Hydraulic control system of bulldozer blade and control method

A technology of a hydraulic control system and a control method, which is applied to earth movers/excavators, construction, etc., and can solve problems such as low service life of blade cylinders and high difficulty in arranging internal parts of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

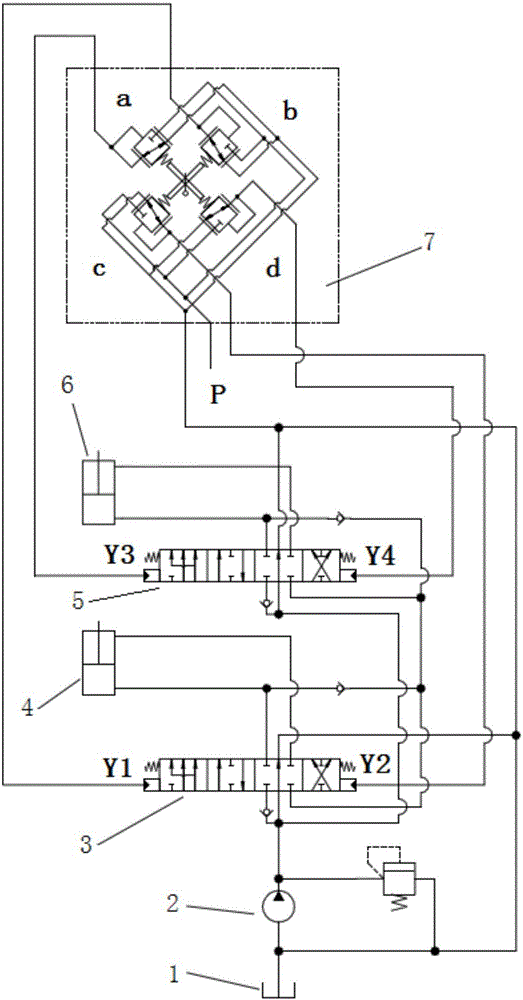

[0033] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

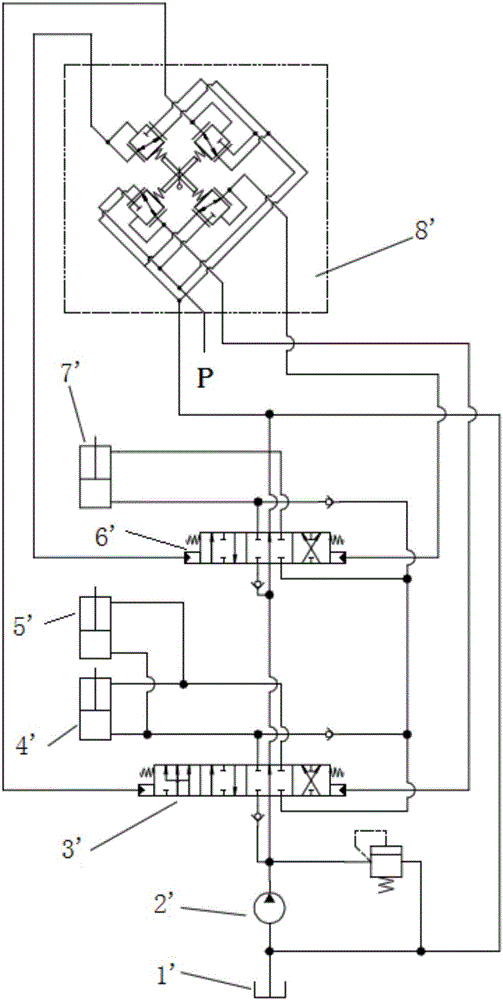

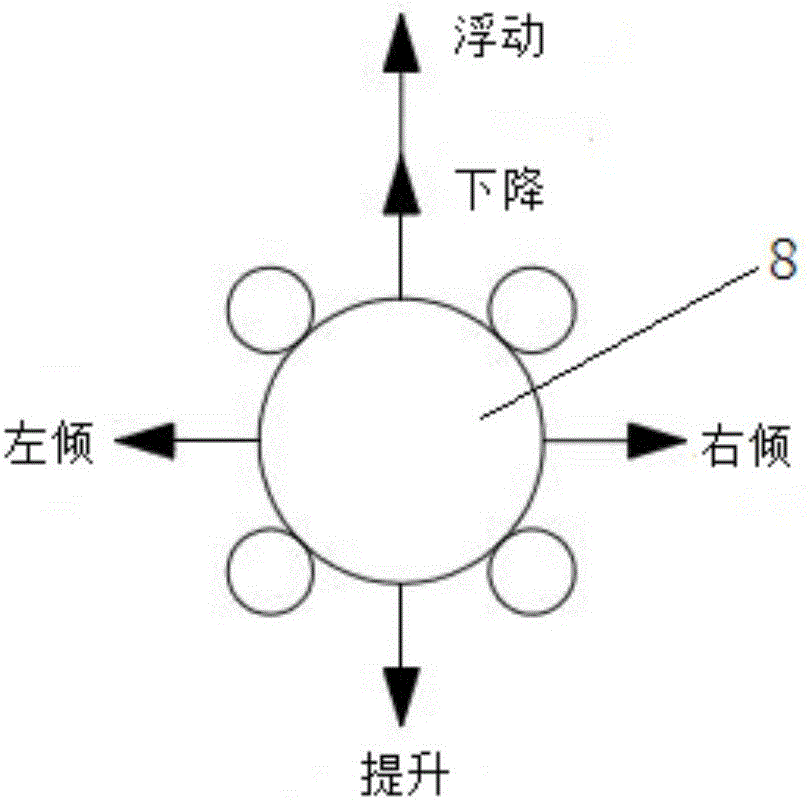

[0034] like Figure 2-3 As shown, the present invention provides a hydraulic control system for a bulldozer blade, including a fuel tank 1 , a hydraulic pump 2 , a right lift valve 3 , a right lift cylinder 4 , a left lift valve 5 , a left lift cylinder 6 and a pilot control valve 7 .

[0035] The right poppet valve 3 and the left poppet valve 5 are both four-position six-way valves. The oil in the oil tank 1 is connected to the oil inlets of the right poppet valve 3 and the left poppet valve 5 after passing through the hydraulic pump 2, and the right poppet valve 3 is connected with the oil inlet. The left lift valve 5 is arranged in parallel, the oil outlet of the right lift valve 3 is connected with the right lift cylinder 4 and the oil tank 1, and the oil outlet of the left lift valve 5 is connected with the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com