Continuous fastener tape turning-around and cutting-off unit and zipper manufacturing equipment adopting continuous fastener tape turning-around and cutting-off unit

A technology for cutting units and zipper tapes, applied in the direction of application, sliding fastener components, fasteners, etc., can solve the problems that cannot meet the needs of full automation of zipper manufacturing equipment, and have not been seen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

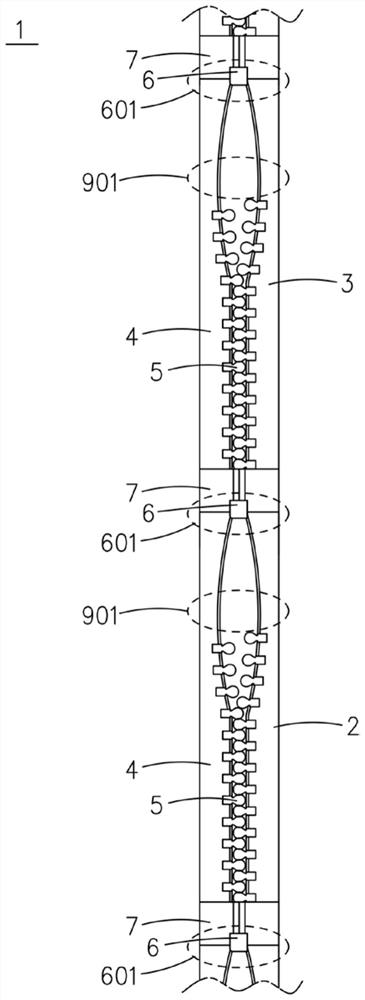

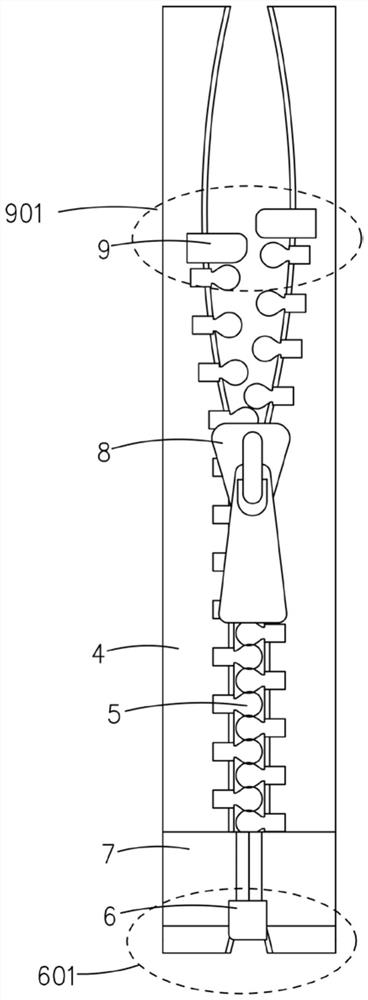

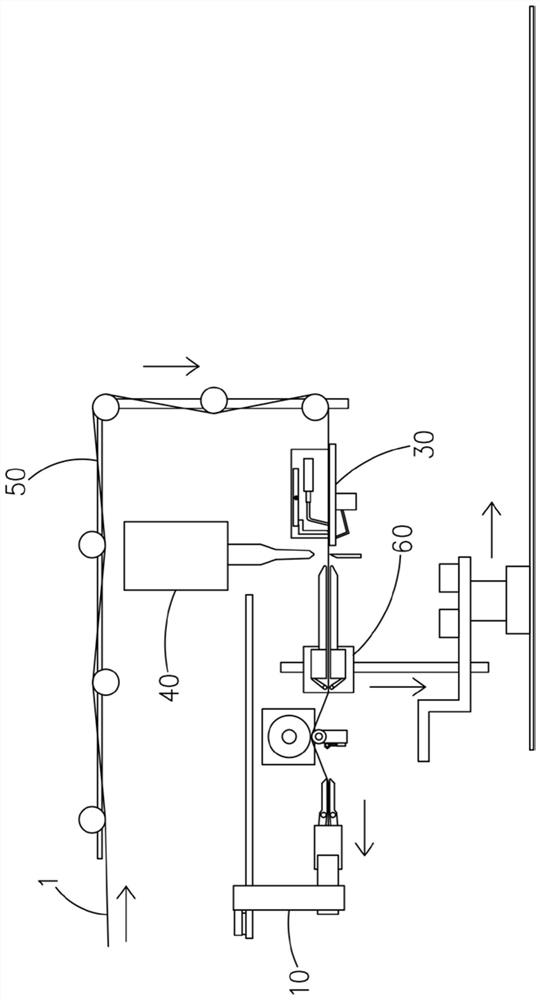

[0046] see image 3 , the continuous zipper tape U-turn of the present invention, cutting unit, comprise the drawstring device 10 that is used to pull the continuous zipper tape 1 to advance, the positioning device 30 that is used for positioning the lower end stop portion 601 of the zipper, is used for the continuous zipper tape 1 The cutting device 40 for cutting between the last upper end stop 901 and the next lower end stop 601, the belt guide device 50 for guiding the continuous zipper tape 1 to turn around, and the zipper for turning around and cutting. Conveying device 60 for delivery.

[0047] see image 3 , 4 , The guide belt device 50 includes a horizontal L-shaped guide wheel bar 51, and a plurality of guide wheels 52 are mounted on the guide wheel bar 51, and the plurality of guide wheels 52 are distributed along the guide wheel bar 51 in a horizontal L-shape. The belt-drawing device 10 is located below the belt-guiding device 50 , and together with the belt-gui...

Embodiment 2

[0052] see Figure 10 , the equipment before the zipper manufacture of the present invention includes a gluing device 110, a punching device 120, a sizing device 130, a box pin forming device 140, and also includes the continuous zipper tape U-turn and cutting unit described in Embodiment 1; Gluing device 110, punching device 120, sizing device 130, box pin forming device 140 are provided with continuous zipper tape U-turn, cutting unit, by gluing device 110, punching device 120, sizing device 130, box pin forming device 140 The manufactured continuous zipper tape 1 enters the tape guide device 50 in the continuous zipper tape U-turn and cutting unit, and then is turned around and cut. The pre-manufacturing equipment of the zipper of the present invention, through the conveying device 60 in the continuous zipper tape U-turning and cutting unit, can realize automatic connection with the zipper head threading, forming top stop and other processes.

Embodiment 3

[0054] see Figure 11 , the post-manufacturing equipment of the zipper of the present invention includes the head-threading device 210, the upper stop forming device 220, the discharge device 230, and also includes the continuous zipper tape U-turn and cutting unit described in Embodiment 1; on the head-threading device 210, the upper Before the forming device 220 and the discharge device 230, the continuous zipper tape U-turn and cutting unit are arranged, and the zipper after the continuous zipper tape U-turn, the cutting unit U-turn, and the cutting passes through the conveying device 60 in the continuous zipper tape U-turn and cutting unit, and enters the The head device 210, and then reaches the top stop forming device 220, the discharge device 230, and carries out the head piercing, forming the top stop and discharging. The post-manufacturing equipment of the zipper of the present invention, through the continuous zipper tape U-turn and the tape guide device 50 in the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com