Tunnel type oven berth mechanism suitable for automatic online and offline

A tunnel-type, berth technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of affecting product quality, reducing production efficiency, scalding danger, etc., to avoid abnormal wear and tear, accurate automatic pick and place, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

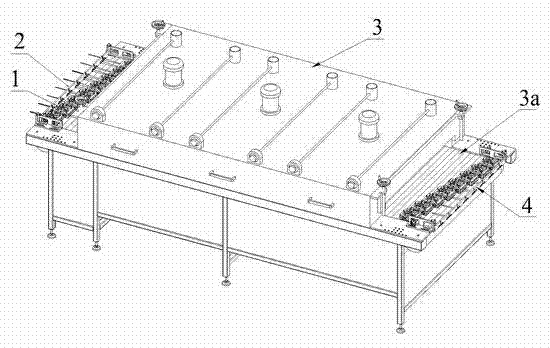

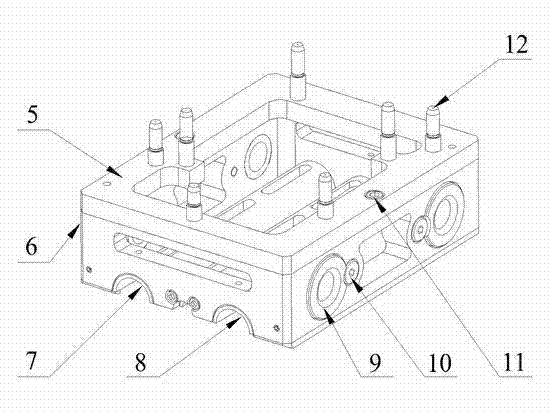

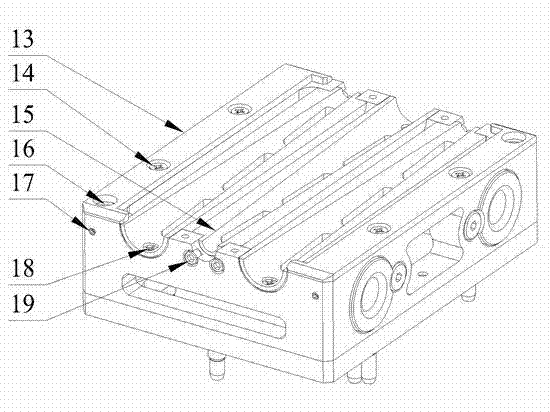

[0027] Below in conjunction with accompanying drawing, the present invention will be further described:

[0028] Such as Figure 1-5 As shown, a tunnel-type oven berth mechanism suitable for automatic loading and unloading, including an entrance berth group 4, an exit berth group 2 and a carrier 1, the entrance berth group 4 is set on the tunnel-type oven through the side mount I20 3 at the inlet end, the outlet berth group 2 is set at the outlet end of the tunnel oven 3 through the side mount II 26, there is a gap between the inlet berth group 4, the outlet berth group 2 and the chain plate 3a of the tunnel oven 3, The carrier 1 is automatically transported from the entry berth group 4 to the exit berth group 2 through the chain plate 3a.

[0029] Such as Figure 4 As shown, the entrance berth group 4 includes a front bank plate 23, the two ends of the front bank plate 23 are connected with the adjustment buckle I21, and the adjustment buckle I21 is movably connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com