Micro-tension equal-torque metal material straightening method

A metal material and micro-tension technology, applied in the field of metal material straightening, can solve the problems of unreasonable design structure, unfavorable energy saving, wear and other problems, and achieve the effect of improving straightening efficiency, prolonging life and reducing equipment maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

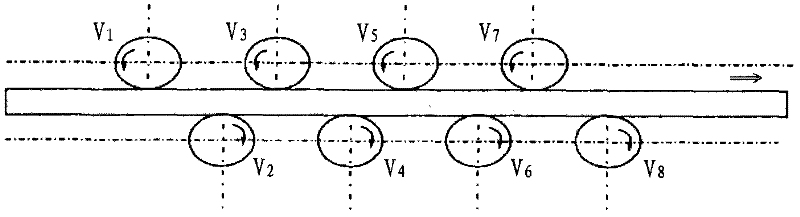

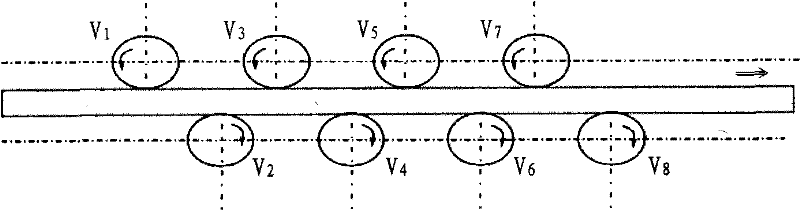

[0024] figure 1 A method for straightening rails with slight tension and equal torque according to an exemplary embodiment of the present invention is schematically shown. Such as figure 1 As shown, in this embodiment, the rail straightening equipment includes 8 straightening rollers with the same roll diameter, and the rotation direction of each straightening roller is as follows: figure 1 shown. The rails run in a direction from left to right (ie, in the direction indicated by the double arrows shown in FIG. 2 ). The above-mentioned 8 straightening rollers arranged along the rail running direction are sequentially recorded as the first straightening roller, the second straightening roller, the third straightening roller, the fourth straightening roller, the fifth straightening roller, and the sixth straightening roller , the seventh straightening roller and the eighth straightening roller, their speeds are recorded as v 1 , v 2 , v 3 , v 4 , v 5 , v 6 , v 7 and v ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com