Single-stage suspension device for bogie of high-speed rail wagon

A high-speed railway and suspension device technology, which is applied in the direction of axle box installation, etc., can solve the problems such as difficult to allocate more suitable longitudinal and lateral positioning stiffness values, and achieve the effects of avoiding abnormal wear, improving the stress state, and facilitating replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the drawings and embodiments.

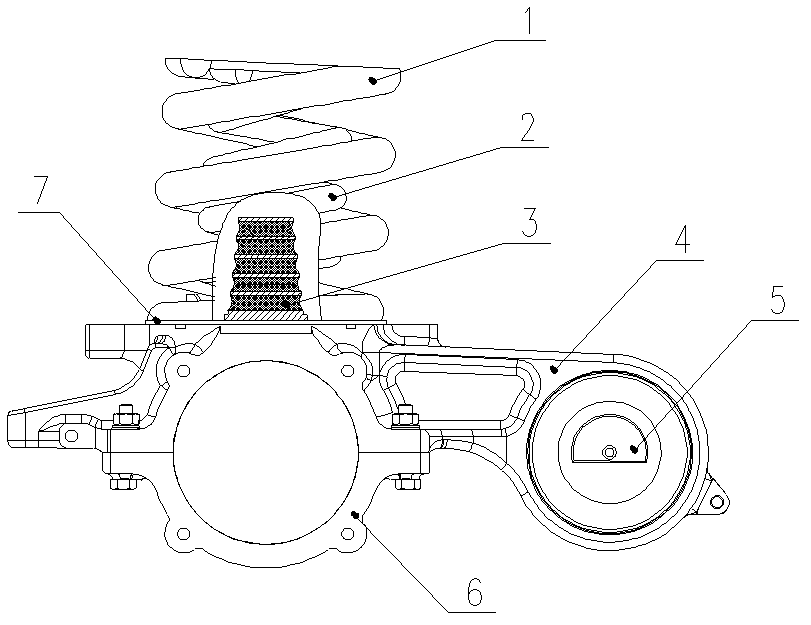

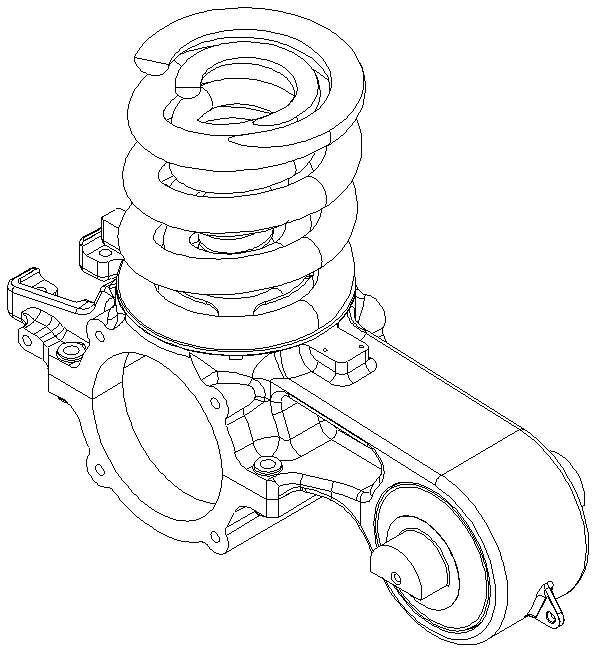

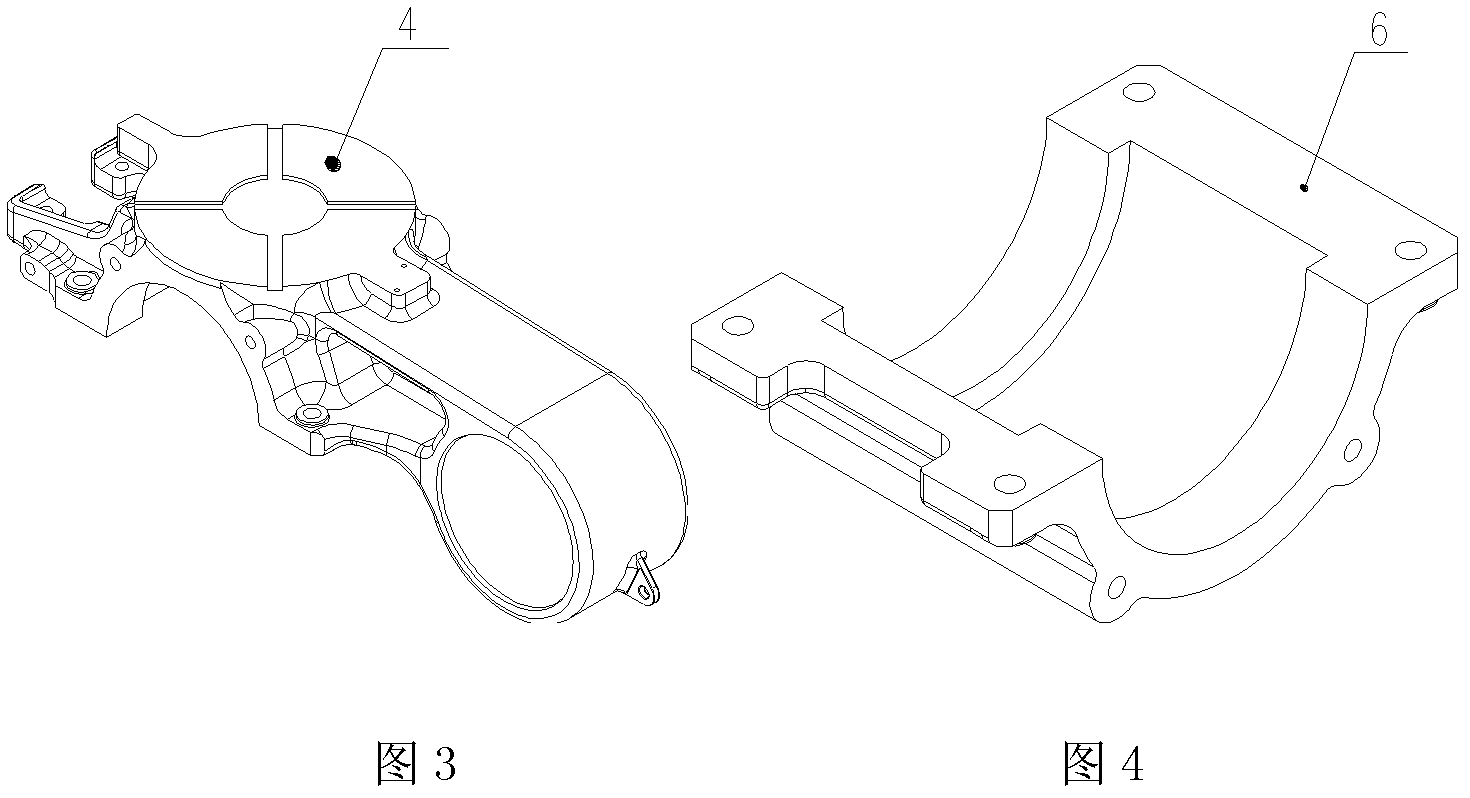

[0022] Such as figure 1 , 2 As shown, the primary suspension device of the high-speed freight car bogie of the present invention includes a primary external circular spring 1, a primary internal circular spring 2, a vertical elastic stop 3, an upper axle box 4, and a rotating arm Elastic rubber node 5, one lower axle box 6, one spring mounting support plate 7. Such as figure 1 Shown. The structure can obtain the longitudinal and lateral stiffness values required by the bogie for high-speed operation by adjusting the longitudinal and lateral stiffness of the elastic rubber node 5 of the boom, and realizes the wear-free design of a series of axle box spring suspension system, and a series of external circular springs. 1 and a series of inner circular spring 2 are placed on the top of the upper axle box 4, so that the elastic rubber node of the arm 5 will not be subjecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com