Tread comprising a ventilated device for countering irregular wear

A protective, tread technology used in tire treads/tread patterns, tire components, transportation and packaging to solve problems such as accelerated aging and reduced fatigue and crack resistance of rubber compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

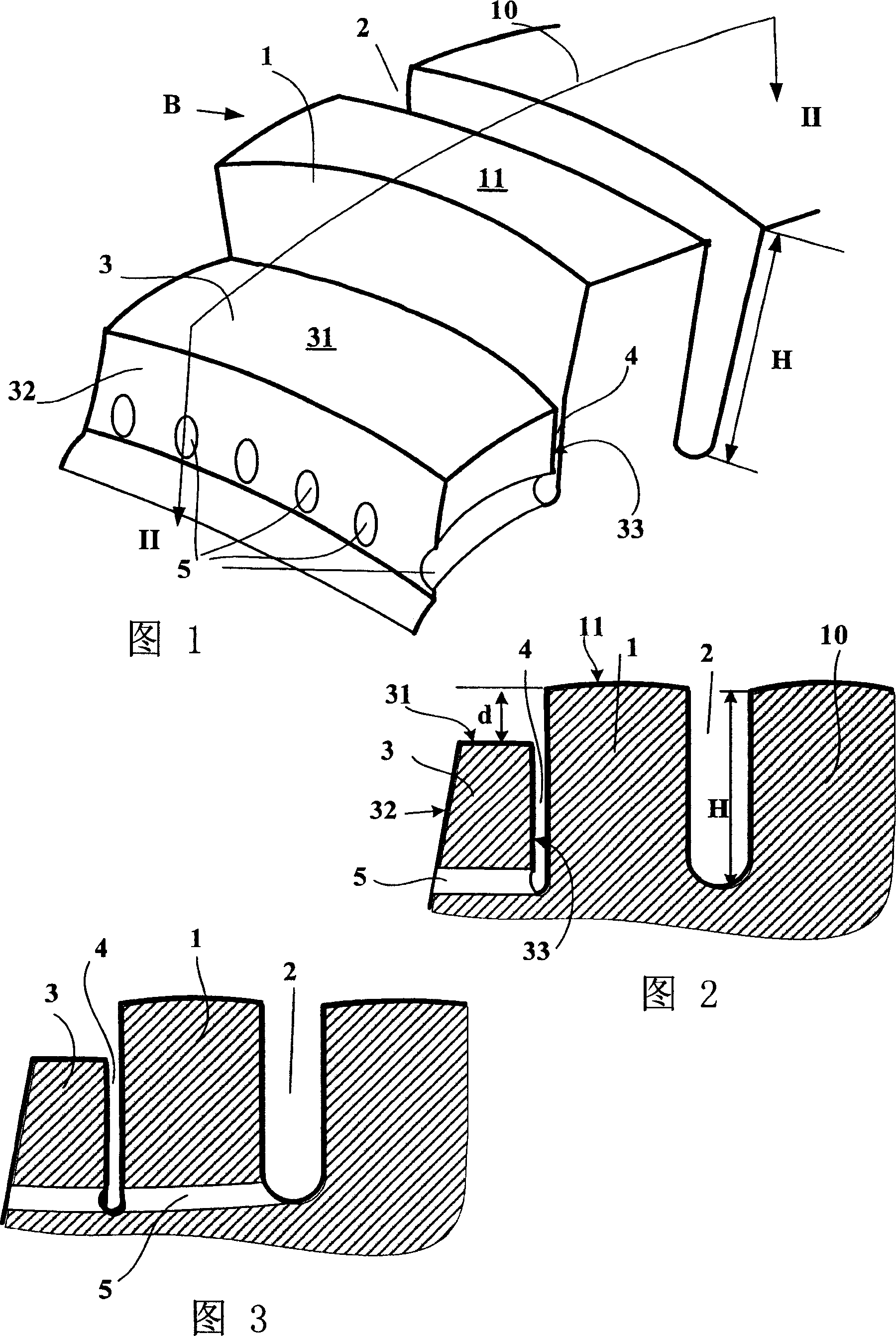

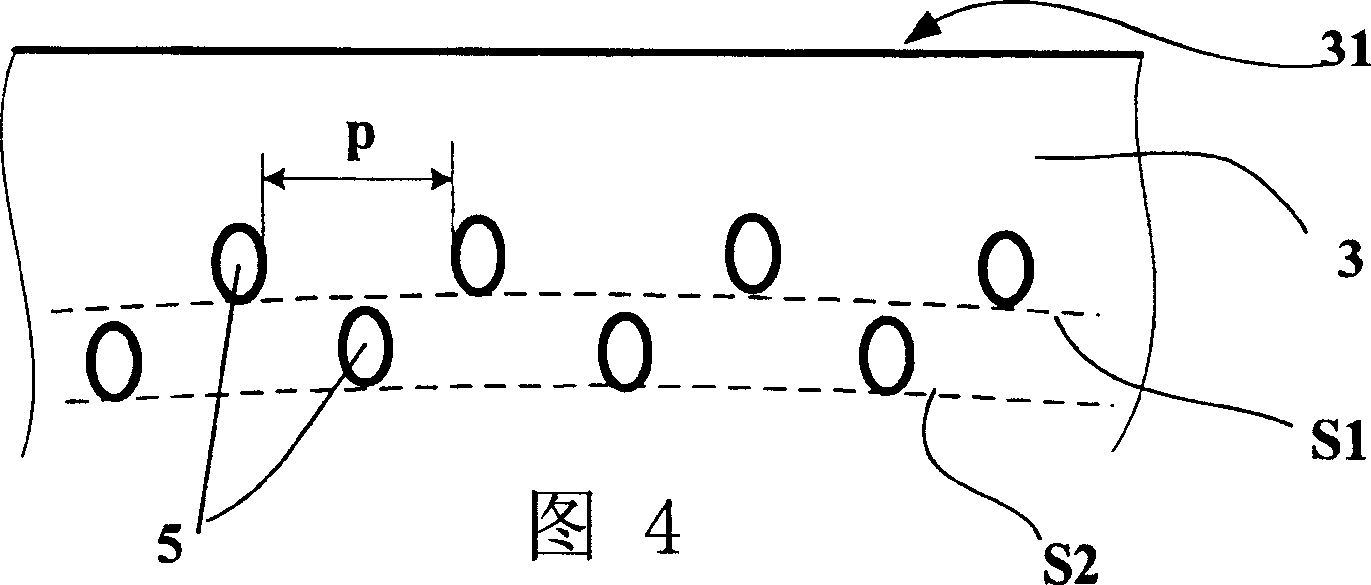

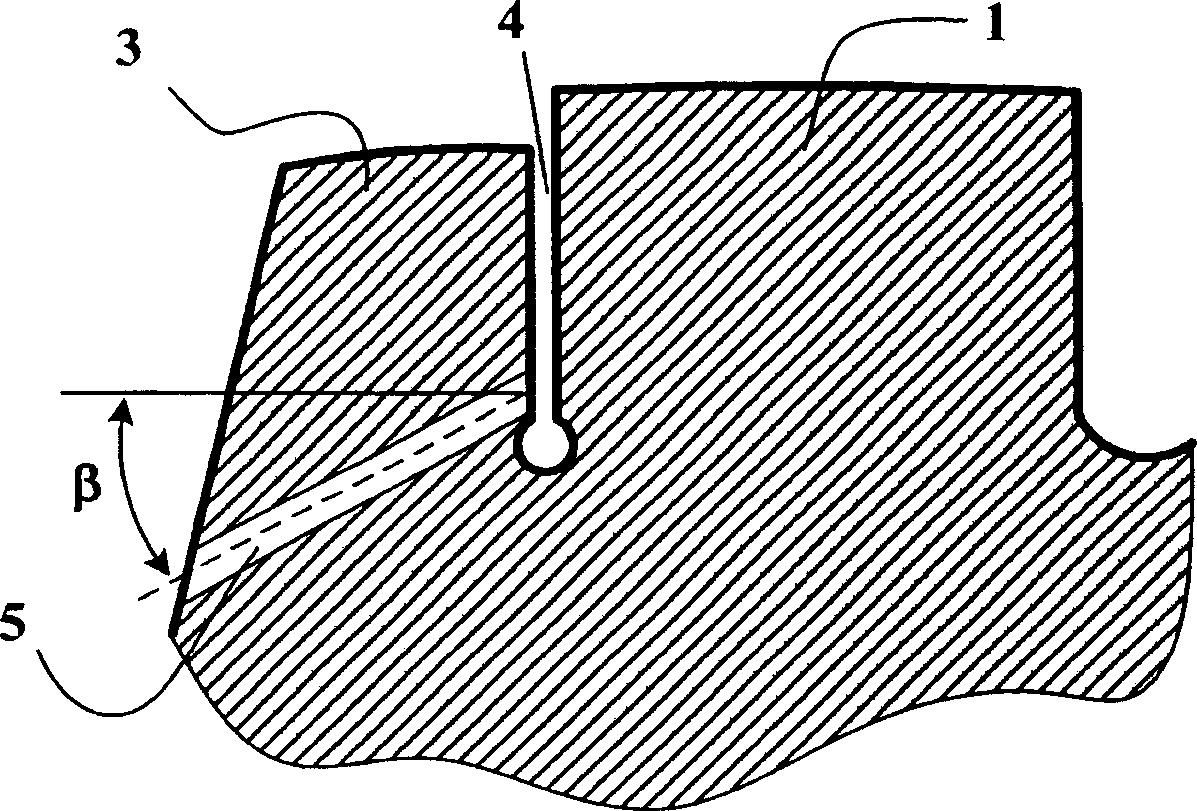

[0022] Figure 1 shows a partial view of a tread B according to the invention, corresponding to a tire of size 315 / 80 R 22.5, comprising a tread formed by a plurality of main treads 1, 10 running in the circumferential direction pattern, said main treads 1, 10 are separated from each other by circumferentially running main grooves 2 of depth H and equal width. Figure 1 shows the edge of a tread with an edge tread 1 provided with an offset tread 3 with a width of less than A notch 4 of 1 mm is separated from the edge tread and this offset tread 3 has the width of the main groove 2 . This incision 4 extends in the thickness of the tread to the same depth as the main groove.

[0023] The offset d, shown here as 1.4 mm, spans between the contact surface 11 of the edge tread 1 forming part of the tread's cap surface and the outer face 31 of the offset tread 3 so that, in the The outer surface 31 is also in contact with the ground under the load of the tire due to the load carried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com