Equipment vibration monitoring system based on multi-point MEMS accelerometer and wireless network

A vibration monitoring system and accelerometer technology, which is applied to vibration measurement in solids, vibration measurement, signal transmission system, etc. Low cost and the effect of preventing equipment resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

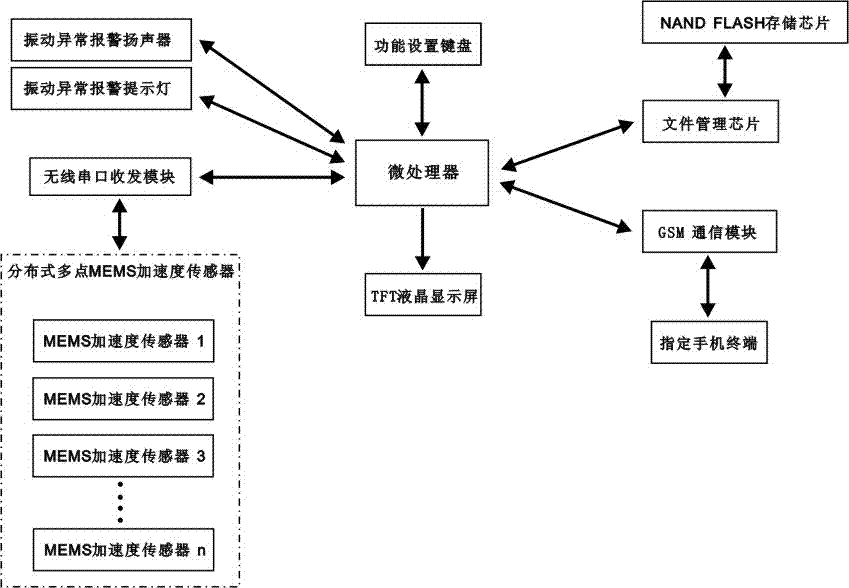

[0009] In order for those skilled in the art to better understand the technical solutions provided by the present invention, examples of the present invention will be described below in conjunction with the accompanying drawings.

[0010] figure 1 It is a structural block diagram of the present invention, the MEMS acceleration sensor in the implementation of the example uses ADXL362, the microprocessor uses MSP430F149, the GSM communication module uses GTM 900B, the file system management chip uses CH376T, the high-speed NAND Flash storage chip uses K9GBG08U0A, and the wireless communication module uses 433MHZ RS485 Wireless serial transceiver module.

[0011] When the system is running, the distributed multi-point MEMS acceleration sensor collects the acceleration data of each point of the device under test in real time, and the data is sent back to the system through the wireless communication network and compared with the preset acceleration threshold to determine whether ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com