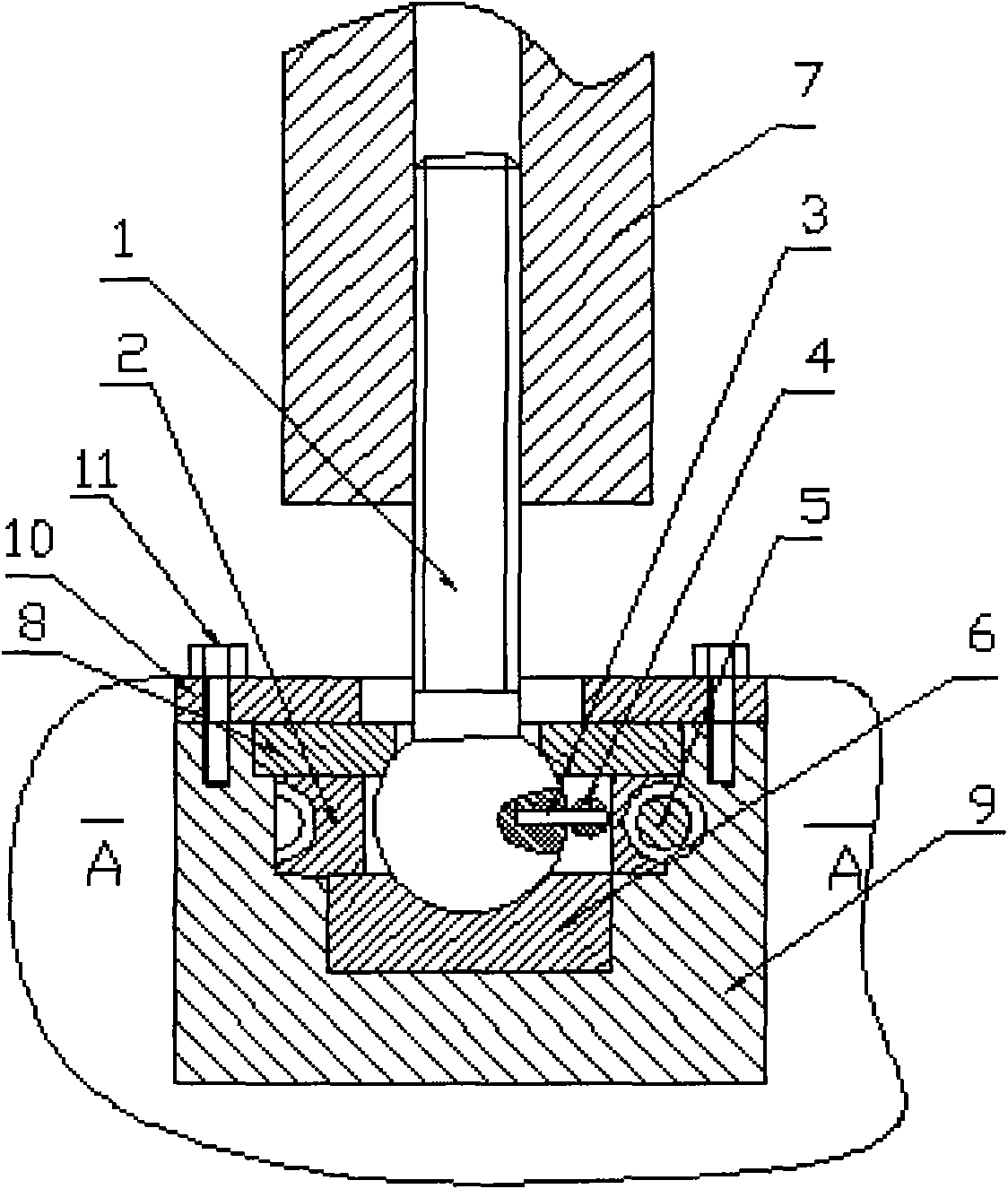

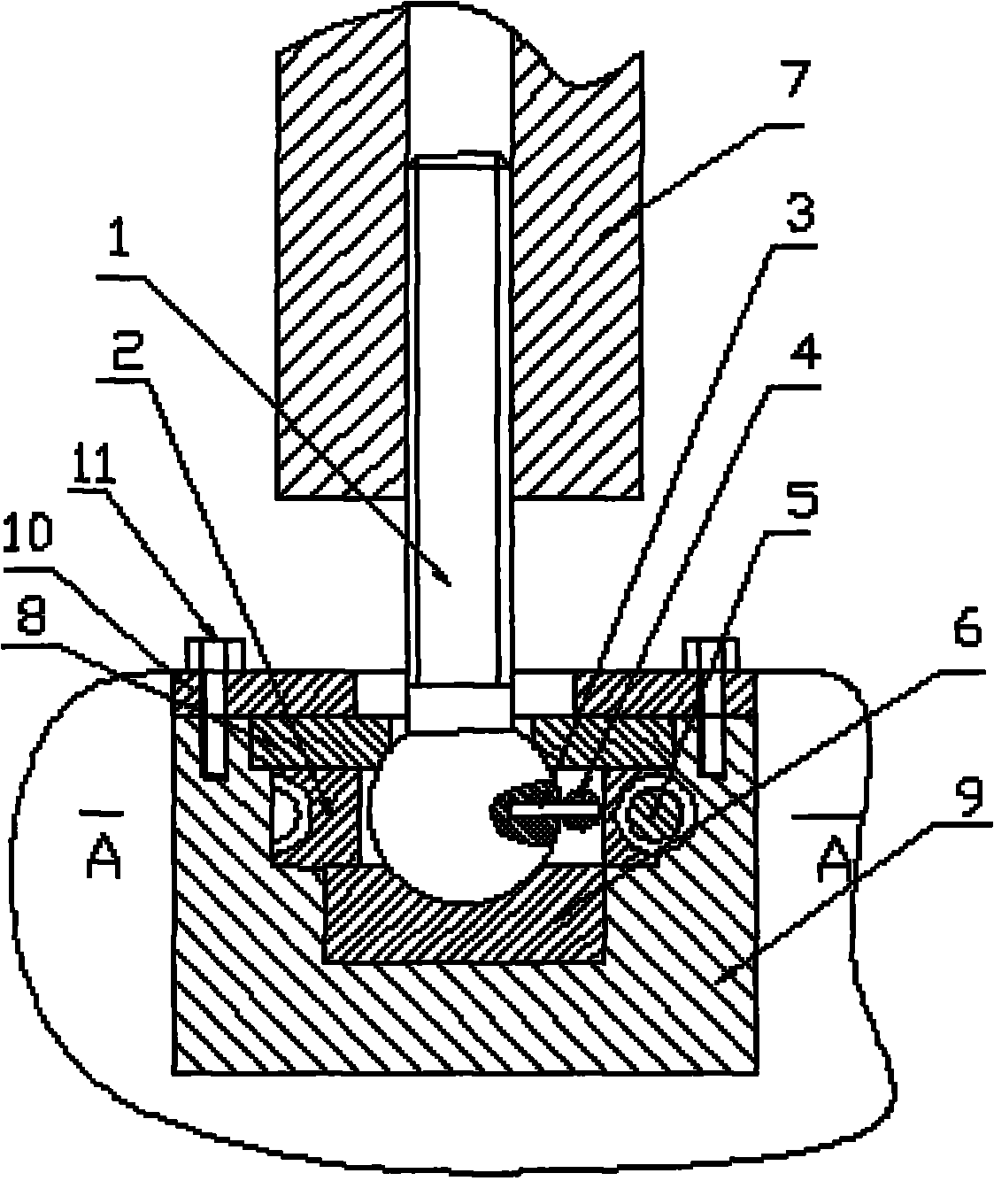

Novel structure for connecting ball screw and worm gear

A connecting mechanism and turbine technology, applied in the field of presses, can solve the problems of easy gnawing of positioning pins, abnormal wear of moving parts, easy blocking of positioning pins, etc., so as to prolong the service life and avoid abnormal wear and tear. stuck effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

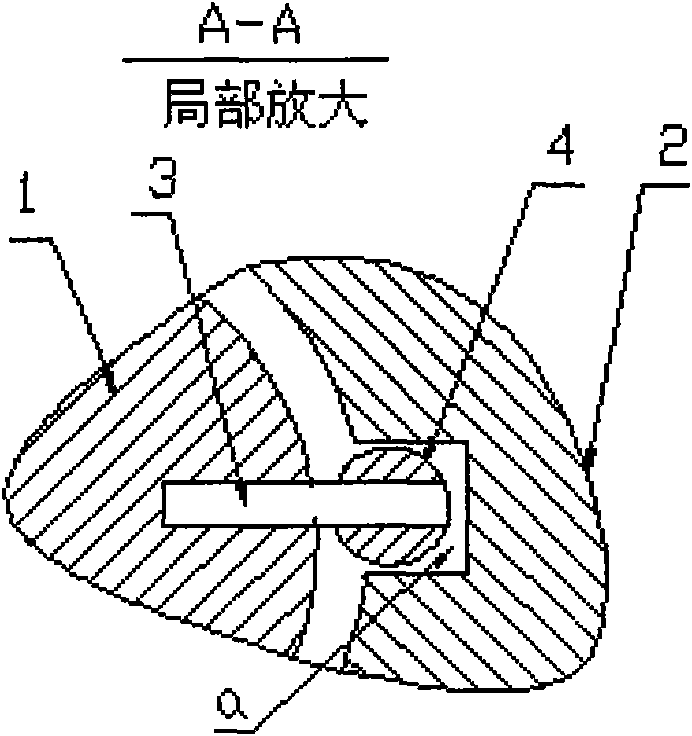

[0010] Install the lower ball bowl (6) to the bottom of the turbine case (9), install the worm rod (5) to the correct position of the turbine case (9), and place the turbine ( 2) Correct installation, to ensure that the worm gear (2) and the worm rod (5) are properly meshed, install the positioning pin (3) into the blind hole of the spherical part of the ball screw (1), and at the same time place the positioning pin on the protruding ball part (3) Install the upper joint ball (4), align the joint ball (4) with the notch on the turbine (2), pass the ball of the ball joint screw (1) through the middle hole of the turbine (2) and install At the ball bowl part of the lower ball bowl (6), pass the upper ball bowl (8) through the upper part of the ball screw (1), and install it correctly on the top of the turbine case (9), and put the gland plate (10 ) is installed on the turbine casing (9) and fixed with bolts (11) at the same time. Finally, install the connecting rod (7) on top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com