Efficient distillation vacuum cooler

A vacuum cooling and high-efficiency technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of cooling leakage, affecting heat exchange effect, low heat exchange efficiency of distillation vacuum cooler, etc. The effect of preventing breakage, prolonging service life and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

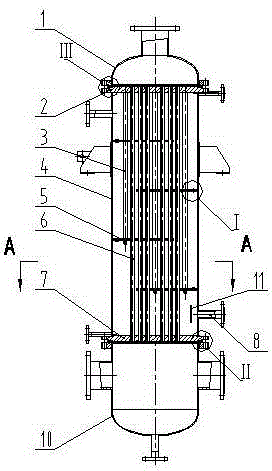

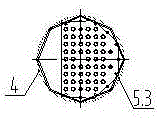

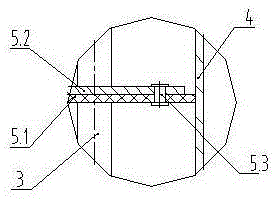

[0024] The high-efficiency distillation vacuum cooler shown in the accompanying drawings includes an upper head 1, an upper tube sheet 2, a cylinder body 4, a lower tube sheet 7, a lower head 10, a cooling water inlet pipe 8, several tie rods 3, and several baffles 5. A number of heat exchange tubes 6; the upper tube plate 2 and the lower tube plate 7 are respectively welded and connected to the upper and lower ends of the cylinder 4; the baffle plate 5 is placed in the cylinder 4 through the tie rod 3; the cooling water inlet pipe 8 is placed horizontally and fixed Connected to the tube wall at the lower part of the cylinder body 4; the baffle 5 is a composite baffle, including a flexible baffle 5.1 and a rigid baffle 5.2, and in this embodiment, the flexible baffle 5.1 is a soft plastic plate (other implementations In an example, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com