Wire feeding device for arc welding robot

A technology of wire feeding device and robot, which is applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of wearing wire feeding tube conductive head, aggravating abnormal wear, and blocking wire feeding tube passage, etc. Silk stability, preventing tangling and knotting, and ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be clearly and completely described below.

[0035] The directional terms such as "upper", "lower", "inner", "outer", "one end" and "another end" in the present invention are all for the convenience of describing the structural relationship of the wire feeding device of the present invention, and cannot be understood as a limitation of the present invention.

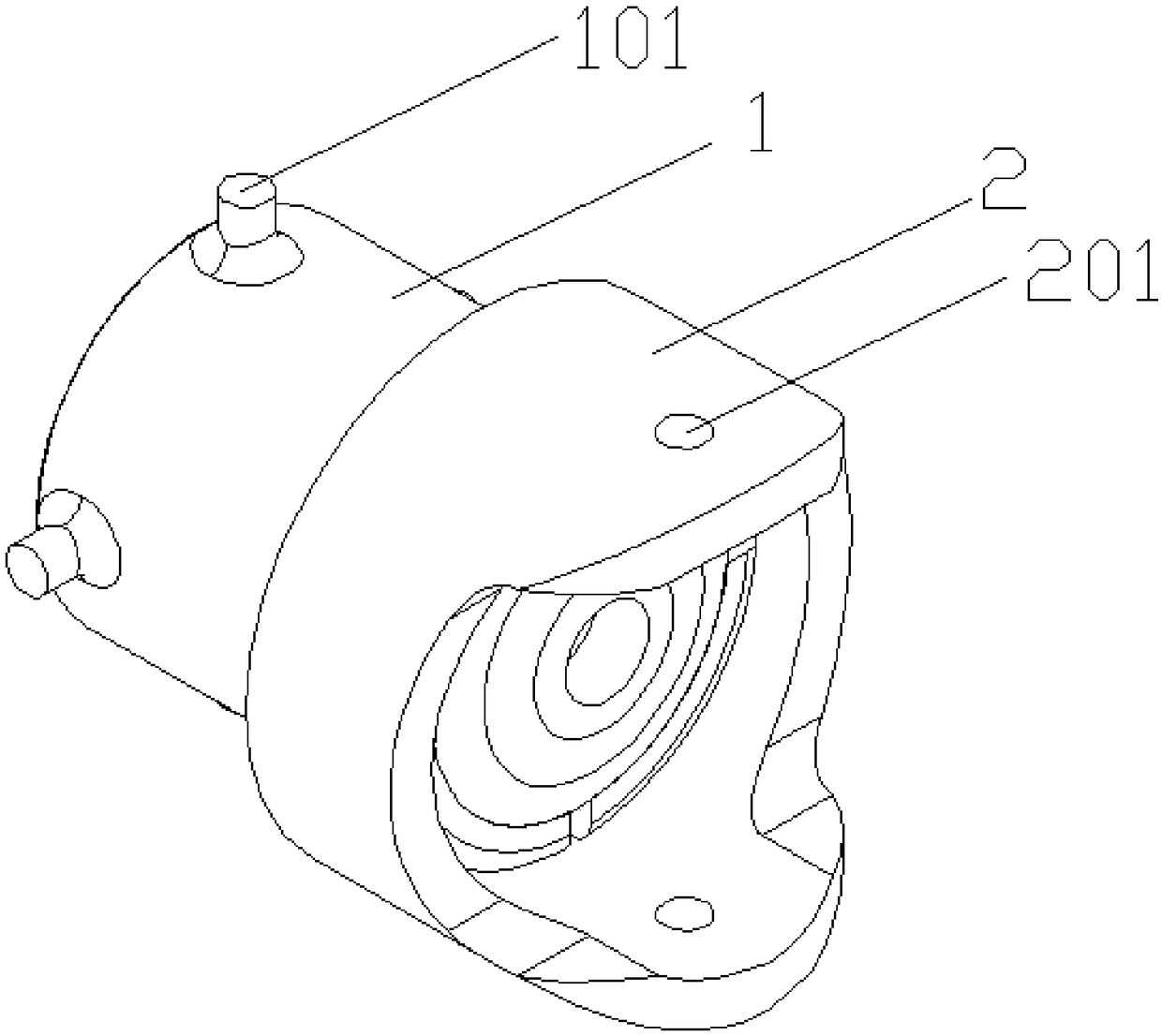

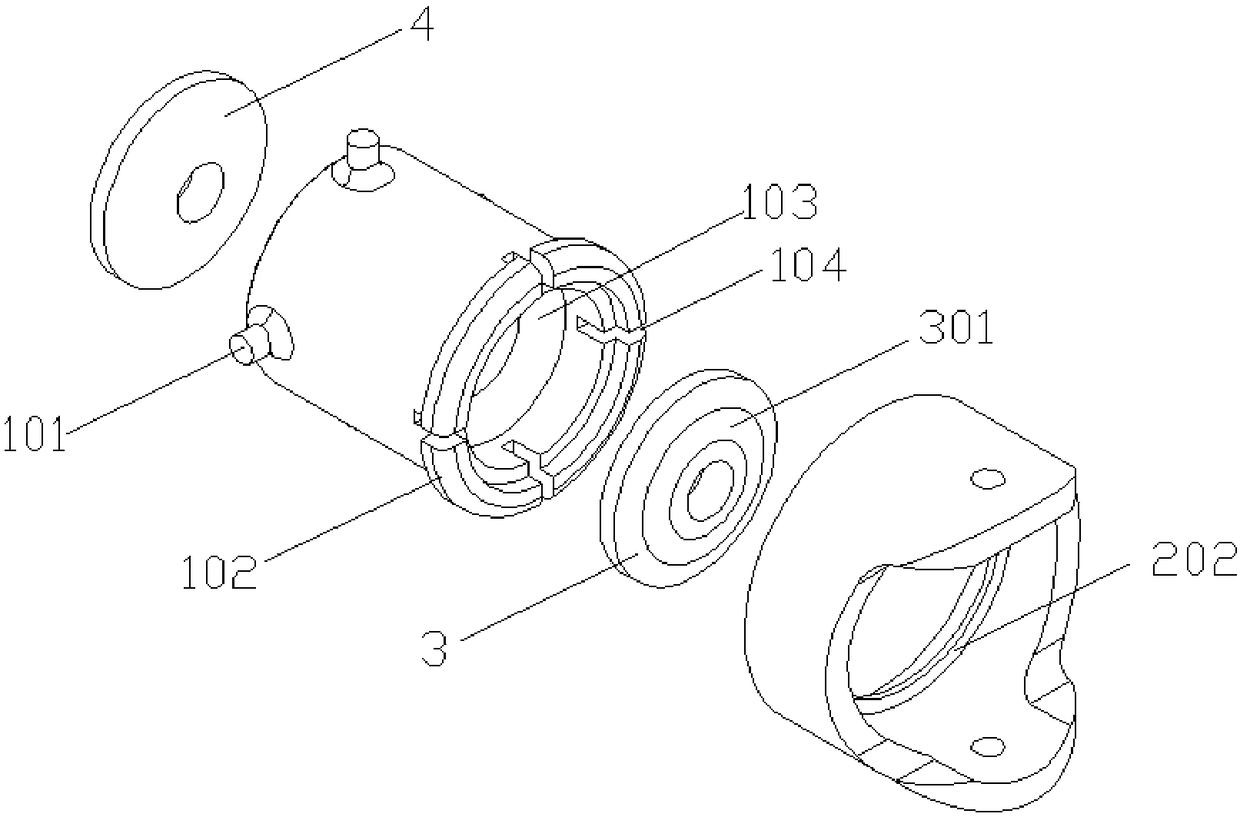

[0036] Such as figure 1 As shown, a wire feeding device for an arc welding robot includes at least two wire feeding tubes, and every two wire feeding tubes are connected by a connecting piece;

[0037] The wire feed tube includes:

[0038] Tube body 1, sealing upper cover 3 and sealing lower cover 4, sealing upper cover 3 and sealing lower cover 4 are arranged at both ends of tube body 1, respectively used for sealing both ends of tube body 1, sealing upper cover 3 and sealing lower cover 4 The middle hole is set at the center, and the welding wire passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com