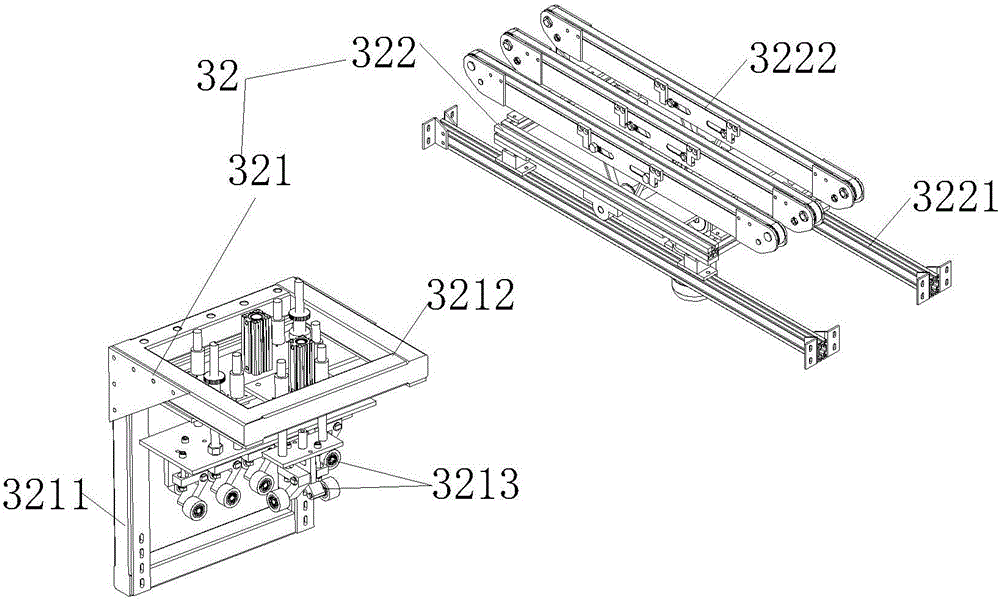

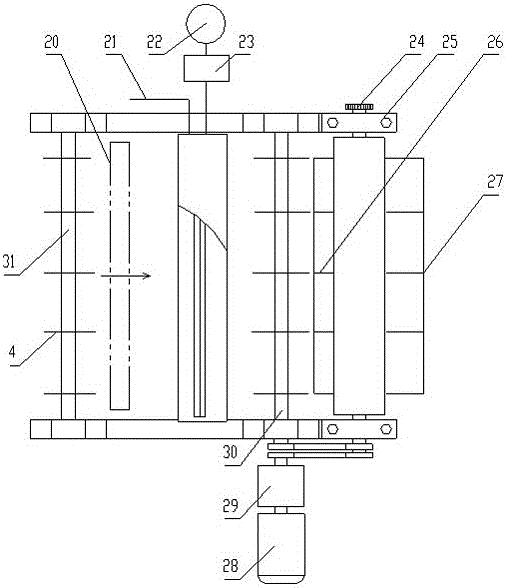

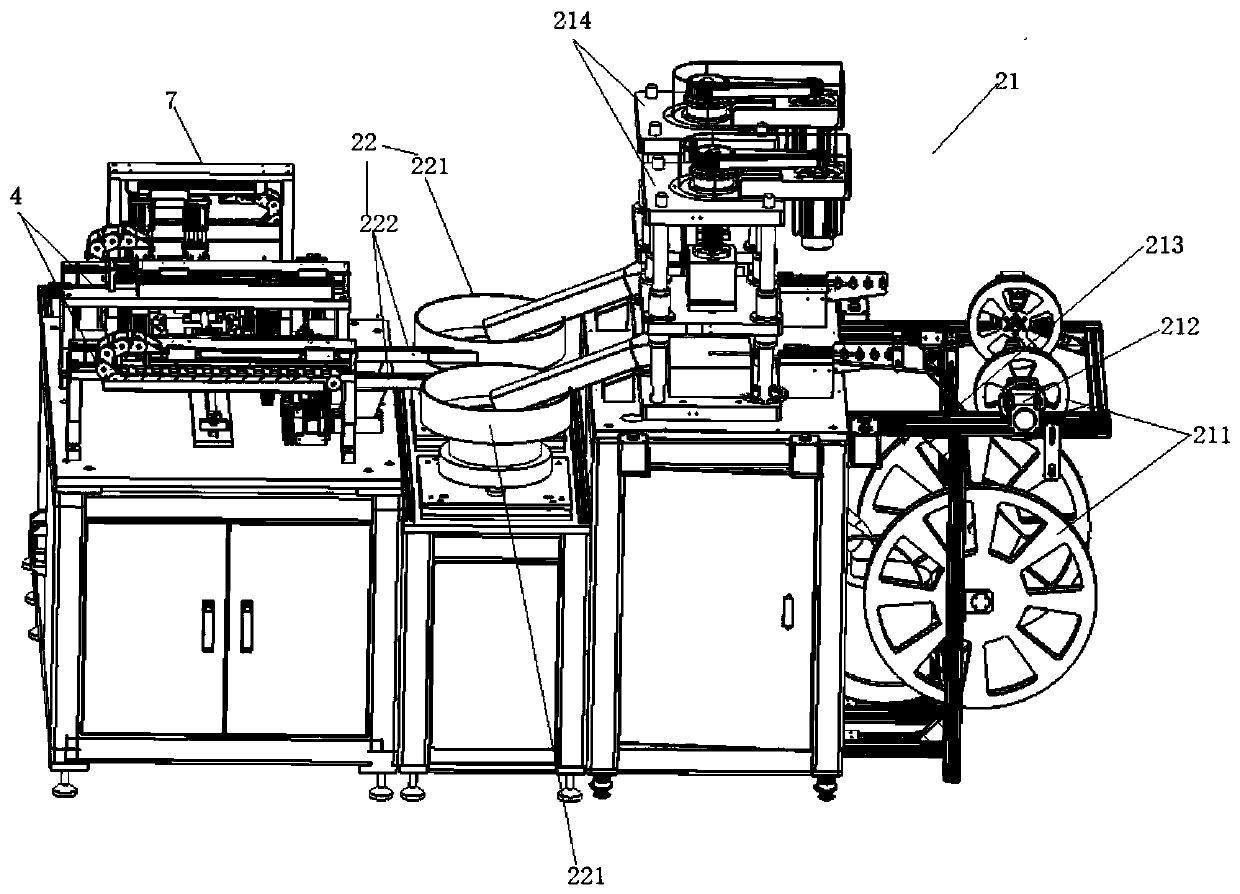

Unattended automatic sampling device for pharyngeal test

PendingCN113576545AImprove comfortReduce labor intensitySurgeryVaccination/ovulation diagnosticsThroatPhysical medicine and rehabilitation

The invention relates to the field of pharynx swabs, in particular to an unattended automatic sampling device for a pharynx test. A sampling conveying mechanism drives the conveyor belt body to transport along the length direction of the conveyor belt body, and the conveyor belt body is pre-loaded with a plurality of pharynx test sample bodies in an isolated manner along the length direction; a sampling mechanism comprises a sampling table with sampling openings, and the sampling conveying mechanism drives the conveying belt body to enable the throat test sample bodies to sequentially pass through the sampling openings. Compared with the prior art, the invention has the beneficial effects that the sampling task of pharyngeal tissues can be automatically, softly, quickly and accurately completed on a sampled sample in a pollution-free, full-isolation, identifiable, standardized and modularized manner in a man-machine cooperation manner, the sampling accuracy is improved, and the comfort level of a sampled person is improved.

Owner:东莞市千弘电子科技有限公司

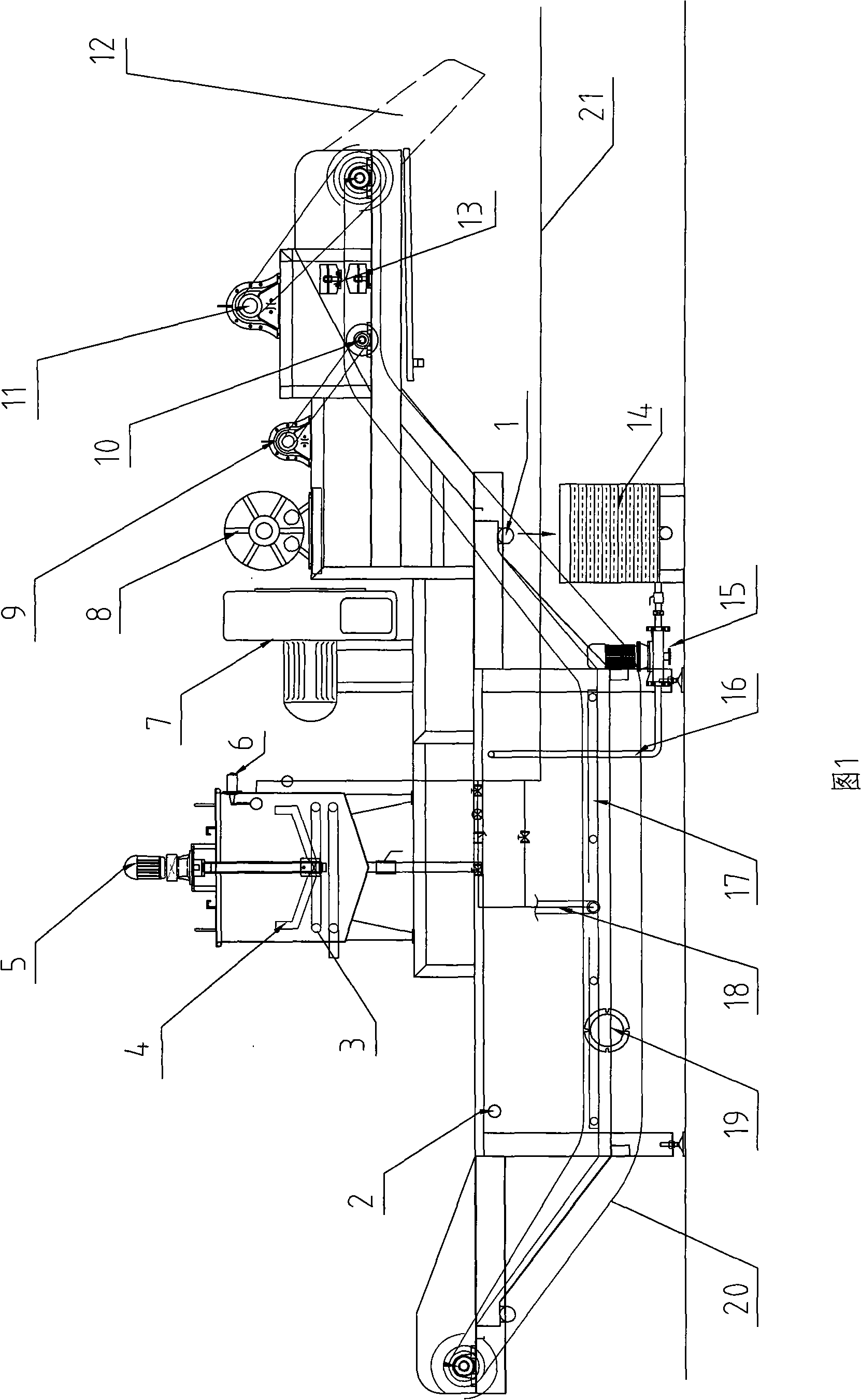

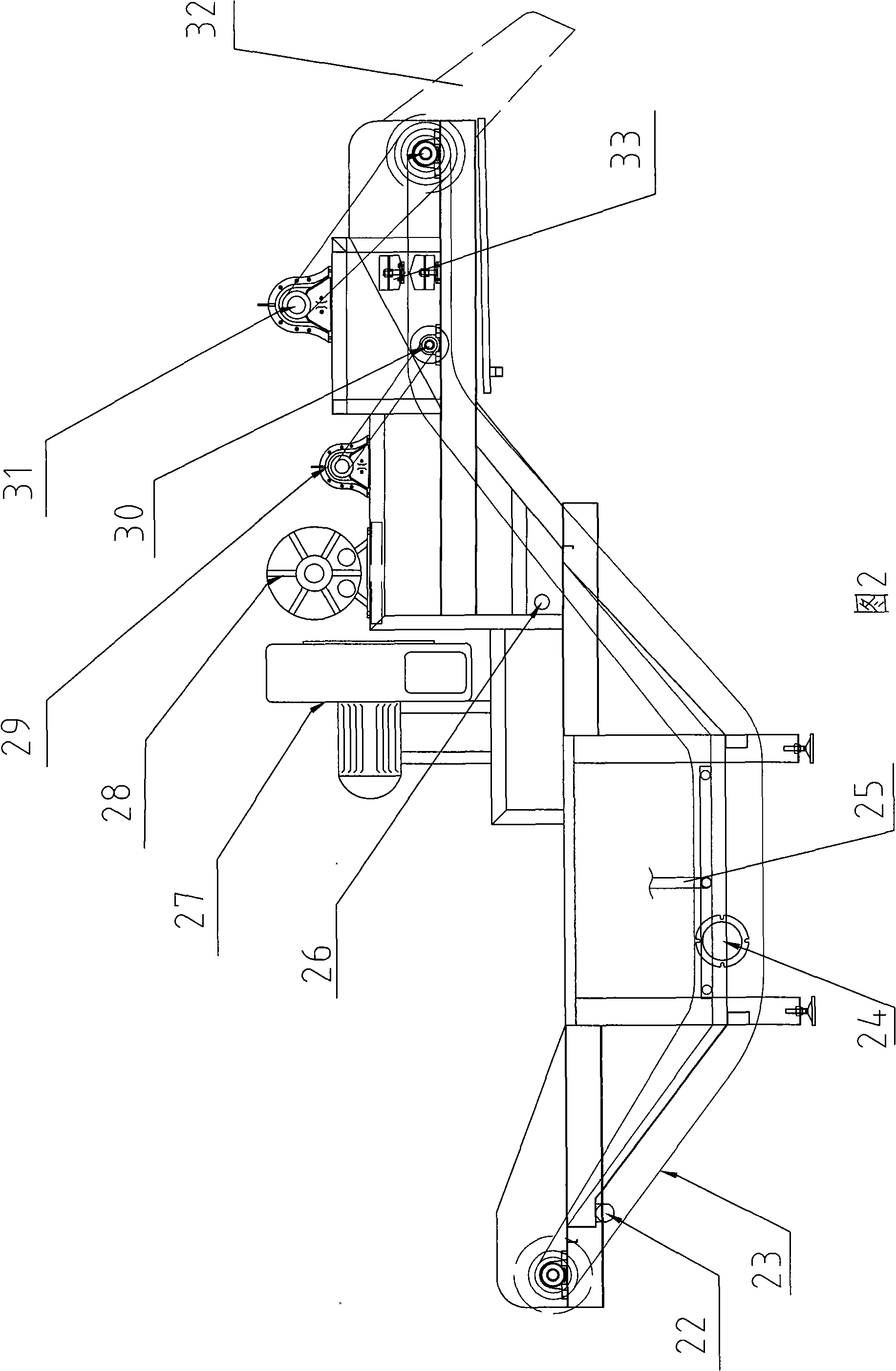

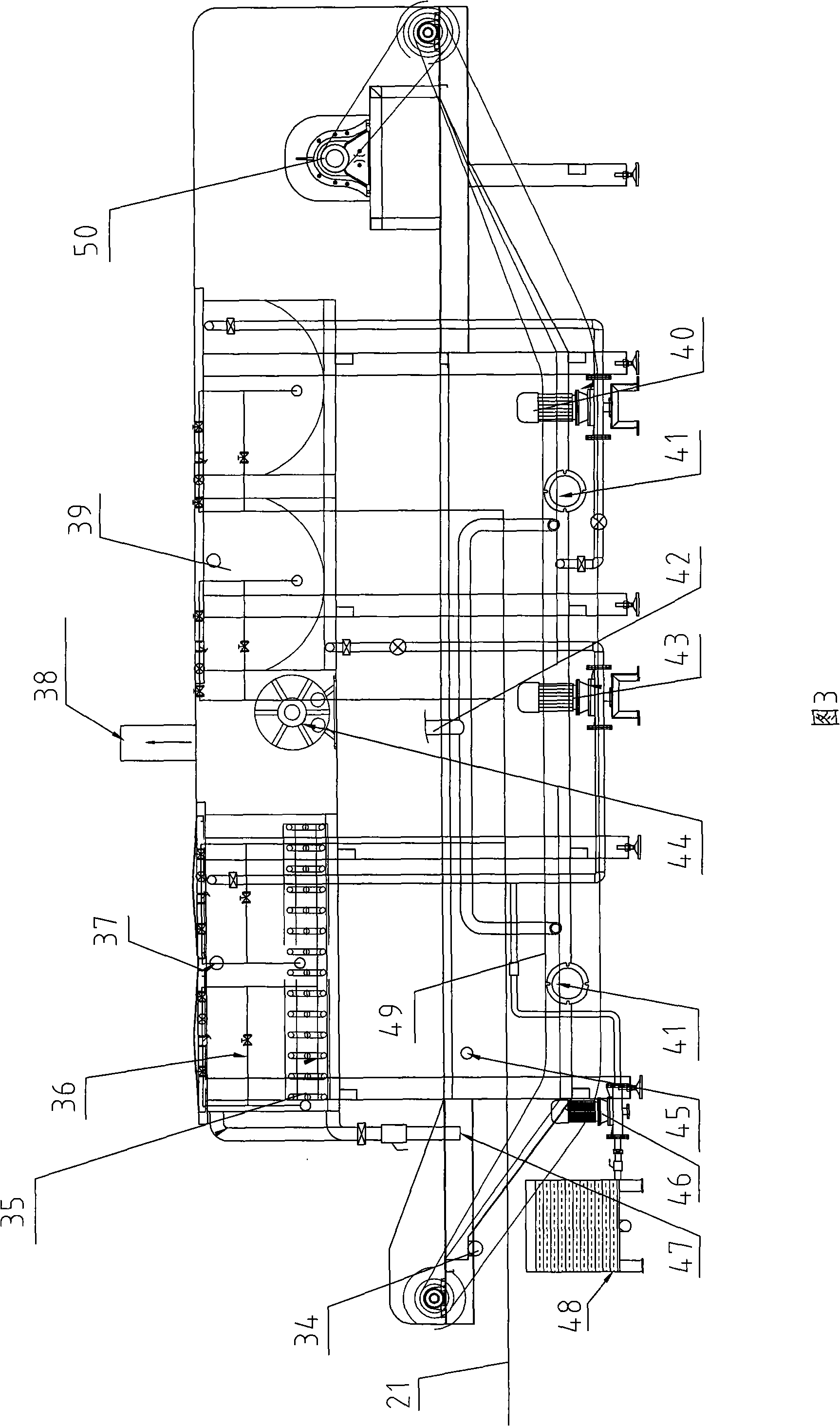

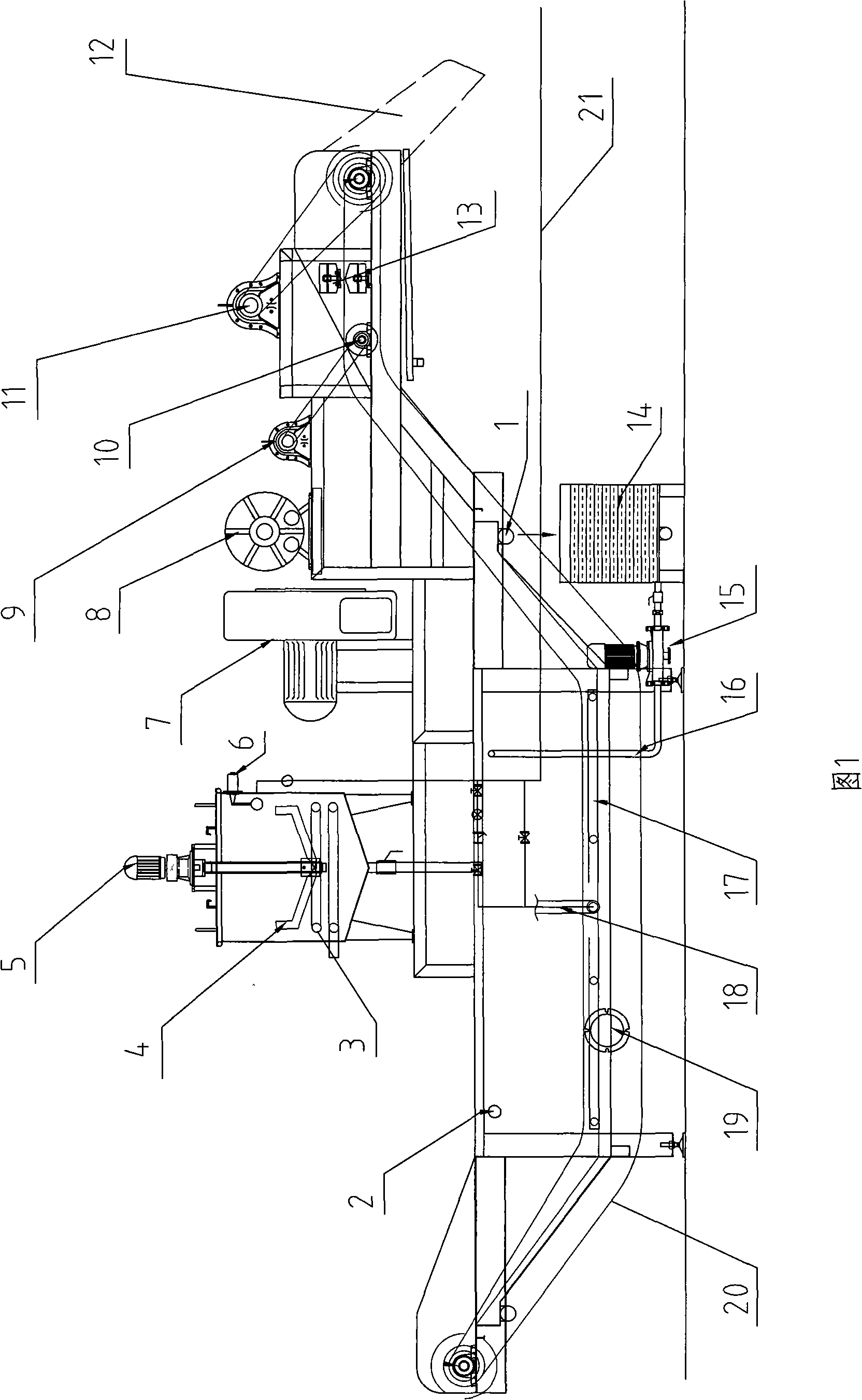

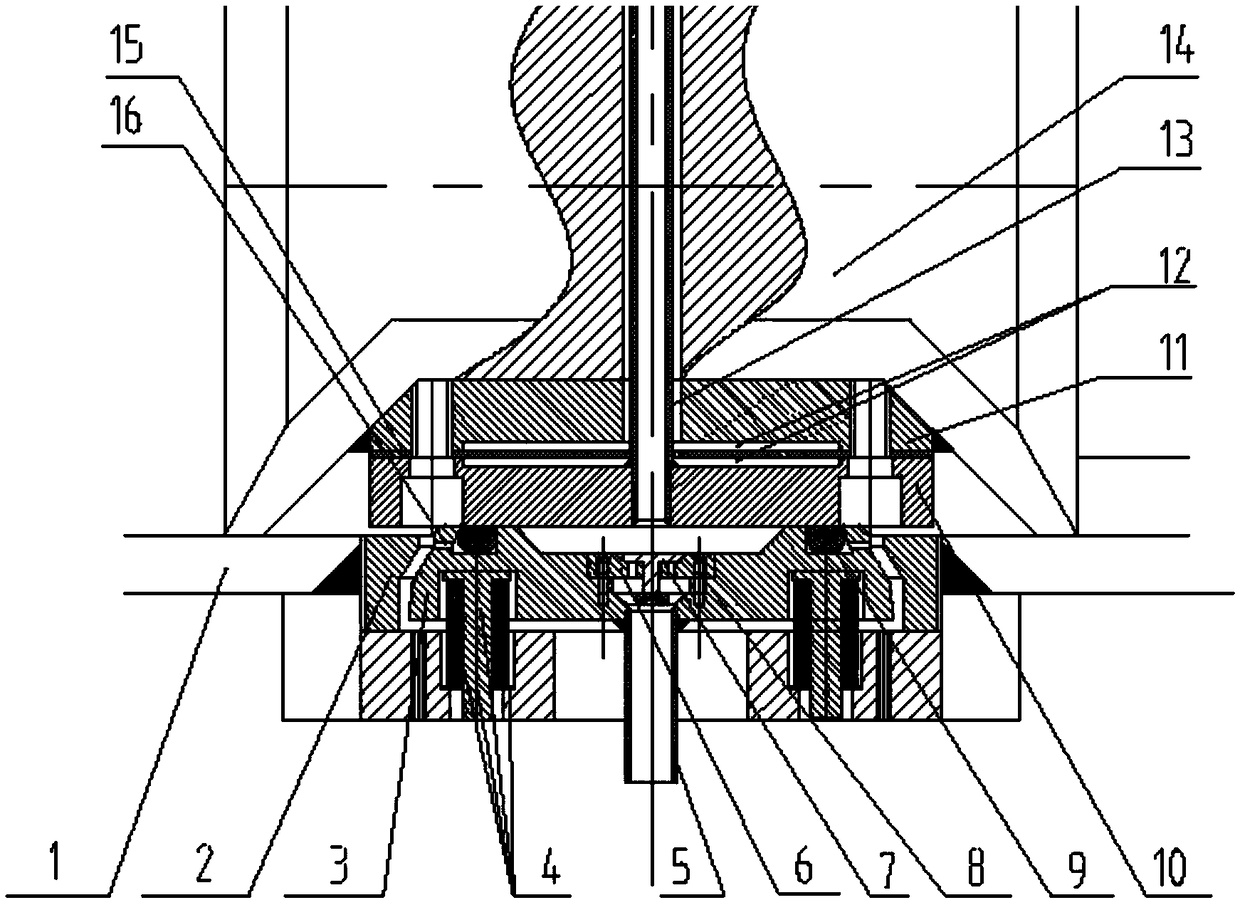

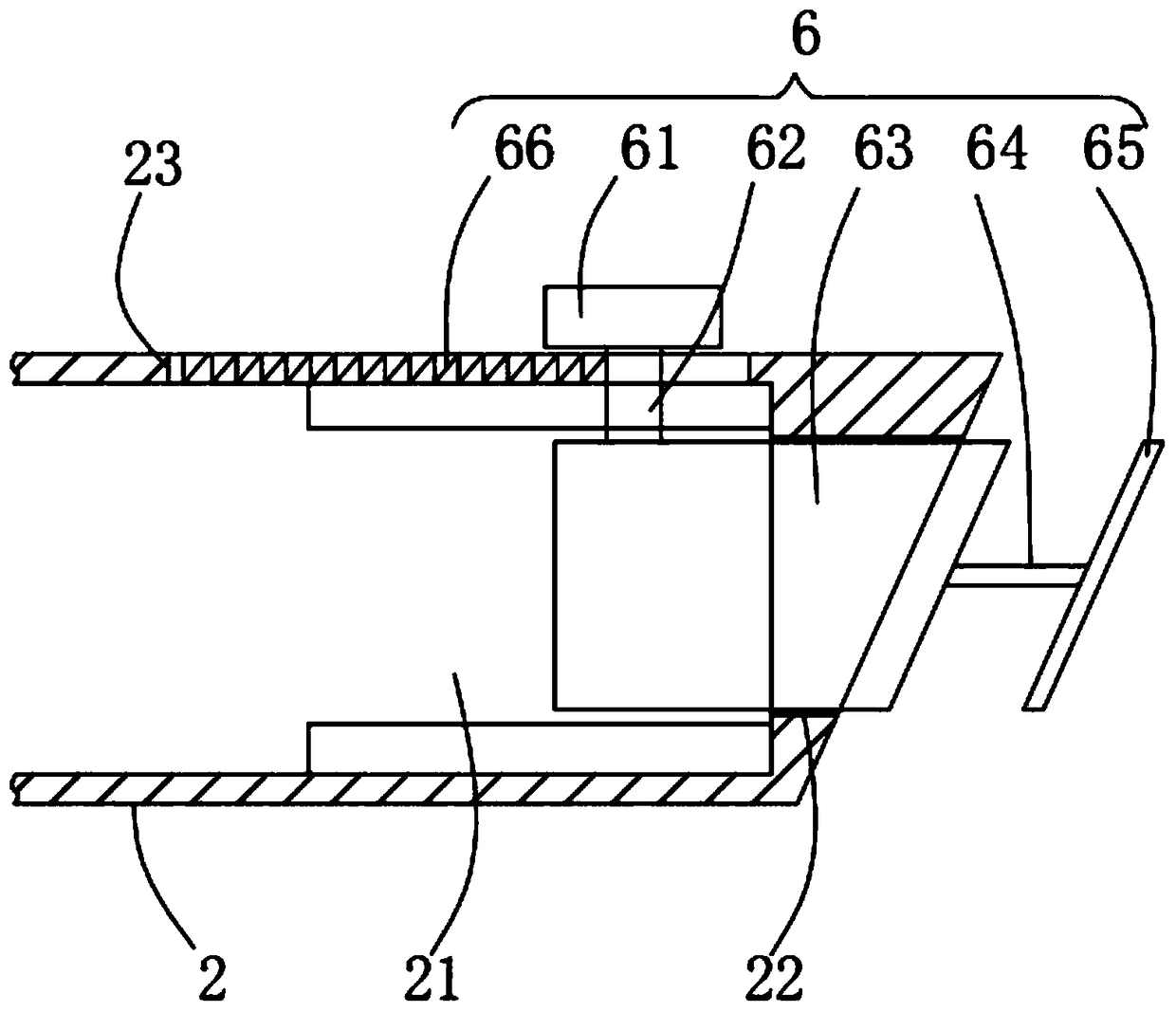

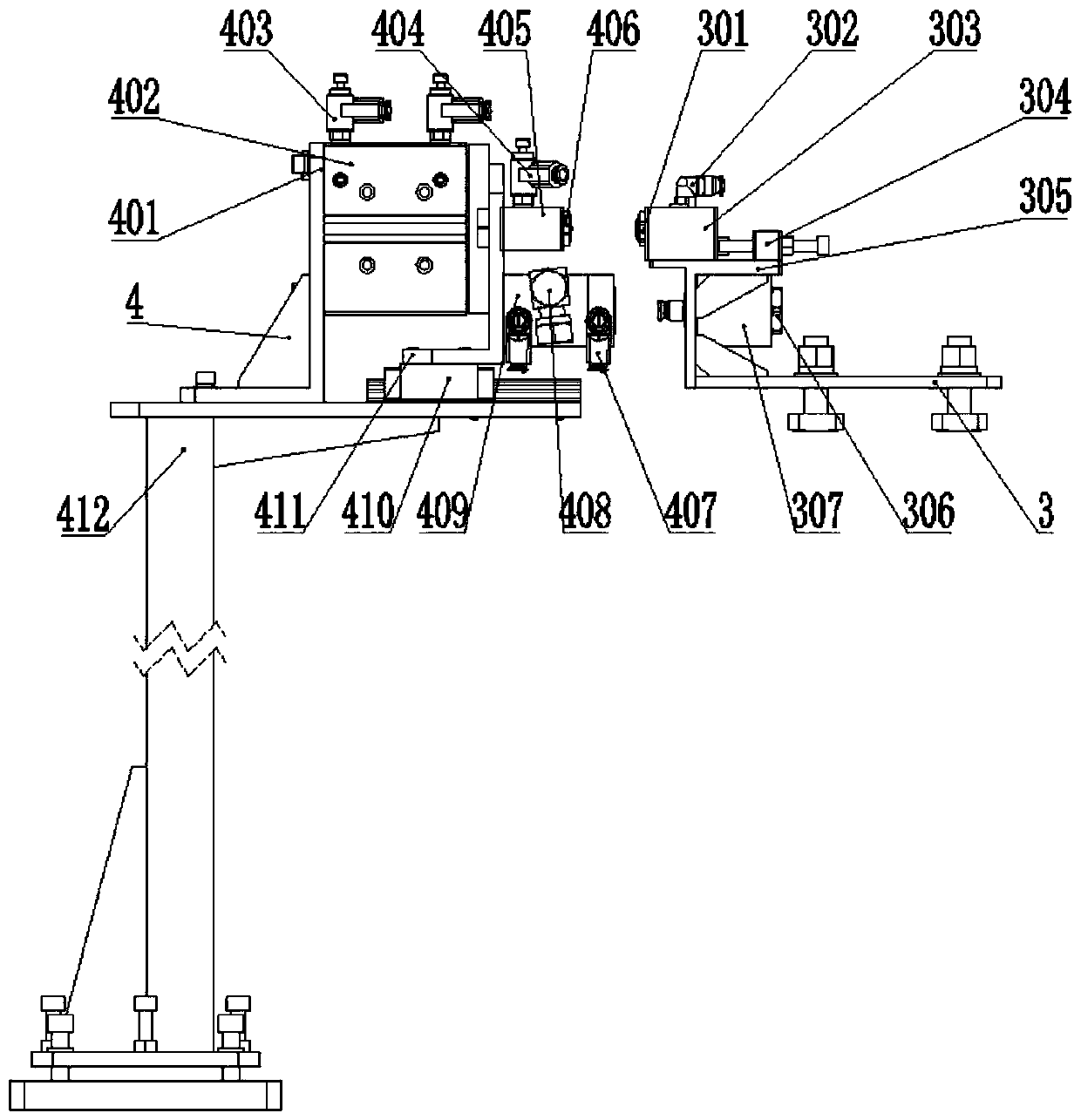

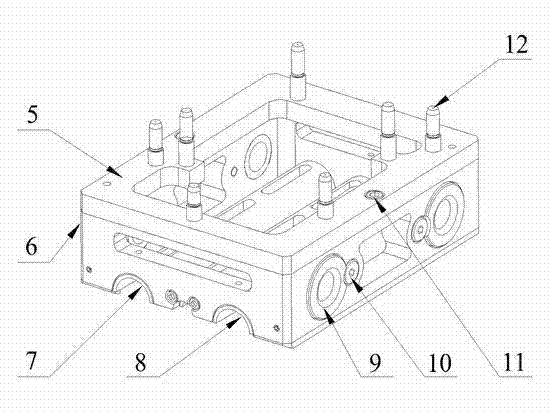

Oil and gas pipeline automatic connecting device for machine tool automatic clamp

ActiveCN111300100AImplement external referencesAvoid destructionWork clamping meansPositioning apparatusEngineeringGas supply

The invention relates to the field of machine tool auxiliary devices, in particular to an oil and gas pipeline automatic connecting device for a machine tool automatic clamp. An internal quick plug assembly comprises an oil pressure quick plug and an internal gas circuit automatic connector, the internal gas circuit automatic connector is arranged on an internal gas distributing block, an externalquick plug assembly comprises an external gas circuit automatic connector and an oil pressure quick socket, the external gas circuit automatic connector is arranged on an external gas distributing block, the oil pressure quick socket and the external gas distributing block are arranged on a movable adapter plate, the oil pressure quick socket is in butt joint with the oil pressure quick plug, theexternal gas circuit automatic connector is in butt joint with the internal gas circuit automatic connector, the oil pressure quick socket is provided with an external oil circuit joint, the externalgas distributing block is provided with an external gas source joint, and the oil pressure quick plug and the internal gas distributing block are provided with internal joints for being connected with a machine tool automatic clamp. According to the device, automatic oil and gas supply of the machine tool automatic clamp is realized, arrangement of a moving pipeline is reduced, and operation intervention of an original system of the machine tool by automatic modification and integration is reduced.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

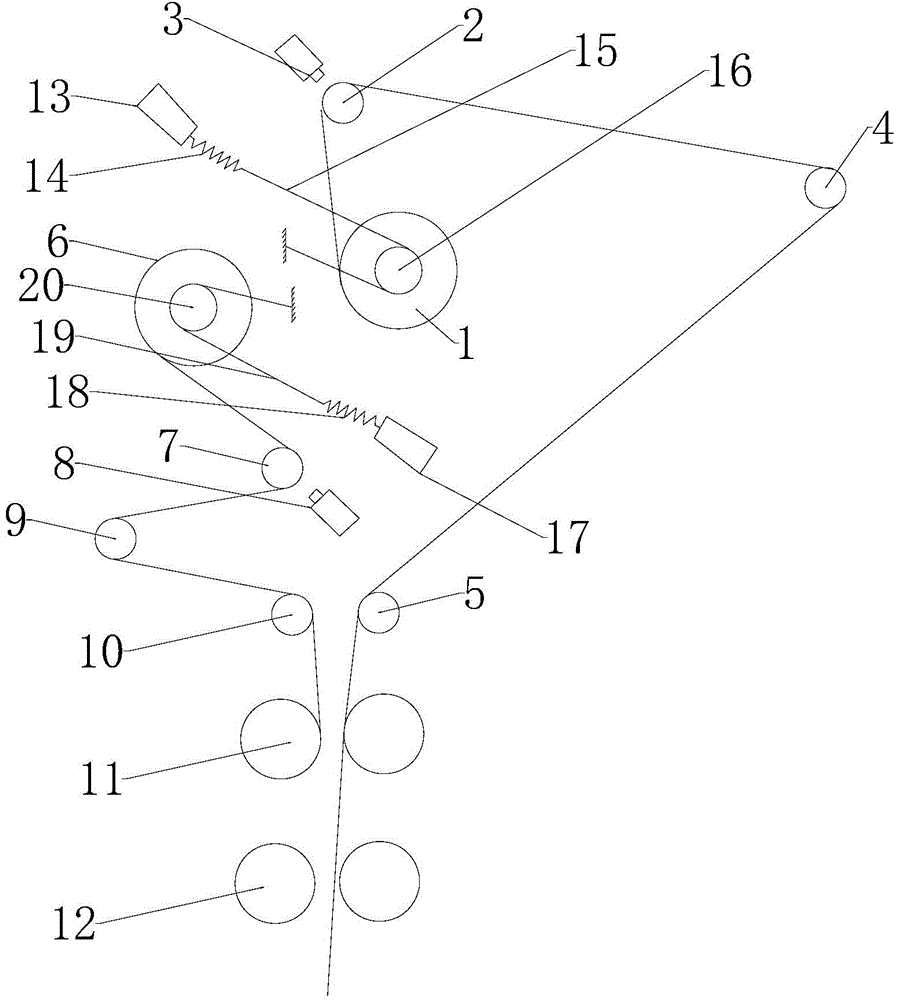

Coil package material automatic following device

InactiveCN104401775AAvoid looseRealize automatic connectionArticle deliveryWebs handlingPackaging machine

The invention relates to a coil package material automatic following device, which comprises a coiled material disc, a first tension roll, a first proximity switch, a first guide roll, a second guide roll, a to-be-coiled material disc, a second tension roll, a second proximity switch, a third guide roll, a fourth guide roll, a sheet replacement clamping roll and a traction roll, wherein the first proximity switch is arranged near the first tension roll, the second proximity switch is arranged near the second tension roll, a first brake device is arranged at the first tension roll, and is connected with the first proximity switch by a signal, and a second brake device is arranged at the second tension roll, and is connected with the second proximity switch by a signal. By adopting the structure, the coil package material automatic following device has the advantages that the structure is simple and reasonable, the automatic following of sheets is realized, the number of shutdown times of a packaging machine is reduced, the sheet replacement auxiliary time is saved, and the production efficiency of the packaging machine is improved.

Owner:CHANGZHOU YONGAN SECURITY SERVICE

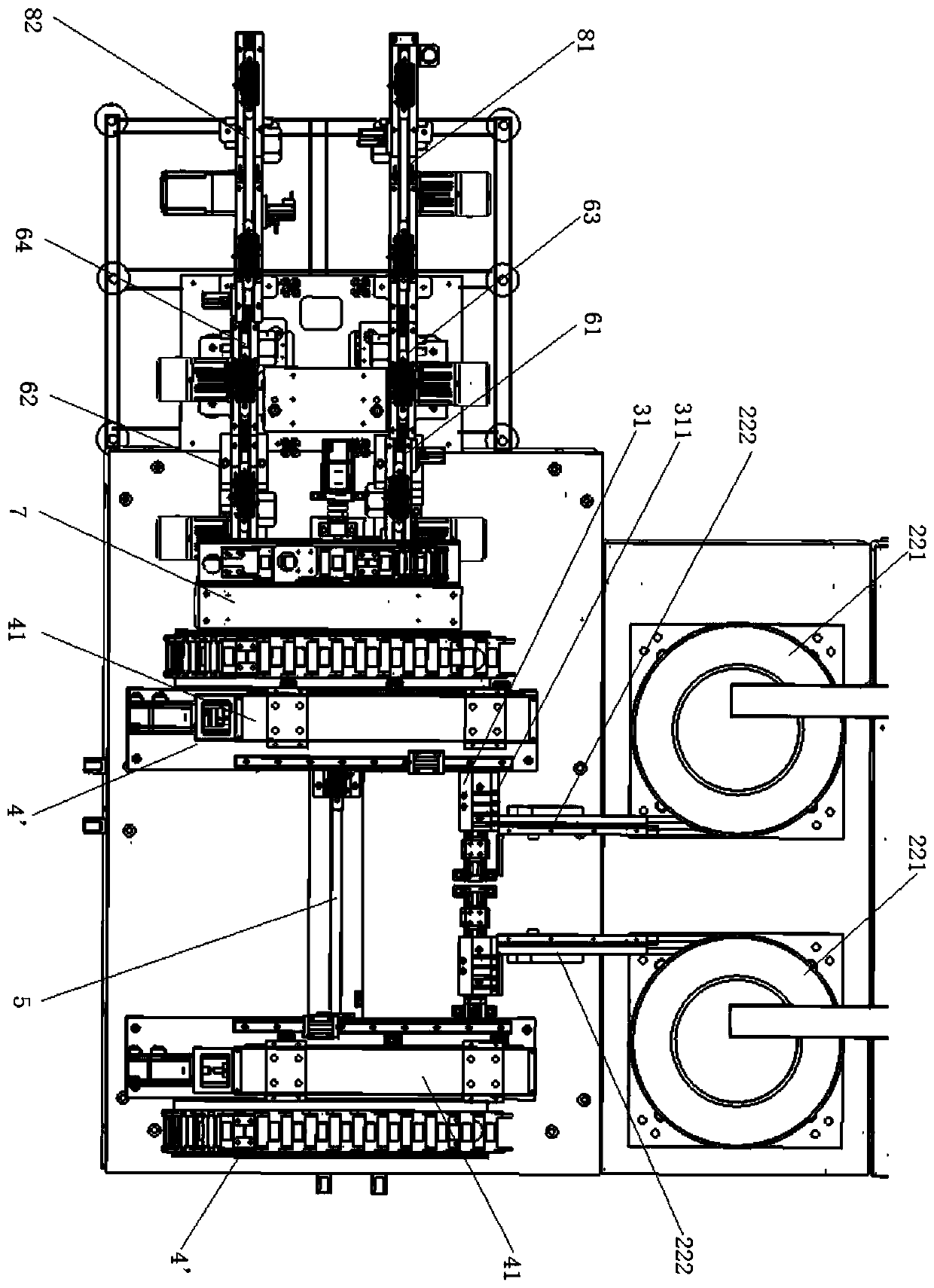

Circulating feeding system

PendingCN110654856AUninterrupted automatic feedingUninterrupted recyclingConveyor partsProcess engineeringTransfer mechanism

The invention discloses a circulating feeding system comprises a processing area, a shipping area and a loading and unloading area; the processing area is internally provided with an element processing mechanism and a temporary storage mechanism; the element processing mechanism is used for processing and outputting a finished element product; the temporary storage mechanism is used for temporarily storing an element output by the element processing mechanism; the shipping area is internally provided with a material taking mechanism and a conveying mechanism; the conveying mechanism comprisesa carrying disc for carrying an element and a conveying device; the carrying disc is driven by the conveying device to move; the material taking mechanism takes out the temporarily stored element andmount the element on the carrying disc; the loading and unloading area is internally provided with an output and recovery mechanism and a transfer mechanism; the output and recovery mechanism outputsthe carrying disc carrying the finished element product to the outside and recovers an empty carrying disc input from the external; and the transfer mechanism transfers the carrying disc between the output and recovery mechanism and the conveying mechanism.

Owner:SUZHOU RS TECH

Rod heat treatment equipment

ActiveCN109652636AEvenly heatedRealize automatic connectionRotary drum furnacesHeat treatment process controlHeating oilEngineering

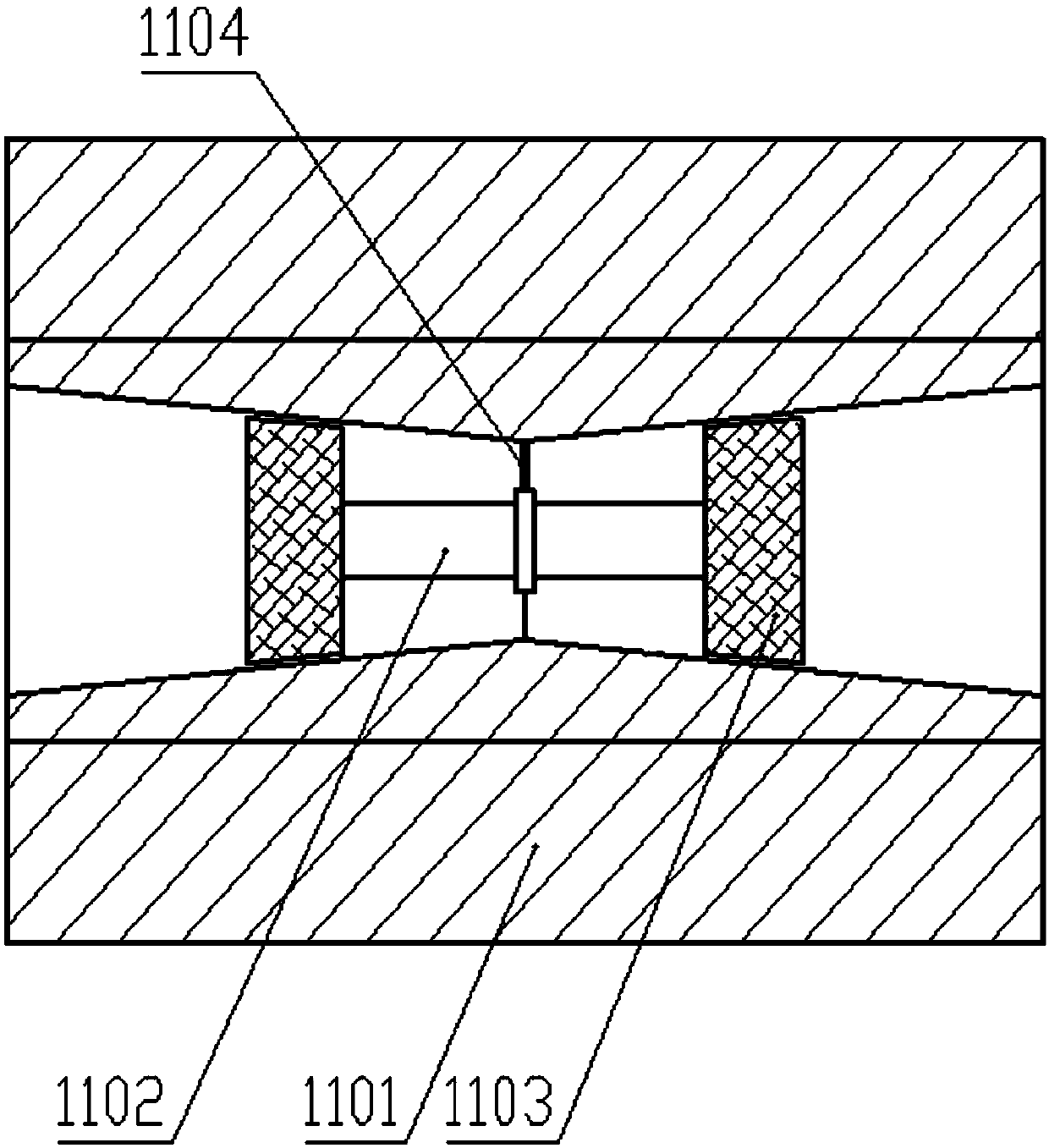

The invention discloses rod heat treatment equipment which comprises a heating furnace for containing rods. The heating furnace is spherical, the heating furnace is internally hollow and is uniform inwall thickness, the heating furnace is filled with heating oil , the heating furnace is internally provided with a plurality of layers of clamping rods for clamping the rods in parallel, the rod heattreatment equipment further comprises an external stove for containing the heating furnace, a constant pressure control valve comprises a valve body, a control hole is formed in the axis of the valvebody and formed by coaxially connecting two sections of conical through holes in a mirror symmetry butting mode, and small ports of the two through holes are integrally connected. A sensing element used for detecting flowing of fluid in a pipeline is arranged on the pipeline between a liquid drainage pipe and the constant pressure control valve, and the sensing element is connected with the controller. The rod heat treatment equipment is easy and convenient to operate, capable of carrying out even heating while containing multiple rods, stable and reliable in heat supply system and extremelygood in heat treatment effect.

Owner:六安市志鹏金属加工有限公司

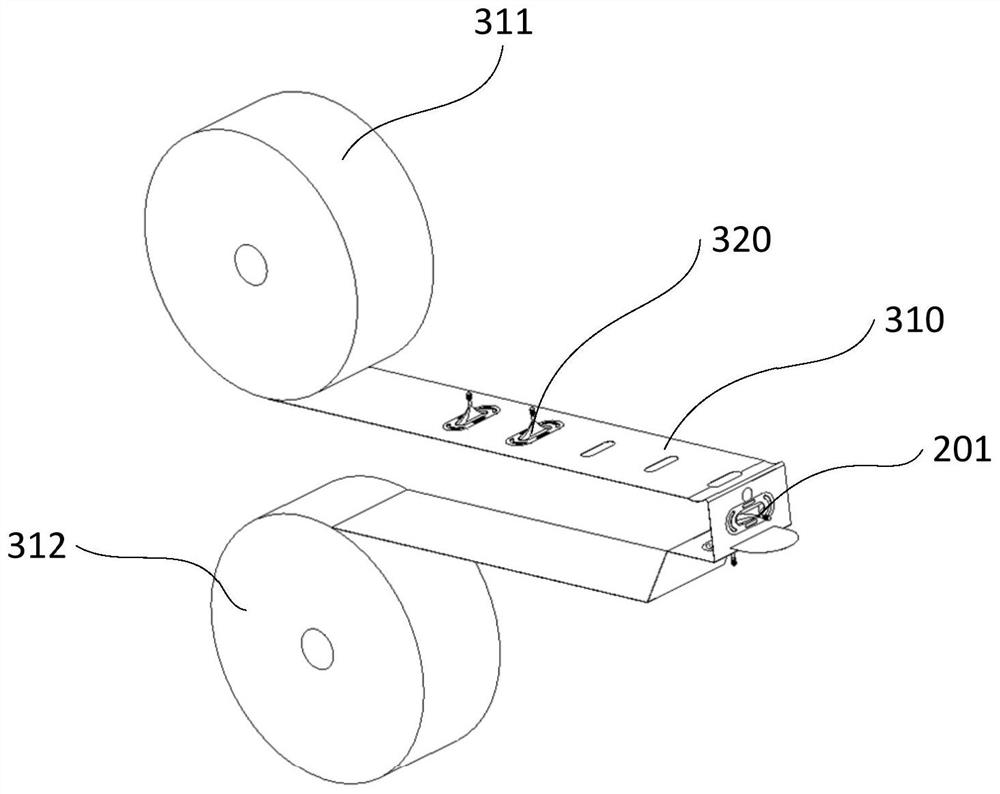

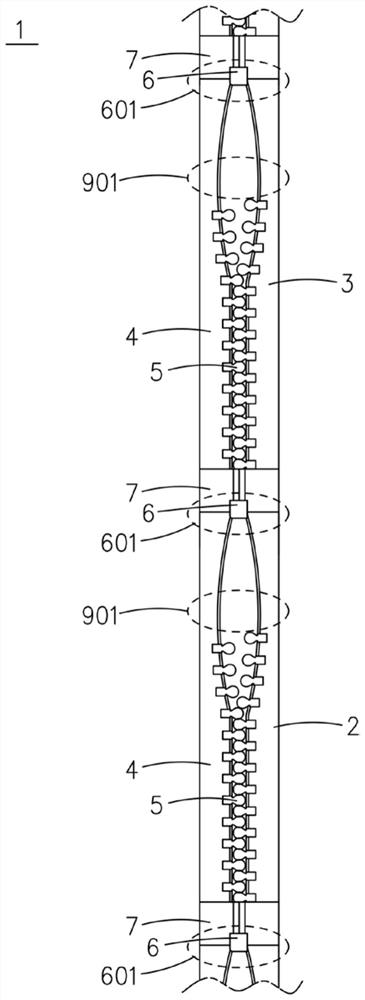

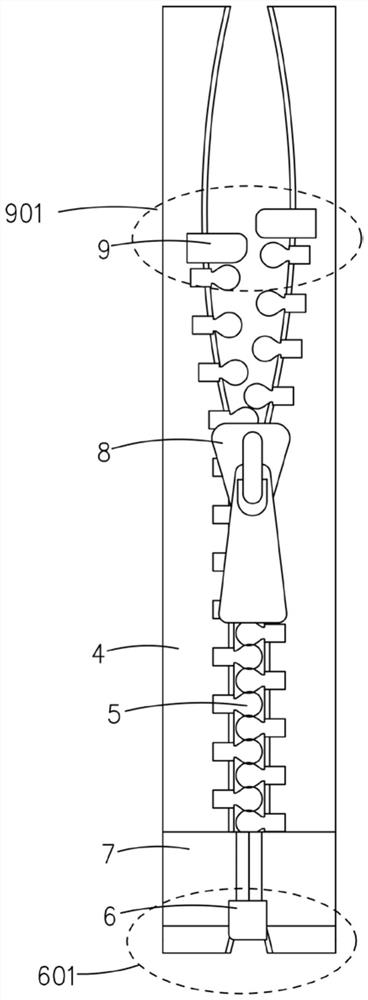

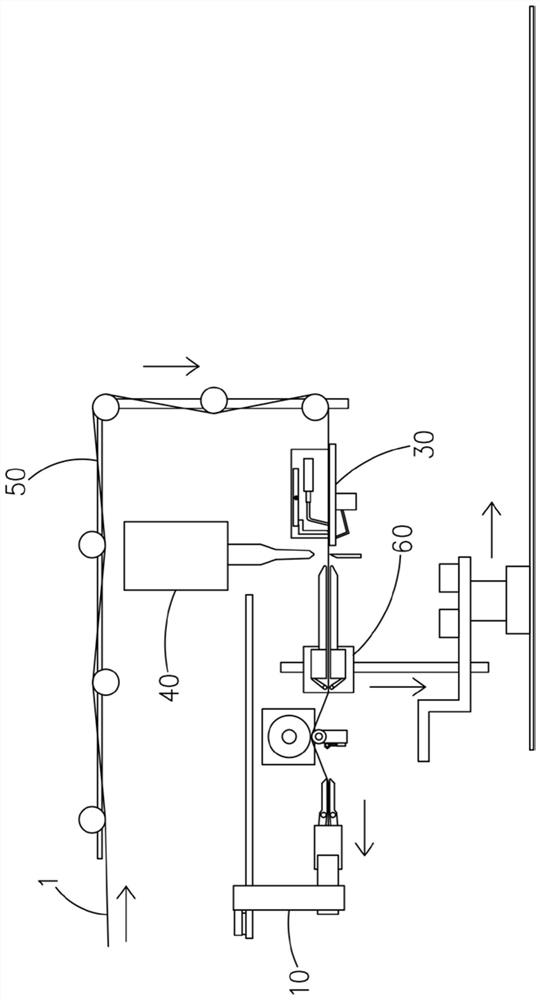

Continuous fastener tape turning-around and cutting-off unit and zipper manufacturing equipment adopting continuous fastener tape turning-around and cutting-off unit

PendingCN112293876AGuaranteed uptimeImprove processing efficiencySlide fastenersMechanical engineeringIndustrial engineering

The invention discloses a continuous zipper tape turning-around and cutting-off unit which comprises a tape pulling device used for pulling a continuous zipper tape to advance, a positioning device used for positioning a lower end stop part of the zipper and a cutting-off device used for cutting off the continuous zipper tape between an upper end stop part and a lower end stop part; the unit further comprises a tape guiding device is used for guiding the continuous zipper tape to turn around and advance, and a conveying device used for conveying the zipper which turns around and is cut off. The positioning device, the cutting-off device, the conveying device and the zipper tape pulling device are sequentially arranged in the turning advancing direction of the continuous zipper tape. Through the design and application of the continuous zipper tape turning-around and cutting-off unit, the automation degree of the zipper manufacturing equipment is greatly improved, and the requirement ofpeople for zipper manufacturing automation at present can be met.

Owner:SHENZHEN GUANZHONG TECH CO LTD

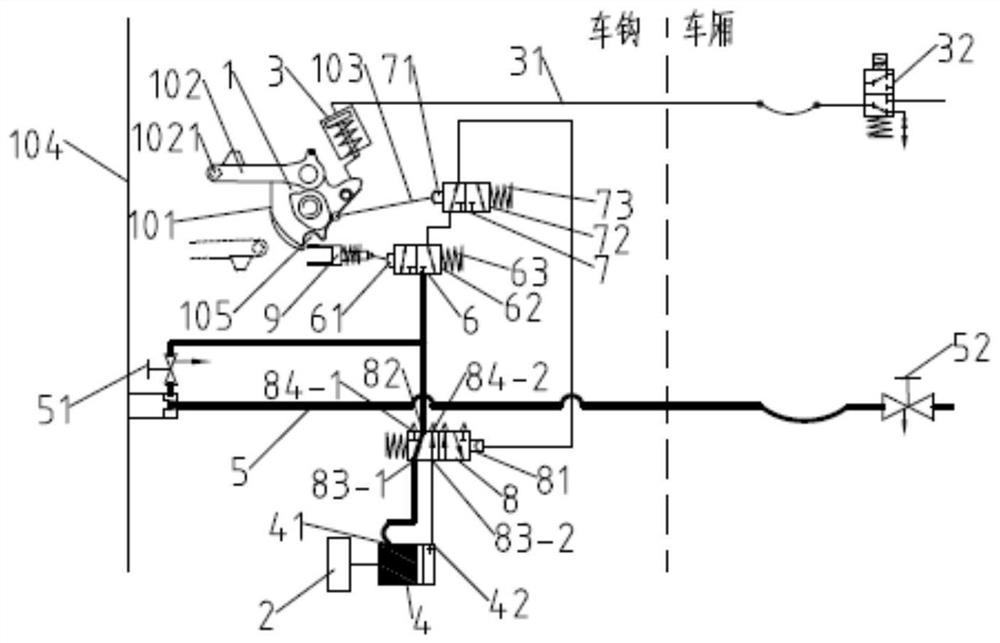

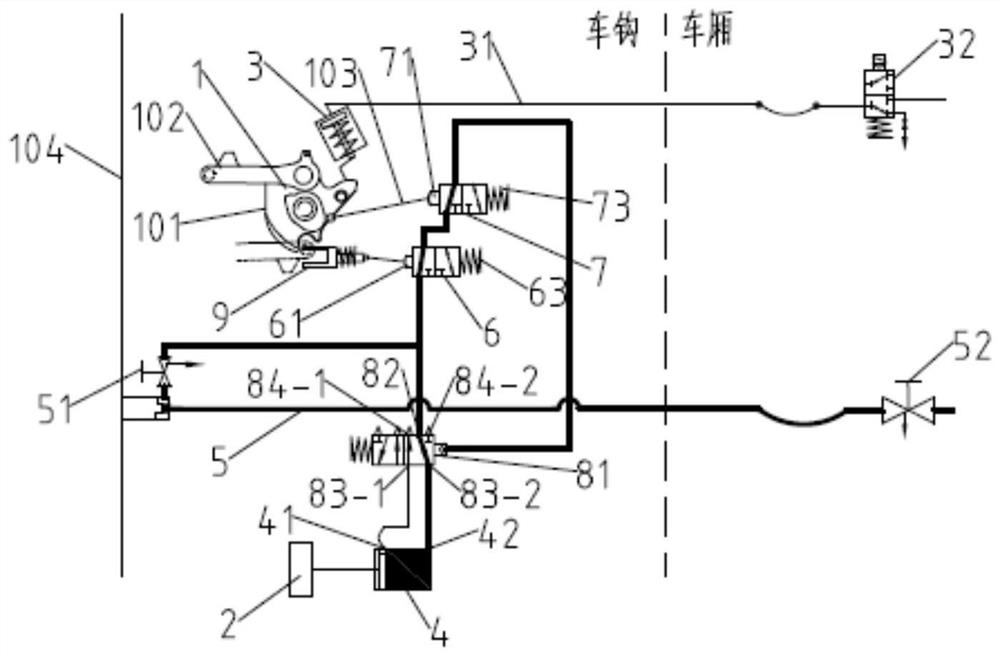

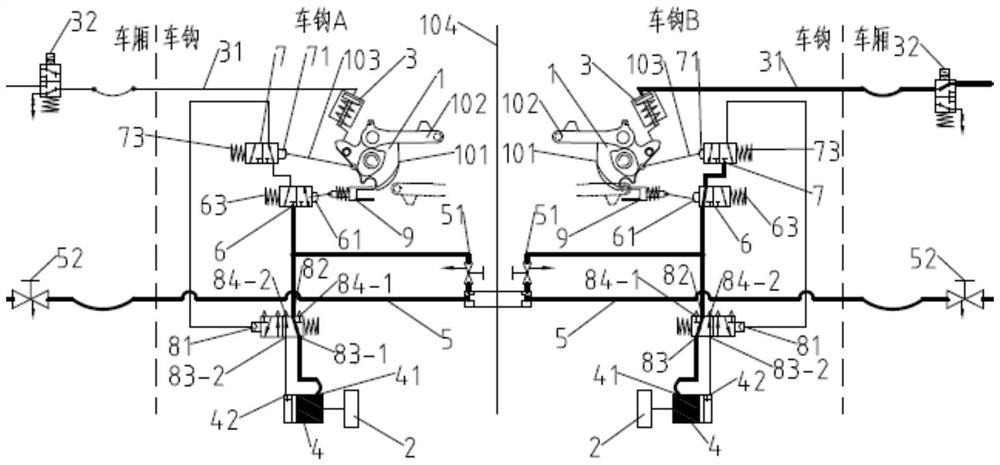

Car coupler automatic control system

ActiveCN112644554AThe overall structure is simple and reliableRealize automatic connectionRailway coupling accessoriesAutomatic controlControl system

The invention provides a car coupler automatic control system. The car coupler automatic control system comprises a main air pipe and an uncoupling pipeline; the main air pipe is divided into two paths; the first path comprises a first limiting switch connected with the main air pipe and a second limiting switch connected with the first limiting switch and communicated to a contact of a two-position five-way pneumatic control valve; the other path is communicated with an air inlet of the two-position five-way pneumatic control valve; the uncoupling pipeline is connected with a uncoupling cylinder; and a working port of the two-position five-way pneumatic control valve is connected with the pushing cylinder. According to the coupler automatic control system, under the single-coupler state, stretching out of the electrical coupler can be achieved through triggering of the first limiting switch, and retracting of the electrical coupler can be achieved through triggering of the second limiting switch.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

Automatic wiring method of integrated circuit layout after lessening experiment

ActiveCN103136385ARealize automatic connectionImprove verification speedSpecial data processing applicationsIntegrated circuit layoutTape-out

The invention discloses an automatic wiring method of an integrated circuit layout after a lessening experiment. The total layout is divided into an upper area, a lower area, a left area and a right area. For any one area, two-layer metal wiring is utilized. The metal wiring either comprises transverse wires-vertical wires from top to bottom-transverse wires, or comprises transverse wires-vertical wires from bottom to top-transverse wires. The automatic wiring method can rapidly achieve automatic wiring of the integrated circuit layout after the lessening experiment, original manual wiring needing a long time is shortened to a few minutes, and tape-out verification of integrated circuit chips is speeded up.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

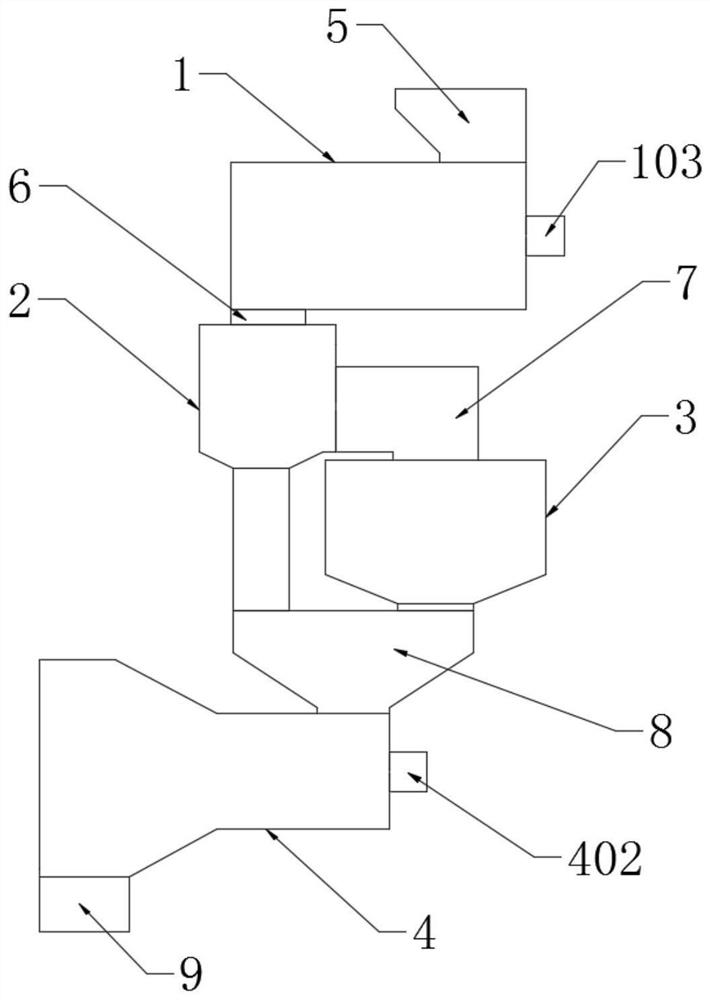

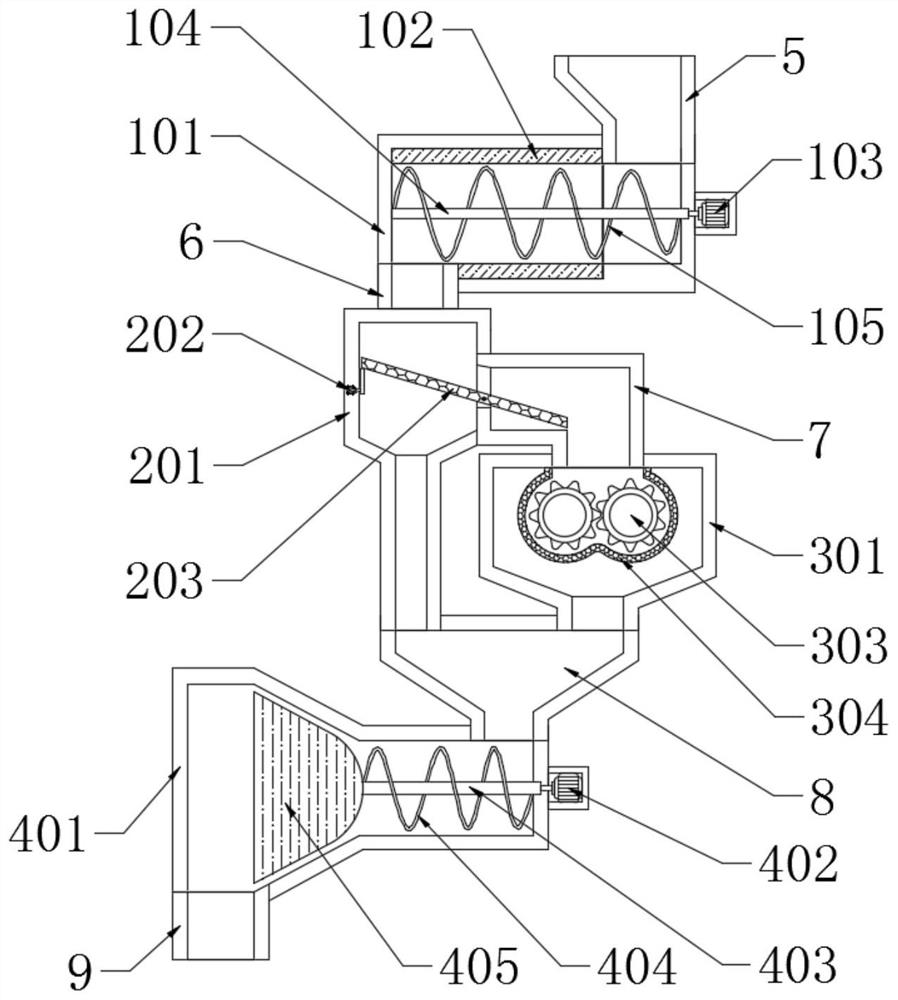

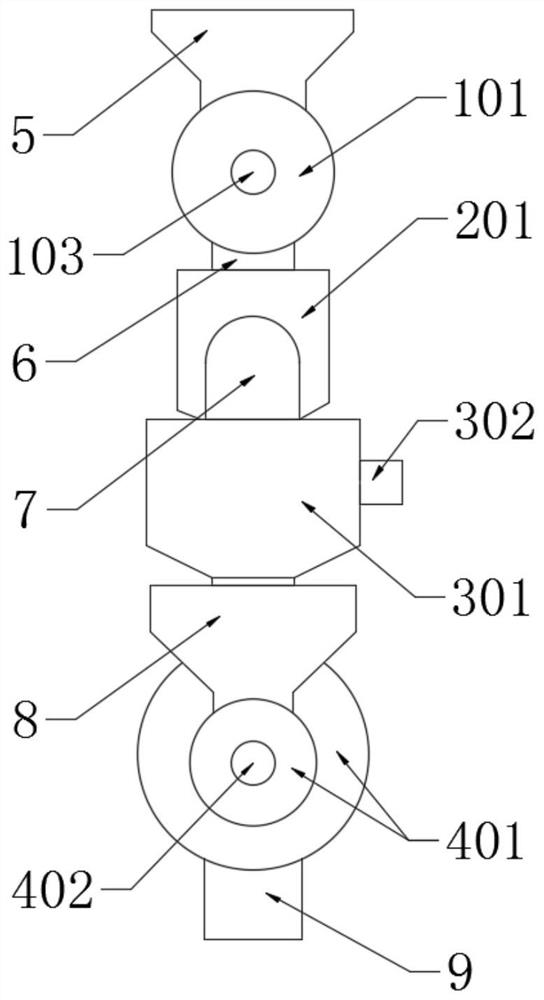

Production equipment for casting residue superfine slag powder and production method based on equipment

ActiveCN113578442AImprove drying effectReduce the difficulty of crushingSievingSolid waste managementSlagProcess engineering

The invention discloses production equipment for casting residue superfine slag powder and a production method based on the equipment. The production equipment comprises a drying mechanism, wherein a feeding hopper is arranged at the top end of the drying mechanism; a material guiding pipe is arranged at the end, away from the feeding hopper, of the drying mechanism; a screening mechanism is arranged on the side, away from the drying mechanism, of the material guiding pipe; a conveying pipe is arranged on the side wall of the screening mechanism; a smashing mechanism is arranged on the side, away from the screening mechanism, of the conveying pipe; a mixing tank is arranged on the side, away from the conveying pipe, of the smashing mechanism; and the mixing tank is connected with the bottom end of the screening mechanism. The production equipment for the casting residue superfine slag powder provided by the invention is novel in structure, high in automation degree, low in required labor intensity, good in grinding effect and high in working efficiency, the whole production process is simple and practical, casting residue slag drying and grinding are effectively integrated, and automatic production is achieved.

Owner:广东韶钢嘉羊新型材料有限公司

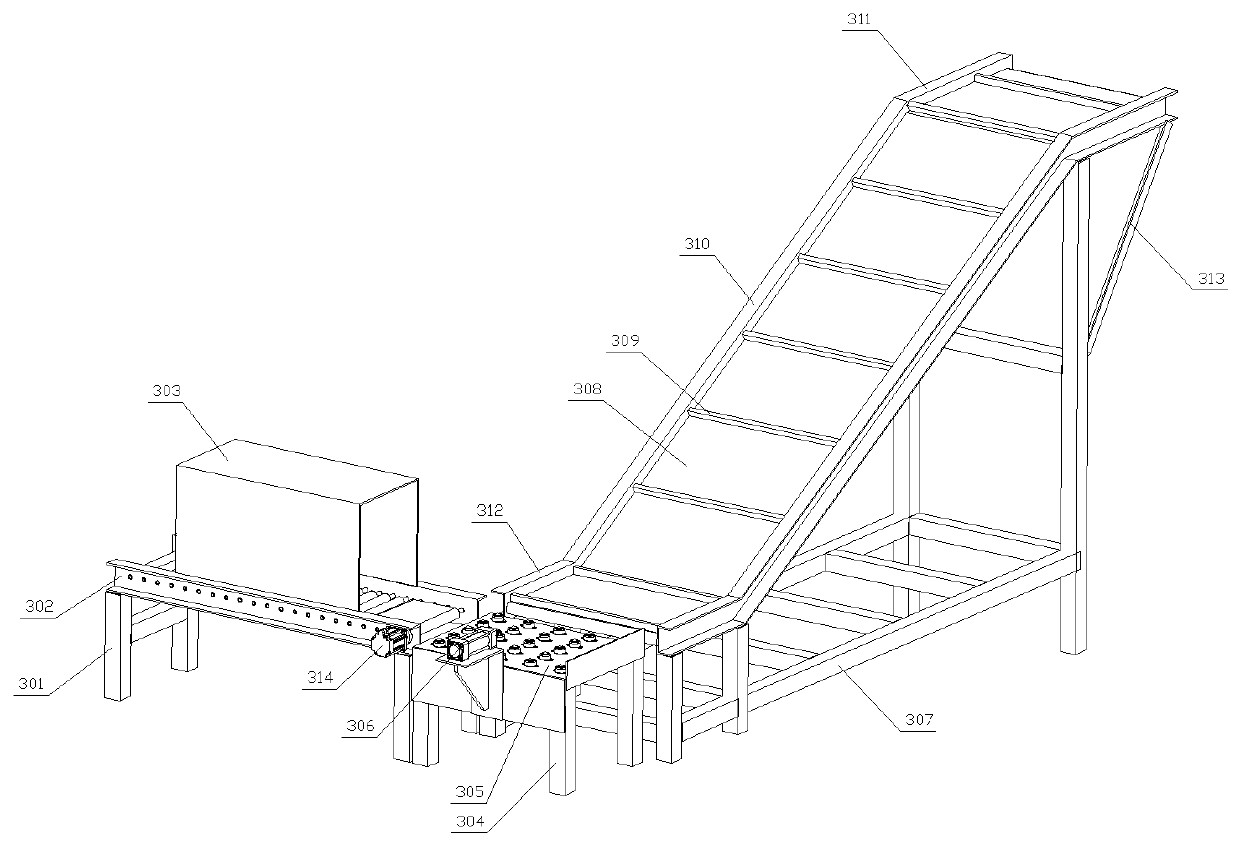

Box sealing and conveying mechanism

PendingCN110371401ARealize automatic connectionReasonable structureConveyorsWrapper twisting/gatheringMechanical engineeringEngineering

The invention discloses a box sealing and conveying mechanism. The box sealing and conveying mechanism comprises an automatic sealing machine assembly sealing a box body, a steering assembly arrangedon the rear part of the sealing assembly, and a conveying assembly arranged on the side part of the steering assembly, wherein the steering assembly pushes the sealed box body onto the conveying assembly; the steering assembly comprises a steering support frame, a steering support plate fixedly installed at the upper end of the steering support frame, and a push cylinder fixedly connected to the side part of the steering support frame through a cylinder installation seat; and universal ball installation seats are uniformly installed on the steering support plate, and a universal ball is installed in each universal ball installation seat. The box sealing and conveying mechanism is simple in structure and convenient to use; a daub box sealed on the automatic sealing machine assembly is pushed onto the conveying assembly through the steering assembly, and the conveying assembly continuously lifts the daub box to a high place, so that stacking operation from top to bottom is facilitated; and automatic connection for automatic box sealing and conveying is realized, so that the manual labor intensity is reduced, and the production efficiency is increased.

Owner:XINGTAI POLYTECHNIC COLLEGE

Tunnel type oven berth mechanism suitable for automatic online and offline

ActiveCN102815531AReliable disengagementAvoid abnormal wear and tearConveyor partsEconomic benefitsOnline and offline

The invention discloses a tunnel type oven berth mechanism suitable for automatic online and offline and belongs to the technical field of product postprocessing auxiliary devices. The mechanism comprises an entrance berth group, an exit berth group and a carrier, the entrance berth group is arranged at the entry end of a tunnel type oven through a lateral seat frame I, the exit berth group is arranged at the exit end of the tunnel type oven through a lateral seat frame II, gaps are reserved among the entrance berth group, the exit berth group and a link plate, and the carrier is automatically conveyed from the entrance berth group to the exit berth group through the link plate. According to the tunnel type oven berth mechanism suitable for the automatic online and offline, when the tunnel type oven is used for baking products, the automatic online and offline is achieved, unmanned and automated joint of working procedures from start to finish are convenient to achieve, the production cost is greatly reduced, the production efficiency is improved, the risk of human injuries caused by high temperature overflow wind of the oven entrance and exit is prevented, the product reject ratio caused by the fact that the manual picking and placing of products are prone to pollute product surfaces is avoided, the economic benefits are improved, and the tunnel type oven berth mechanism is easy to popularize and apply.

Owner:怡得乐电子(杭州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com