Cloth pressing pin drive structure of sewing machine

A technology for presser feet and sewing machines, applied in the field of sewing machines, can solve the problems of affecting the service life and abnormal wear of the push rod, and achieve the effect of improving the service life and avoiding abnormal wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The driving structure of the presser foot of the sewing machine of the present invention will be described below.

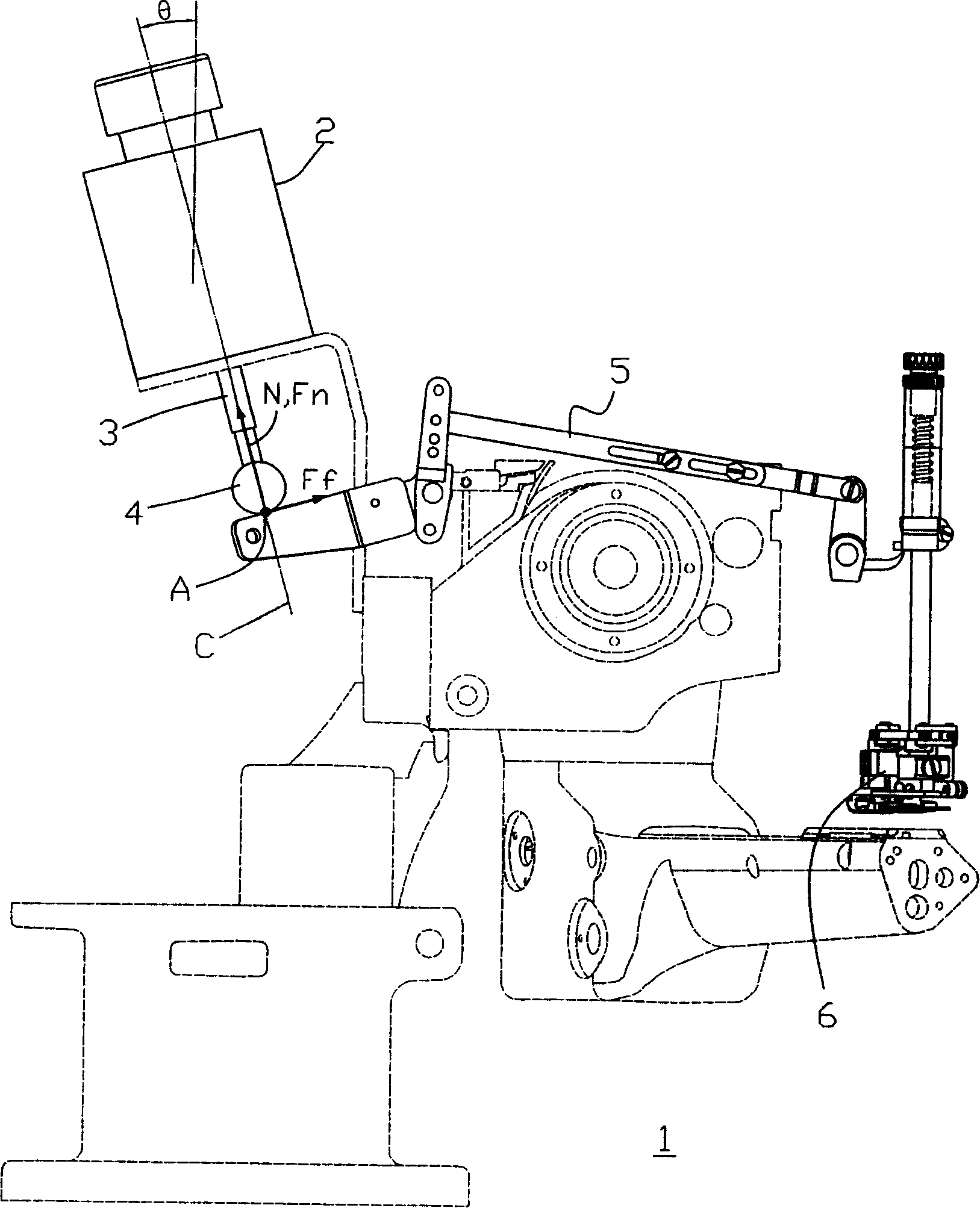

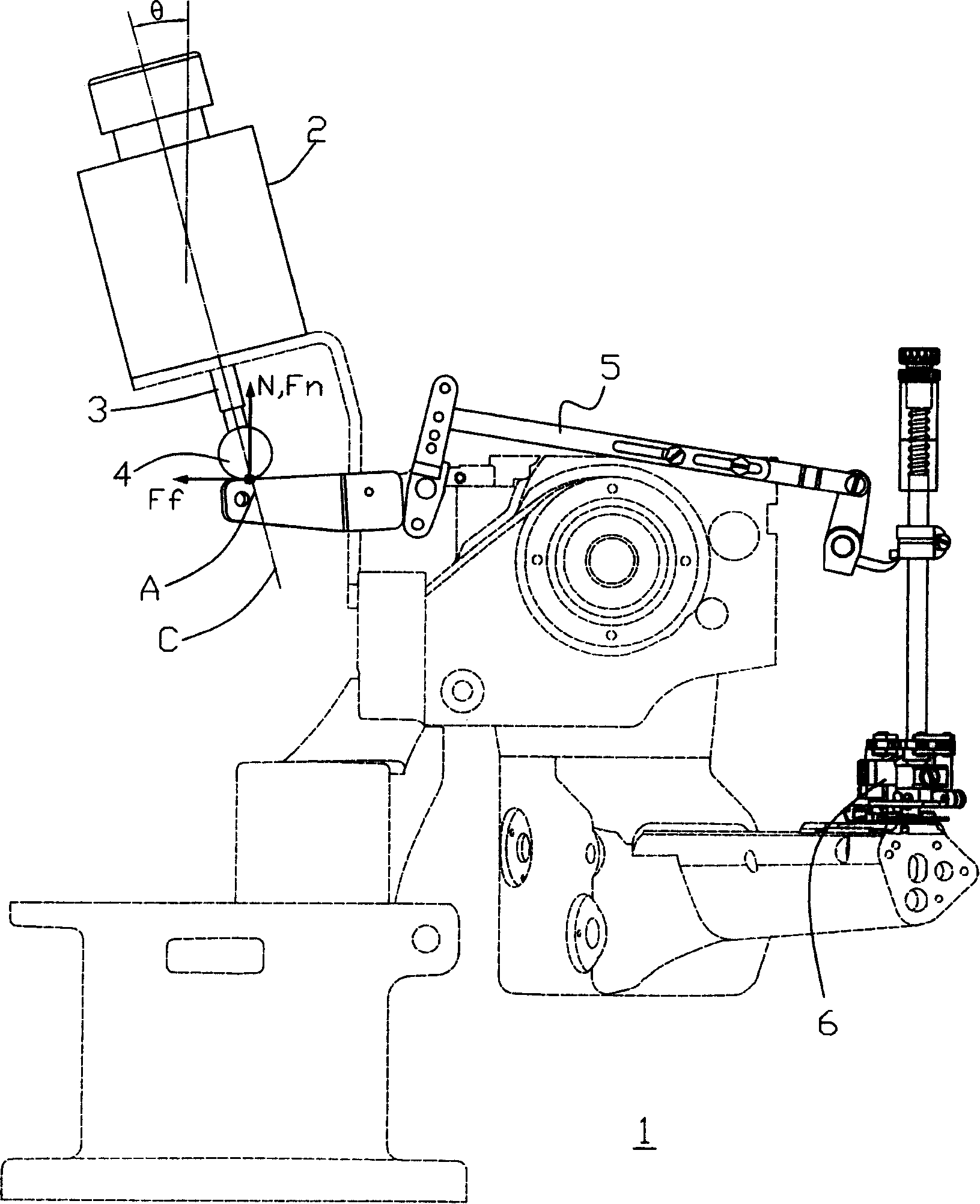

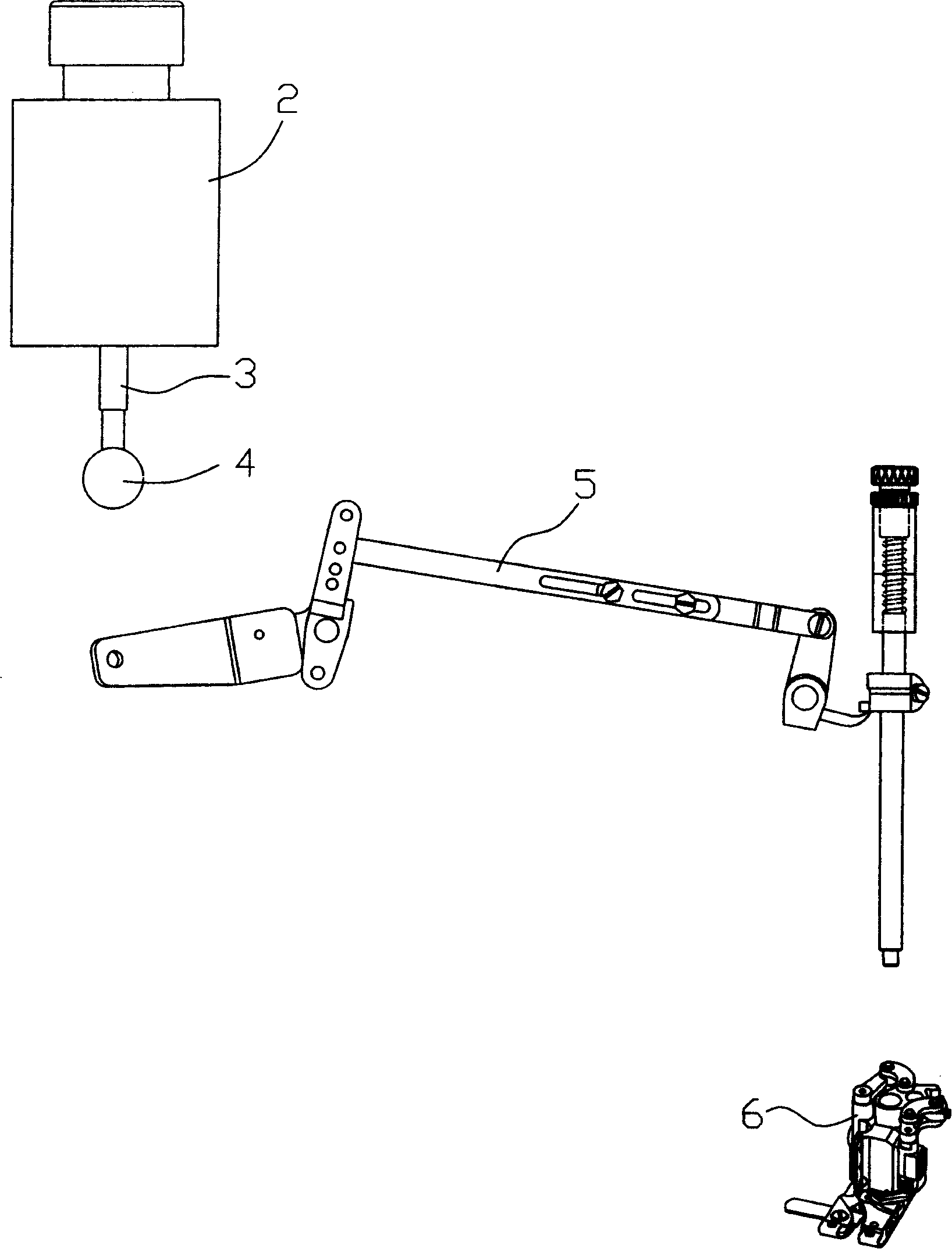

[0020] figure 1 In the first embodiment of the cloth presser foot drive structure of the sewing machine of the present invention, the cloth presser foot is a schematic diagram of the state where the cloth presser foot is located at the highest position of the lifting foot; figure 2 It is a schematic diagram of the state where the presser foot is at the presser position in the same embodiment; image 3 In an exploded view, the components illustrated in this embodiment can be clearly shown. As shown in the figure, a link group 5 for driving the cloth presser foot 6 is provided in the sewing machine 1, so that the cloth presser foot 6 of the linkage group 5 generates a cloth presser or lifter action. In this embodiment, the axial direction of the actuator 2 and the vertical reference line form an inclination angle θ, the push rod 3 in the actuator 2 can telesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com