Power supply system and power supply unit thereof

An electric energy supply system and electric energy supply technology, applied in the manufacture of electrical components, non-aqueous electrolyte batteries, and electrolyte batteries, etc., can solve problems such as poor yield and reliability of welding projects, reduced efficiency of battery cells, and difficult contact conditions. To achieve the effect of simplifying the assembly and manufacturing engineering, reducing the manufacturing process, and reducing the number of interfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

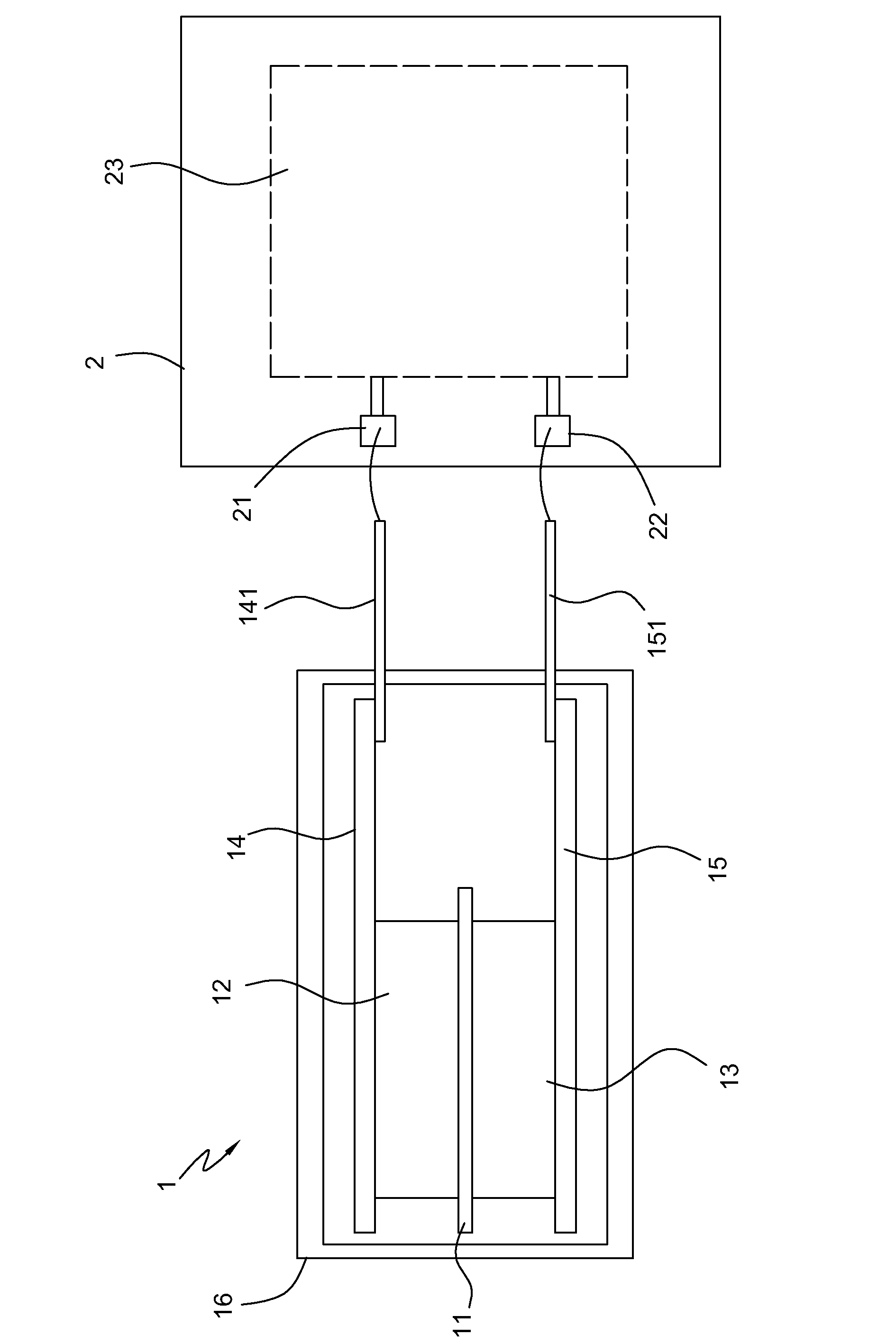

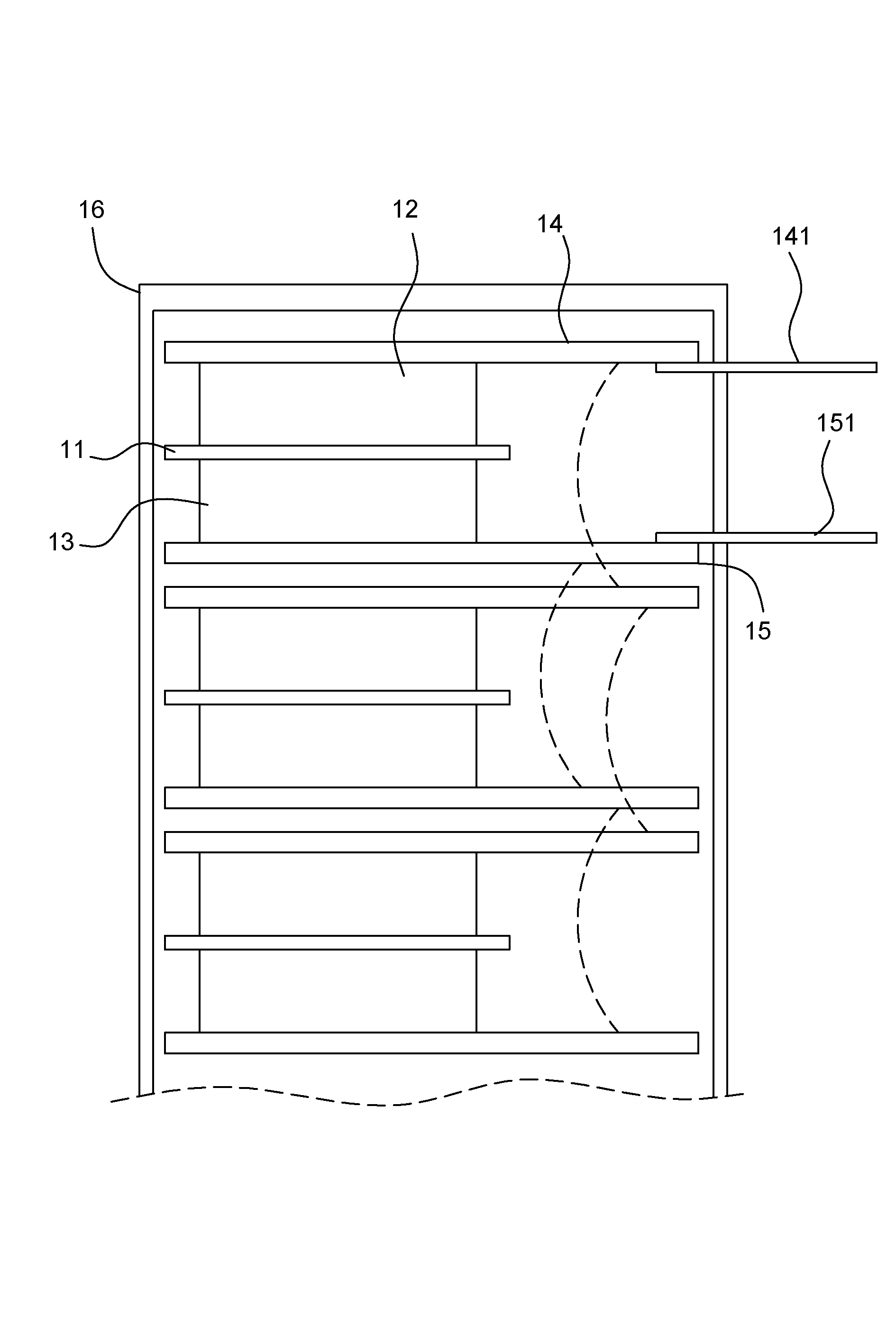

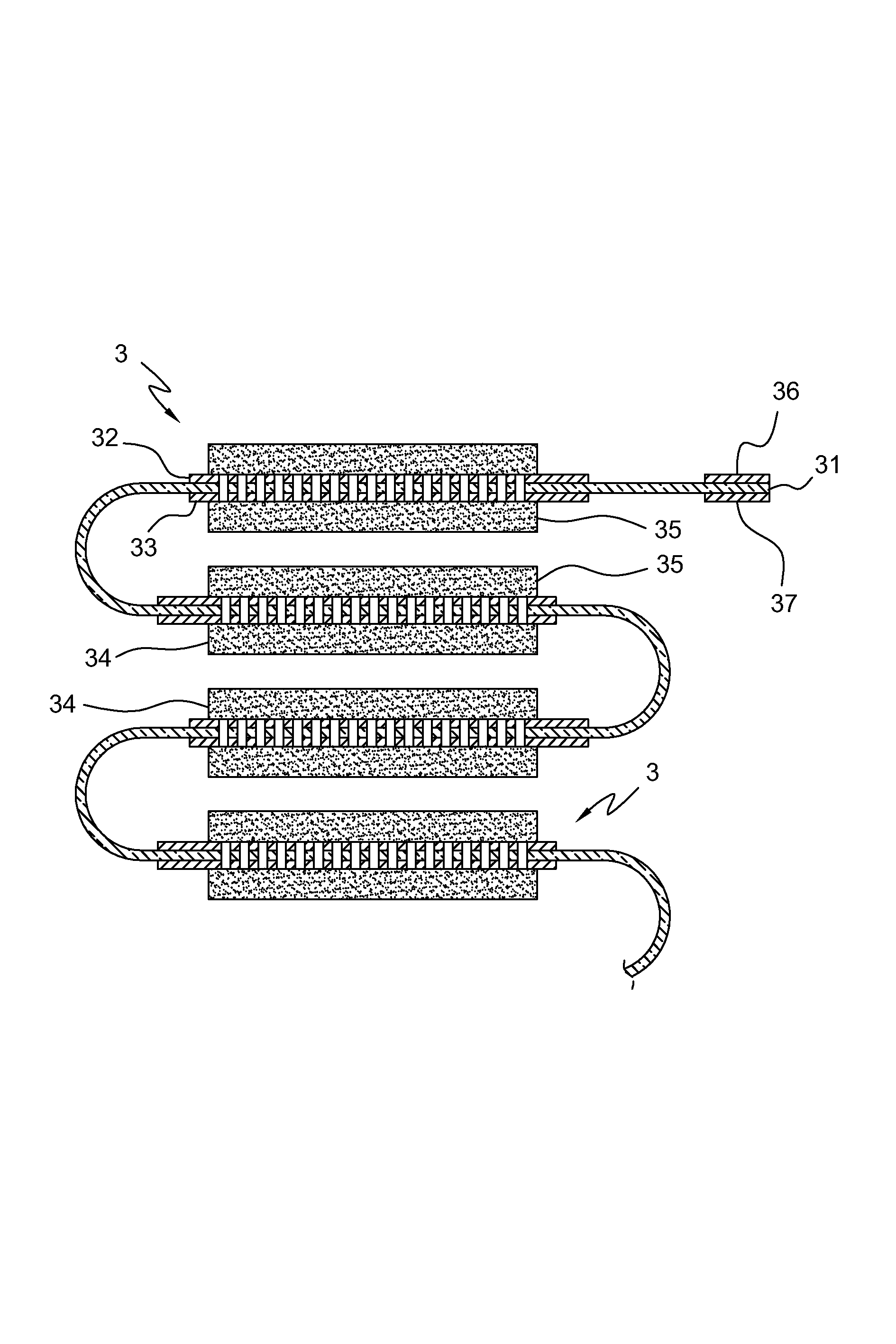

[0060] Please refer to FIG. 2 , which is a schematic cross-sectional view of a power supply unit according to a preferred embodiment of the present invention. The power supply unit 3 includes a substrate 31, a first collector layer 32, a second collector layer 33, a first active material layer 34, and a second active material layer 35, wherein the substrate 31 includes an isolated conduction region 311 and a phase The adjacent external line connection area 312 has a plurality of micro-holes 313 on the isolation conduction area 311, and the first collector layer 32 is located on one side of the substrate 31, and has a plurality of micro-holes 313 corresponding to the isolation conduction area 311. The micro-holes 321 ; the second collector layer 33 is located on the other side of the substrate 31 and has a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com