Patents

Literature

91results about How to "Avoid abnormal wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

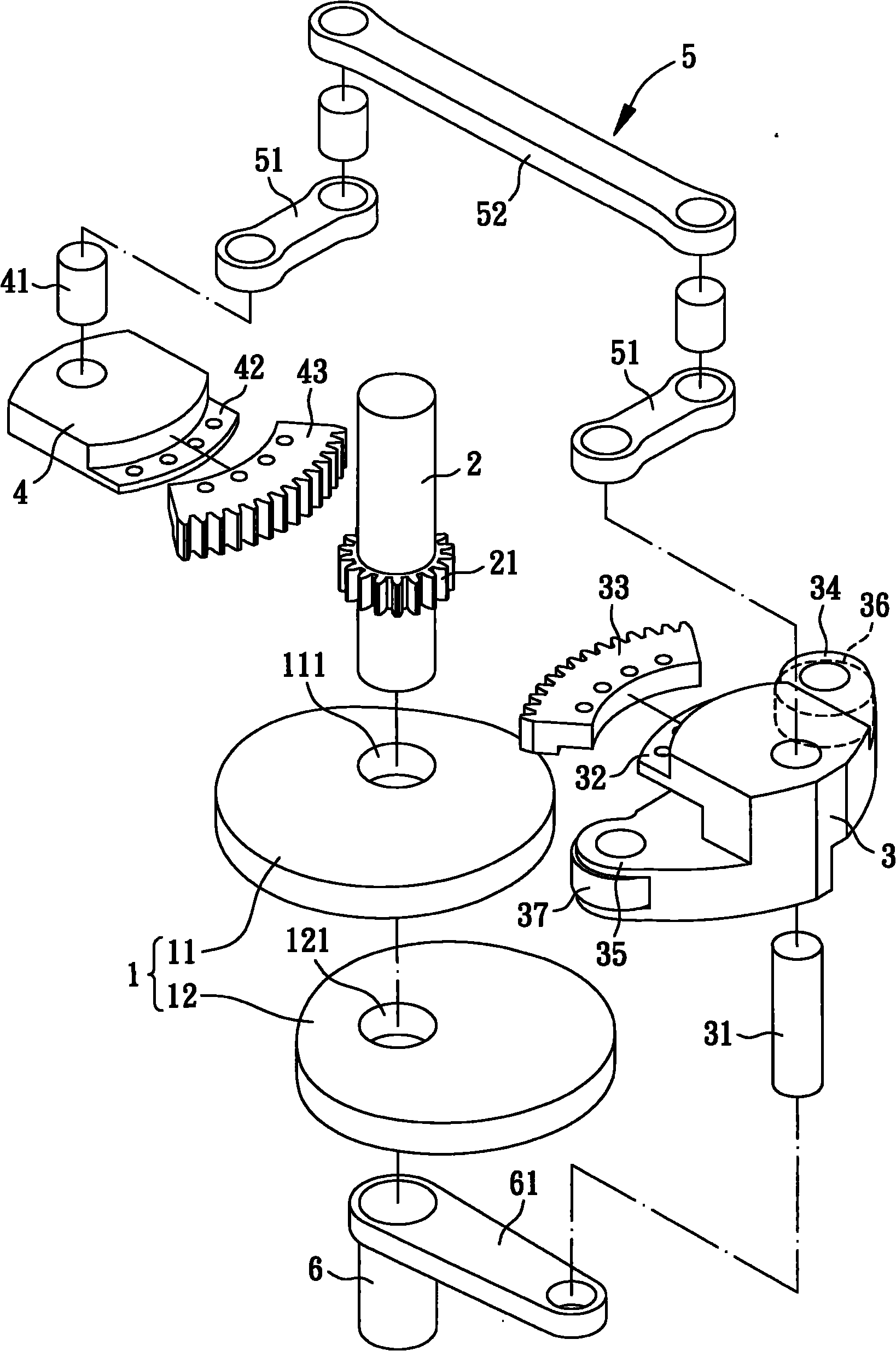

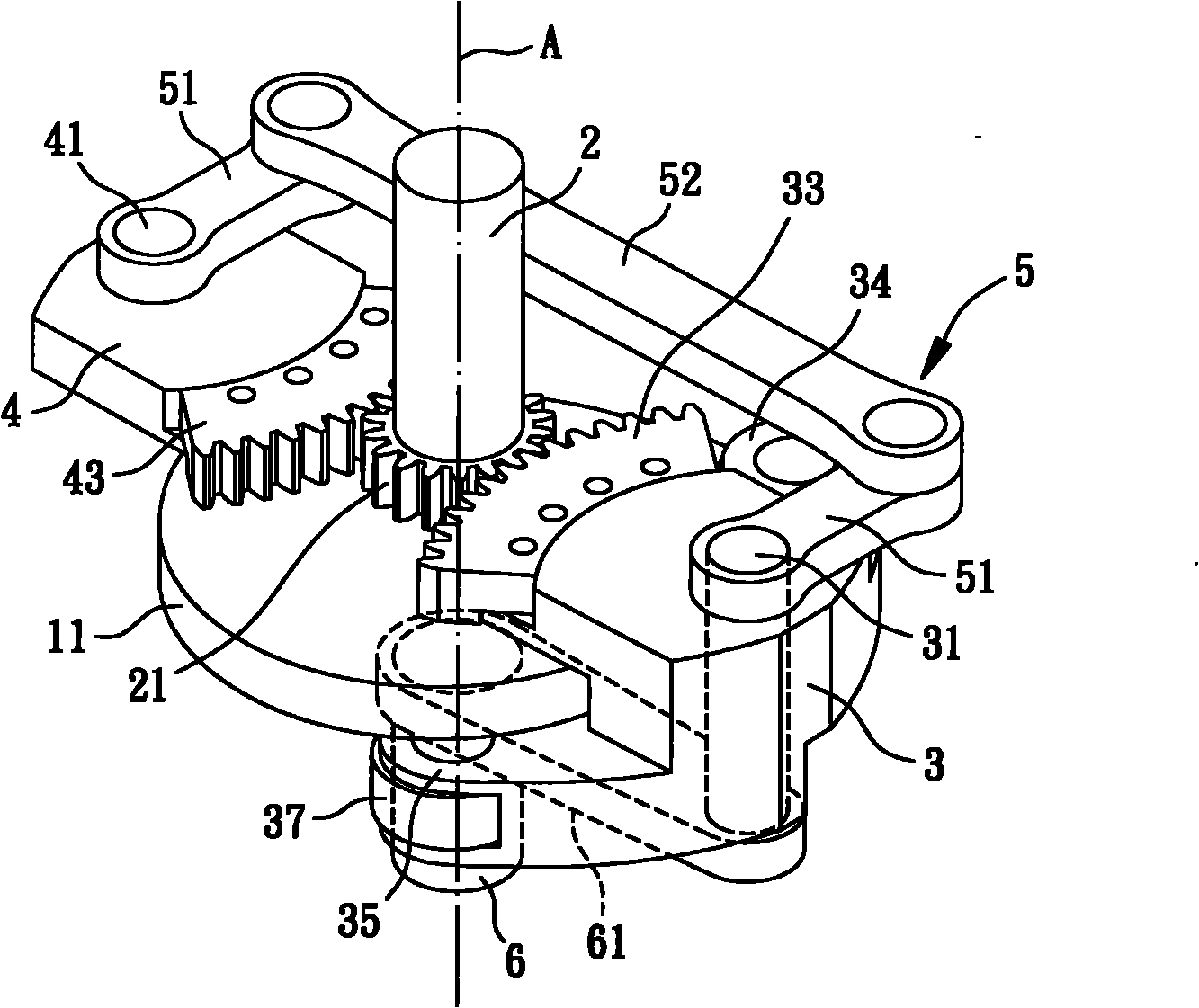

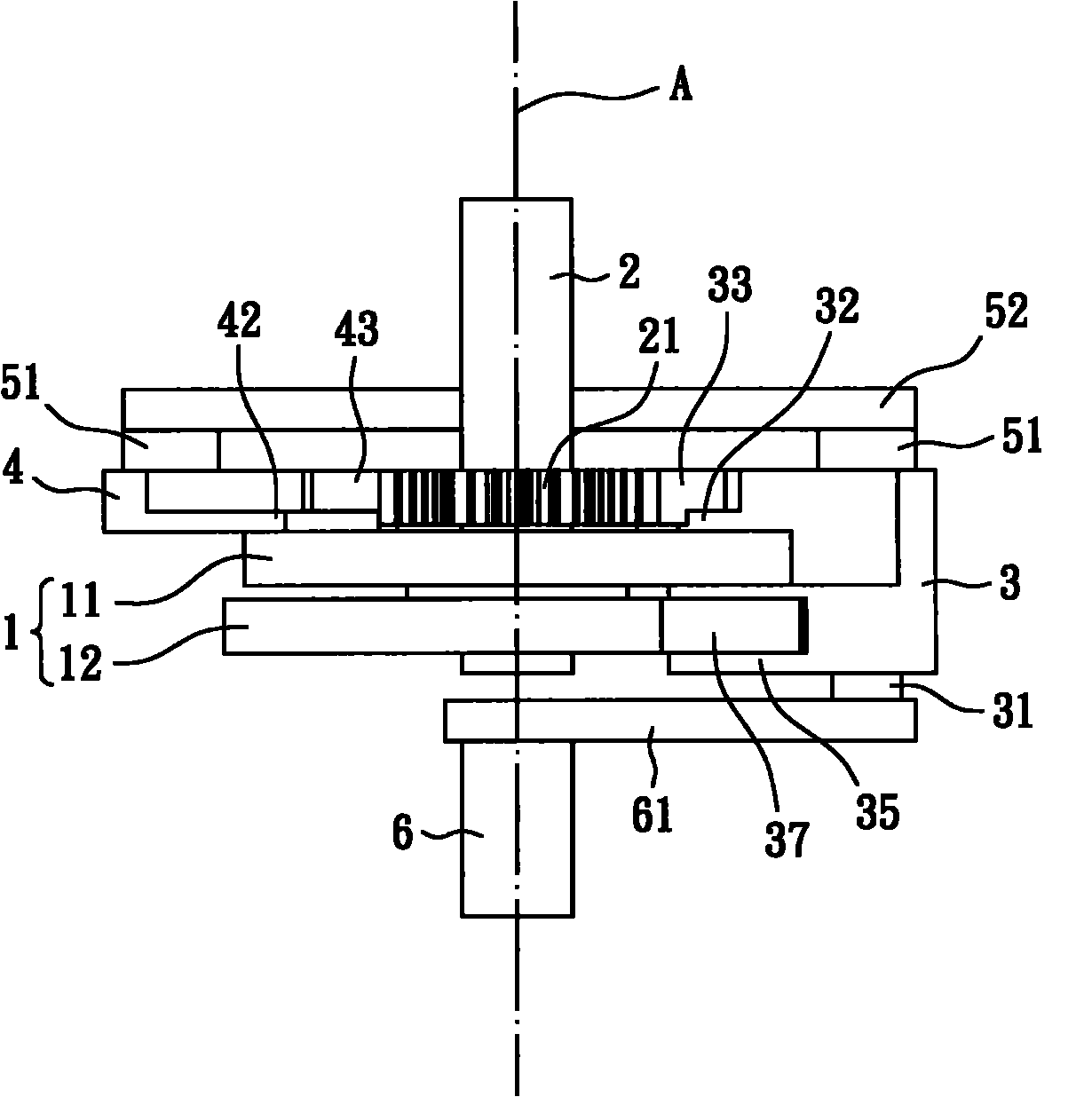

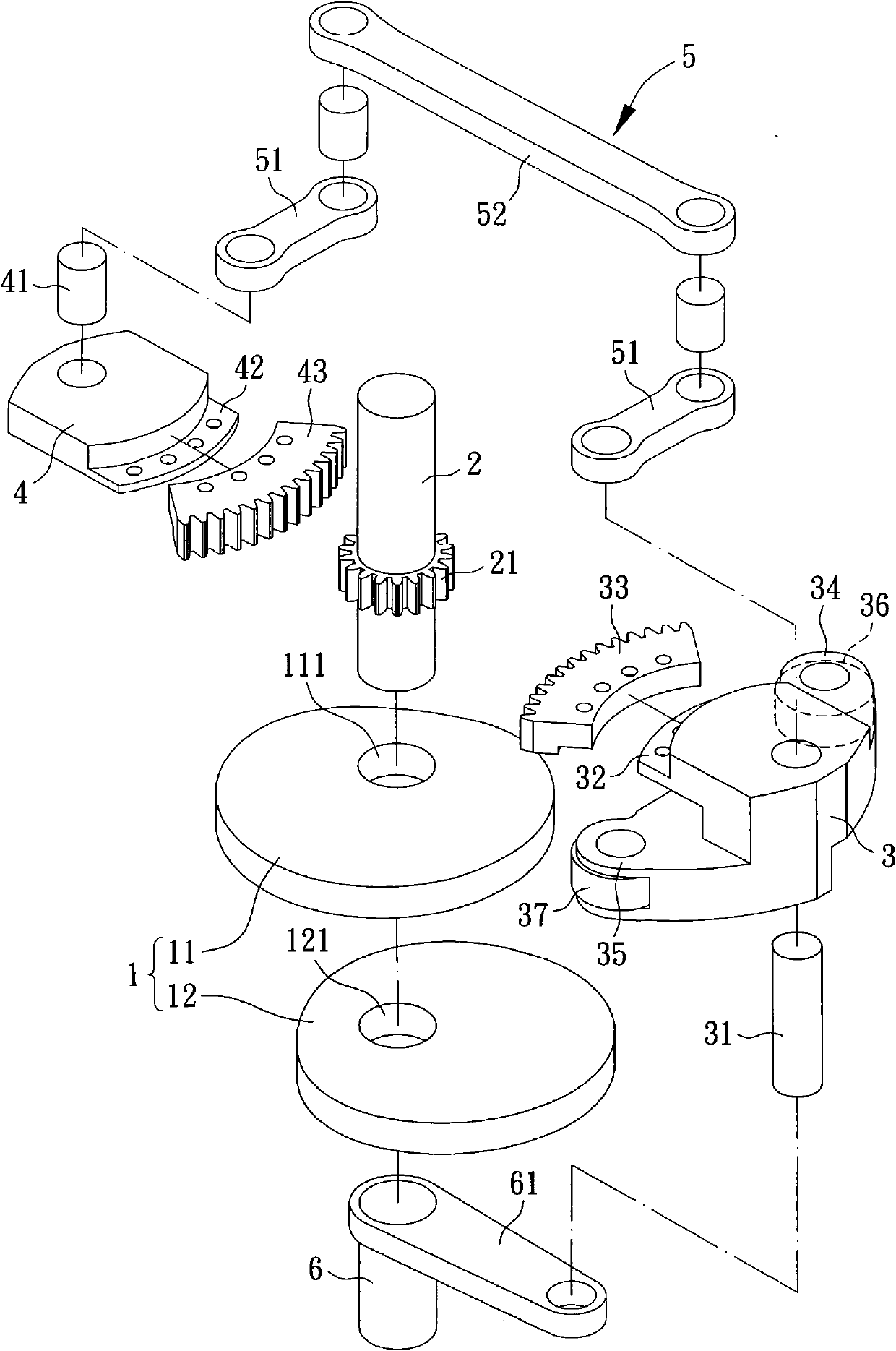

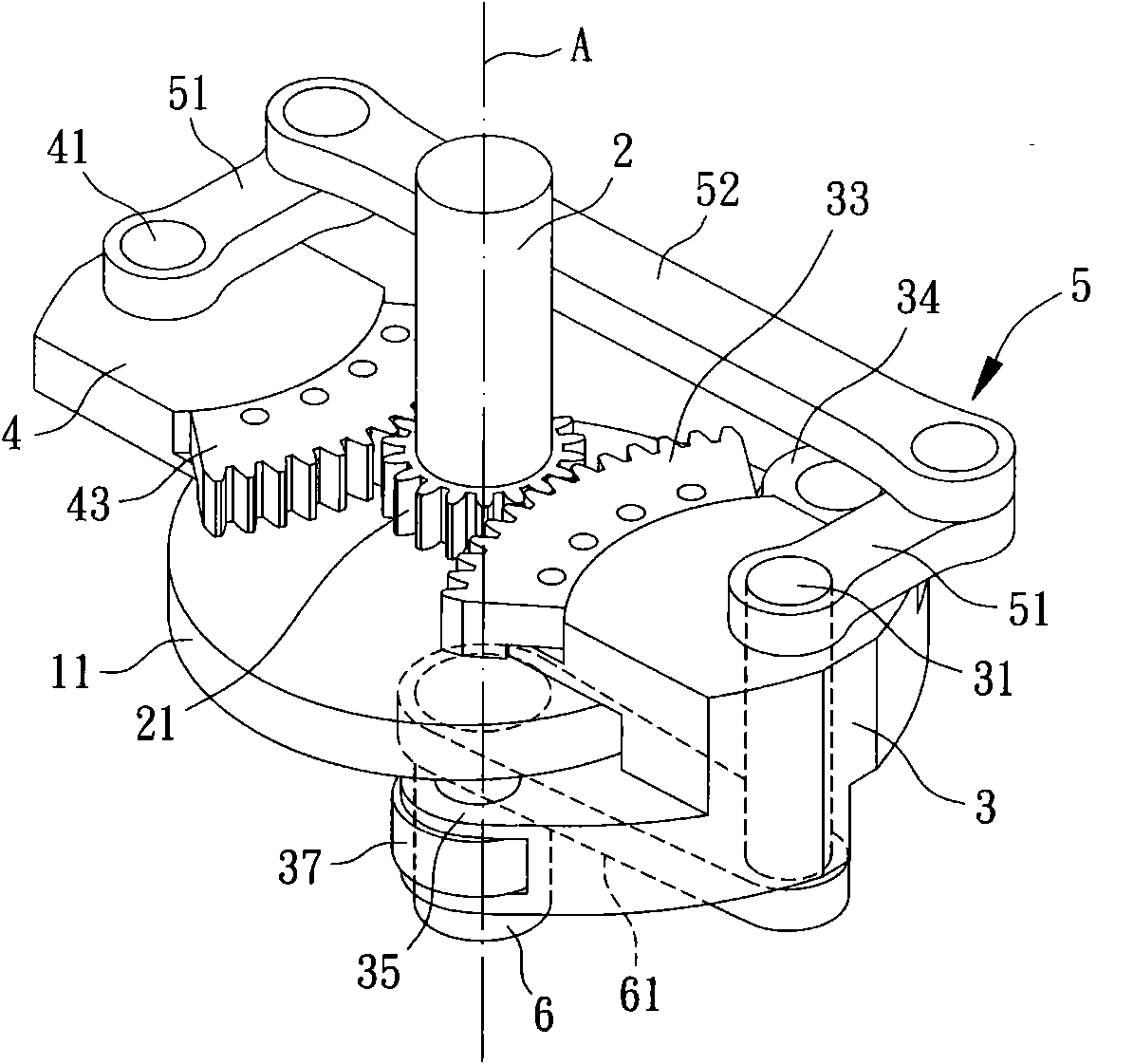

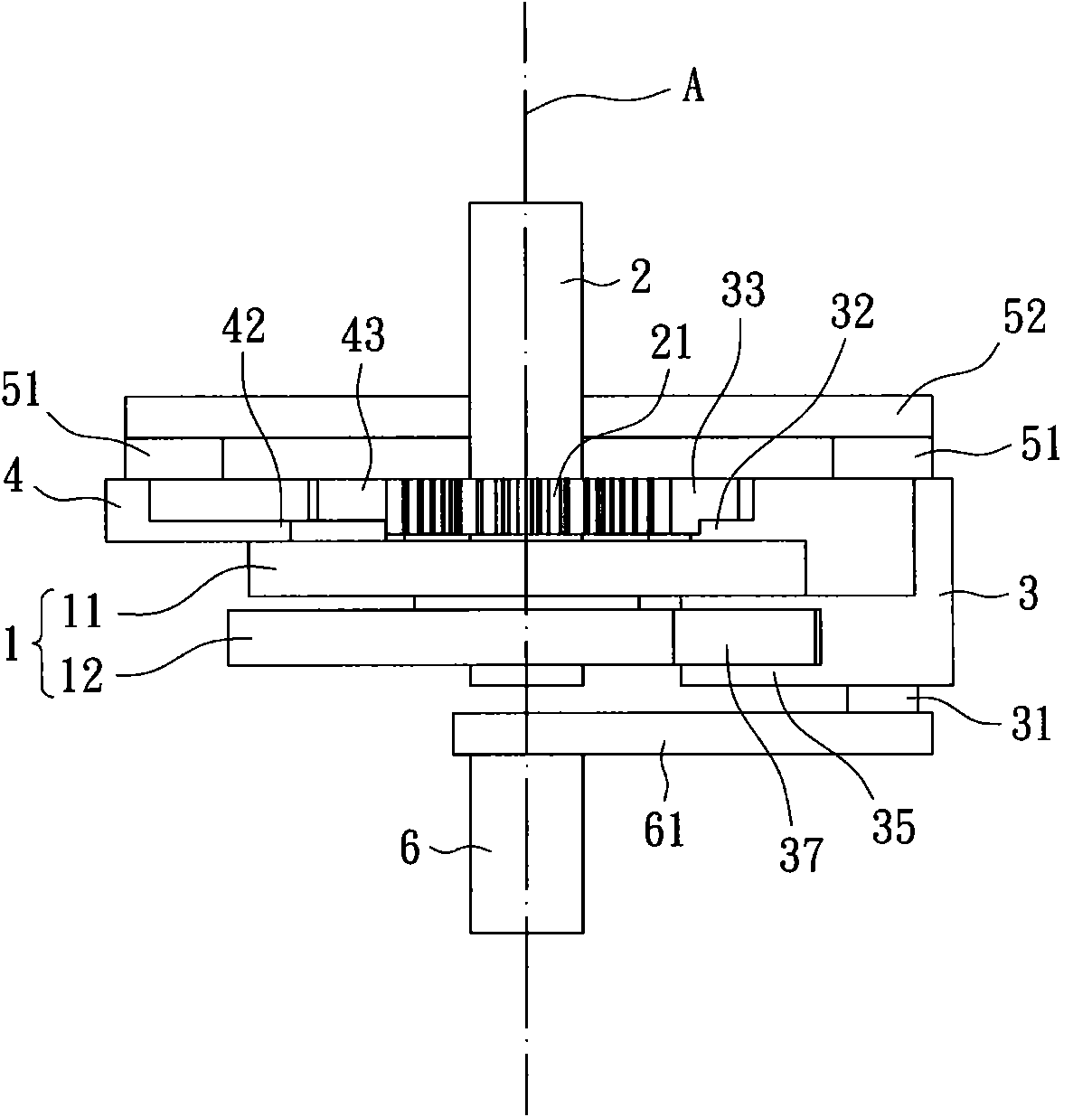

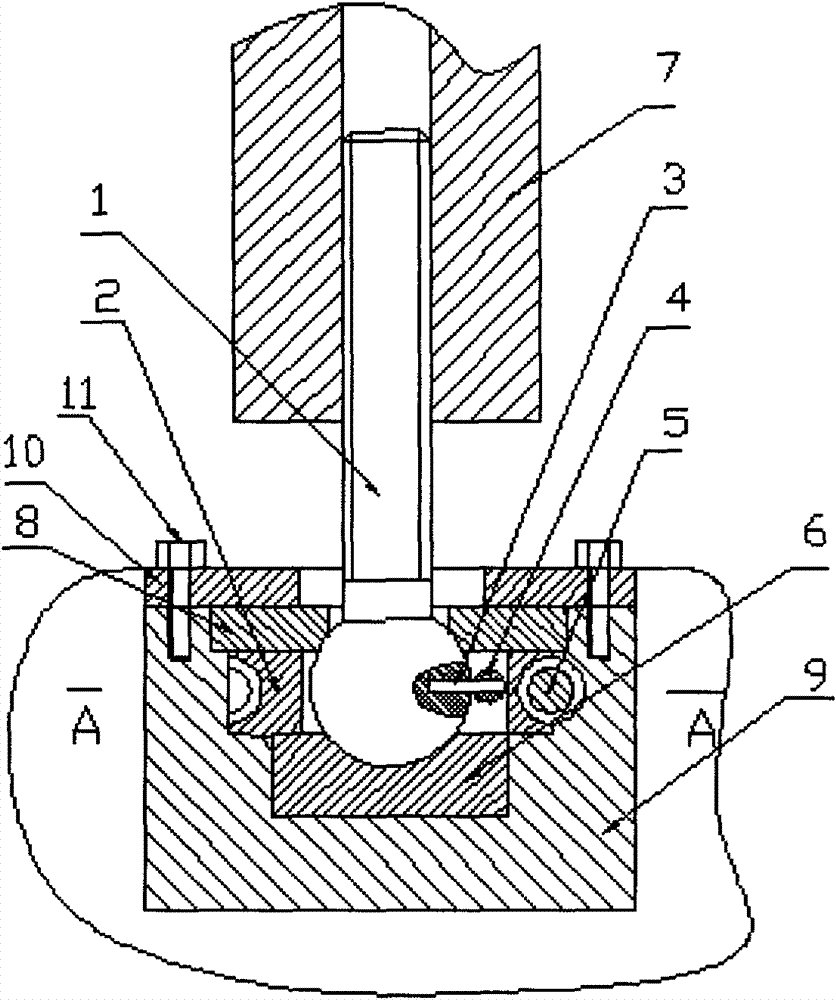

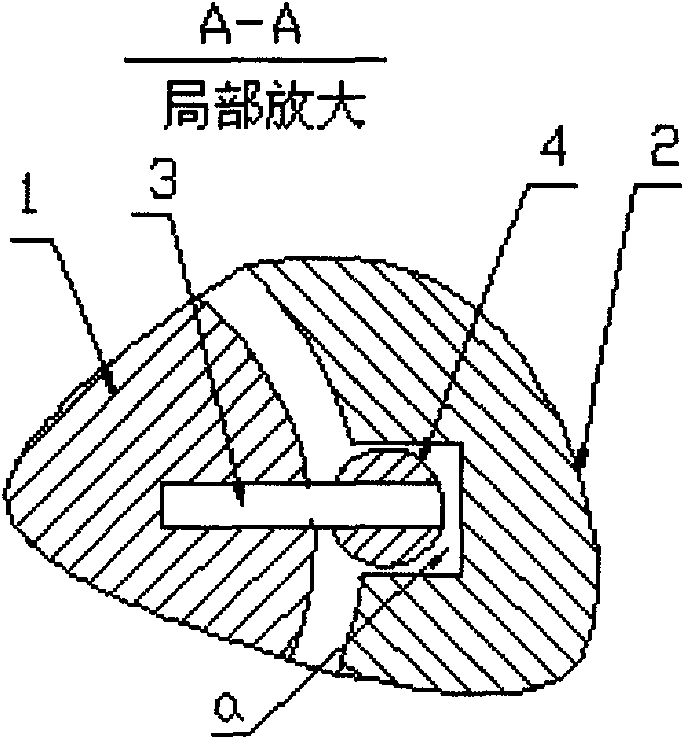

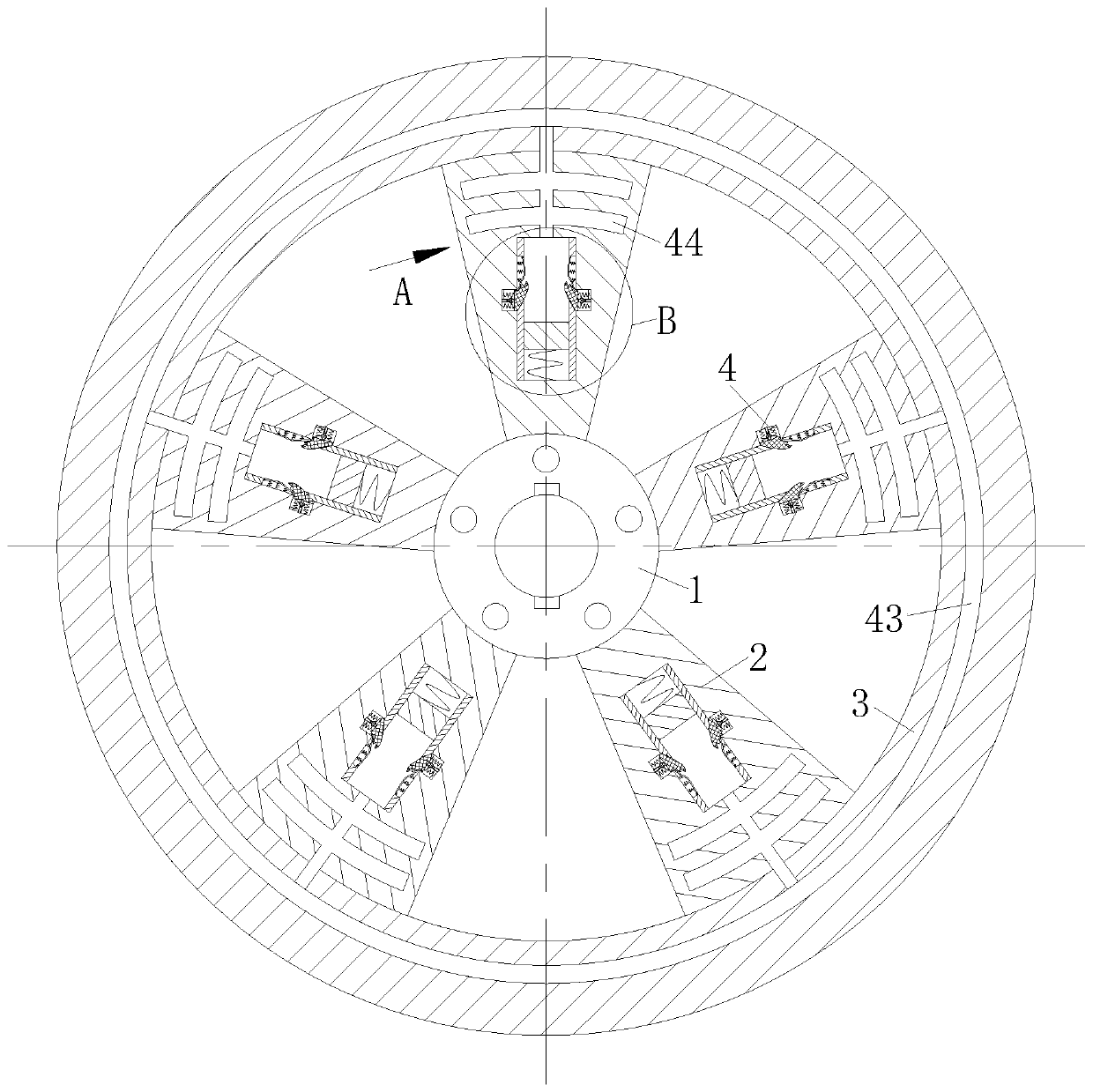

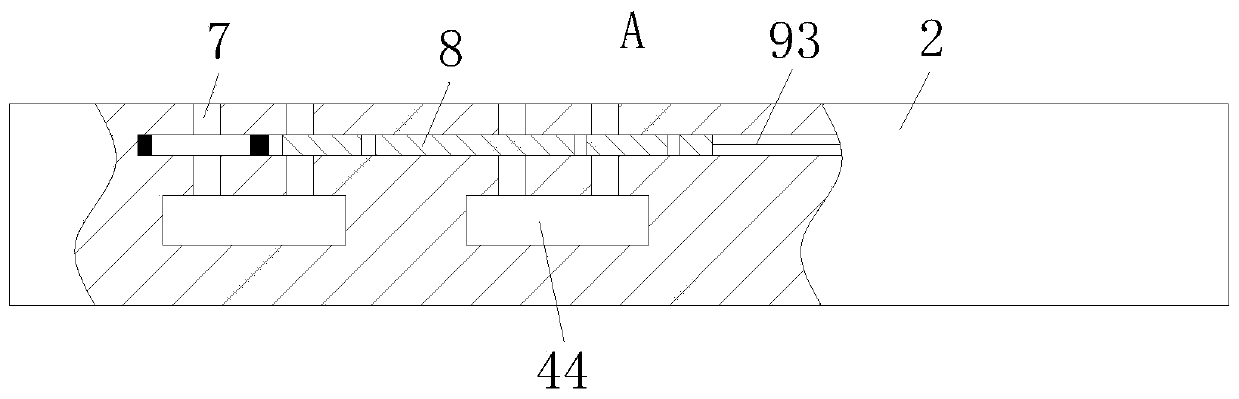

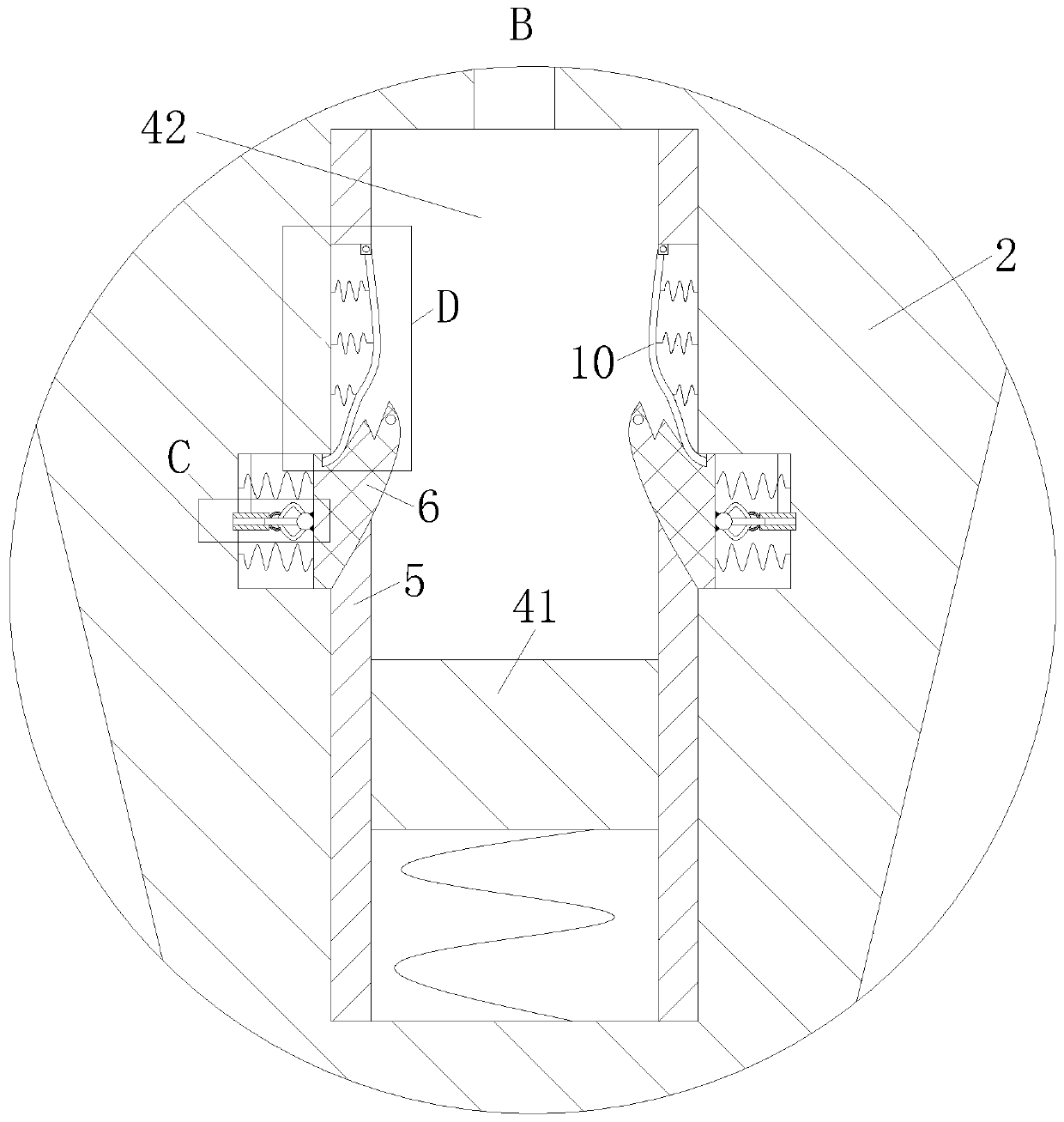

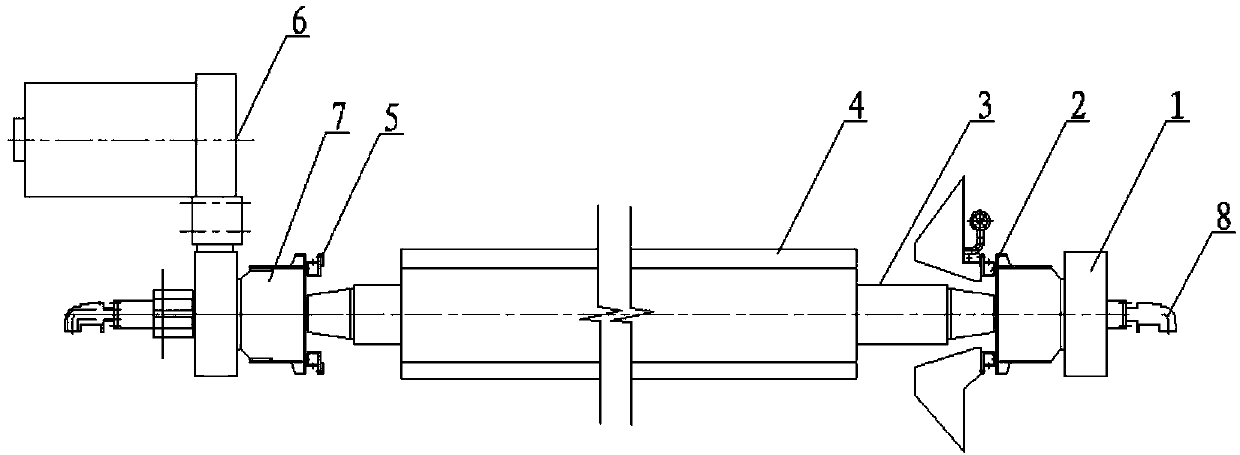

Transmission mechanism with intermittent output action

InactiveCN102121511AReduce unilateral loadSmall difference in qualityGearingGear wheelDynamic balance

The invention discloses a transmission mechanism with an intermittent output action, which comprises a conjugate cam group, an output shaft, two rocker arm blocks, a transmission connecting rod group and an input shaft, wherein the conjugate cam group comprises two cams; the output shaft is pivoted in the center of the base circle of the two cams and is provided with a sun gear; the two rocker arm blocks are provided with a planetary gear respectively; the two planetary gears are engaged with the sun gear; one rocker arm block is pivoted with two rollers; the two rollers are contacted with the two cams respectively; the transmission connecting rod group is arranged between the two rocker arm blocks to make the two rocker arm blocks actuated synchronously; the input shaft and the output shaft are positioned on the same common axis; and the input shaft is used for driving the two rocker arm blocks to rotate through a planet carrier. Therefore, the stress of the sun gear is uniformly dispersed on the engaged sides of the two planetary gears, so that the dynamic balance of a device can be achieved and the mechanism can be applied to high-speed occasions.

Owner:SUN YAT SEN UNIV

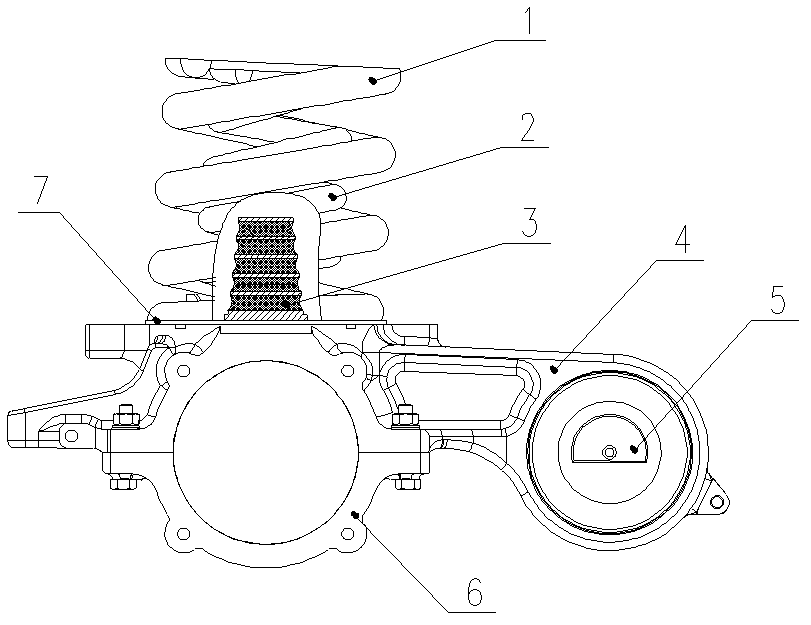

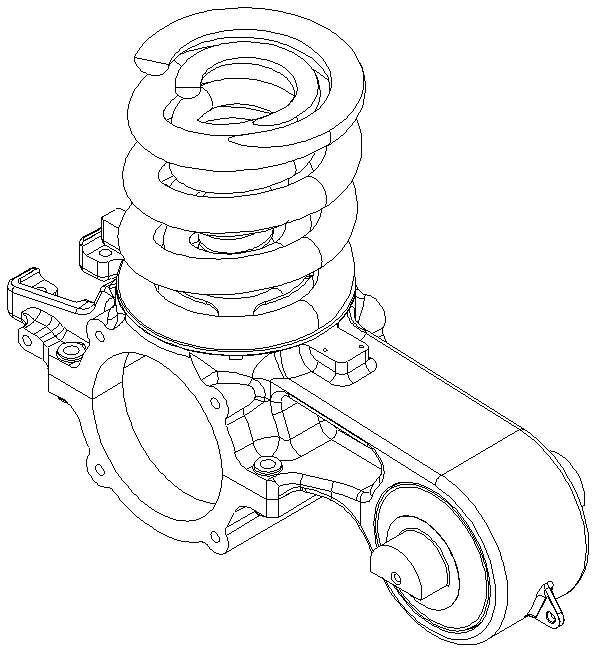

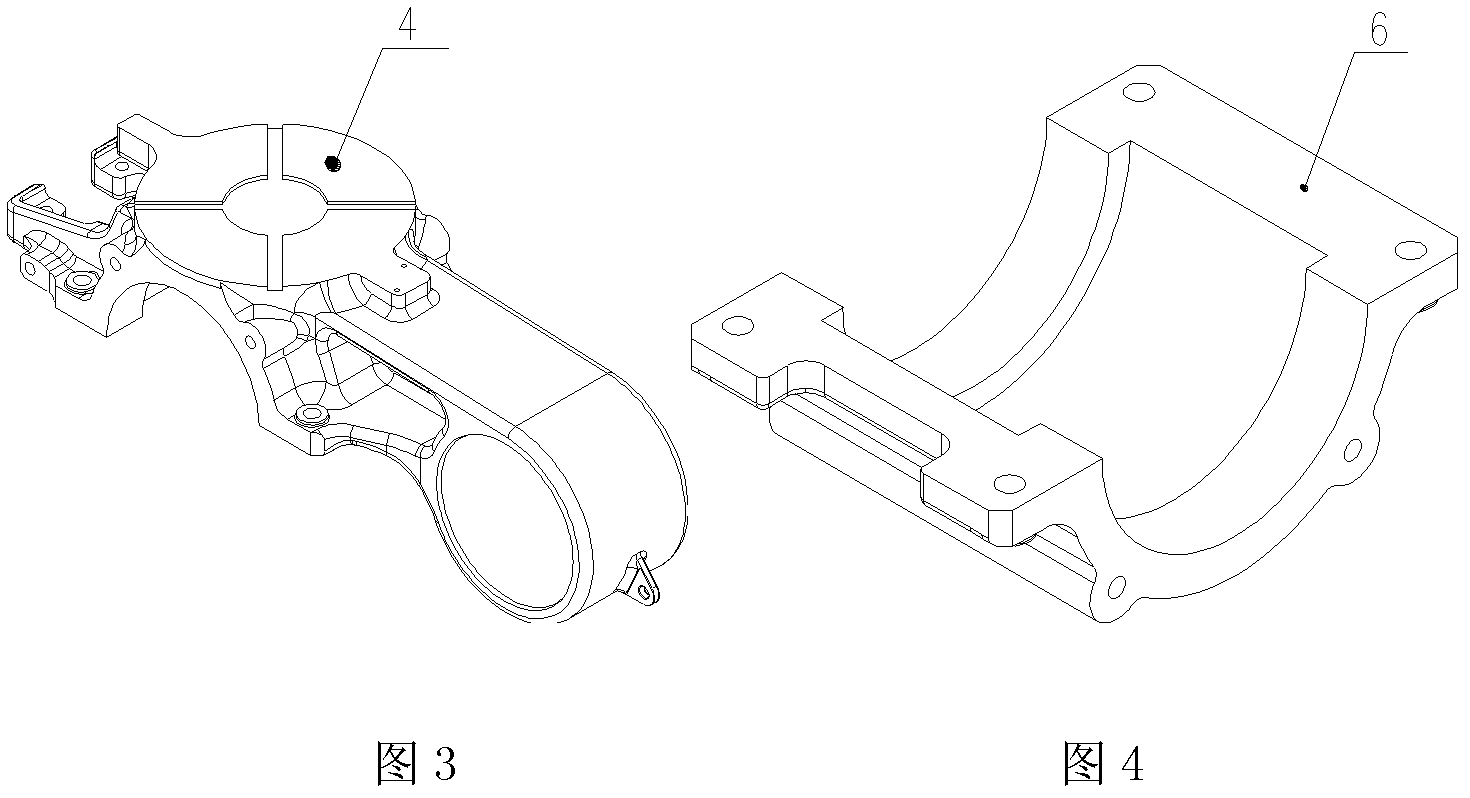

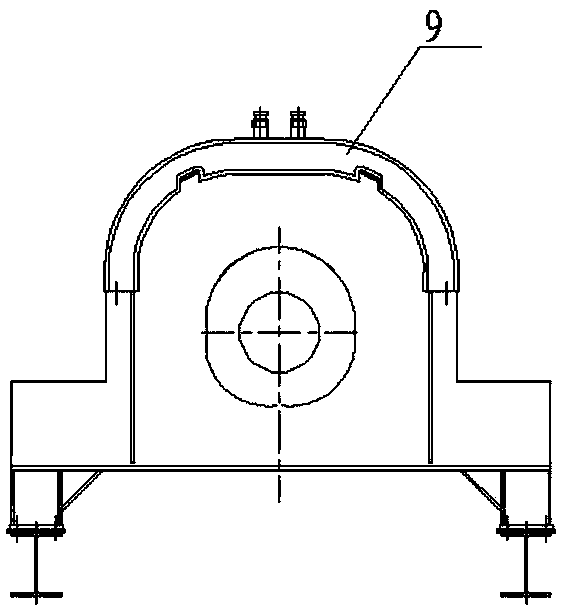

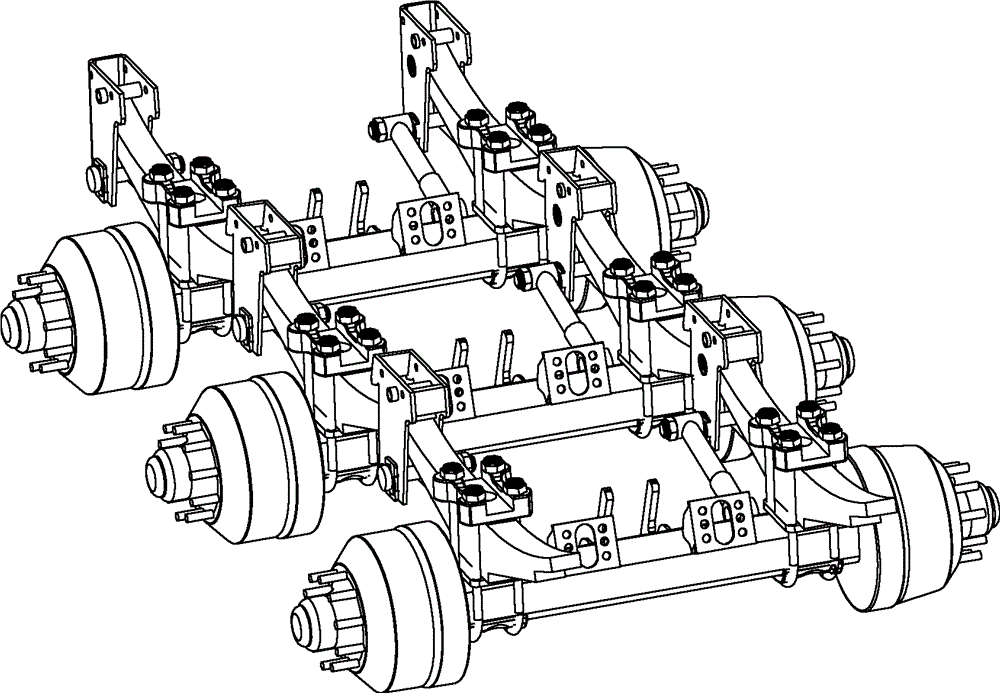

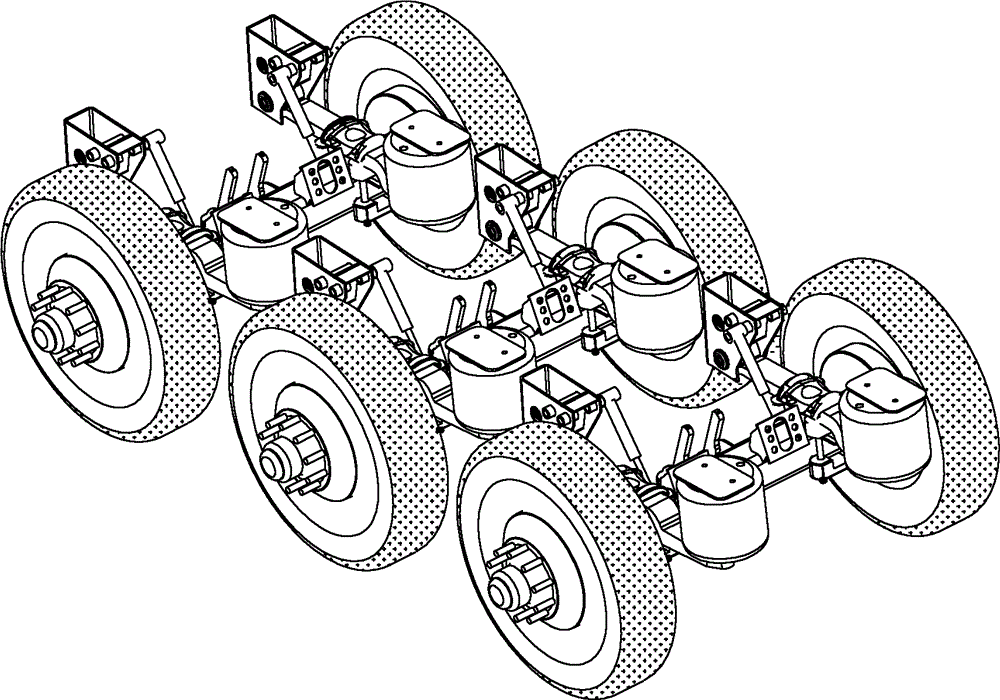

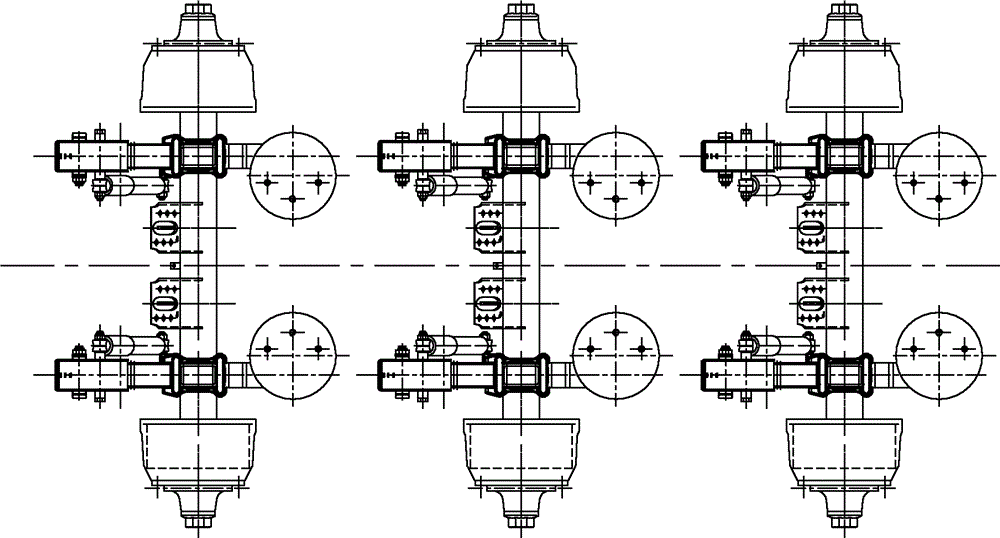

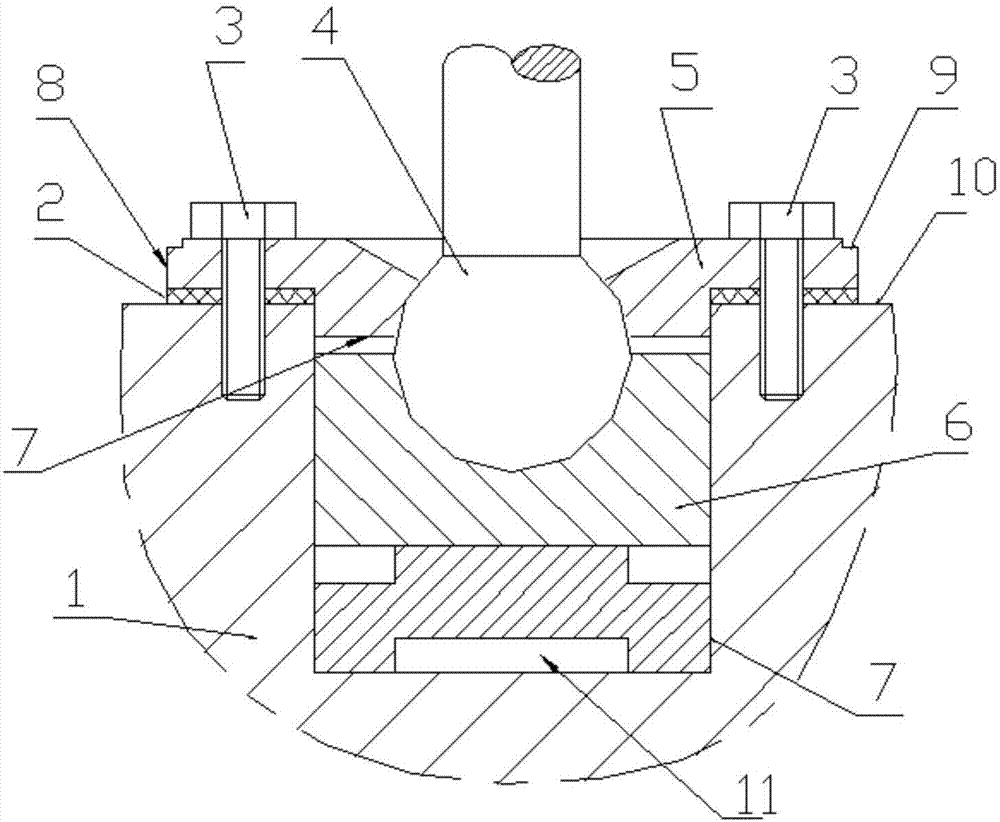

Single-stage suspension device for bogie of high-speed rail wagon

InactiveCN102490752AImprove the state of stressImprove reliabilityAxle-boxes mountingBogieSingle stage

The invention discloses a single-stage suspension device for a bogie of a high-speed rail wagon. The device comprises a rocker arm type shaft box, wherein one end of the shaft box is connected with a wheel set, and the other end of the shaft box is connected with a framework through a rocker arm elastic rubber pitch point; the rocker arm type shaft box has a separated type positioning structure; and the positioning structure of the rocker arm type shaft box specifically comprises an upper shaft box and a lower shaft box which are in butt joint with each other up and down. By the suspension device, the requirement that the highest shaft weight is 18t when the highest speed of the wagon is 200km / h can be met; and the suspension device has the remarkable characteristics of simple structure, convenience for maintenance and reliably performance.

Owner:CRRC SHANDONG CO LTD

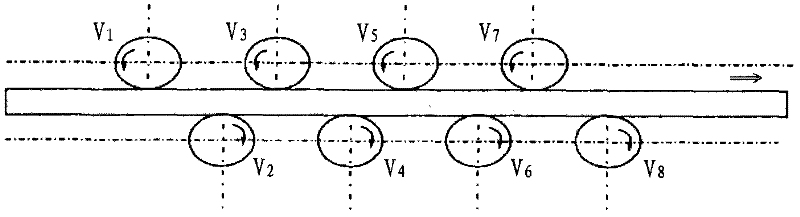

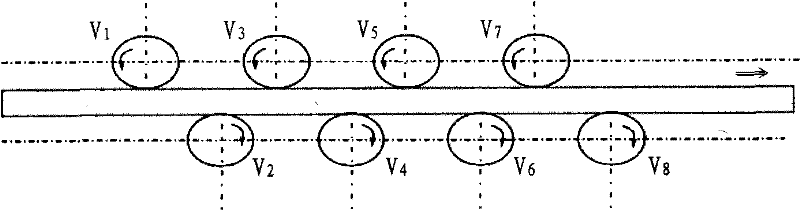

Micro-tension equal-torque metal material straightening method

InactiveCN102172680ANo compressive stressAvoid abnormal wear and tearMetallic materialsInternal stress

The invention provides a micro-tension equal-torque metal material straightening method. In the method, by regulating the linear speeds of all straightening rollers, the liner speeds of the straightening rollers increase gradually in the feeding direction of a metal material under a condition that a metal material straightening process is carried out normally and the torques of the straightening rollers are equal. When the micro-tension equal-torque metal material straightening method provided by the invention is used, the micro-tension and equal-torque straightening of metal materials is realized; therefore, the sudden changes of the torques of the straightening rollers are avoided and the pressure stress and internal stress of the metal materials are avoided, the quality of the metal material is improved, the service life of straightening equipment is prolonged, and the straightening efficiency is improved.

Owner:PANGANG GRP ENG TECH +2

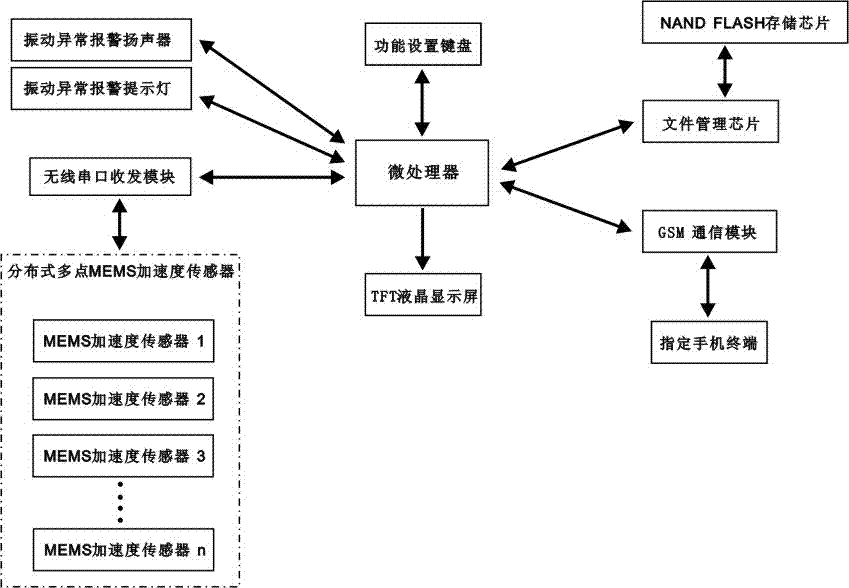

Equipment vibration monitoring system based on multi-point MEMS accelerometer and wireless network

InactiveCN103900678AAvoid resonanceAvoid abnormal wear and tearVibration measurement in solidsTransmission systemsAccelerometerMonitoring system

The invention discloses an equipment vibration monitoring system based on a multi-point MEMS accelerometer and a wireless network. All point location acceleration data of monitored equipment are collected in real time by the system through a distributed multi-point MEMS acceleration sensor, the data are transmitted back to the system through a wireless communication network, comparative analysis is carried out on the data and a preset acceleration threshold value, whether vibration abnormal alarm prompts are triggered or not is judged, and thus the overall vibration state of the monitored equipment can be learnt comprehensively in time. The equipment vibration monitoring system based on the multi-point MEMS accelerometer and the wireless network can effectively solve the problems of equipment sympathetic vibration and equipment abnormal abrasion caused by sudden abnormal vibration of a certain part of the monitored equipment and yield decline caused by the equipment sympathetic vibration and the equipment abnormal abrasion. The equipment vibration monitoring system based on the multi-point MEMS accelerometer and the wireless network is especially suitable for industrial enterprises with production lines and large-scale manufacturing equipment, and is low in cost and high in reliability.

Owner:CHENGDU MICRO ENVIRON ENVIRONMENTAL MONITORING EQUIP

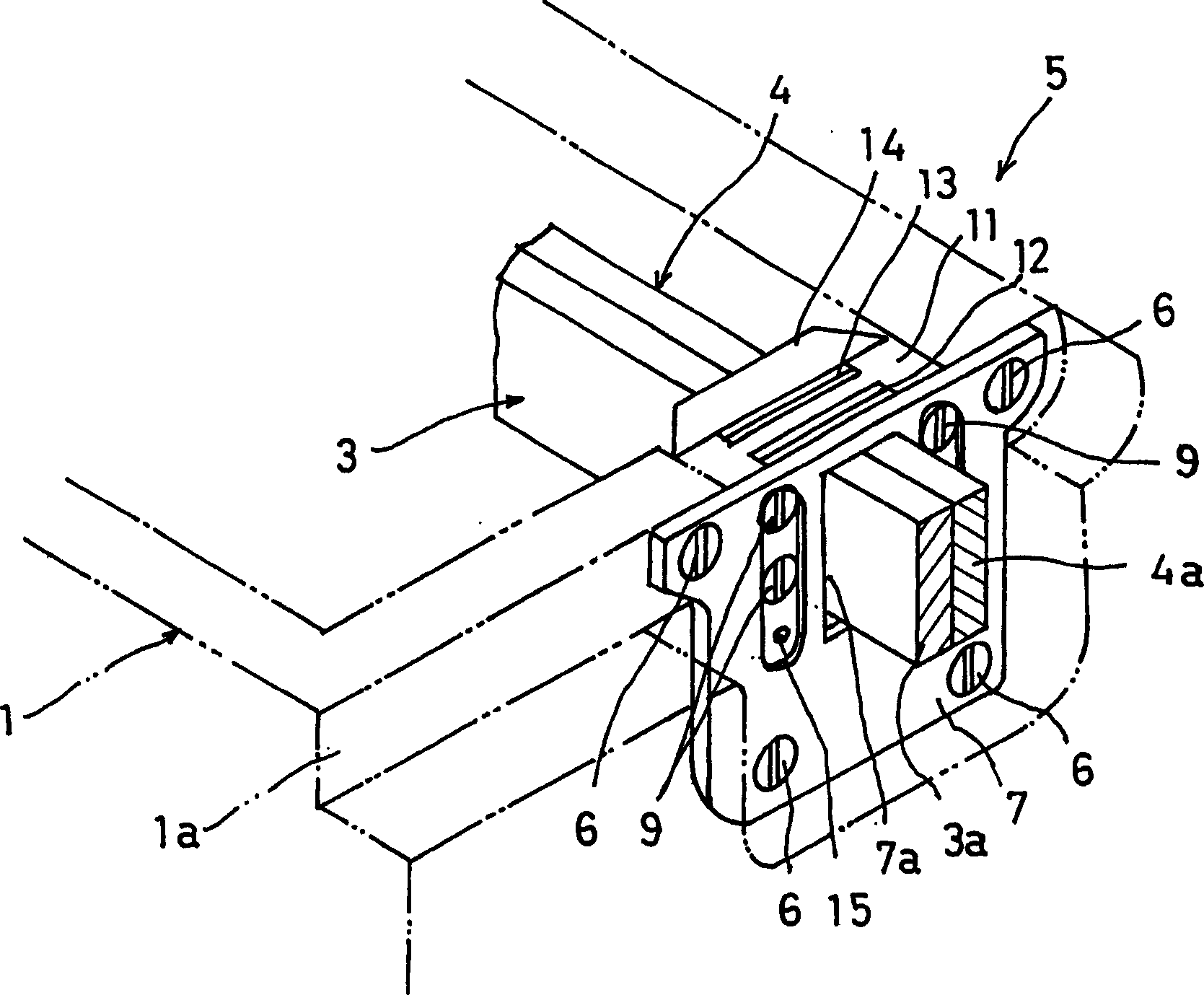

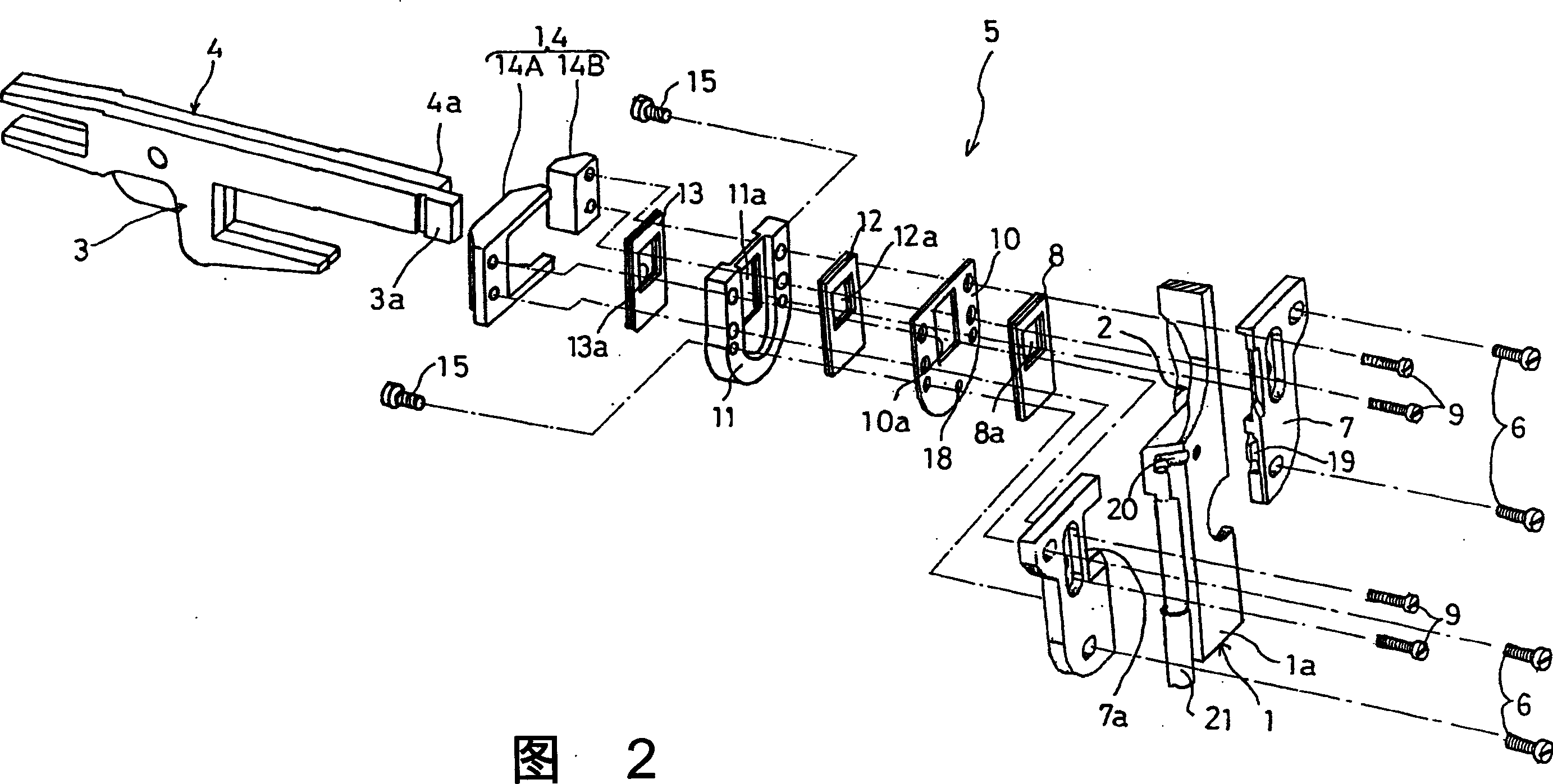

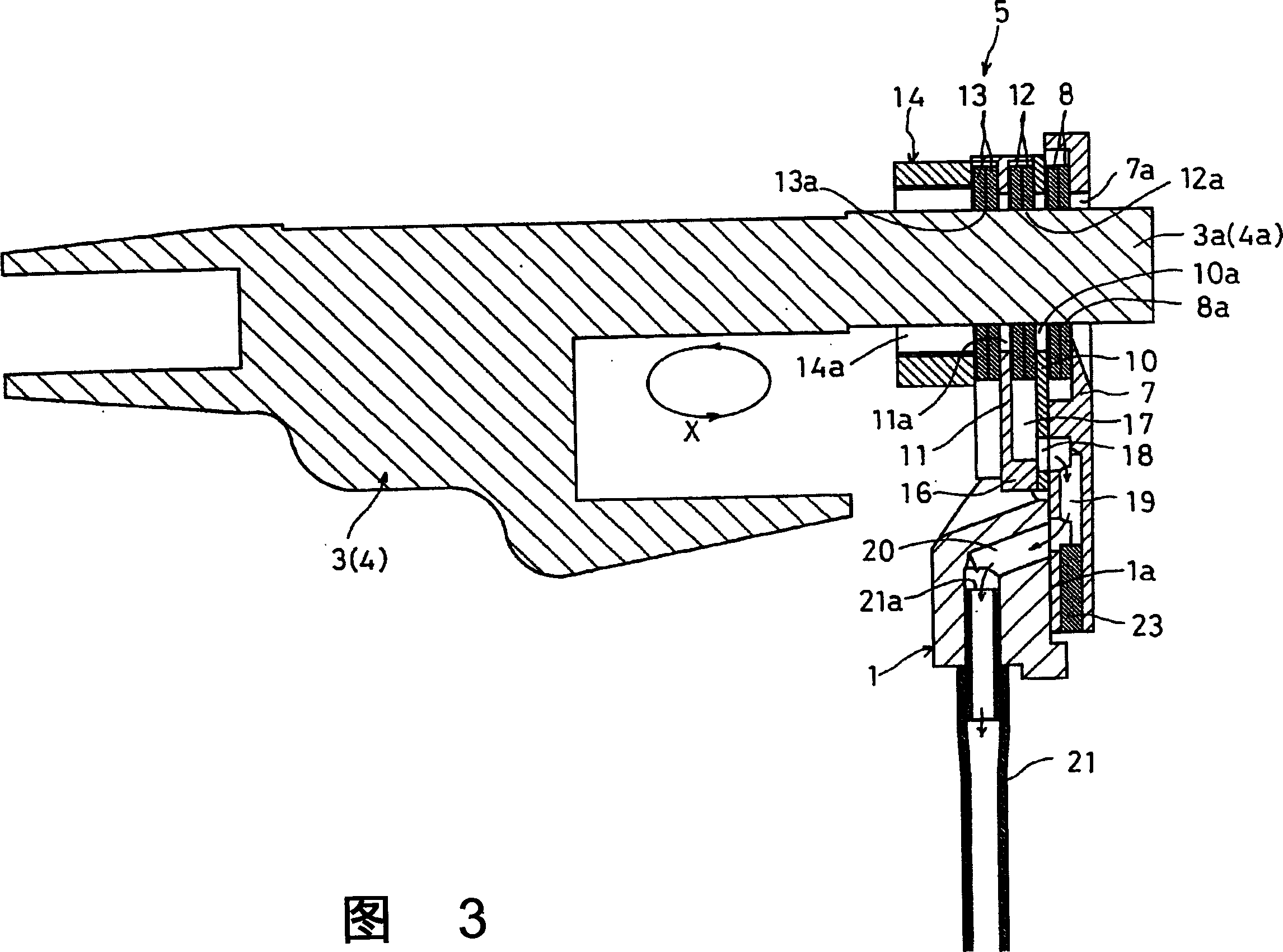

Oil leakage-proof and dust-proof device of sewing machine

InactiveCN1840770AImprove scraping effectPrevent leakageLubrication/cooling devicesLubrication elementsEngineeringLubricant

The invention relates to a structure, wherein the dust-proof flexible sealing plate is clamped between the cloth feeding table guide element fixed to cover the seamer support and the front cloth feeding table sealing guide element; at the same time. between the front cloth feeding table sealing guide element and the back cloth feeding table sealing guide element, between the back cloth feeding table sealing guide element and the sealing compress cover, the first and second flexible sealing plates are clamped for avoid oil leakage; the lubricant scraped by the first flexible sealing plate from the outer circumference of cloth feeding table is stored in oil storage; the stored lubricant via oil recycle tube is recycled; therefore, the invention can realize the effect of lubricant, to avoid staying scraped lubricant; and realize better dust-proof effect.

Owner:YAMATO SEWING MASCH MFG CO LTD

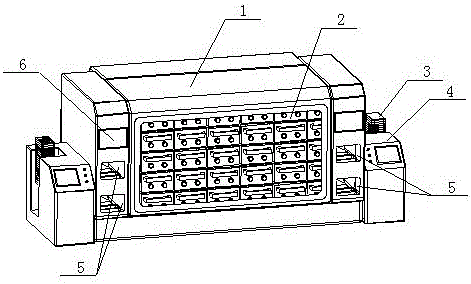

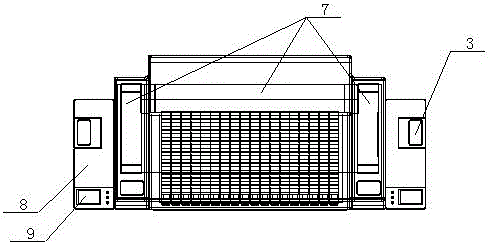

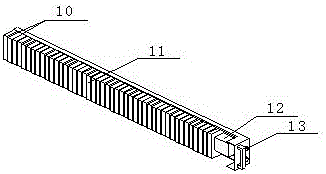

Smart drugstore

InactiveCN106347918AImprove space utilizationLarge storage capacityConveyorsStorage devicesMedicineDrug product

The invention provides a smart drugstore and relates to the technical field of medical apparatuses and instruments. The smart drugstore comprises a drugstore body, wherein a drug outlet system and a storage system are arranged in the drugstore body and are both connected with a drug control unit, horizontal drug storage combined modules are arranged in the storage system, and the storage system adopts dense horizontal modules for drug storage, is maximum in storage and high in space utilization rate and is 2-3 times of a traditional chute type storage system in space utilization rate. The storage system can storage more than 880 drugs, meanwhile can be expanded according to the actual demand, is provided with full-automatic horizontal drug putting manipulators and can arrange storage varieties and quantity according to the actual situation of a hospital. The drug outlet system adopts an overall drug outlet mode, the time for completing a single prescription is 6-8 seconds, and 500-700 prescriptions can be processed per hour. Multiple drug delivery flow channels in the drug outlet system can be freely adjusted as required, and drug storage and drug outlet rationality are ensured.

Owner:广东欧创机器人集团有限公司

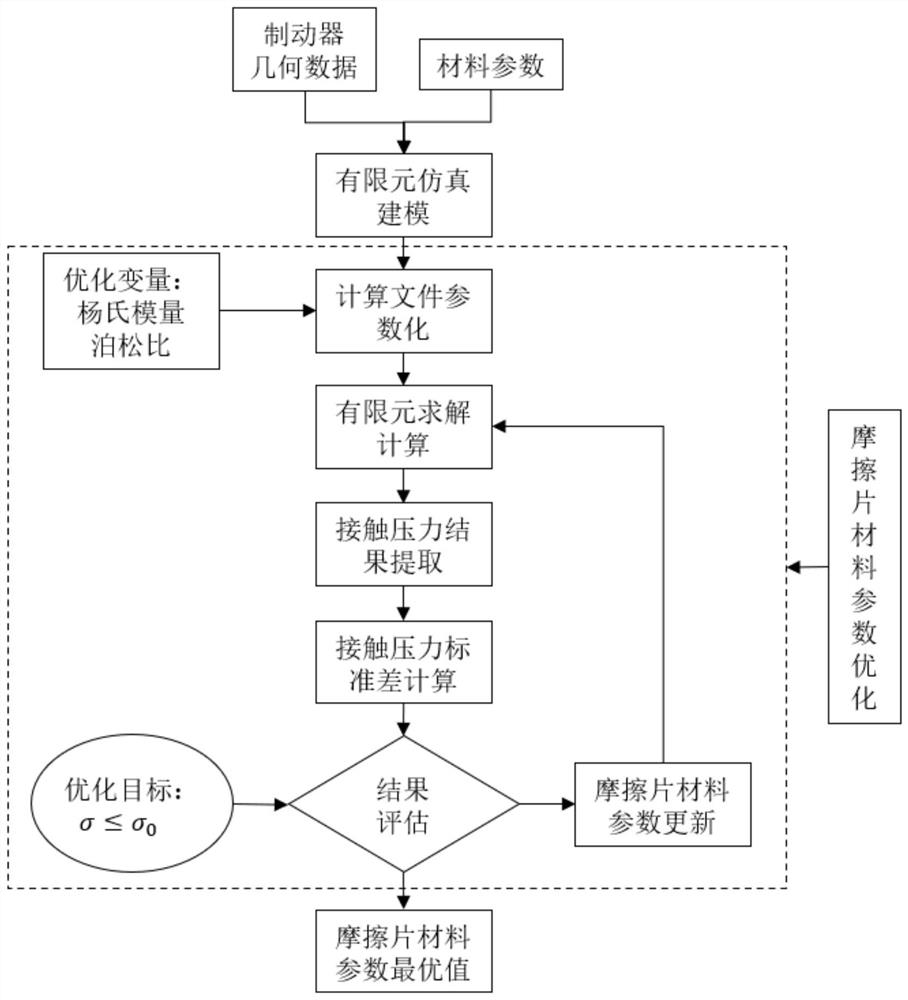

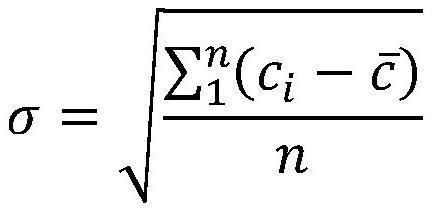

Friction plate optimization method based on contact pressure of friction plate and brake disc

ActiveCN113051802AOptimizing Material ParametersUniform contact pressureGeometric CADDesign optimisation/simulationThermodynamicsElement model

The invention discloses a friction plate optimization method based on contact pressure of a friction plate and a brake disc. The method comprises the following steps: establishing a finite element model according to geometric parameters of a brake and material parameters of each component, and performing static solution on the established finite element model to obtain contact pressure data between the friction plate and the brake disc; according to the contact pressure data between the friction plate and the brake disc in the brake, calculating the standard deviation of the contact pressure of each unit of the friction plate , and when the standard deviation of the contact pressure of each unit of the friction plate is larger than a preset target value, adjusting material parameters of the friction plate in the brake until the standard deviation of the contact pressure of each unit of the friction plate is smaller than or equal to a preset target value. According to the method, the unit contact pressure standard deviation serves as an index for evaluating the uniformity degree of the contact pressure, so that the contact pressure between the brake disc and the friction plate is uniformly distributed as far as possible, and the problems of abnormal abrasion of the brake disc and the friction plate and brake shaking and brake noise caused by the abnormal abrasion are avoided.

Owner:DONGFENG MOTOR GRP

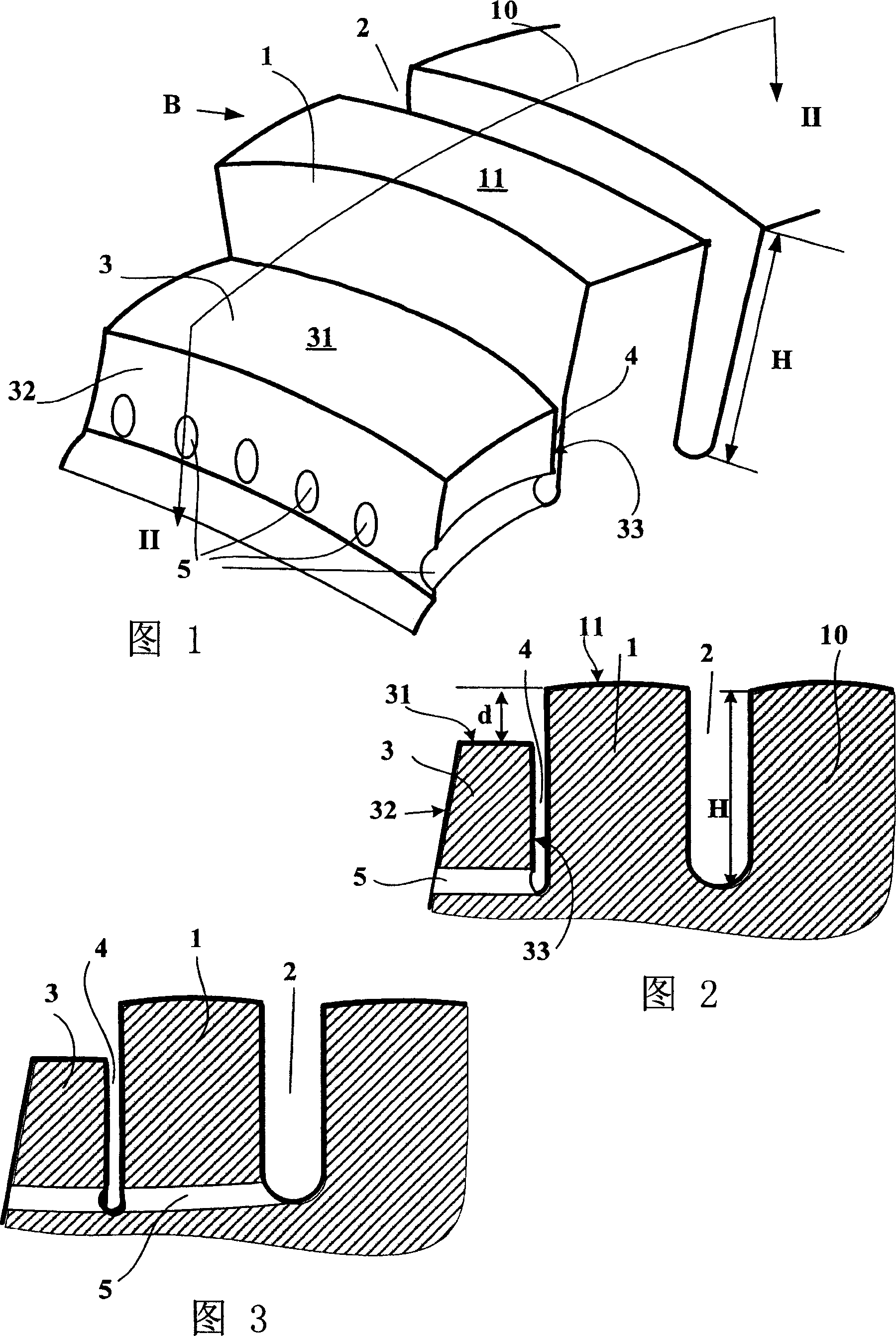

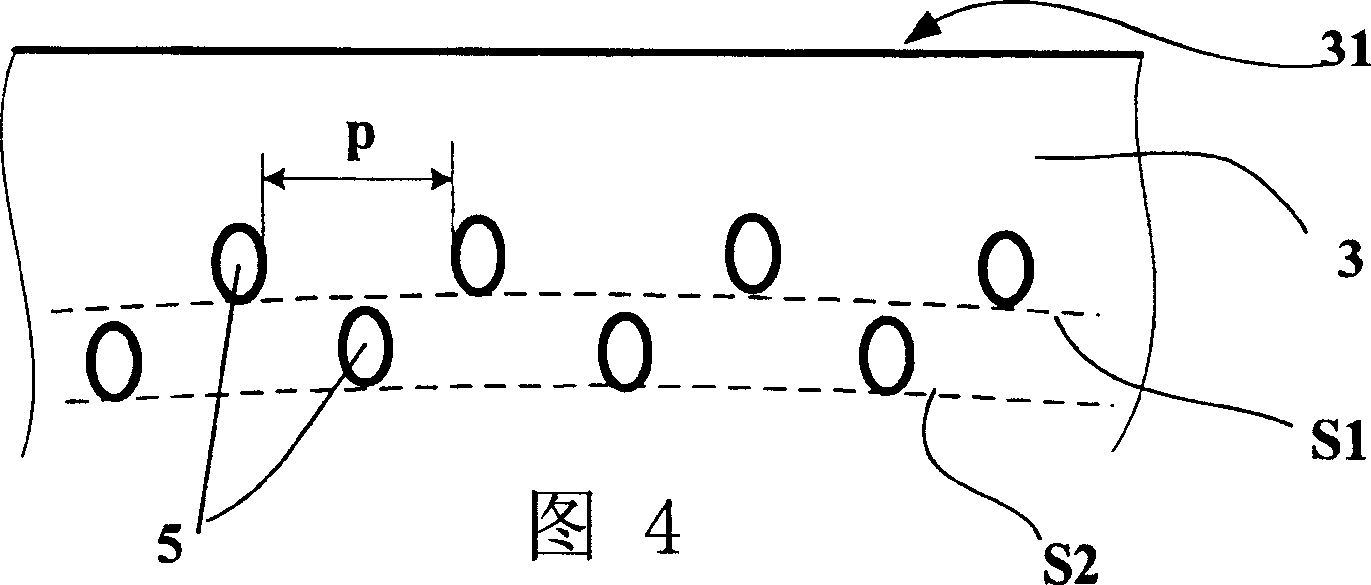

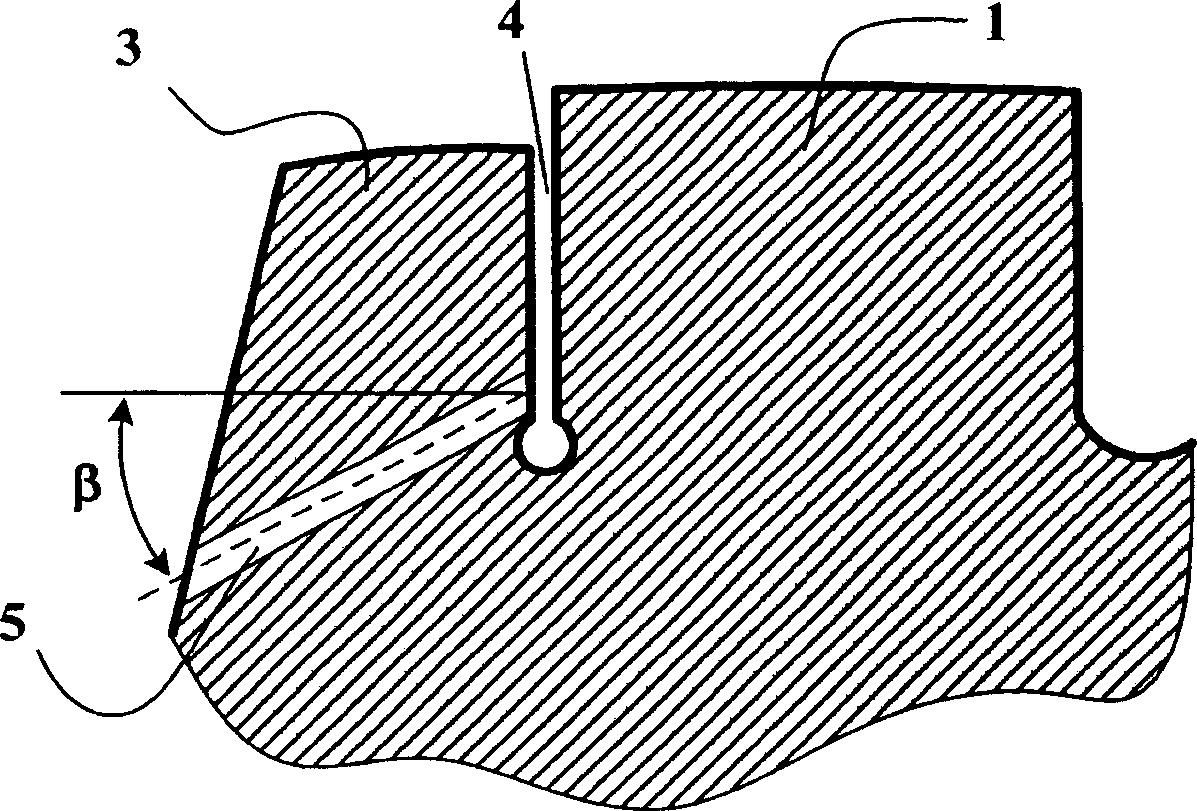

Tread comprising a ventilated device for countering irregular wear

InactiveCN1805857AAvoid abnormal wear and tearReduced compressive strengthTyre tread bands/patternsEngineeringTread

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

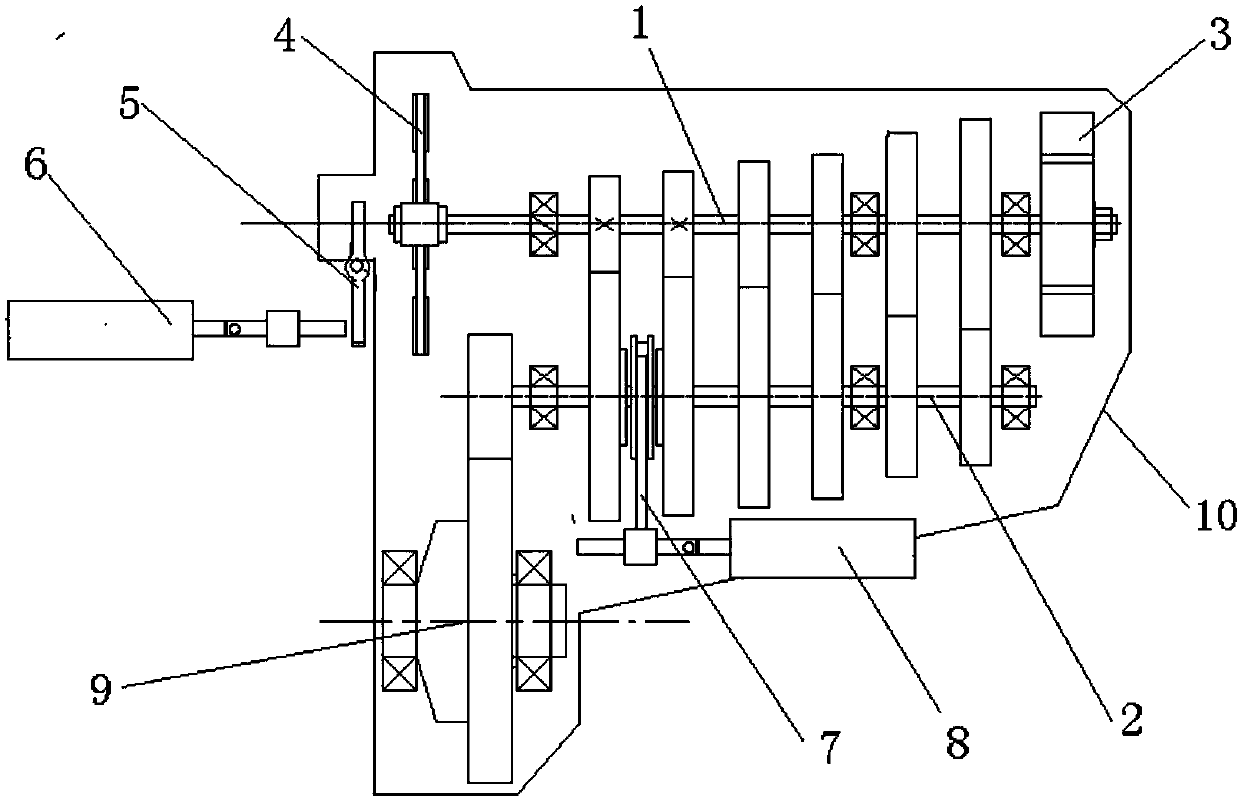

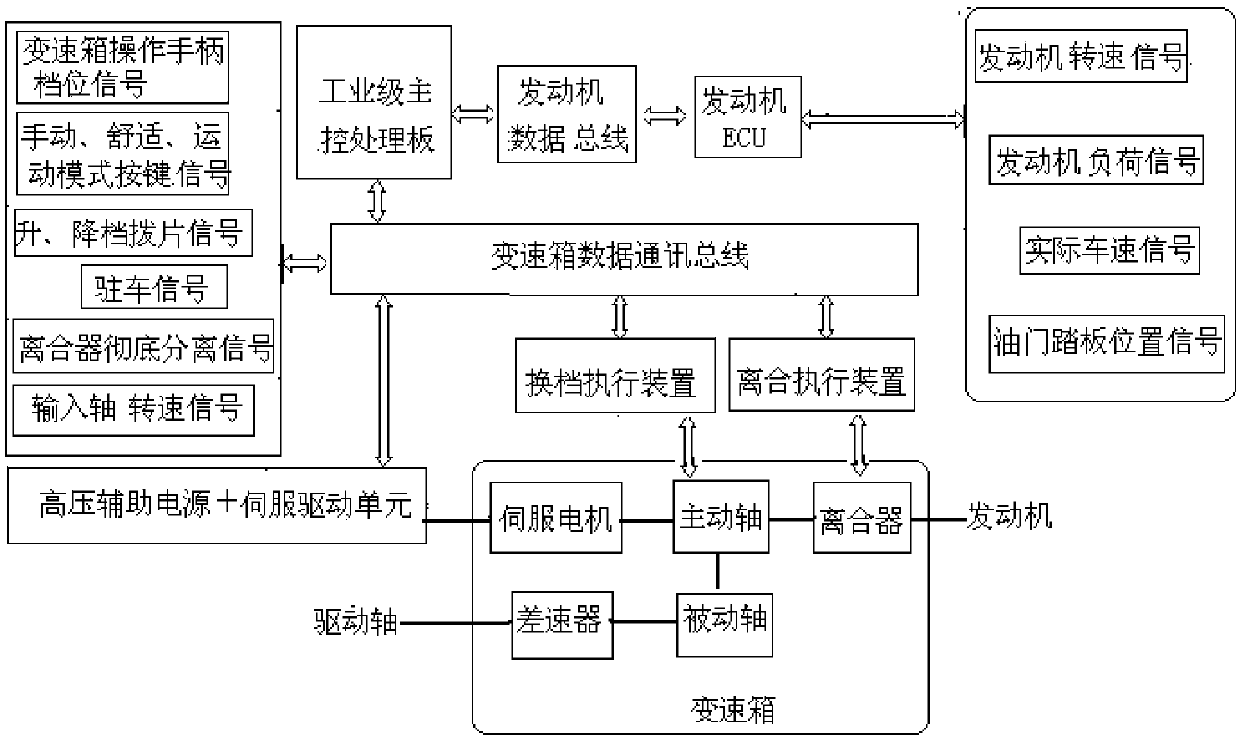

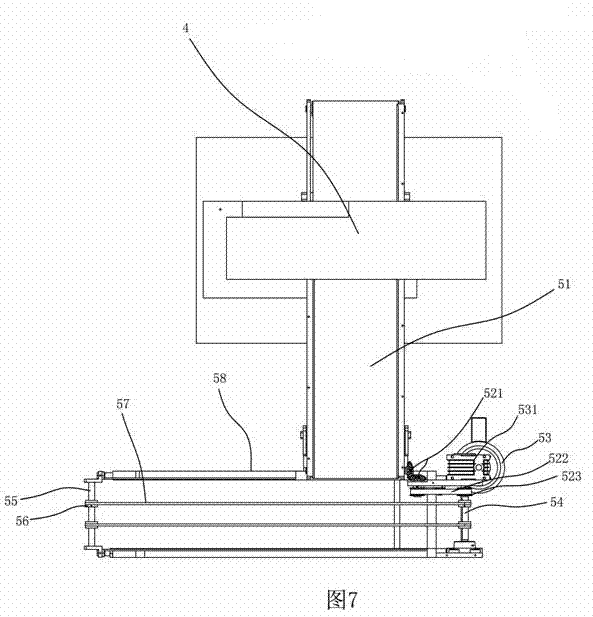

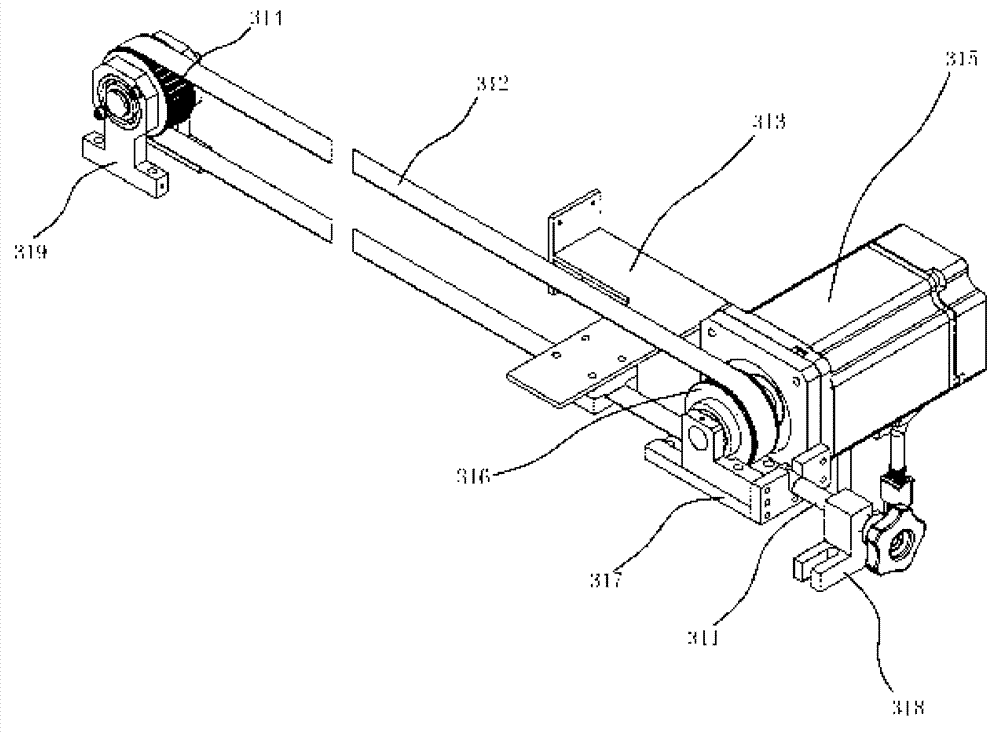

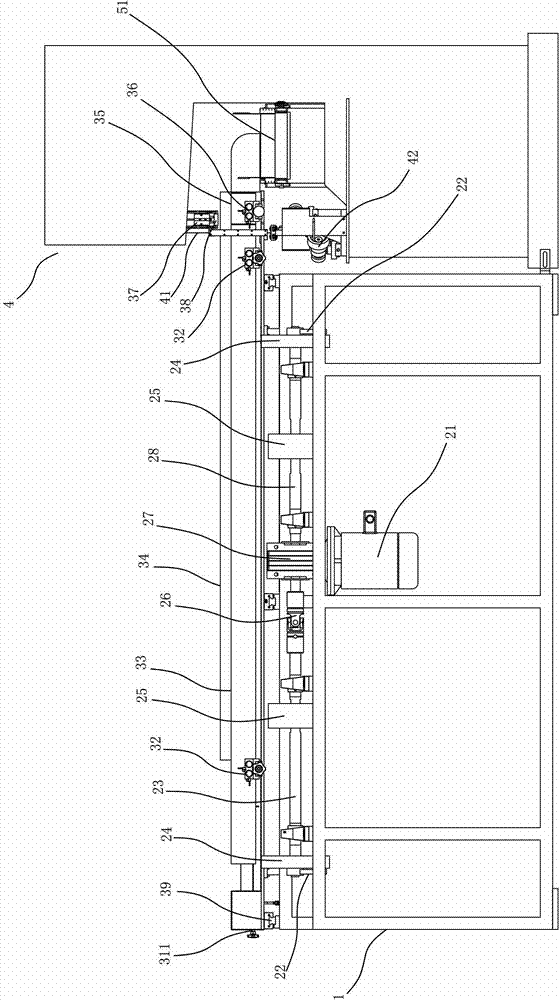

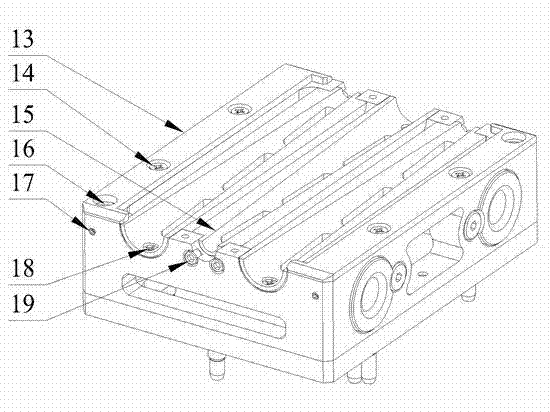

Intelligent automatic speed change system based on manual speed change box and working method thereof

InactiveCN109681625AAvoid abnormal wear and tearAvoid damageControlled membersGearing controlFuel efficiencyWorking set

The invention discloses an intelligent automatic speed change system based on a manual speed change box and a working method thereof. The system comprises a manual speed change box body and an intelligent control device. The intelligent control device is composed of an electromechanical execution part and an intelligent control module part. The electromechanical execution part comprises a speed change execution device, a clutch execution device and a gear shifting execution device. According to the system, by means of combination of all mechanisms, the rapid automatic gear shifting process andthe better gear shifting corresponding characteristic of a car are achieved, thus an engine and the speed change box are at the optimal operation state, good fuel efficiency is obtained, abnormal wear and damage caused by manual operation are avoided, and operation and use efficiency of vehicles are improved.

Owner:SHANDONG UNIV OF SCI & TECH

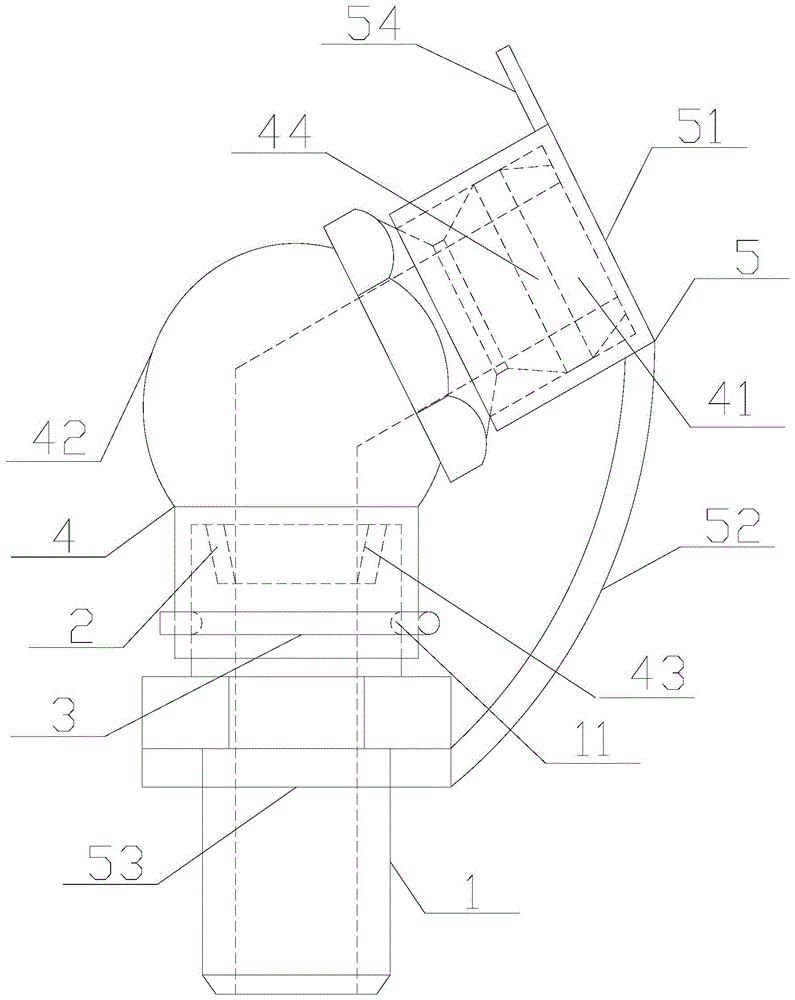

Transmission mechanism with intermittent output action

The invention discloses a transmission mechanism with an intermittent output action, which comprises a conjugate cam group, an output shaft, two rocker arm blocks, a transmission connecting rod group and an input shaft, wherein the conjugate cam group comprises two cams; the output shaft is pivoted in the center of the base circle of the two cams and is provided with a sun gear; the two rocker arm blocks are provided with a planetary gear respectively; the two planetary gears are engaged with the sun gear; one rocker arm block is pivoted with two rollers; the two rollers are contacted with the two cams respectively; the transmission connecting rod group is arranged between the two rocker arm blocks to make the two rocker arm blocks actuated synchronously; the input shaft and the output shaft are positioned on the same common axis; and the input shaft is used for driving the two rocker arm blocks to rotate through a planet carrier. Therefore, the stress of the sun gear is uniformly dispersed on the engaged sides of the two planetary gears, so that the dynamic balance of a device can be achieved and the mechanism can be applied to high-speed occasions.

Owner:SUN YAT SEN UNIV

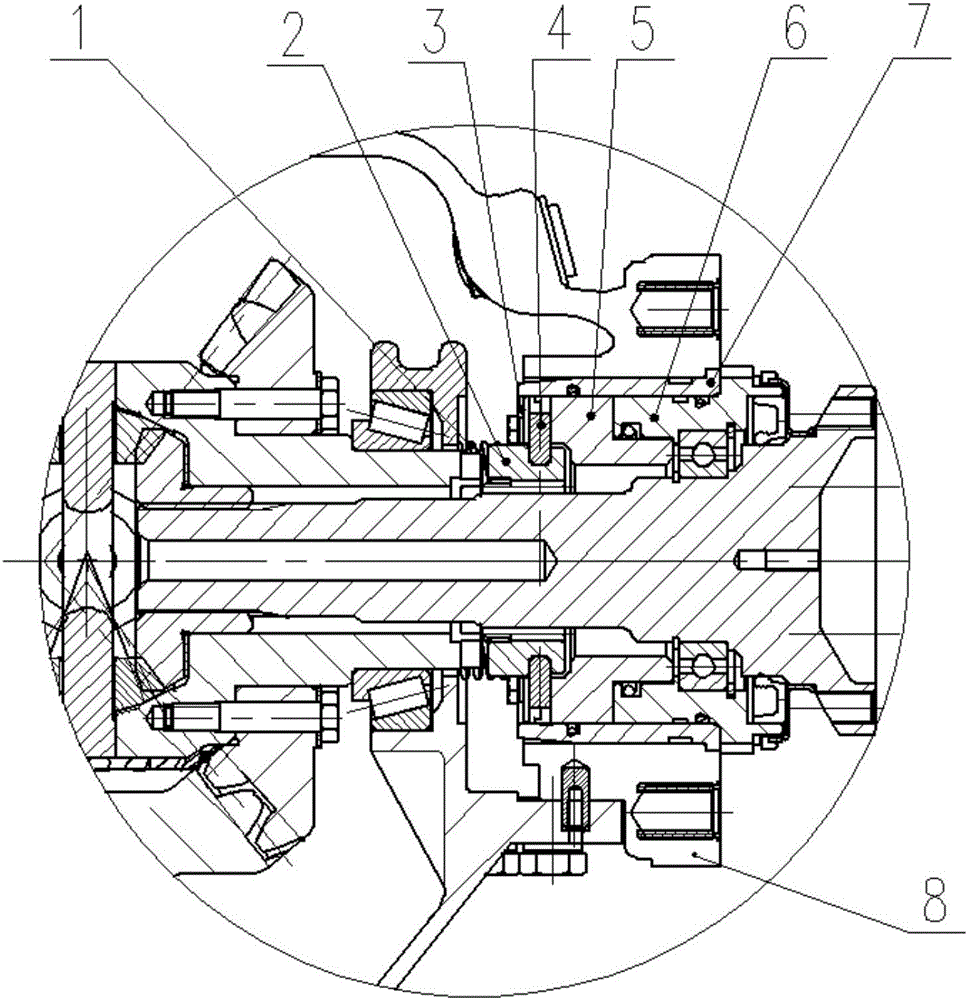

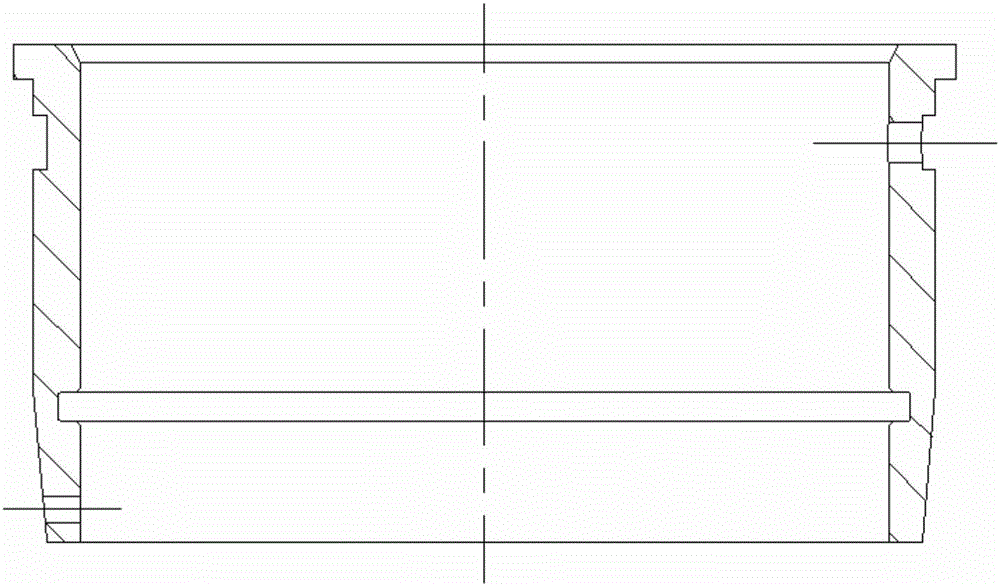

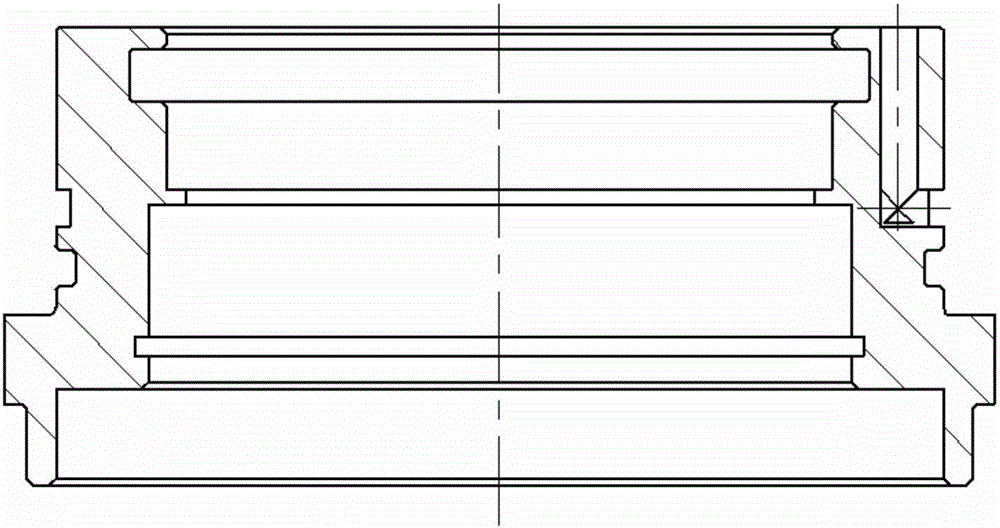

Air hammer with double-rod piston

The invention discloses an air hammer with a double-rod piston. The air hammer comprises a cylinder, wherein a cylinder cover is arranged on the cylinder; a piston, a piston pin and a connecting rod are arranged inside the cylinder; the piston pin is arranged below the piston; the connecting rod is connected with the piston pin; a lower guide sleeve is arranged around the connecting rod; a crank and a crankshaft are connected at the other end of the connecting rod; an upper guide sleeve is arranged in the cylinder cover and comprises a guide hole and a sealing device installed on the lower part inside the guide hole; and an upper piston rod is connected above the piston and penetrates through the guide hole and extends out of the cylinder cover. The air hammer has the following beneficial effects that abnormal wear is avoided, thus prolonging the service lives of the piston and the cylinder and prolonging the service life of the air hammer.

Owner:海安县威仕重型机械有限公司

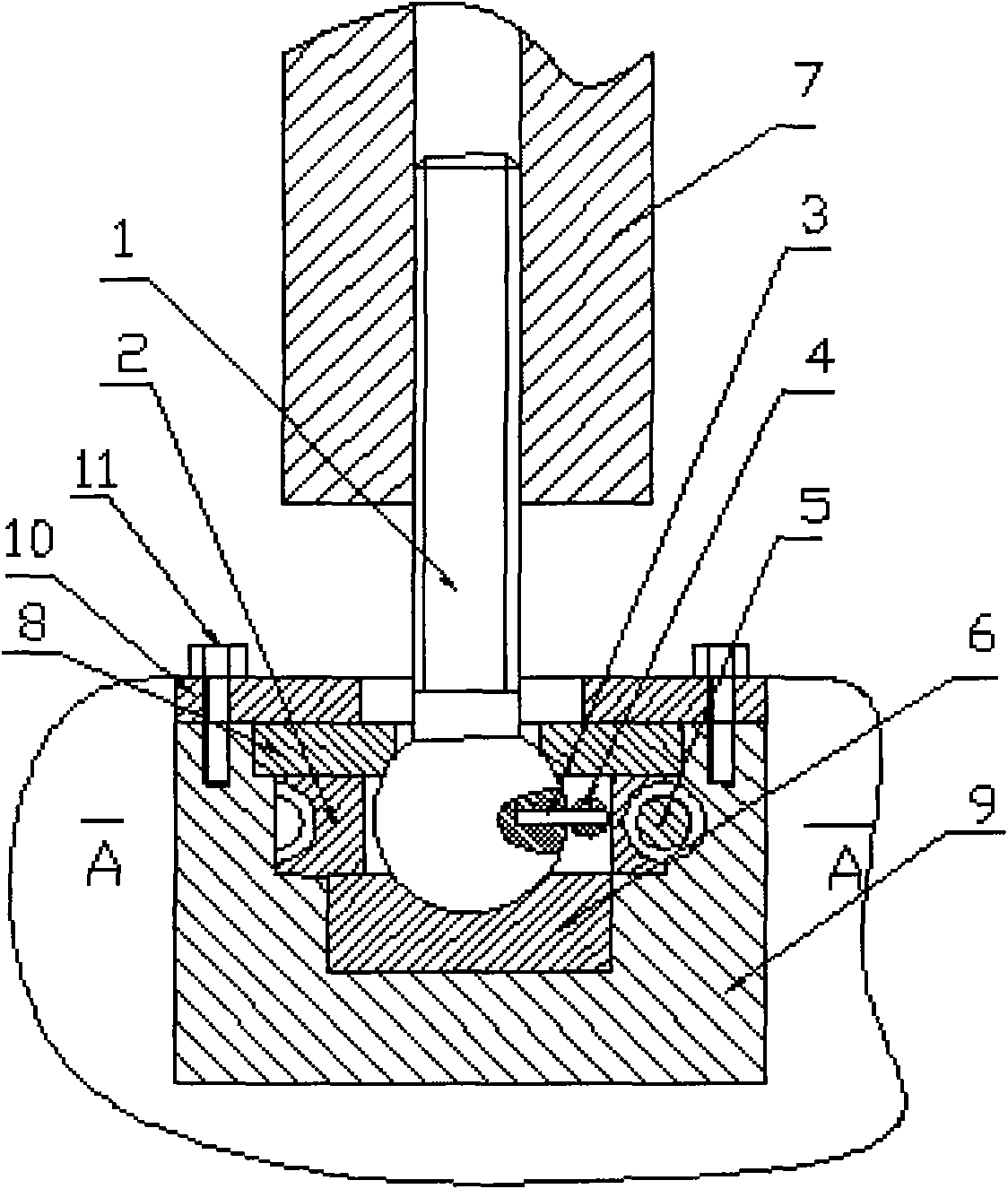

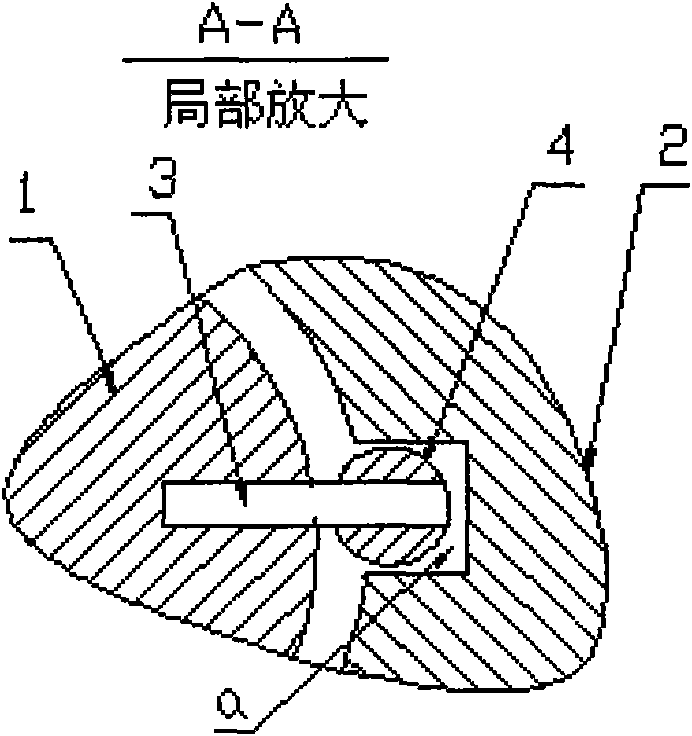

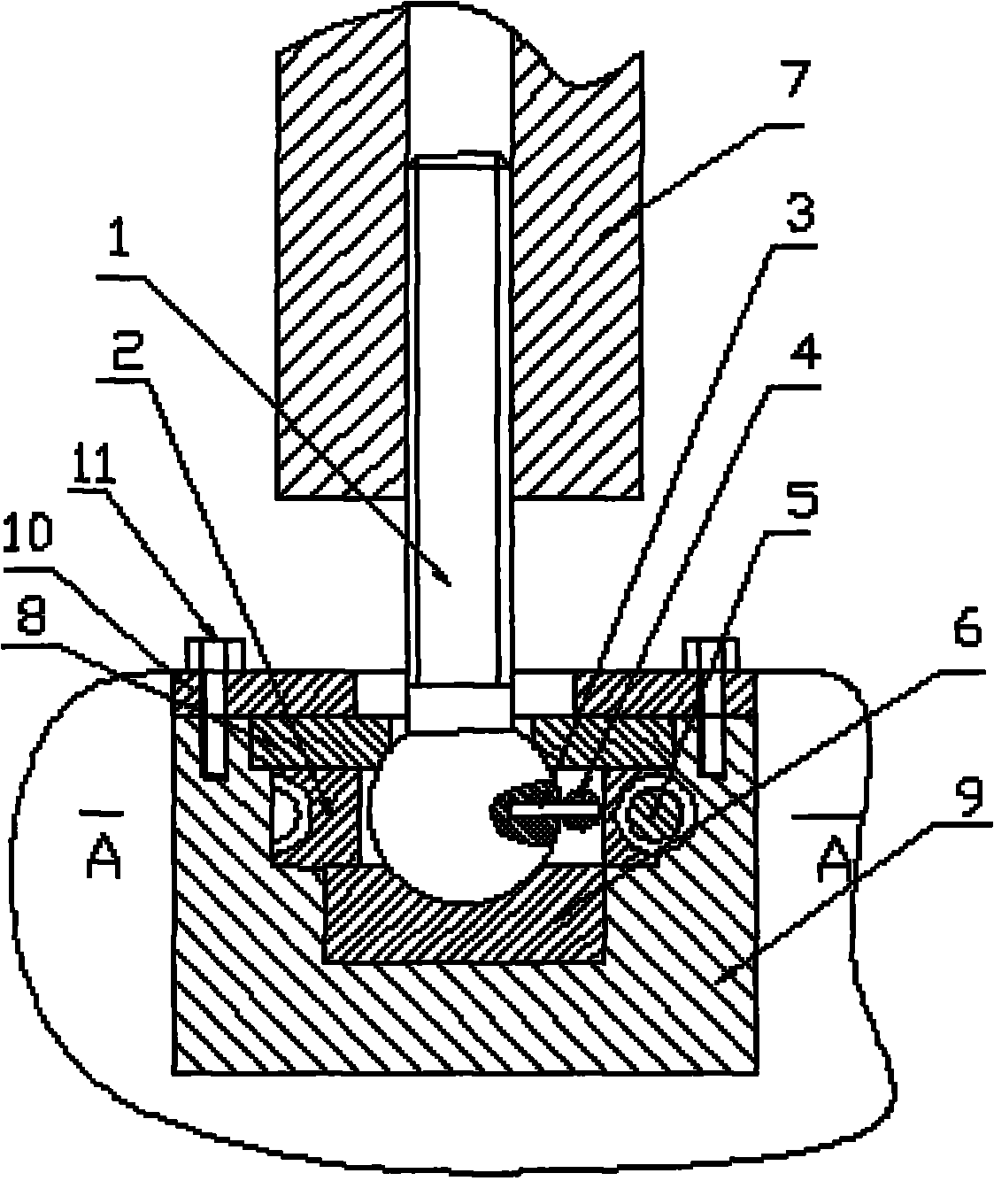

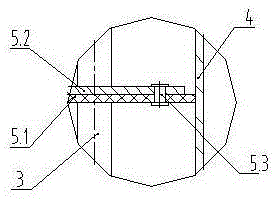

Connecting device of bulb lead screw and worm gear

Provided is a connecting device of a bulb lead screw and a worm gear. A lower ball bowl is installed at the bottom of a turbine box, a worm is installed at the position of the upper middle portion of the turbine box, a turbine is installed in a cavity of the turbine box, the turbine is correctly meshed with the worm, a locating pin is installed in a bulb blind hole of the bulb lead screw, simultaneously a joint ball is installed on the locating pin protruding out of a ball, the joint ball right faces to a notch on the turbine, the ball of the bulb lead screw penetrates through a middle hole of the turbine to be installed on a ball bowl portion of the lower ball bowl, an upper ball bowl penetrates through the upper portion of the bulb lead screw to be installed on the turbine box, a pressing and covering board is installed on the turbine box, simultaneously the pressing and covering board is fixed through a bolt, and finally a connecting rod is installed on the bulb lead screw.

Owner:赵守永

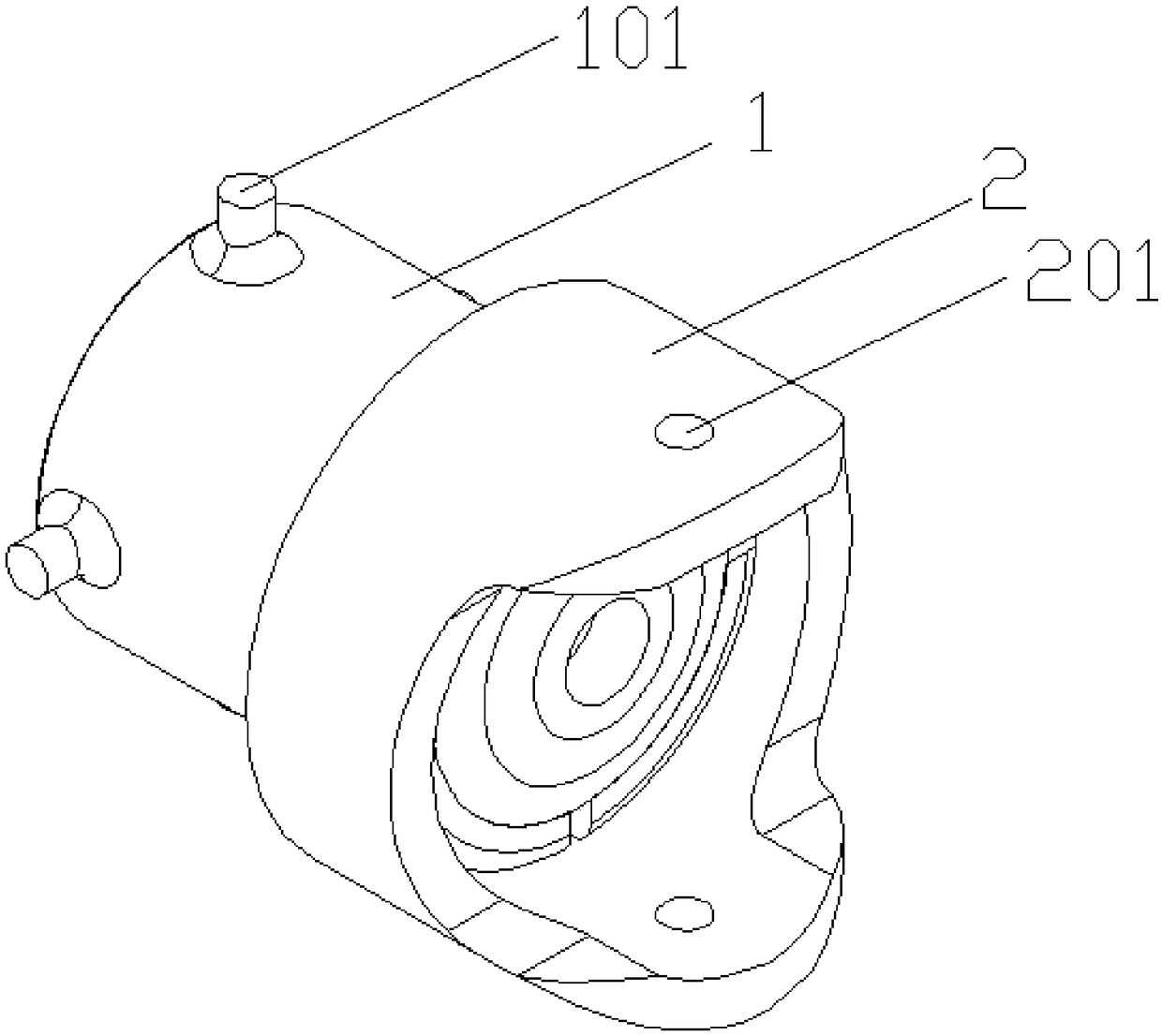

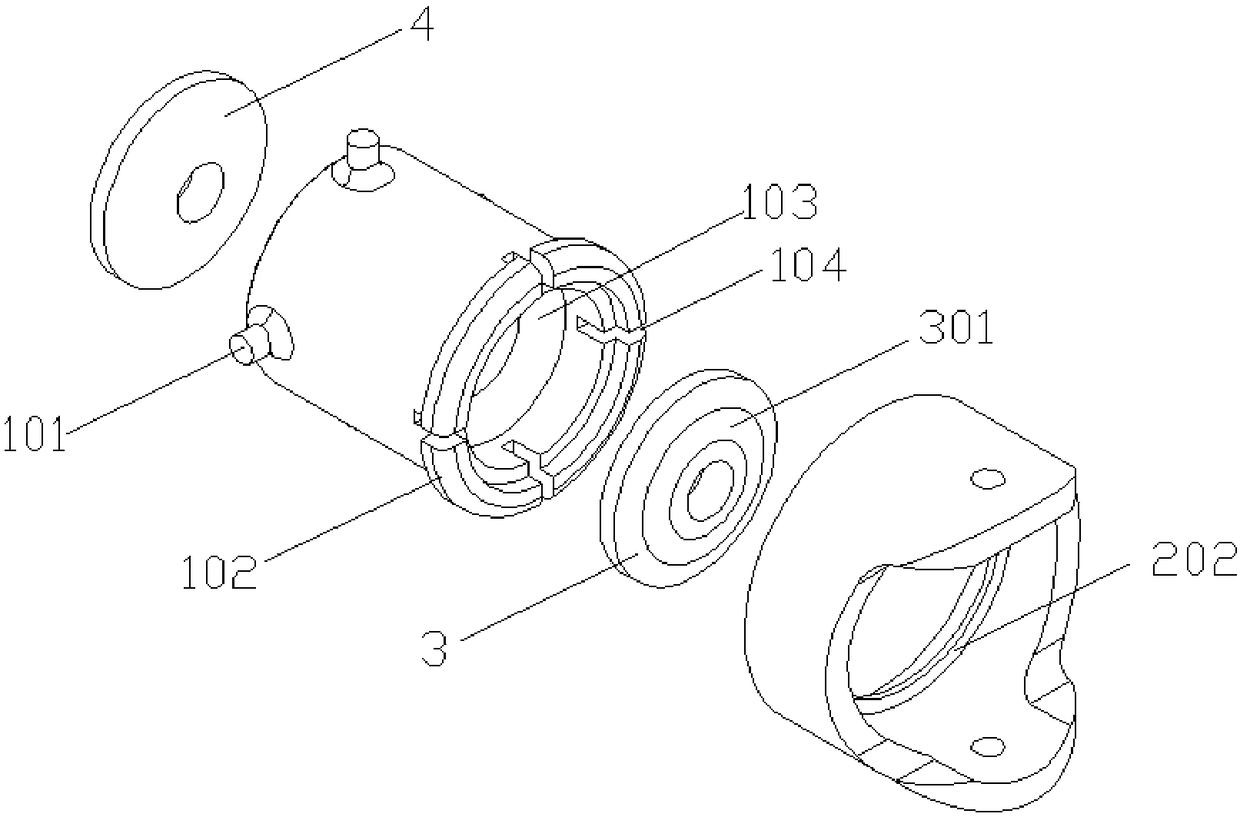

Sleeve shaft type differential locking mechanism

InactiveCN106678329AGood effectRealize the locking functionDifferential gearingsLocking mechanismPiston

The invention provides a sleeve shaft type differential locking mechanism. The locking mechanism is arranged on a half shaft in a drive axle and connected with a differential shell, and comprises a spring, a chain wheel, a chain wheel bracket for fixing the chain wheel, a slide block, a piston, a bearing base and a steel sleeve arranged on the outer sides of the parts, which are arranged in the same one axial direction in sequence; and the chain wheel and the piston, the piston and the bearing base, and the piston and the steel sleeve are all coaxial. The locking mechanism adopts a more compact structure to realize a differential locking function, prevents the structure of projecting such devices as a poking fork on the side surface of an output end, reduces the total size of the drive axle, radially positions the piston and the steel sleeve through dowel pins, and prevents the piston from rotating in the working process to cause abnormal wear.

Owner:CHINA NORTH VEHICLE RES INST

Novel structure for connecting ball screw and worm gear

InactiveCN101863135ACausing gnawingAvoid abnormal wear and tearToothed gearingsPressesUpper jointBall screw

The invention discloses a novel structure for connecting a ball screw and a worm gear, which connects the ball screw and the worm gear in a way that: a lower ball cup is arranged at the bottom of a worm gear case; a worm is arranged at a proper position on the worm gear case; the worm gear is correctly arranged in a cavity of the worm gear case in a way that the worm gear is ensured to be correctly meshed with the worm; a positioning pin is arranged in a blind hole of a ball part of the ball screw; simultaneously an upper joint ball body is arranged on the positioning pin on the protruded ball part, and is aligned with a nick on the worm gear; the ball part of the ball screw passes through a centre hole of the worm gear to be arranged on a ball cup part of the lower ball cup; an upper ball cup passes through the upper part of the ball screw and is correctly arranged on the worm gear case; a pressure cover plate is arranged on the worm gear case and is simultaneously fixed by bolts; and finally a connecting rod is arranged on the ball screw.

Owner:尹克善

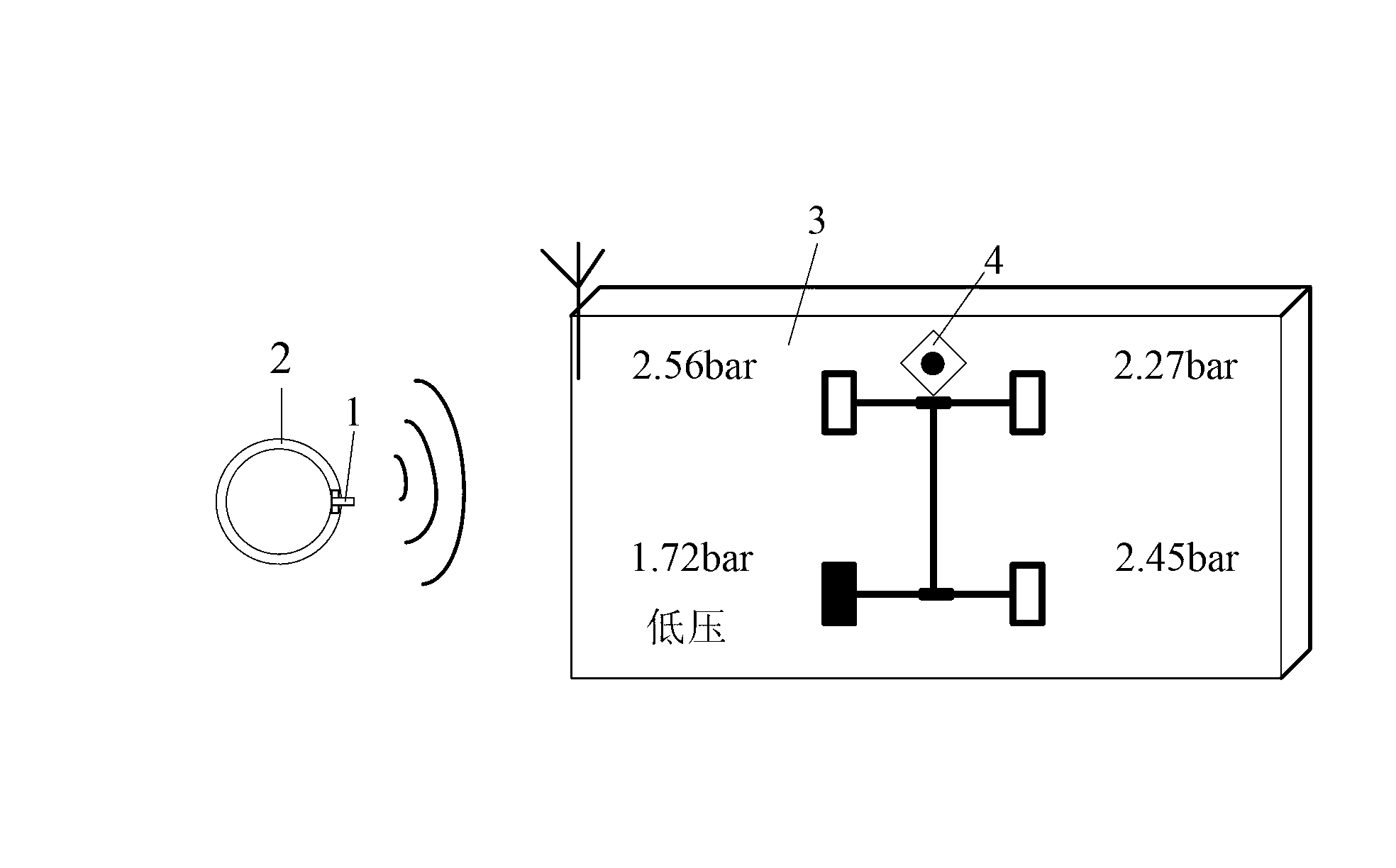

Tire pressure monitoring system self-adapted to altitude

InactiveCN103303078APrevent tire blowoutAvoid tire damageTyre measurementsRadio frequencyDriving safety

The invention provides a tire pressure monitoring system self-adapted to altitude. The tire pressure monitoring system at least comprises a sensor module, a receiver and an air pressure sensor, wherein the sensor module is arranged inside a tire; the receiver is mounted in a cab; the sensor module and the receiver are in communication connection in a wireless radio frequency manner; the air pressure sensor is connected with the receiver. According to the tire pressure monitoring system disclosed by the invention, an accurate tire pressure value can be obtained through correcting an absolute pressure value of the tire, so that the accurate monitoring of the tire pressure is realized and the driving safety is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

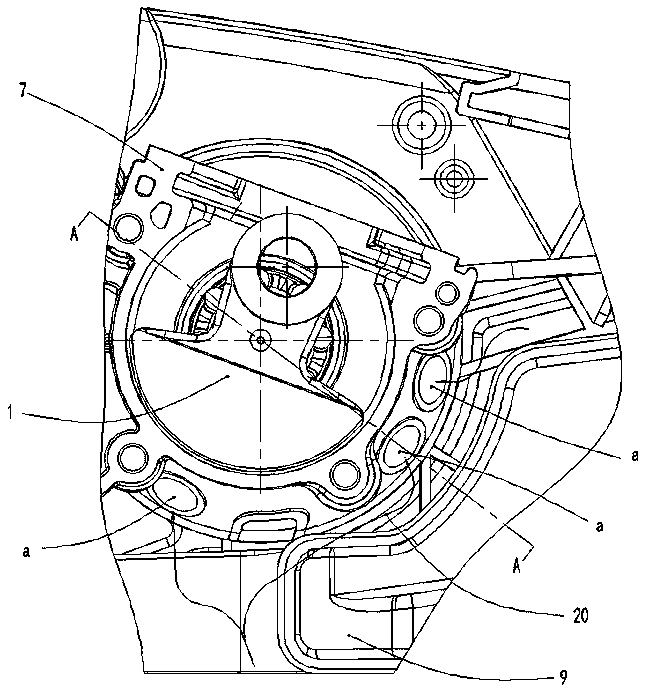

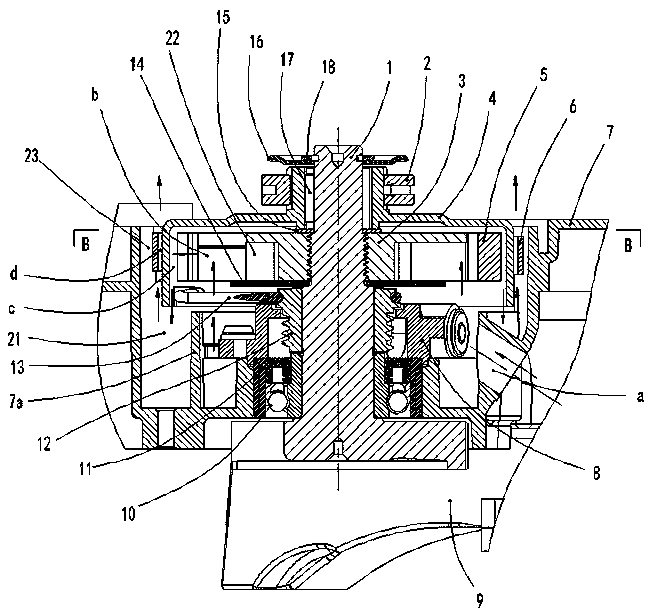

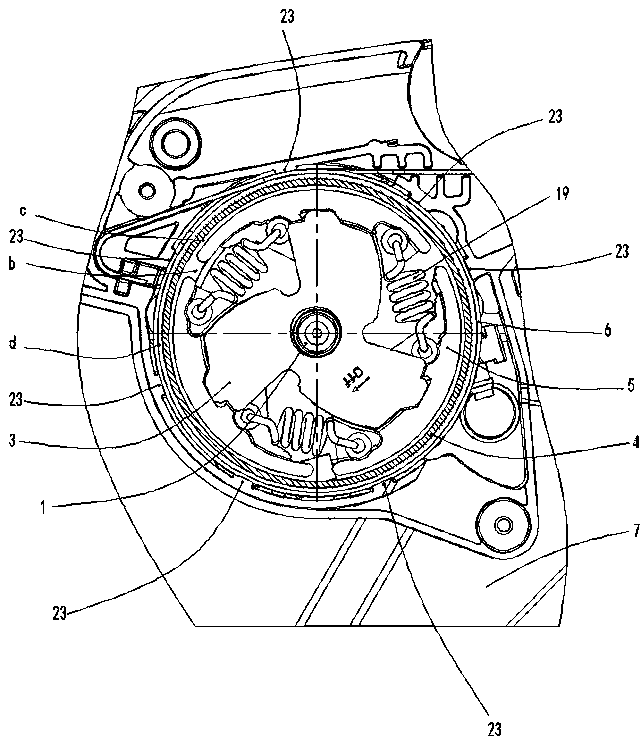

Chain saw separation and connection device air-cooling device

PendingCN110587724AReduce the temperatureImprove cooling effectFriction clutchesChain sawsClutchAir volume

The invention discloses a chain saw separation and connection device air-cooling device comprising a right box body, a right crank, a holder, shoe blocks, a separation and connection device shell anda brake band. The right crank is installed on the right box body. The holder is fixed to the right crank. The separation and connection device shell is arranged on the right crank. The brake band is arranged on the separation and connection device shell in a sleeving manner. The shoe blocks are correspondingly arranged on the holder, connected with one another through separation and connection device springs and limited in the separation and connection device shell through an outer cover of the separation and connection device shell. Right box air inlet holes are formed in the right box body.An annular flow guide piece is arranged at the bottom of a separation and connection device chamber of the right box body. An annular jet flow passageway is formed by the annular flow guide piece andthe outer wall of the separation and connection device chamber. The outer cover of the separation and connection shell corresponds to the center position of the annular jet flow passageway. An air volume regulation piece is installed on the portion, on the lower portion of the holder, on the right crank. After the structure is adopted, the chain saw separation and connection device air-cooling device has the advantages of being simple and reasonable in structure, good in cooling effect, high in saw cutting efficiency, low in service life and capable of blowing internal sawdust and the like.

Owner:ZHEJIANG ZHONGJIAN TECH

Paper roll slitter machine

ActiveCN103042554BQuick cutImprove cutting efficiencyMetal working apparatusDrive shaftPulp and paper industry

Owner:杭州海纳机械有限公司

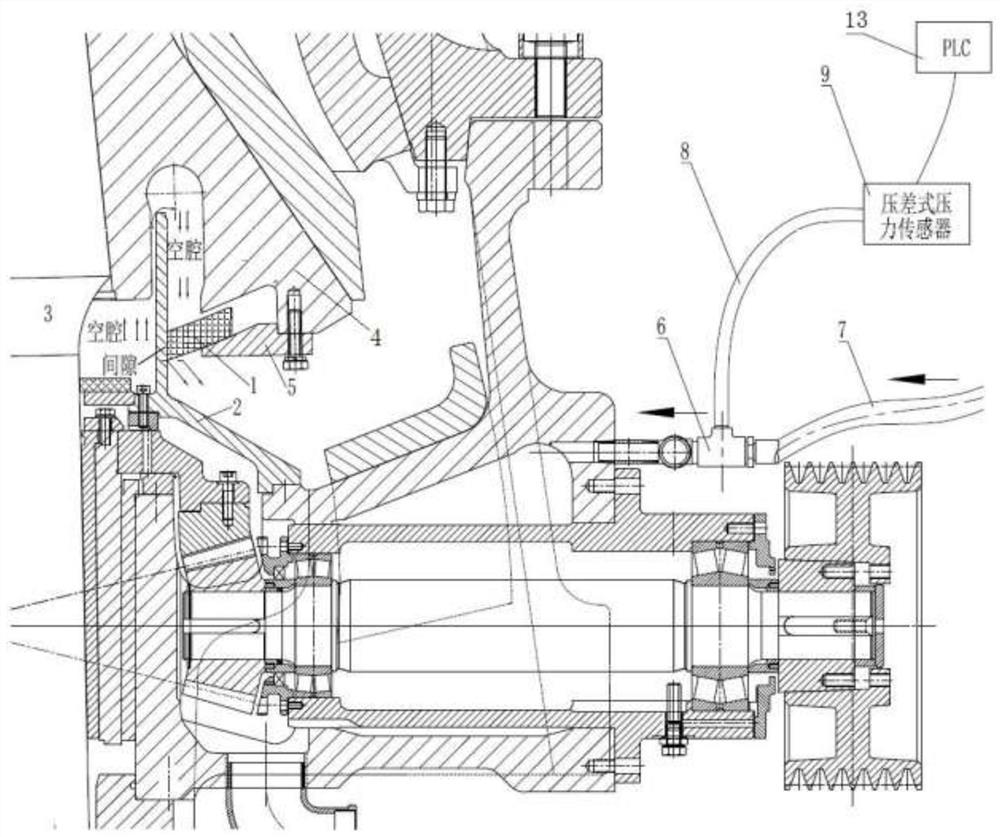

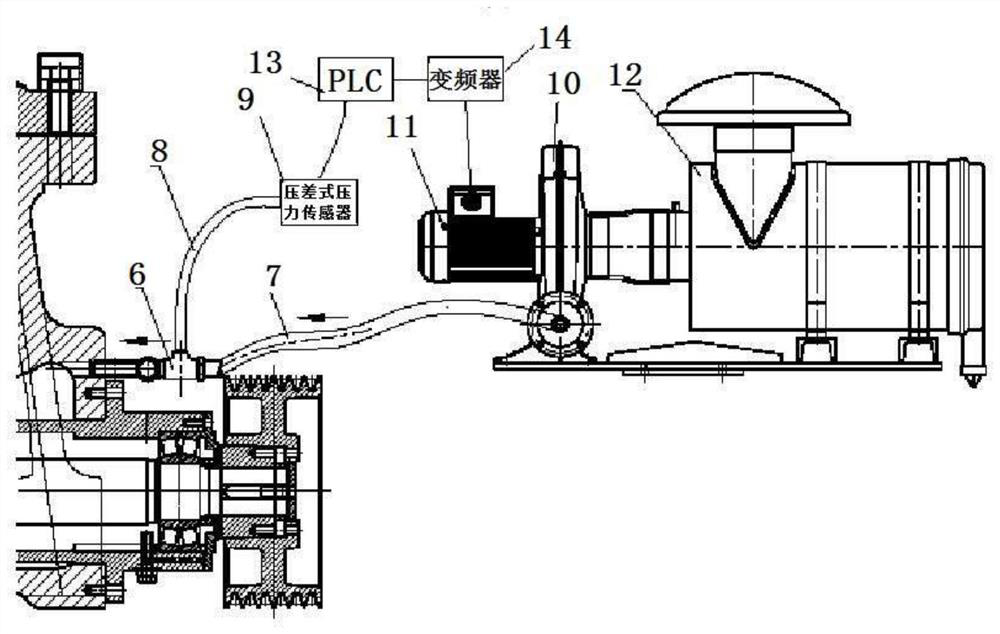

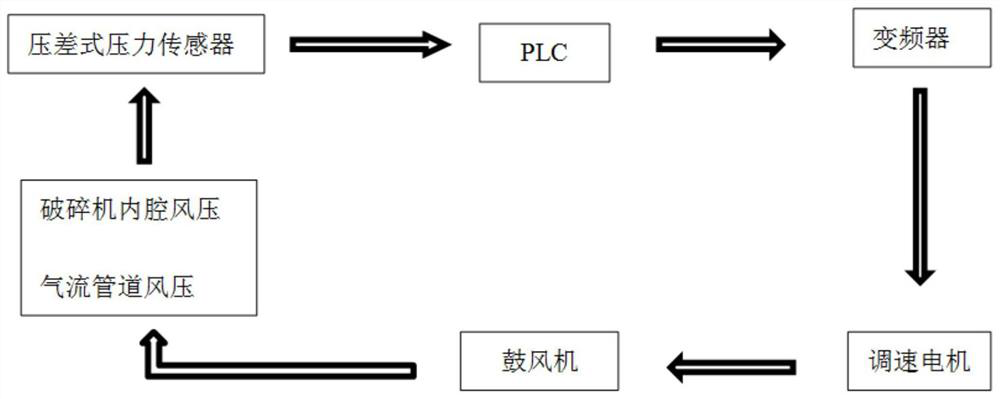

Intelligent wind pressure control method for positive pressure dustproof system of hydraulic cone crusher

PendingCN112718222AAvoid enteringAvoid pollutionGrain treatmentsFrequency changerDifferential pressure

The invention discloses an intelligent wind pressure control method for a positive pressure dustproof system of a cone crusher. The method involves an air blower provided with a speed adjusting motor, a frequency converter, a PLC, a differential pressure type pressure sensor, a pipeline for connecting the air blower with equipment, and an equipment airflow channel, wherein the PLC is connected with the differential pressure type pressure sensor and the frequency converter. According to the method, in the equipment operation process, the differential pressure type pressure sensor is used for monitoring the wind pressure in the pipeline in real time and on line, and continuously inputting analog signals into the PLC, the PLC is used for control, once the monitored analog signals do not accord with the preset wind pressure value of the PLC, the PLC sends an instruction to adjust the frequency converter, and the frequency converter controls and adjusts the rotating speed of the speed adjusting motor according to the instruction, so that the output wind pressure of the air blower is changed until the preset value is reached, dust is effectively prevented from entering an equipment cavity, lubricating oil is prevented from being polluted, and normal operation of the equipment and the service life of key parts are ensured.

Owner:南昌矿机集团股份有限公司

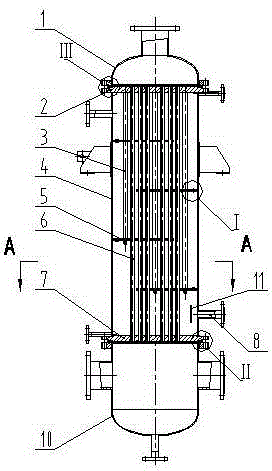

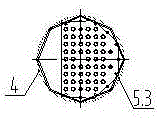

Efficient distillation vacuum cooler

InactiveCN106643223AAvoid short circuitImprove heat transfer efficiencyHeat exchanger casingsStationary tubular conduit assembliesInterference fitDistillation

The invention discloses an efficient distillation vacuum cooler. The efficient distillation vacuum cooler comprises an upper head, an upper pipe plate, a barrel body, a lower pipe plate, a lower head, a cooling water inlet pipe, pull rods, baffle plates and heat exchange pipes. The upper pipe plate and the lower pipe plate are welded and connected to the upper end and the lower end of the barrel body correspondingly. The baffle plates are arranged in the barrel body through the pull rods. The cooling water inlet pipe is horizontally arranged and fixedly connected to the pipe wall of the lower portion of the barrel body; the baffle plates are composite baffle plates and comprise the flexible baffle plates and the rigid baffle plates; the flexible baffle plates and the rigid baffle plates are connected through non-detachable connection structures; and the outer edges of the flexible baffle plates protrude from the rigid baffle plates and are in interference fit with the inner wall of the barrel body. According to the further improvement, the flexible baffle plates are soft plastic plates or aluminum-plastic plates; the joint, close to the inner wall of the barrel body, of the upper end surface of the lower pipe plate and the barrel body, as well as the joint, close to the inner wall of the barrel body, of the lower end surface of the upper pipe plate and the barrel body are both provided with annular grooves; and a partition plate is arranged in the barrel body, so that an outlet of the cooling water inlet pipe is separated from the heat exchange pipes. The efficient distillation vacuum cooler is high in heat exchange efficiency, small in welding stress, reliable and durable.

Owner:JIANGSU JINGTAI PETROCHEM EQUIP CO LTD

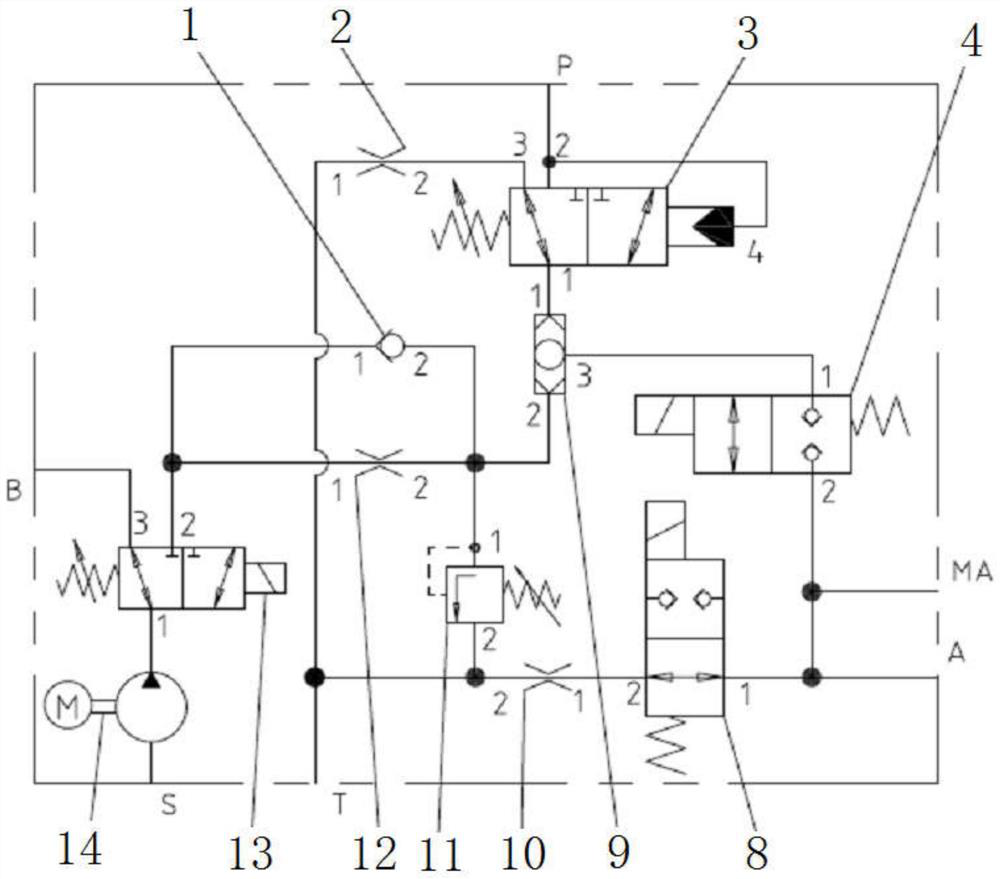

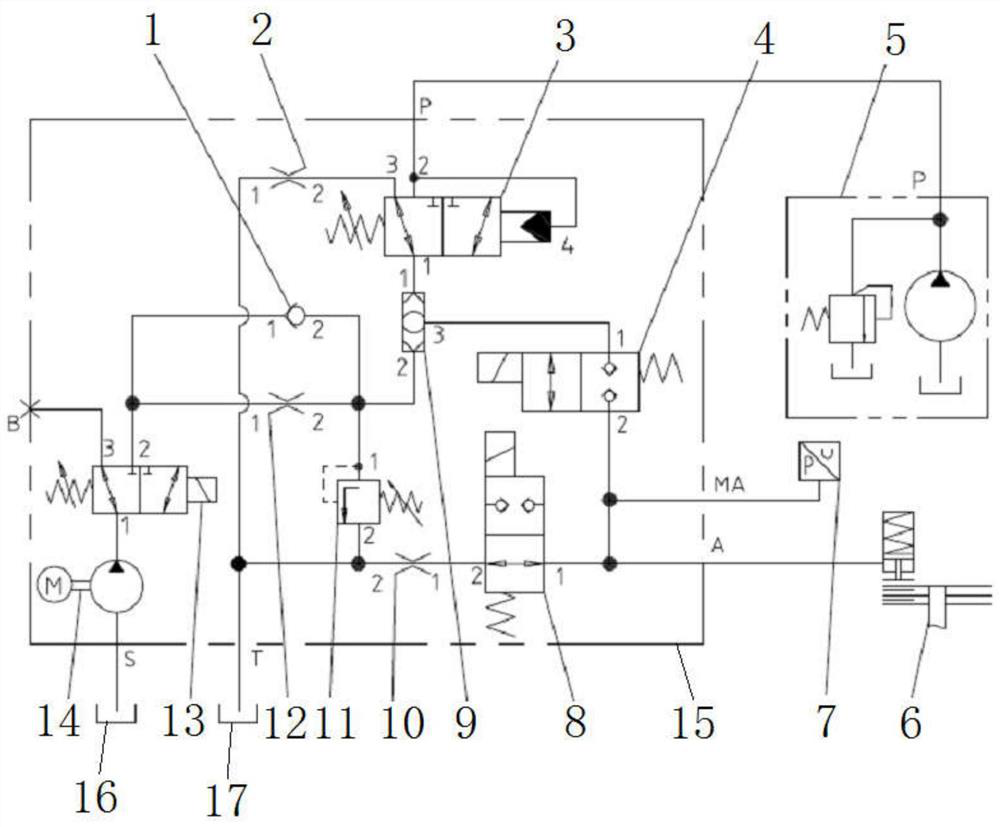

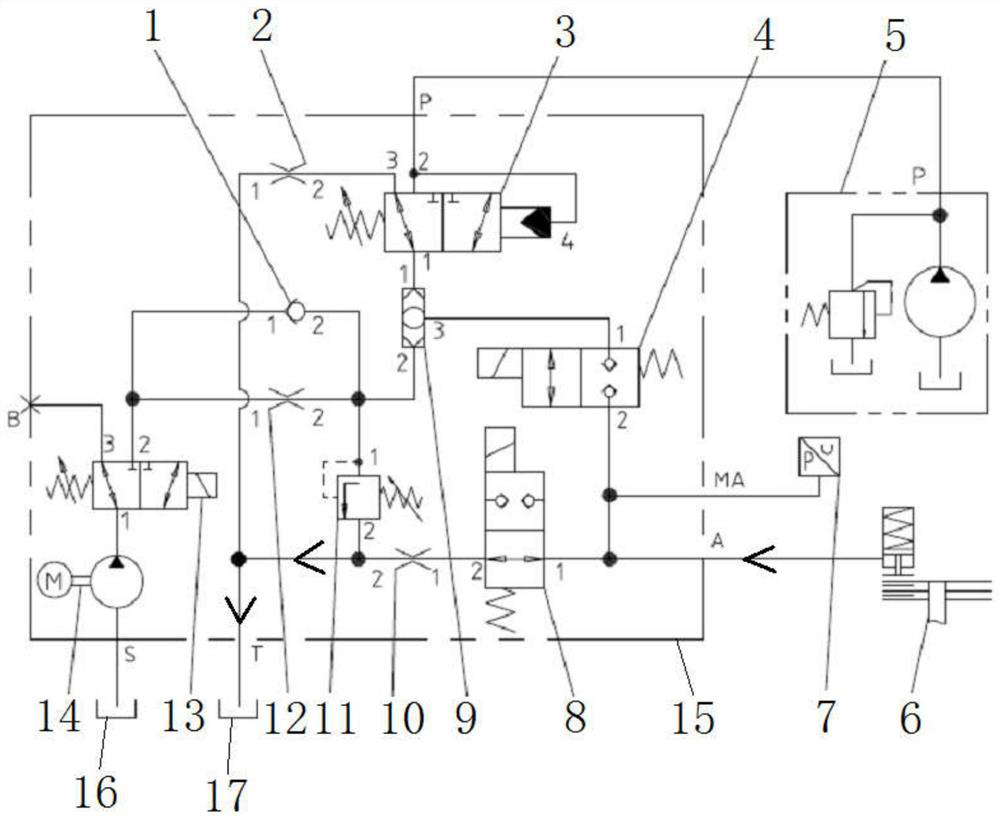

Hydraulic parking and emergency trailer control device and wheeled engineering vehicle

ActiveCN112937535AImprove parking handling performanceRealize emergency towing functionBraking action transmissionBrake safety systemsControl theoryParking brake

The invention provides a hydraulic parking and emergency trailer control device and a wheeled engineering vehicle. The hydraulic parking and emergency trailer control device comprises a direct-current motor pump (14), a first two-position three-way reversing valve (3), a second two-position three-way reversing valve (13), a shuttle valve (9) and a first two-position two-way reversing valve (4); hydraulic oil can sequentially pass through the direct-current motor pump (14), the second two-position three-way reversing valve (13), the shuttle valve (9) and the first two-position two-way reversing valve (4) and then is output from an oil port 2 of the first two-position two-way reversing valve (4). The hydraulic parking and emergency trailer control device can realize the functions of parking brake release, stable parking, emergency trailing, ramp automatic parking, running automatic release and the like of a wheeled vehicle, and provides intelligent control for running and parking of the wheeled engineering vehicle.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Wire feeding device for arc welding robot

PendingCN108161181AReduce resistanceGuaranteed flexibilityArc welding apparatusForeign matterFeeding tube

The invention provides a wire feeding device for an arc welding robot. The wire feeding device comprises at least two sections of wire feeding tube, every two sections of wire feeding tube are connected through a connecting piece. Each section of feeding tube comprises a tube body, a sealing upper cover and a sealing lower cover, middle holes are formed in the centers of the sealing upper covers and the centers of the sealing lower covers, welding wires penetrate through the holes, and convex columns are arranged on the outer wall of one end of the pipe body; the connecting pieces sleeve the other end of the tube body, and the connecting pieces are rotationally hung on the convex columns of the next section of wire feeding pipe. According to the wire feeding device, winding and knotting ofthe welding wires are prevented, the traditional integrated wire feeding tube is divided into a plurality of sections and each section is rotationally connected through the connecting pieces, so thatthe sealing performance of the wire feeding tube is guaranteed, abnormal abrasion caused by dust, foreign matters and the like entering the welding wire tube is prevented, and meanwhile, the flexibility of the wire feeding tube is guaranteed to a certain degree. In addition, balls are arranged at the two ends of the tube body correspondingly, and in the wire feeding process, the balls roll relative to the welding wires, so that the wire discharging stability of the wire feeding device is improved, and the wire feeding resistance is reduced.

Owner:王秀伟

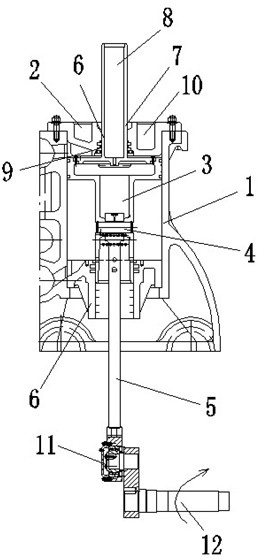

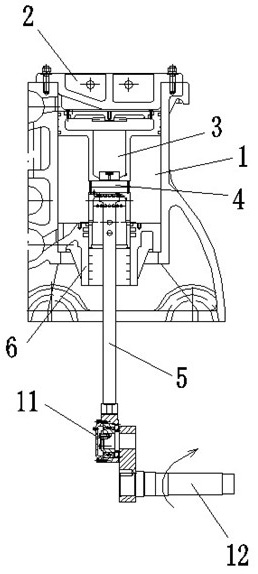

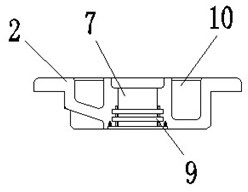

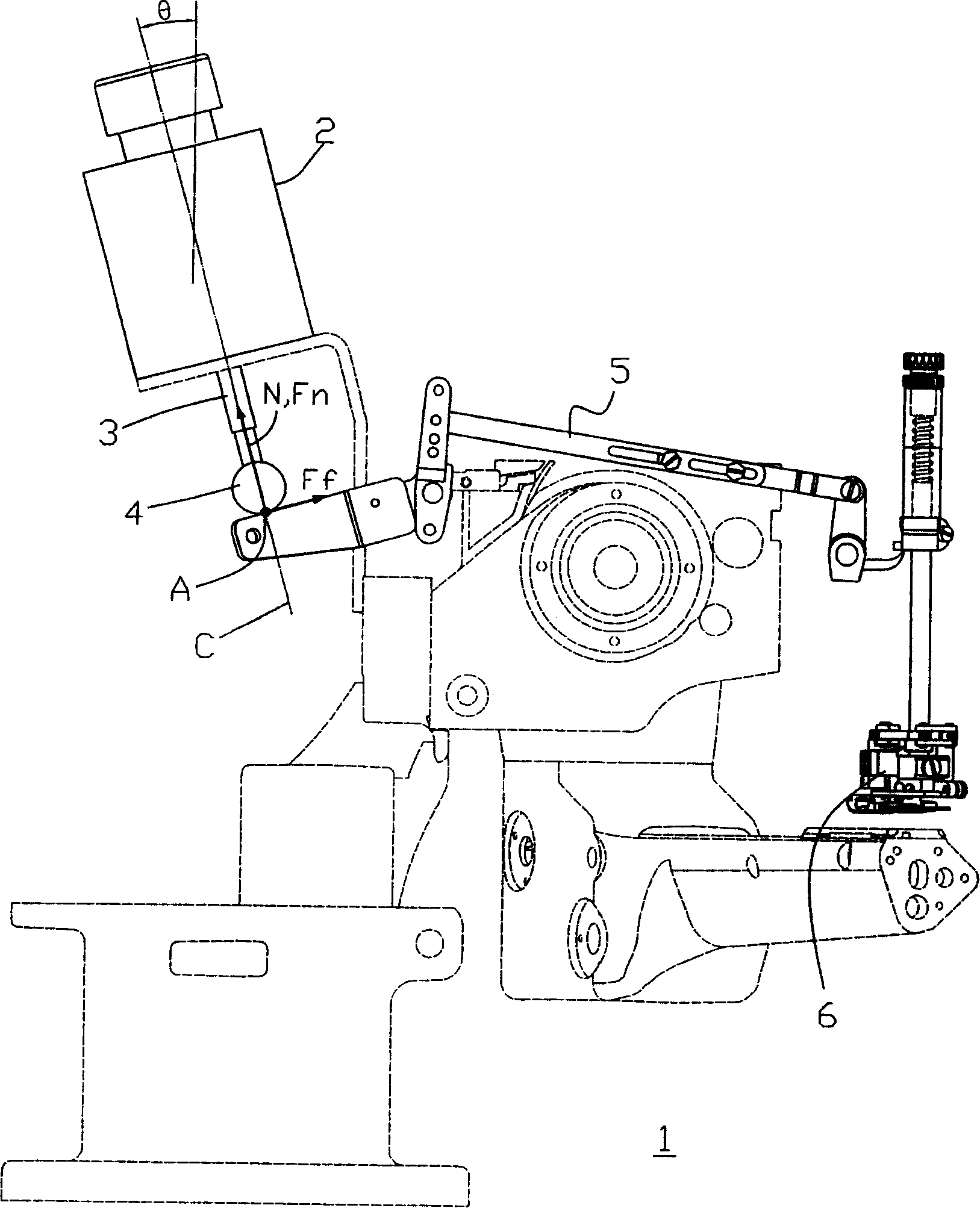

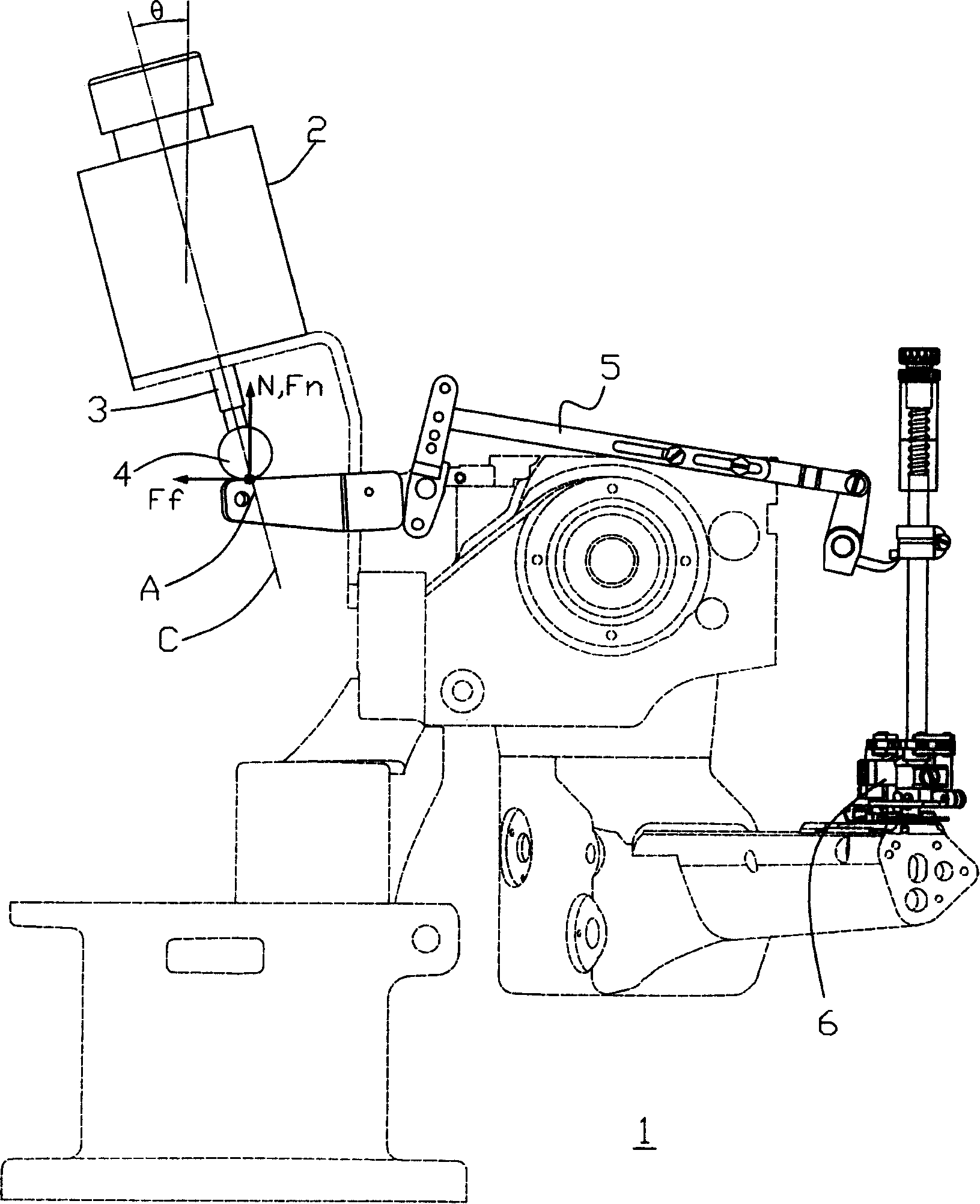

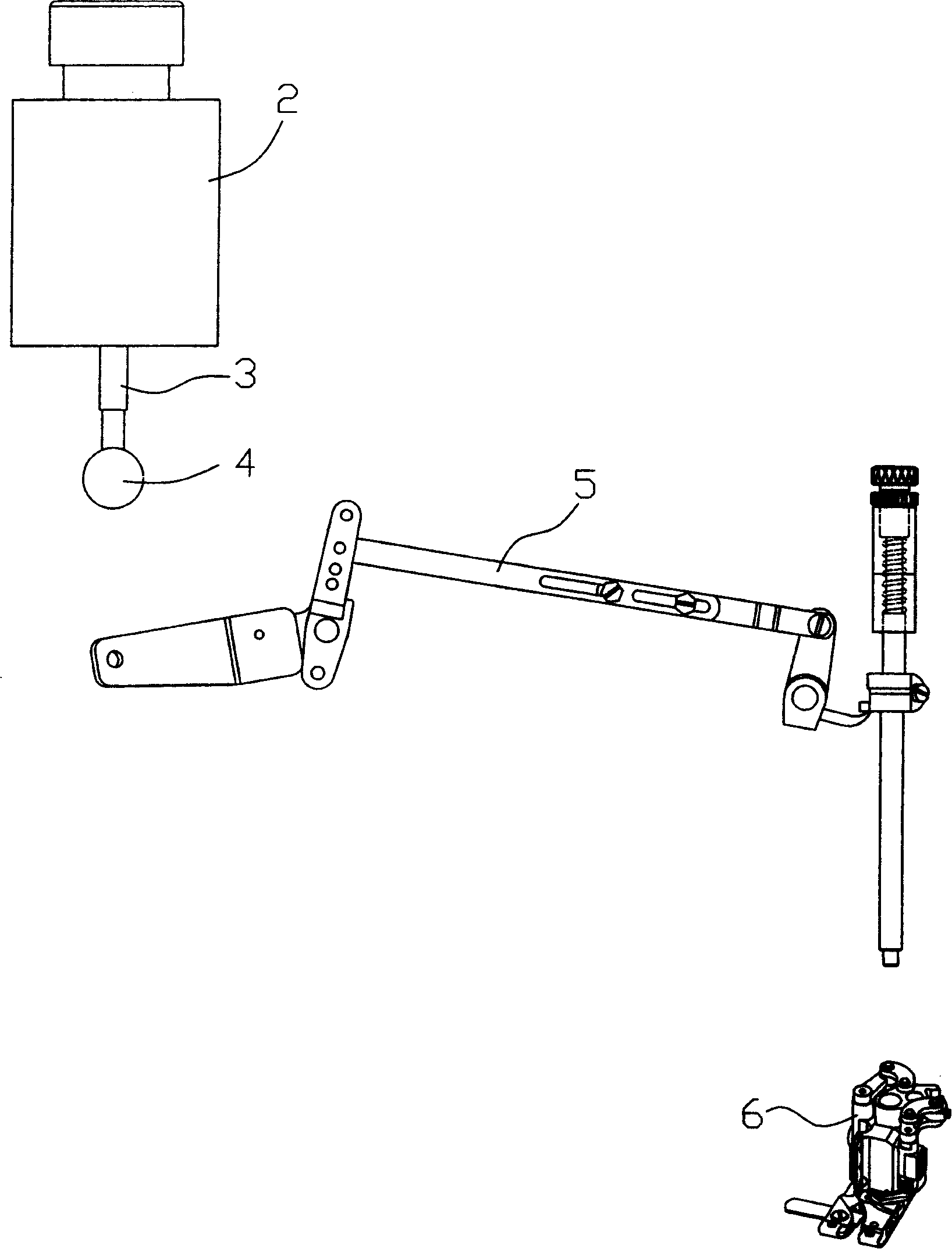

Cloth pressing pin drive structure of sewing machine

InactiveCN101173427AExtended service lifeAvoid abnormal wear and tearPressersRelative displacementEngineering

The invention discloses a drive structure of cloth pressing foot for a sewing machine, which is characterized in that: a push rod of an actuator does not directly push a linkage but pushes through a roller; friction can be avoided due to sliding through the rolling of the roller even if relative displacement of the push rod for the actuator opposing to the contact point of the linkage is produced between the starting and the ending of driving, thereby avoiding lateral force due to the friction between the push rod of the actuator and the linkage; when the cloth pressing foot is lifted to the highest point, the roller is propped against normal line of the contact surface on the contact point of the linkage and coincides at the axial extending line of the push rod; the contact point between the linkage and the roller is arranged at the axial extending line of the push rod for the actuator; eccentric force can be avoided upon the push rod, thereby avoiding abnormal abrasion that the push rod leans toward one side.

Owner:MING JANG SEWING MACHINE

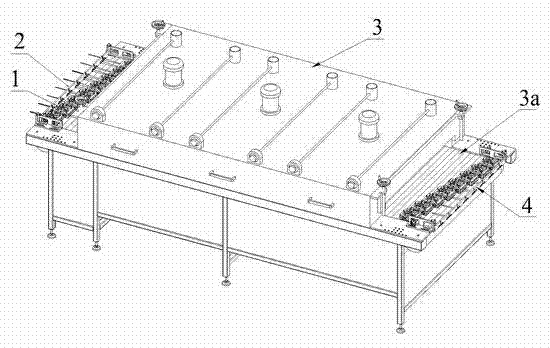

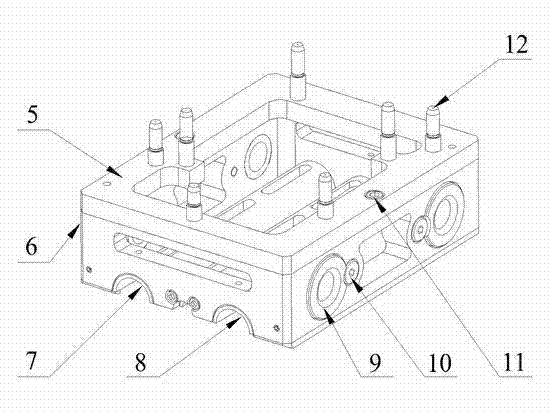

Tunnel type oven berth mechanism suitable for automatic online and offline

ActiveCN102815531AReliable disengagementAvoid abnormal wear and tearConveyor partsEconomic benefitsOnline and offline

The invention discloses a tunnel type oven berth mechanism suitable for automatic online and offline and belongs to the technical field of product postprocessing auxiliary devices. The mechanism comprises an entrance berth group, an exit berth group and a carrier, the entrance berth group is arranged at the entry end of a tunnel type oven through a lateral seat frame I, the exit berth group is arranged at the exit end of the tunnel type oven through a lateral seat frame II, gaps are reserved among the entrance berth group, the exit berth group and a link plate, and the carrier is automatically conveyed from the entrance berth group to the exit berth group through the link plate. According to the tunnel type oven berth mechanism suitable for the automatic online and offline, when the tunnel type oven is used for baking products, the automatic online and offline is achieved, unmanned and automated joint of working procedures from start to finish are convenient to achieve, the production cost is greatly reduced, the production efficiency is improved, the risk of human injuries caused by high temperature overflow wind of the oven entrance and exit is prevented, the product reject ratio caused by the fact that the manual picking and placing of products are prone to pollute product surfaces is avoided, the economic benefits are improved, and the tunnel type oven berth mechanism is easy to popularize and apply.

Owner:怡得乐电子(杭州)有限公司

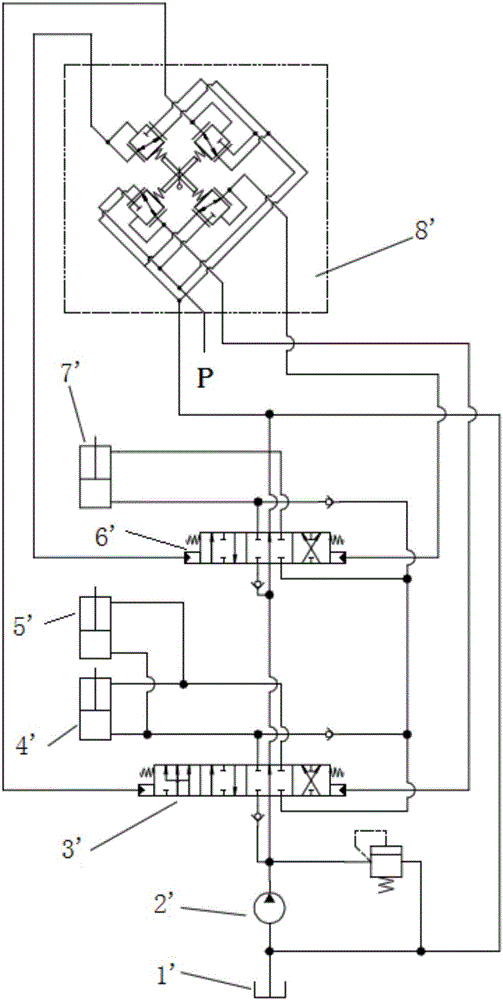

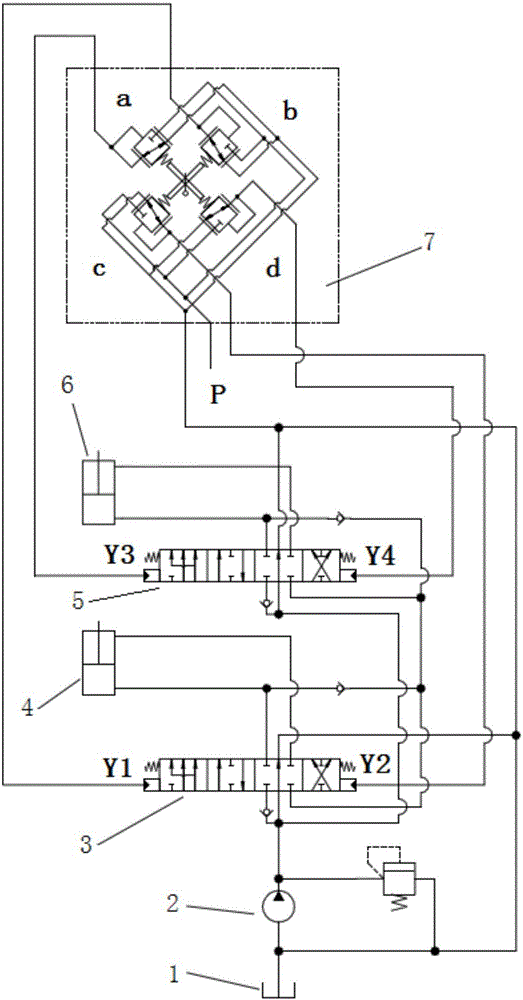

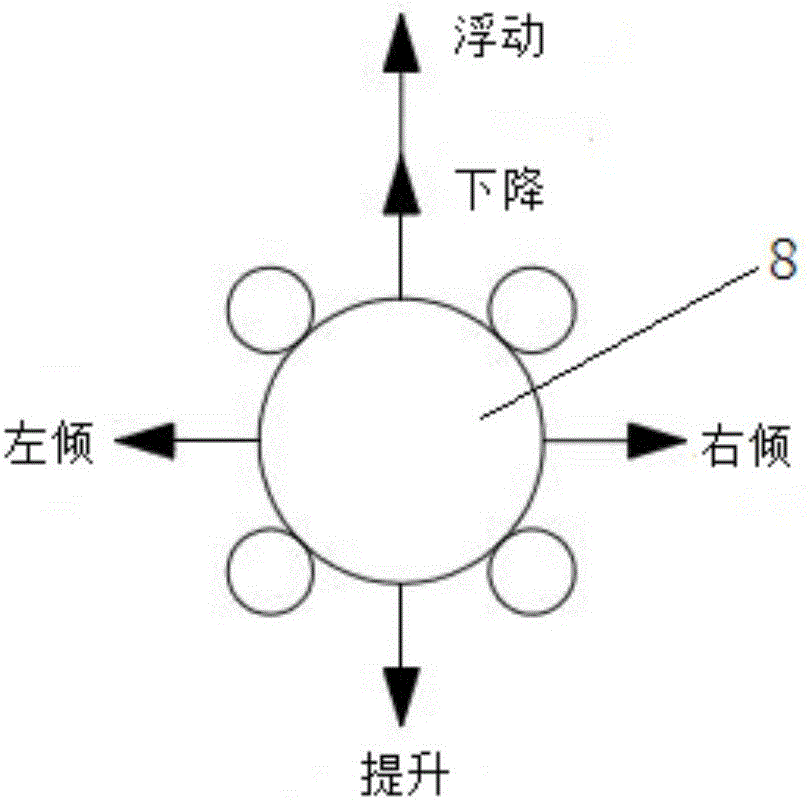

Hydraulic control system of bulldozer blade and control method

ActiveCN106703100AAvoid abnormal wear and tearExtended service lifeSoil-shifting machines/dredgersEngineeringHigh pressure

The invention relates to the technical field of bulldozers, particularly to a hydraulic control system of a bulldozer blade and a control method. The hydraulic control system comprises a pilot control valve, a left lift valve, a left lift cylinder, a right lift valve and a right lift cylinder, wherein the pilot control valve controls the left lift valve and the right lift valve; and the left lift valve and the right lift valve respectively control the left lift cylinder and the right lift cylinder. According to the hydraulic control system, through operation of a handle, oil is introduced or drained at pilot control ends on the two sides of the left lift valve and the right lift valve, the left lift cylinder and the right lift cylinder are in the stretched or compressed state, and lifting, falling and floating of the blade are achieved; or one of the left lift cylinder and the right lift cylinder is in the stretched state and the other of the left lift cylinder and the right lift cylinder is in the compressed state, inclination action of the blade is achieved, when a traditional blade is inclined, in-cylinder abnormal high pressure caused by passive stretching or compression of the lift cylinders of the blade is avoided, and the service life of the lift cylinders is effectively prolonged; and inclined cylinders and corresponding pipelines are eliminated, so that the structure of the integral machine is simplified, layout is more simple, and manufacturing cost of the integral machine is reduced.

Owner:SHANTUI CONSTR MASCH CO LTD

Lightweight automobile hub

ActiveCN109895553AAvoid abnormal wear and tearImprove cooling effectWheelsRolling resistance optimizationEngineeringMechanical engineering

The invention belongs to the technical field of automobile parts and particularly relates to a lightweight automobile hub. The lightweight automobile hub comprises a mounting plate, a spoke and a rim,wherein the spoke is connected with the mounting plate and the rim; the spoke is provided with a cooling module for cooling the entire lightweight automobile hub, and the control module comprises sliders, springs, sliding grooves and a cooling groove, and the spoke is provided with the sliding grooves inside which the sliders are slidingly connected through the springs; the rim is provided with the ring-shaped cooling groove; the cooling groove is connected with the sliding grooves through communicating grooves, and the cross section of the communicating grooves is in an I shape; the bottom of a vehicle body is provided with a cooling box, and the bottom of the cooling box is provided with a liquid outlet pipe which is communicated with the cooling groove. The lightweight automobile hub is simple in structure and convenient to operate, and being cooled by the cooling module, can avoid abnormal wearing a tyre due to overhigh temperature.

Owner:浙江欧星环美汽车部件有限公司

Metal particle spiral conveyor used in high-temperature environment

The invention discloses a metal particle spiral conveyor used in a high-temperature environment and belongs to the technical field of material conveying. The conveyor comprises a fixed support, a fixed sealing head, a shaft, a spiral blade, a movable sealing head, a driving device, a movable sealing head adjusting device, a cooling water connector, a water-cooled cover, a sealing rope, a sealing nitrogen connector, a sealing nitrogen nozzle, an adjusting support, a positioning bolt and an adjusting air cylinder. The conveyor has the advantages that a variable-frequency and variable-speed motor is adopted as a power supply, the spiral blade is cooled in a direct and indirect combined mode and is designed to be of a multi-end structure, and the adjusting air cylinder is arranged; in this way, the overall service life of the conveyor is significantly prolonged, the frequency of examining and maintaining the spiral blade is greatly reduced, maintenance cost is greatly reduced, meanwhile, the annual operating rate of a rotary hearth furnace production line is improved, and the manufacturing cost of finished products is further reduced.

Owner:BEIJING SHOUGANG INT ENG TECH

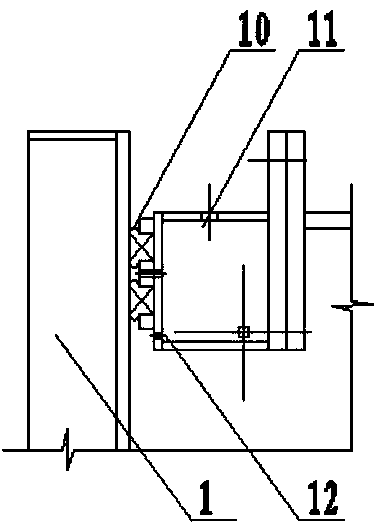

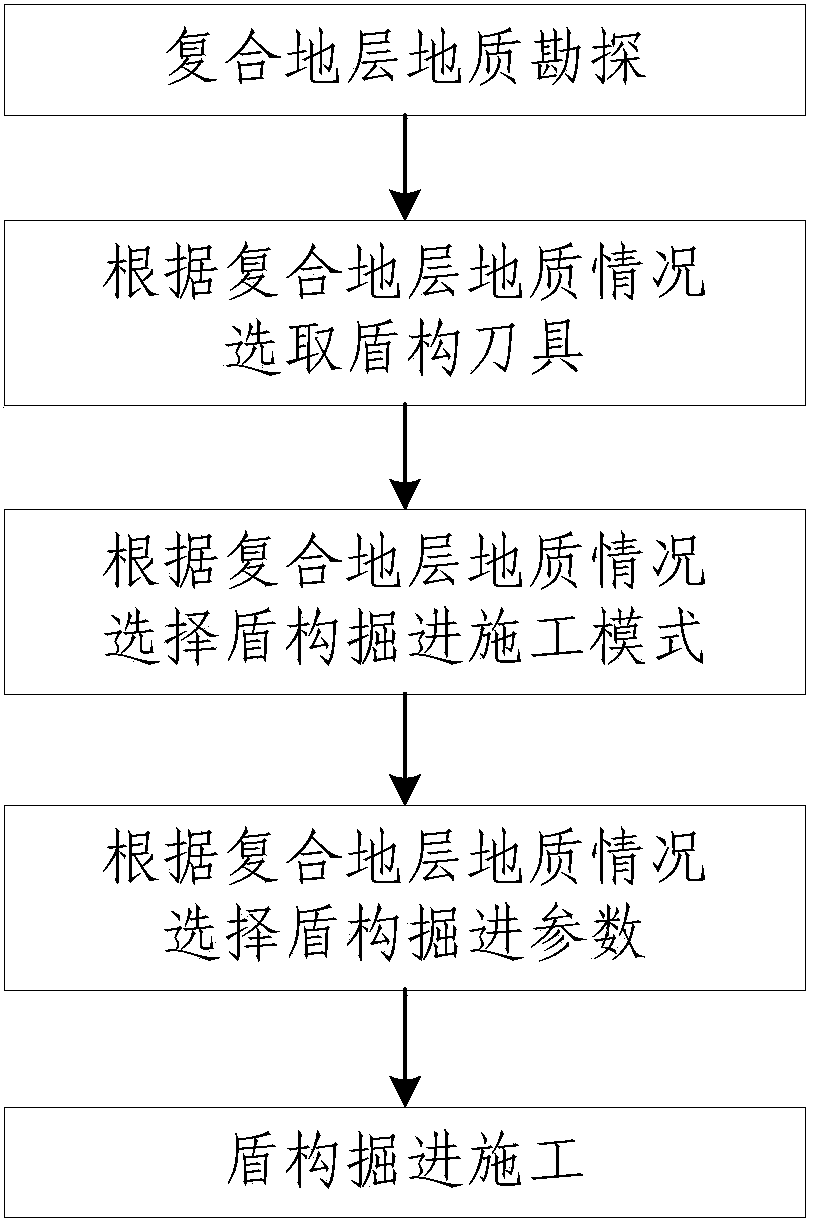

A construction method for shield tunneling in composite strata

The invention discloses a shield tunneling construction method of a composite stratum; the method includes step 1, geological survey of composite stratum; step 2, selection of a shielding cutter according to the geological condition of the composite stratum; step 3, selection of shield tunneling construction mode according to the geological condition of the composite stratum; step 4, selection of shield tunneling parameter according to the geological condition of the composite stratum, wherein the step 4 includes step 401 of calculating push force of a shield tunneling machine; step 402 of calculating torque of the shield tunneling machine; step 5, shield tunneling construction, wherein the step 5 includes step 501 of feeding back the shield tunneling direction; step 502 of adjusting the shield tunneling direction. The shield tunneling construction method is simple in structure and reasonable in design; according to the change of the composite stratum, the method can reasonably select the shield tunneling machine, correctly select the tunneling parameter, prolong the service life of a cutter disk, improve the adaptation of the cutter disk to the composite stratum, and guarantee the safe, rapid and economic performance of the shield construction; thus the method is good in using effect and convenient to popularize and use.

Owner:中铁二十局集团第五工程有限公司

Oil injection nozzle for multifunctional lubricating oil gun

The invention discloses an oil injection nozzle for a multifunctional lubricating oil gun. The oil injection nozzle comprises a connecting flange, a seal ring, a snap spring, a connecting oil injection head and a dustproof cover. The connecting oil injection head is arranged on the connecting flange. The connecting oil injection head is arranged on the connecting flange in a sleeved mode, and the connecting oil injection head and the connecting flange are connected together in a rotatable mode through the snap spring. The seal ring is arranged between a first insertion pipe of the connecting oil injection head and the connecting flange. A second insertion pipe is arranged on the connecting oil injection head and inclines upwards in a gradient mode. The dustproof cover comprises a cover cap, a connecting belt and a sleeve ring. The cover cap is connected with the sleeve ring through the connecting belt. The sleeve ring is arranged on the connecting flange in a sleeved mode. The cover cap covers the second insertion pipe. Compared with the prior art, the oil injection nozzle has the advantages that the phenomenon that some dust or other sharp objects adhere to an oil injection opening and then abnormal abrasion is caused to machine parts can be avoided, oil injection can be convenient, and the phenomenon that the oil injection opening of the oil injection nozzle is blocked by other parts, oil injection can not be conducted, and then abnormal abrasion is caused to mechanical parts can be avoided.

Owner:ZHUJI SAKURA SNOW MACHINERY

Device convenient for adjusting automobile suspension axle distance

ActiveCN102490561BAvoid abnormal wear and tearEasy to adjustResilient suspensionsVehicle frameEngineering

The invention relates to the automobile suspension technology, and specifically discloses a device convenient for adjusting the automobile suspension axle distance. The device comprises a support plate and a fixed-length pull rod, wherein the support plate is fixed on an automobile frame girder; one end of the pull rod is articulated with an automobile axle in fixed connection with an elastic element; the other end of the pull rod is mounted on the support plate through a pull rod connecting piece; the support plate is provided with a horizontal strip support plate through hole for supporting the pull rod connecting piece; an adjusting plate is arranged in the position corresponding to the support plate through hole, and is provided with an adjusting plate guide part in an inclination angle with the horizontal direction; and when the adjusting plate guide part moves up and down on the adjusting plate relative to the support plate, the pull rod connecting piece moves horizontally in the support plate through hole. Through the invention, the axle distance and parallelism can be conveniently adjusted in the automobile assembly or using process so as to prevent abnormal abrasion of automobile tyres and improve the driving safety.

Owner:BPW (MEIZHO) AXLE CO LTD

Mechanical pressure slide block and bulb lead screw connecting device

InactiveCN107322973AAccurate thicknessAvoid abnormal wear and tearPressesEngineeringMechanical pressure

The invention discloses a mechanical pressure slide block and bulb lead screw connecting device. A first reference plane is arranged on a slide block at an upper port part of a blind hole; a second reference plane is arranged on the outer circular edge of a flange; and the thickness of a gasket is obtained by subtracting the thickness of the edge port part of the flange by the distance from the first reference plane to the second reference plane. The thickness of the gasket can be once determined accurately, so that efficiency is high, inconvenience and troubles caused by repeated trial installation of the gasket are prevented, and meanwhile, the phenomenon of abnormal wear of parts caused by inaccurate installation of the gasket and abnormal work of the parts is prevented.

Owner:SUZHOU BLUE KING MACHINE TOOL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com