Automatic wire connecting device for numerical control lathes

A CNC lathe, automatic technology, applied in the field of CNC lathes, can solve problems such as reduced efficiency, and achieve the effect of improving production efficiency and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will be described in detail in conjunction with the accompanying drawings and specific embodiments. The material processed in this embodiment is bar stock, but it is not limited to the processing of bar stock and transshipment.

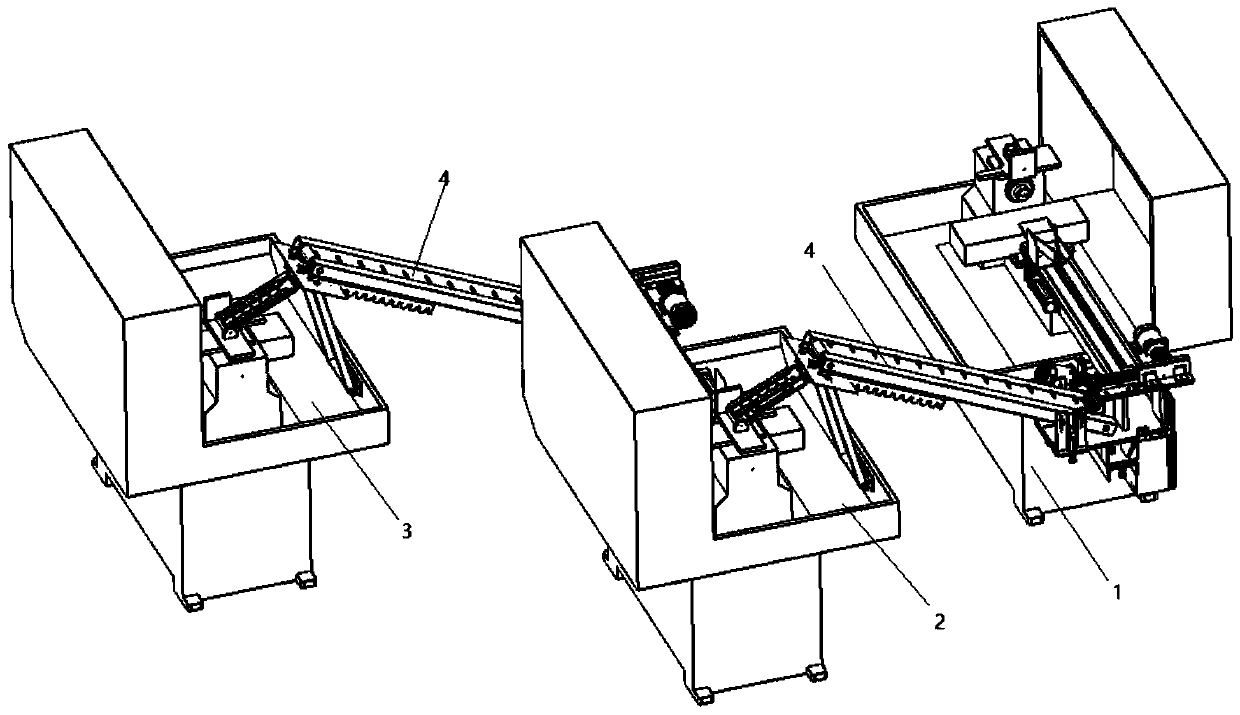

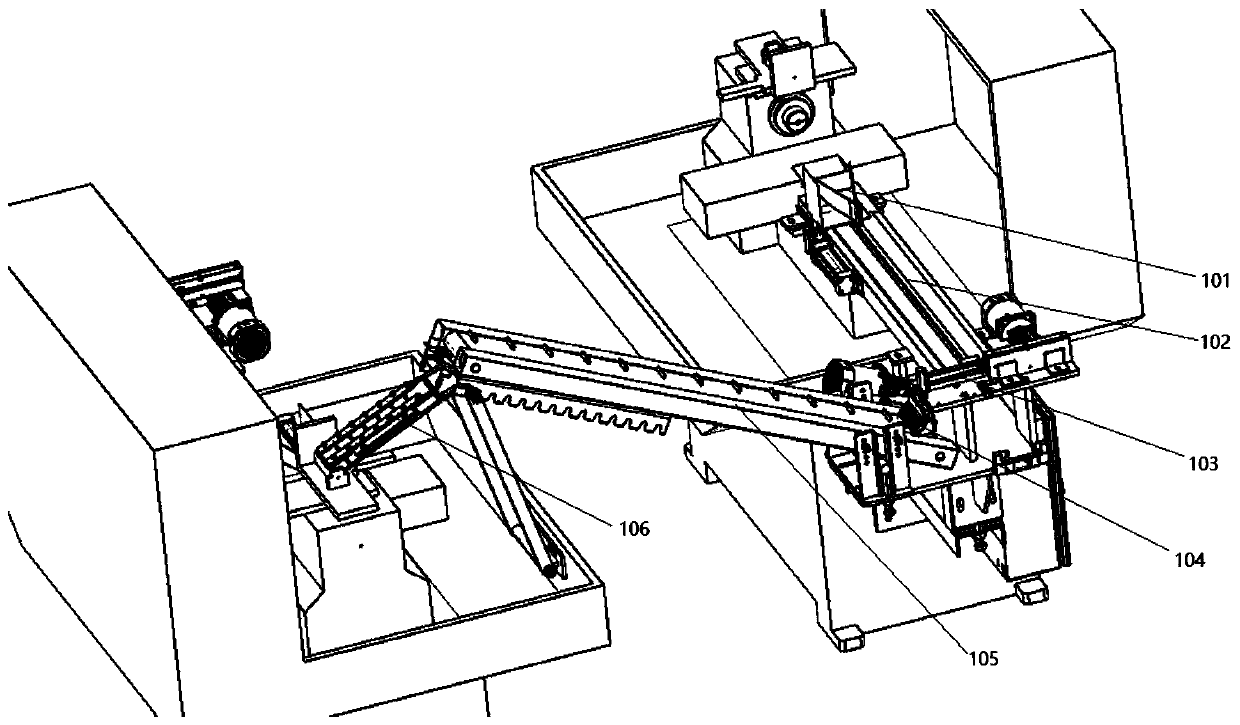

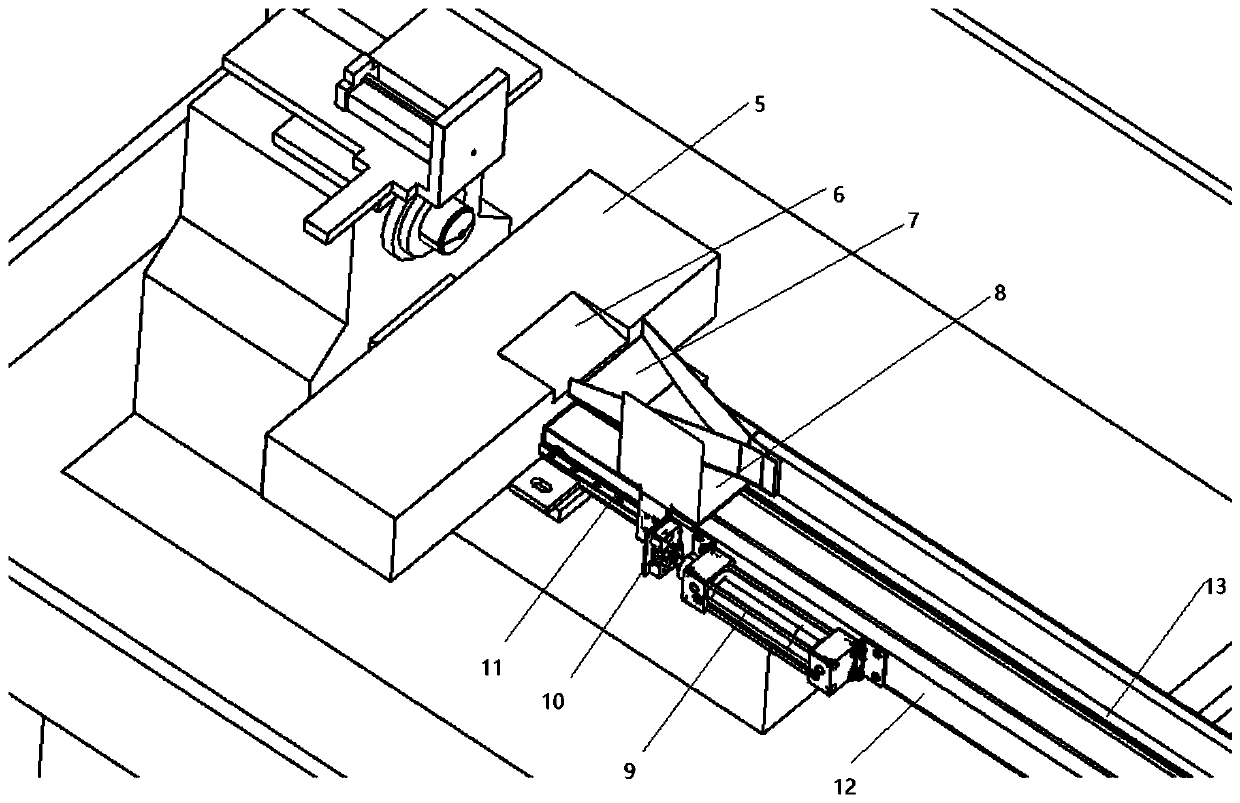

[0024] Such as Figure 1 to Figure 2 As shown, the present invention provides a kind of CNC lathe automatic connection device for the existing problems, including a material receiving device 101, a first conveying device 102, a material pushing device 103, a material bin 104, a second conveying device 105 and Clip assembly 106, the material receiving device 101, the first transfer device 102, the pushing device 103, the material storage bin 104, the second transfer device 105 and the clip assembly 106 are connected in sequence, and the material receiving device 101 starts from the first The CNC lathe 1 receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com