Paper roll slitter machine

A web and slitting machine technology, applied in metal processing, etc., can solve problems such as low slitting efficiency, low cutting efficiency, and potential safety hazards, so as to ensure tension, improve cutting efficiency, and increase service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

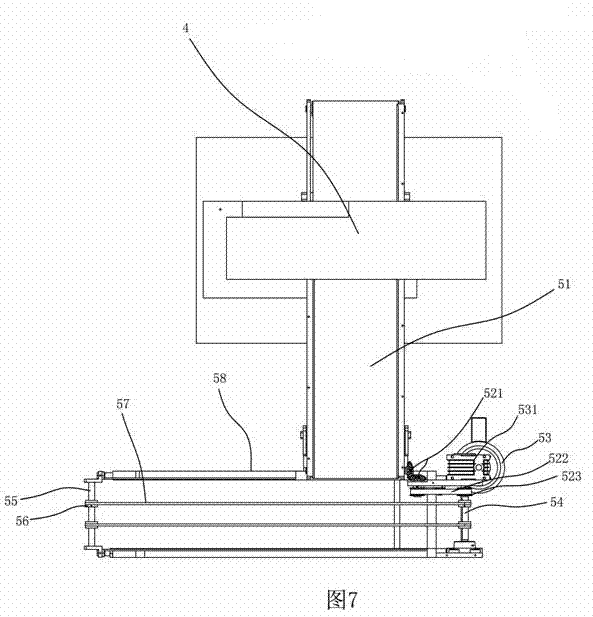

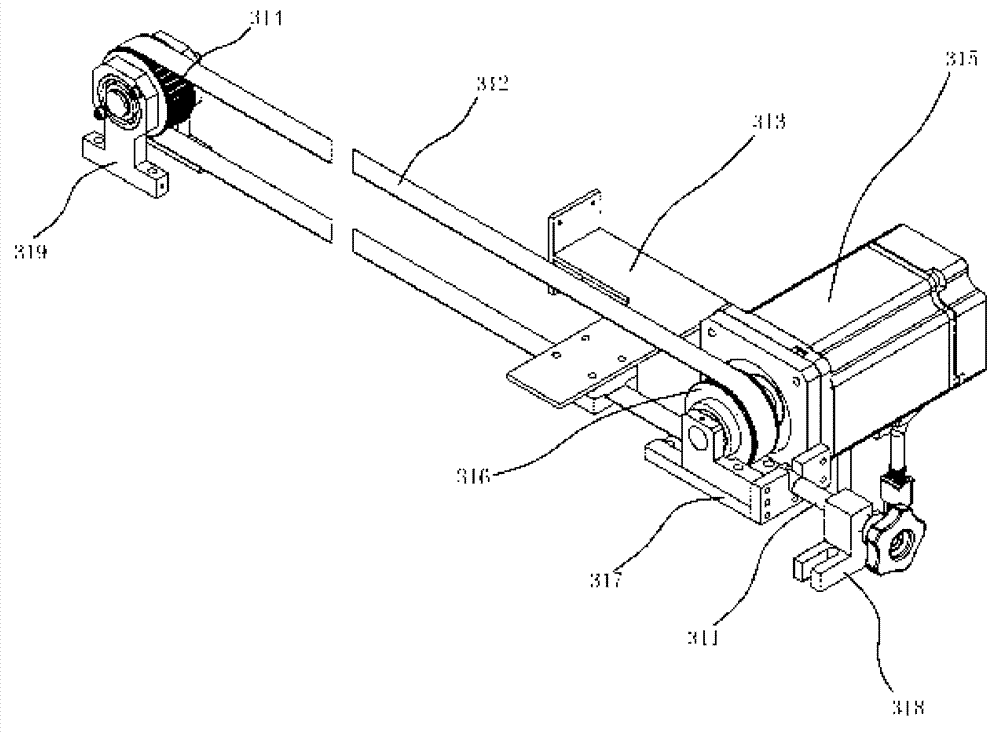

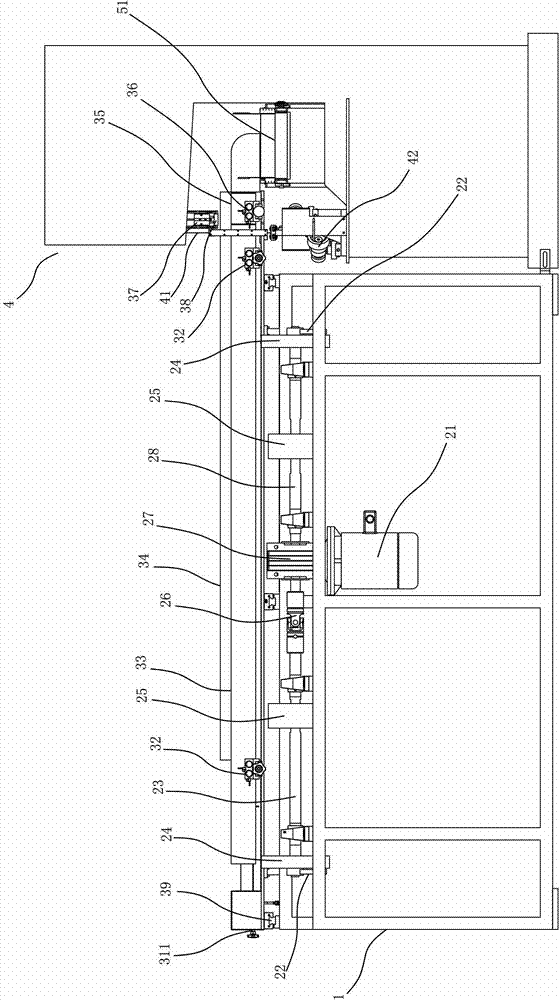

[0033] refer to Figure 1 to Figure 8 As shown, a web slitting machine includes a frame 1, a band saw machine 4, an intermittent paper feeding mechanism that can slide vertically and horizontally on the frame 1, and is set on the frame 1 to connect and drive the intermittent feeding mechanism. The main driving mechanism of the paper mechanism reciprocating longitudinally and horizontally, the finished product conveying mechanism arranged at the output end of the intermittent paper feeding mechanism, the paper storage machine and the control device for automatically supplying the roll paper to the chute 3.

[0034]The band saw machine 4 comprises upper and lower saw wheels (not shown in the casing), a saw blade 41 tensioned between the upper and lower saw wheels and a first motor connected to drive the upper and lower saw wheels to rotate (located in the machine Not shown in the shell), the basic structure of the band saw machine 4 is a known prior art, and will not be describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com