Patents

Literature

37results about How to "Reduce the difficulty of crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

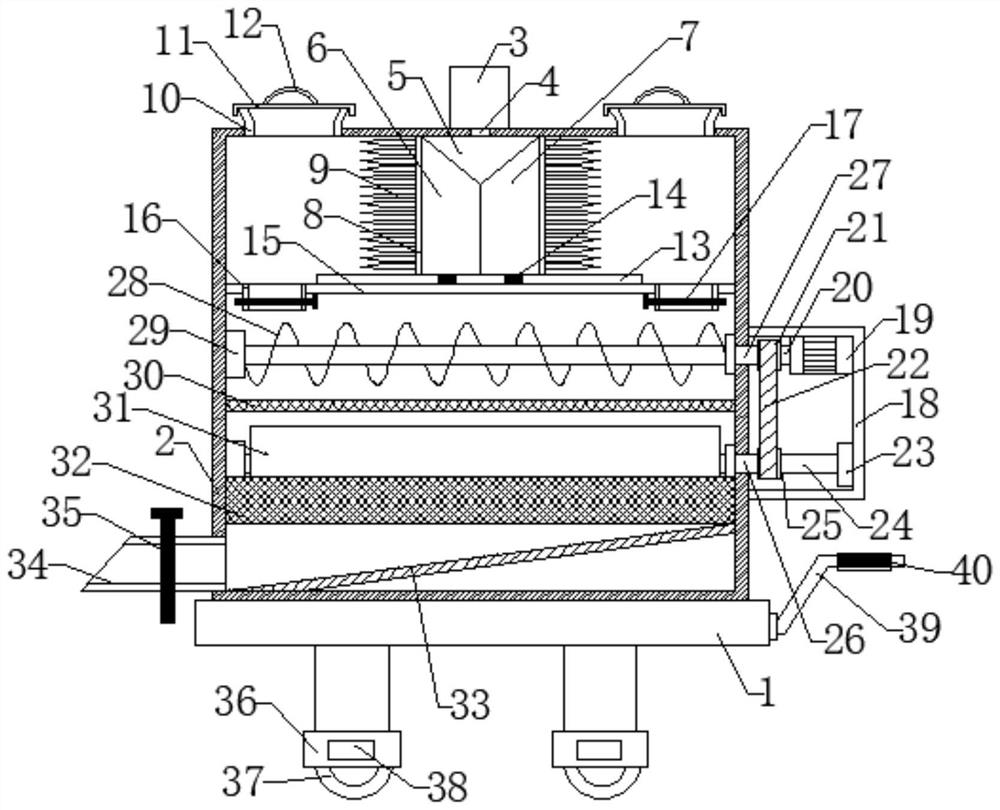

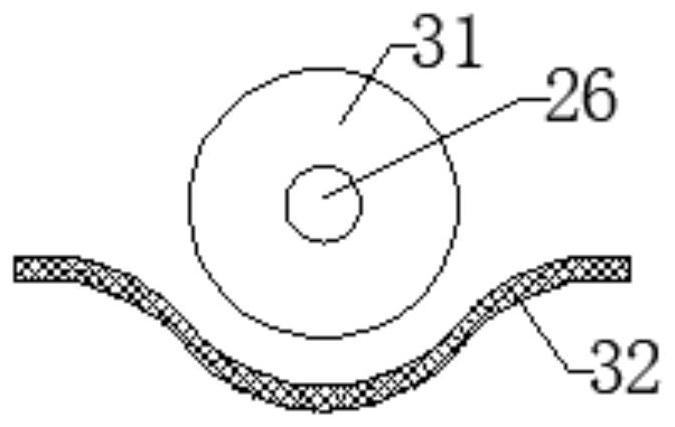

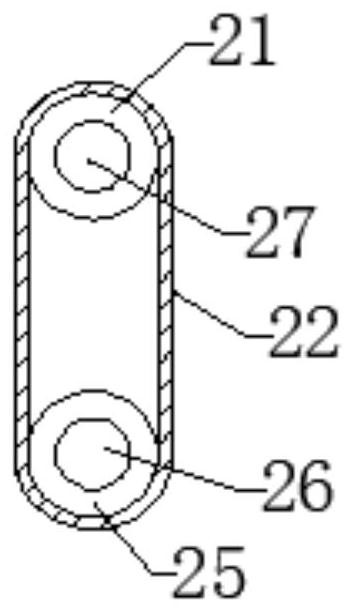

Crushing device for mine

InactiveCN107159403AReduce the difficulty of crushingAchieve recyclingGrain treatmentsElectric machineryEngineering

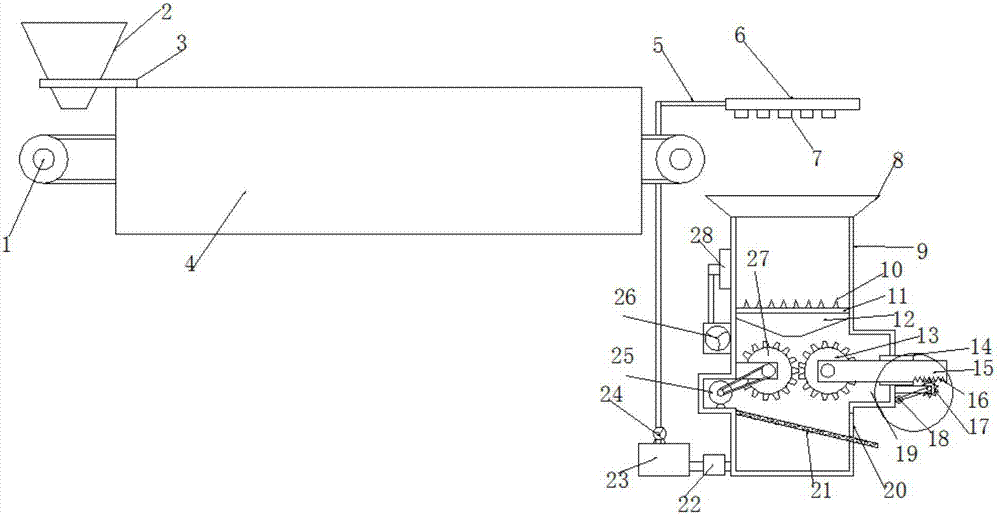

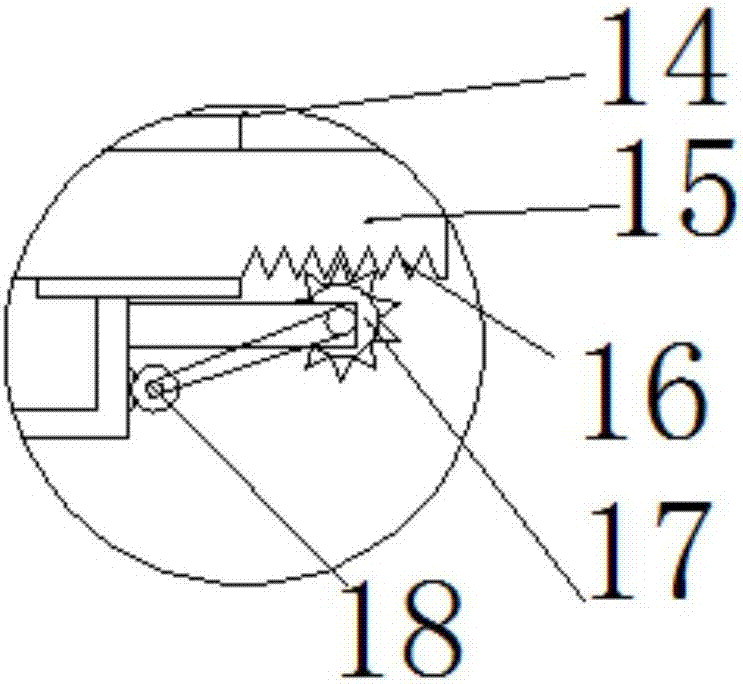

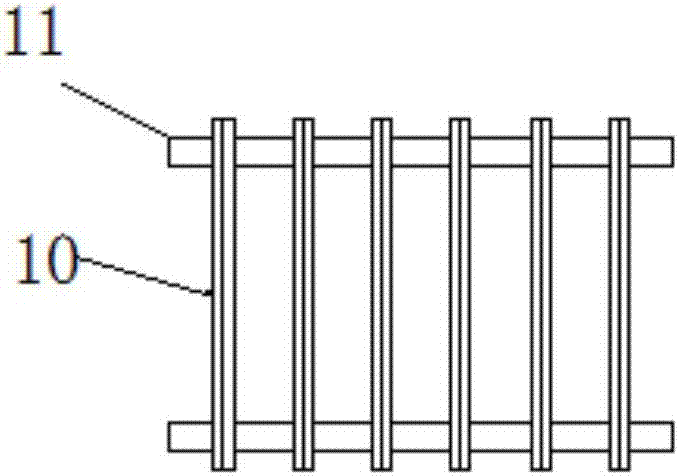

The invention discloses a crushing device for a mine. The crushing device comprises a material feeding conveyor belt and a crushing barrel; the outer side of the conveyor belt is provided with a heating channel, the heating channel is internally provided with a plurality of heating blocks, the left upper position of the conveyor belt is provided with a material adding hopper, and the right lower side of the conveyor belt is provided with the crushing barrel; the upper end of the crushing barrel is fixedly provided with a feeding hopper, a water spraying disc is arranged above the feeding hopper, the lower end face of the water spraying disc is uniformly provided with water spraying openings, the crushing barrel is internally provided with a crushing grid, the position, below the crushing grid, of the crushing barrel is internally provided with a material collection hopper, and the position, below the material collection hopper, of the crushing barrel is internally provided with a fixed crushing gear and a movable crushing gear; and the end of a fixed rotating shaft of the fixed crushing gear is in transmission connection with a crushing motor through a belt, and the crushing motor is fixed into an installation box on the left side of the crushing barrel. The crushing device is simple and reasonable in structure, stone crushing difficulty is lowered through the principle of expansion and contraction of objects, and the service life of the device is prolonged; and meanwhile, recycled utilization of water resources is achieved through the device, and the role of saving water is played.

Owner:贵港市鼎金电子产品有限公司

Method for producing whole wheat flour by performing air flash explosion technology on bran and product thereof

PendingCN108402392AEfficient killingGreat tasteFood thermal treatmentFood preservationPre treatmentHigh pressure

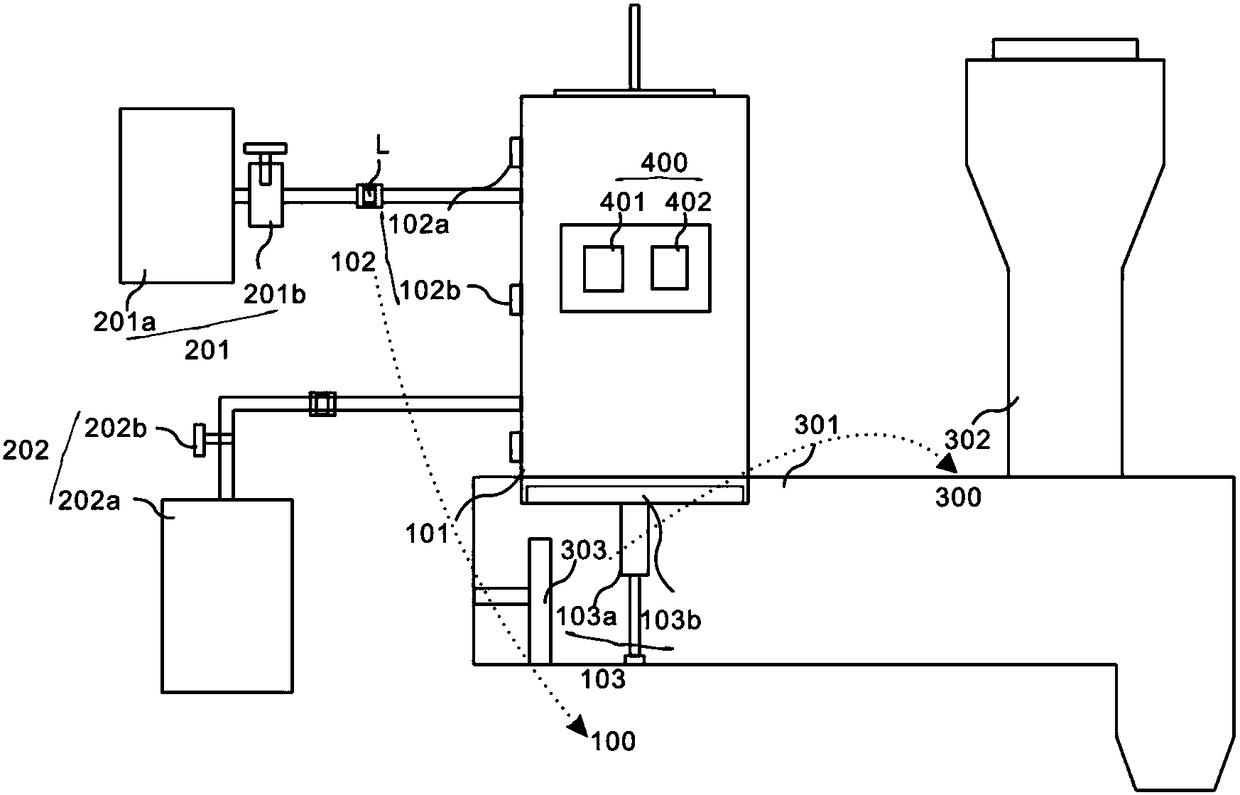

The invention discloses a method for producing whole wheat flour by performing air flash explosion technology on bran and a product thereof. The method for producing whole wheat flour by performing air flash explosion technology on bran comprises the following steps of carrying out pretreatment, namely adjusting water content of bran, performing air flash explosion treatment, and carrying out drying so as to obtain dried bran; and then, carrying out flour blending, namely crushing the dried bran, carrying out sieving, and carrying out mixing with flour so as to obtain the whole wheat flour. The technology for producing whole wheat flour by performing air flash explosion technology on bran aims to solve the problems of existing whole wheat flour, namely liable damages on gluten protein andstarch, difficult powder preparation, short storage time and the like. According to the method for producing whole wheat flour, bran is treated by utilizing air flash explosion technology, wherein airexplosion pressure is provided by an external air compressor and temperature is provided by saturated steam so that pressure and time become two independent controllable parameters; and thus, the temperature can be controlled within a relatively low range. In addition, a relatively high pressure can be simultaneously maintained and instantaneously released so as to reduce activities of lipase andlipoxygenase, and thus, shelf life of the whole wheat flour is prolonged.

Owner:JIANGNAN UNIV

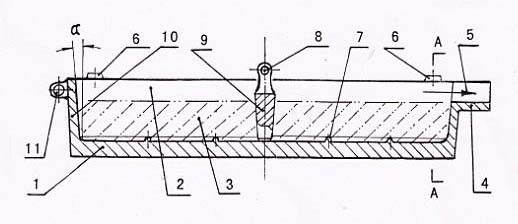

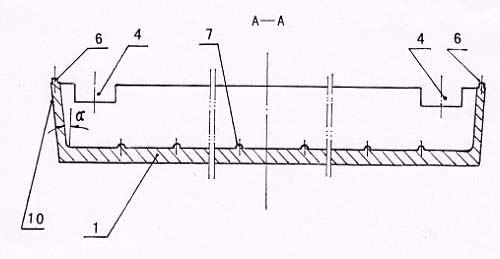

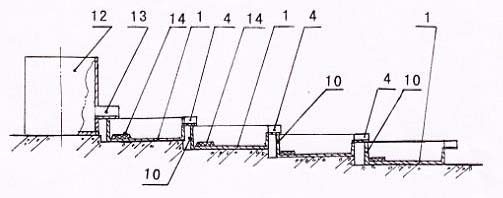

Ingot mould used for casting iron alloy and casting method thereof

ActiveCN102211152AReduce the difficulty of crushingSave human resourcesProcess efficiency improvementCast ironMicro cracks

The invention provides an ingot mould used for casting an iron alloy and a casting method thereof. The casting method comprises the following steps of: mounting an ingot mould set provided with an iron runner into a stepped sequentially-cast arrangement structure in stepped fall positions, arranging the ingot moulds, assembling, demoulding and lifting iron, pouring molten iron, fetching the iron and demoulding, quenching with water and finishing to cast the iron alloy; when the temperature of an iron block is reduced to 700-1000 DEG C, fetching the iron, and quenching an alloy iron block at high temperature with water, thus internal metallographic structure is converted into crisp thick longitudinal columnar crystal and massive micro cracks are produced on the surface, and the crushing difficulty is greatly reduced. By adopting the ingot mould and the casting method provided by the invention, the production conditions can be obviously improved, the labour intensity is alleviated, the crushing processing efficiency and product particle size percent of pass are improved, the energy consumption is reduced, and the economic benefit is increased, and the ingot mould and the manufacturing method thereof have the advantages of simple structure, flexible mounting, convenience in casting operation and convenience in quenching of molten iron block at temperature with water, thus the ingot mould and the manufacturing method thereof have an excellent popularization and application prospect.

Owner:四川川投峨眉铁合金(集团)有限责任公司

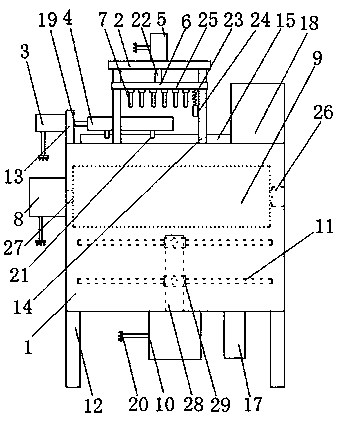

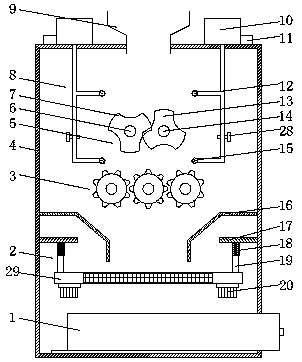

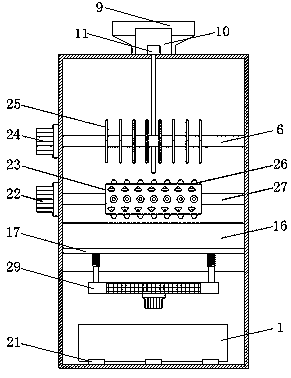

Traditional Chinese medicinal material multi-stage smashing device for decoction piece processing

The invention discloses a traditional Chinese medicinal material multi-stage smashing device for decoction piece processing. The traditional Chinese medicinal material multi-stage smashing device fordecoction piece processing comprises a smashing chamber, a top plate, a first cylinder, a bearing plate, a second cylinder, an adjusting plate, a cutter, a first motor, a smashing roller, a second motor and a smashing rod. The traditional Chinese medicinal material multi-stage smashing device for decoction piece processing is characterized in that the smashing chamber is arranged on a support, thetop plate is arranged on a stand column, the first cylinder is arranged on a positioning plate, the bearing plate is provided with a sliding block, the second cylinder is arranged on the top plate, and the adjusting plate is arranged on the stand column. According to the traditional Chinese medicinal material multi-stage smashing device for decoction piece processing, the bearing plate is connected with a first piston rod and is set to be of a structure of moving on a sliding rail back and forth through the sliding block, as the bearing plate moves on the sliding rail back and forth through the sliding block under action of the first cylinder and the first piston rod, traditional Chinese medicinal materials on the bearing plate can be driven to move back and forth so as to make contact with the cutter and be primarily cut into sections conveniently, the traditional Chinese medicinal material smashing difficulty is reduced, the traditional Chinese medicinal material smashing quality isimproved, and accordingly the decoction piece processing quality is improved.

Owner:张俊辉

Non-autoclaved aerated brick based on industrial, agricultural and construction waste and preparation method thereof

ActiveCN106477983ASmall particlesReduce the difficulty of crushingCeramicwareSodium bicarbonateBrick

The invention discloses a non-autoclaved aerated brick based on industrial, agricultural and construction waste. A specific preparation method comprises the following steps of: mixing concrete and brick slag with polystyrene foaming particles, smashing twice and heating and stirring to obtain modified construction waste; drying and levigating sludge and mixing with straw ash, rice ash and soybean residue, and grinding to obtain modified agricultural waste; mixing the modified construction waste and the modified agricultural waste, and performing dry stirring; adding cement, lime, fly ash, mineral slag, paper pulp waste liquid, NF aliphatic water reducing agent, sodium carbonate, sodium bicarbonate and polypropylene fiber, and mixing; adding water and stirring; and pouring into a mould; and pressing, heating and maintaining to obtain a product. In the invention, the prepared non-autoclaved aerated brick based on industrial, agricultural and construction waste has good heat retaining property; through comprehensive utilization of multiple modified wastes, the non-autoclaved aerated brick has high economy and is green and environment-friendly.

Owner:江西中态环保科技有限公司

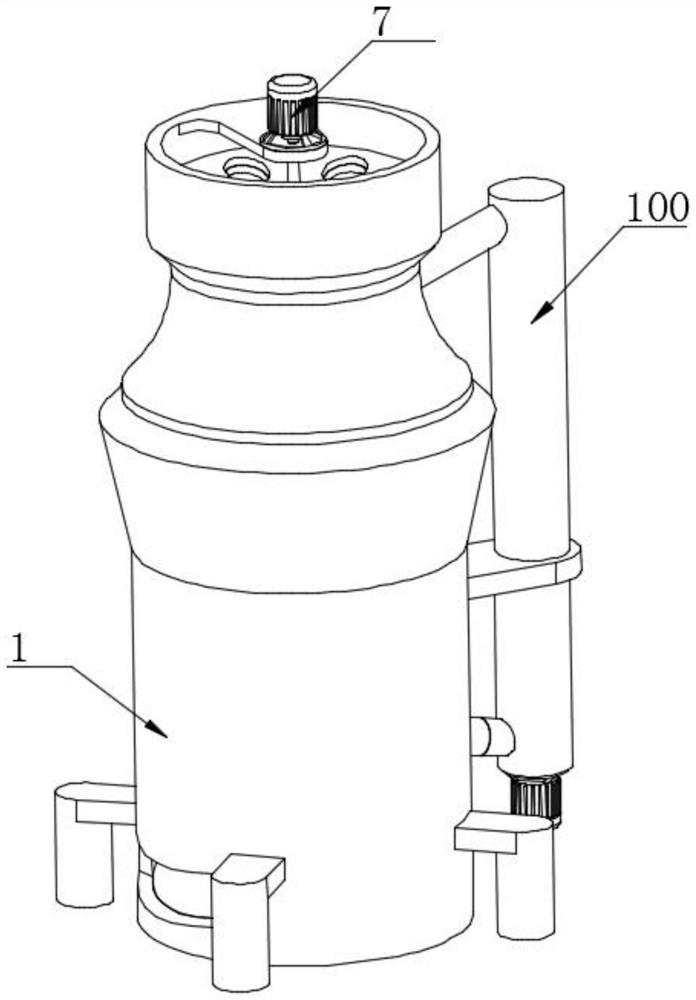

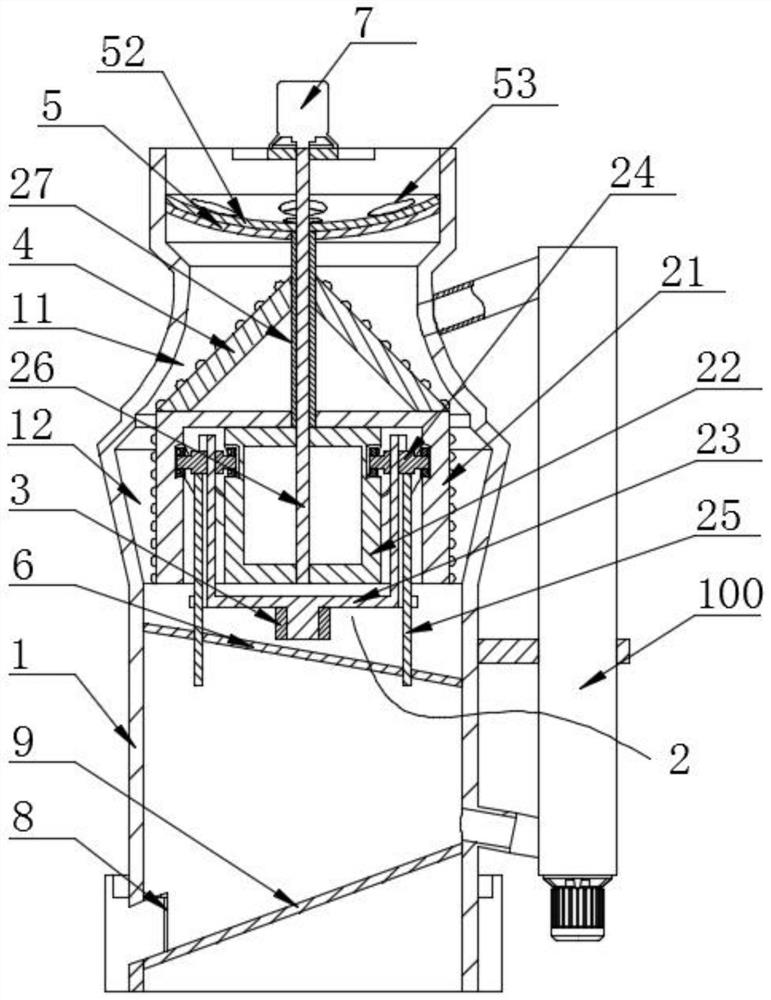

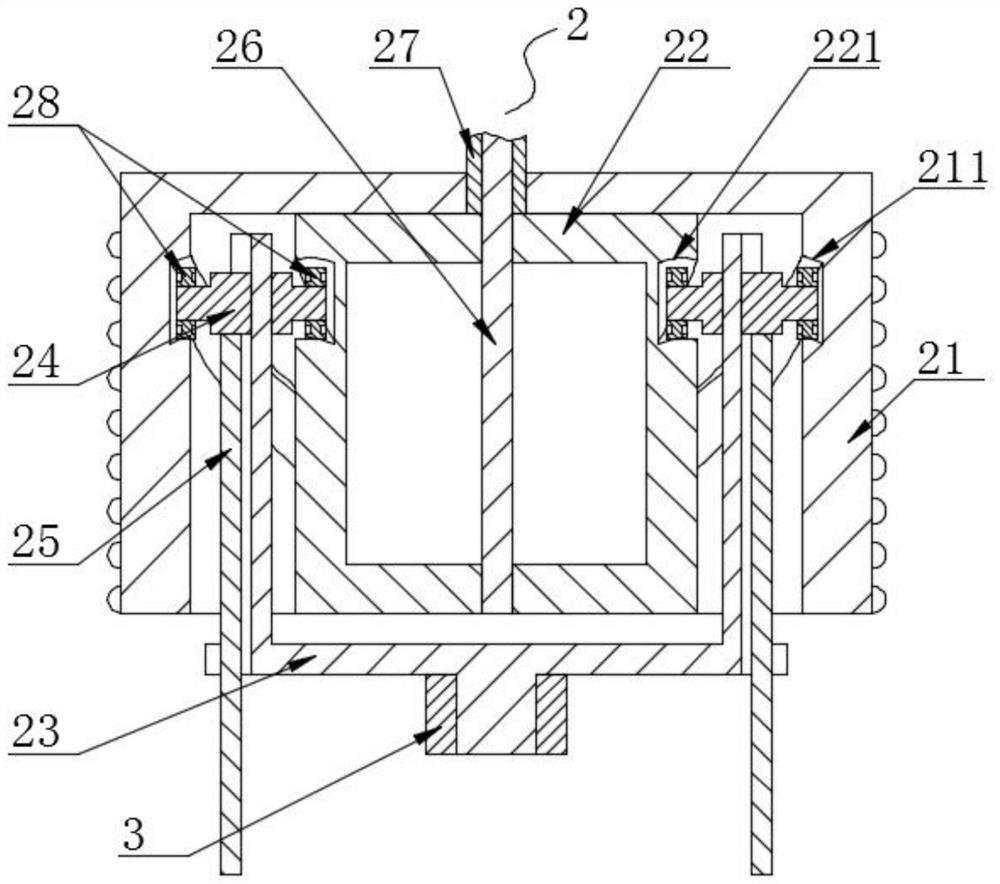

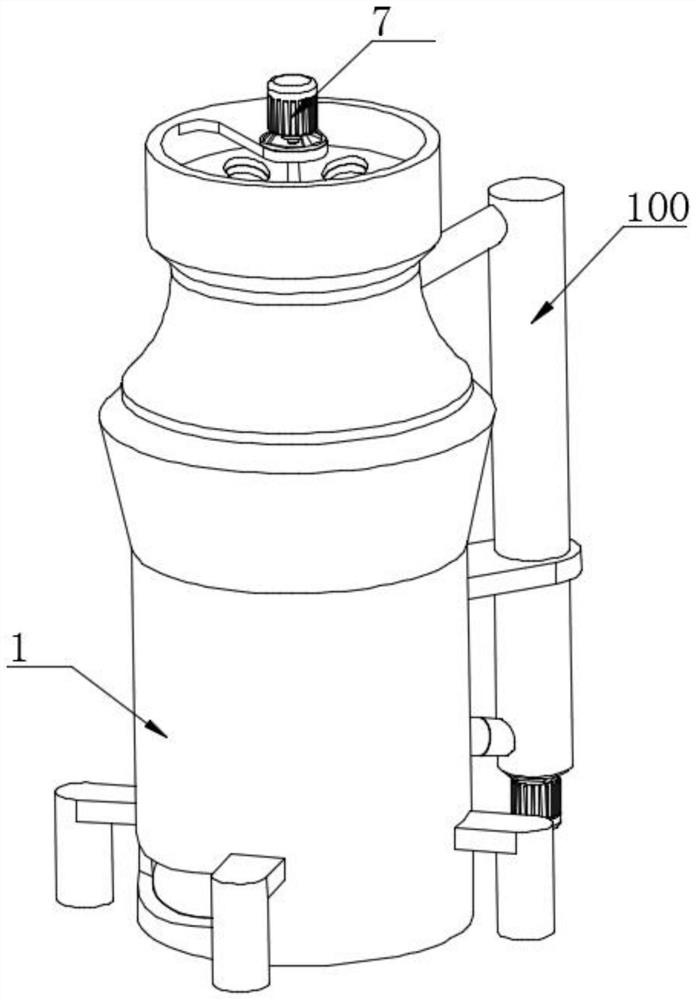

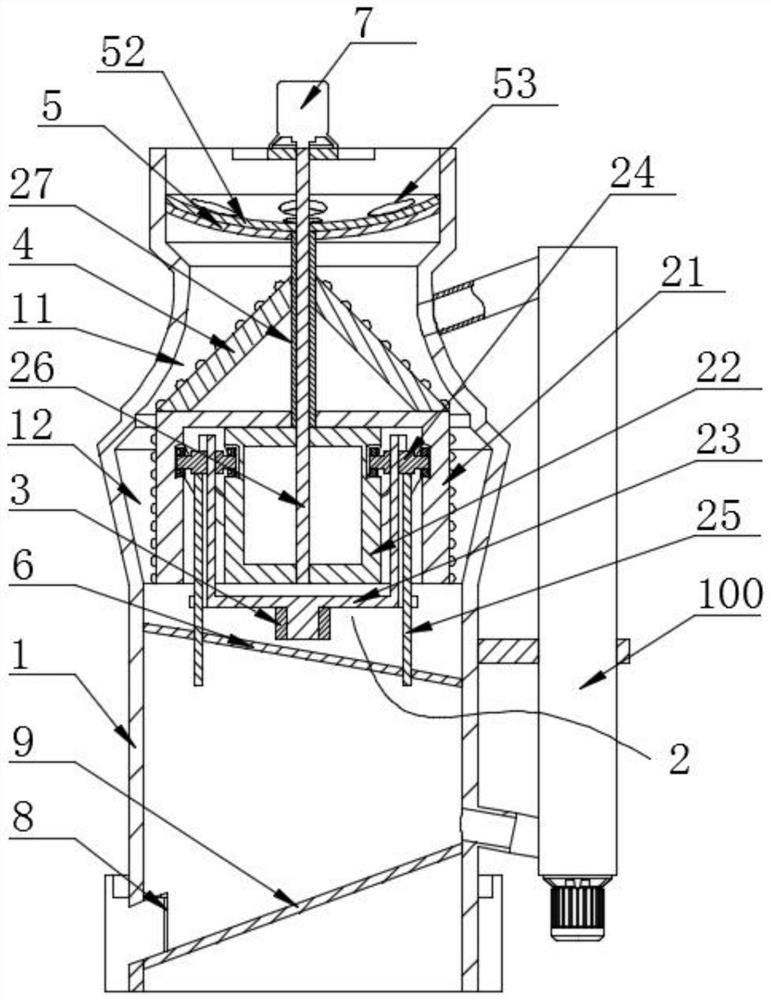

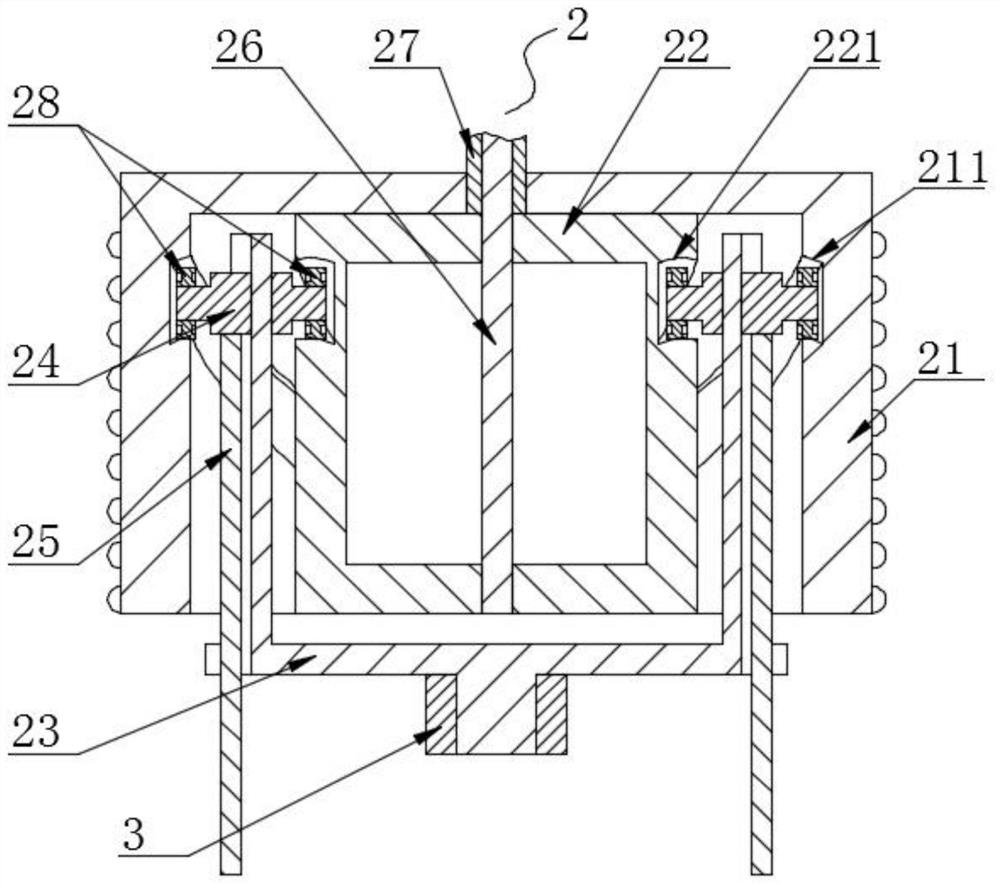

Multifunctional veterinary herbal medicine superfine crushing equipment

The invention discloses a multifunctional veterinary herbal medicine superfine crushing equipment. The superfine crushing equipment comprises a shell, wherein the shell is fixed on a machine frame, agrinding device is arranged in the shell, the grinding device comprises an upper grinding body and a lower grinding body, the upper grinding body and the lower grinding body are of conical umbrella-shaped structures, a rotating shaft I is fixedly connected to the upper end of the upper grinding body, the rotating shaft I is in a tubular shape with openings at two ends, the upper end of the rotating shaft I penetrates through the shell and then is in driving connection with an upper grinding body driving motor arranged on the machine frame, the lower end of the lower grinding body is fixedly connected with a rotating shaft II, and the lower end of the rotating shaft II penetrates through the shell and is in driving connection with a lower grinding body driving motor arranged on the machineframe. The superfine crushing equipment has the characteristics that grinding and superfine crushing are synchronous, multi-stage crushing is achieved, and automatic liquid generation is achieved.

Owner:QINGDAO AGRI UNIV

Field centralized well-rotting fertilizer transformation utilization method of straw

InactiveCN106116772AReduce the difficulty of crushingReduce crushing costsSuperphosphatesOrganic fertilisersTrichoderma reeseiBacillus subtilis

The invention discloses a field centralized well-rotting fertilizer transformation utilization method of straw. According to the method, agricultural straw is harvested together and is smashed when a crop is reaped, and then the agricultural straw is subjected to on-the-spot centralized well-rotting processing. During the well rotting of the straw, soil, calcium superphosphate, urea, water and compound microbial inoculums (including trichoderma reesei, aspergillus niger, saccharomyces cerevisiae and bacillus subtilis) are added into the straw according to a certain proportion; an obtained mixture is mixed, and then the obtained mixture is covered with a film; afterwards, the obtained mixture is further fermented; the straw can be completely well rotted after 17 to 23 days; the mixture is laid open and aired, and then is subjected to on-the-spot fertilizer transformation utilization. The method is simple in treatment way, convenient to operate and low in cost, is easily learned and easily understood by a peasant, has stronger popularization value and application value; the realization of the resource transformation utilization of the straw is facilitated.

Owner:HUAZHONG AGRI UNIV

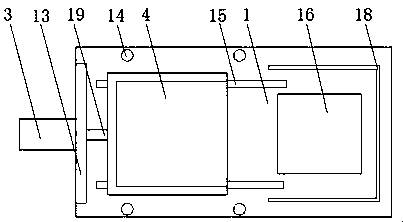

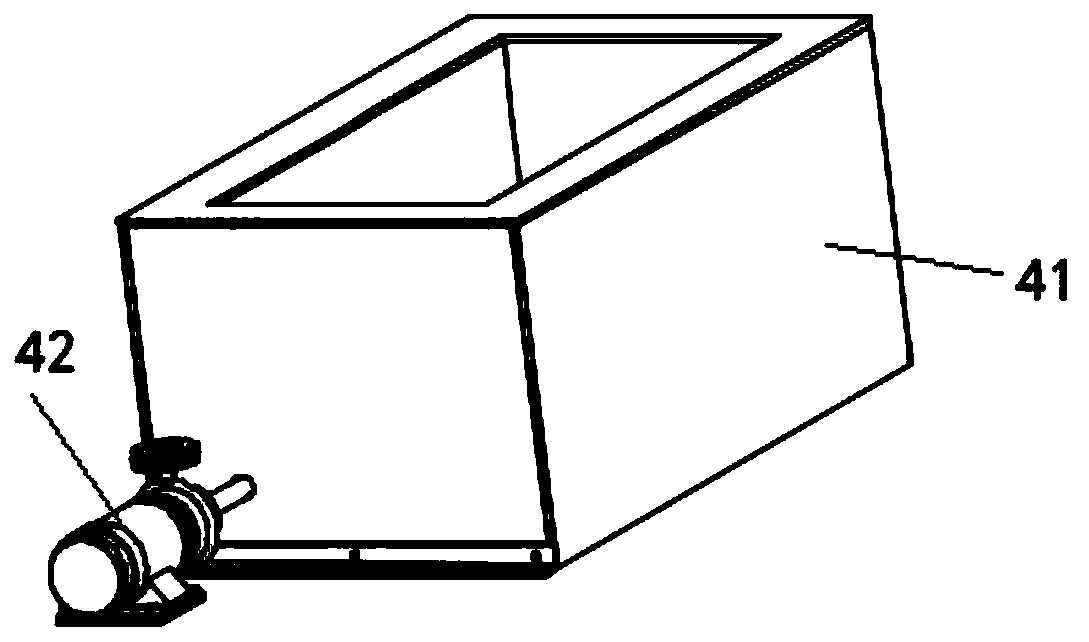

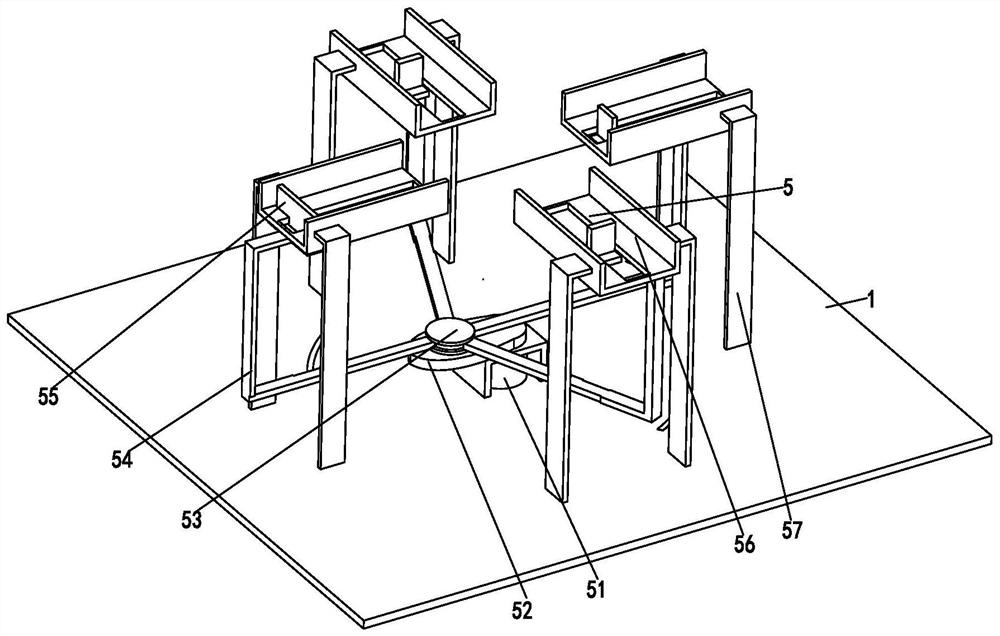

Garment waste leftover material collecting and treating device and using method thereof

ActiveCN111495532AHigh hardnessNo cloggingHollow article cleaningTextile disintegration and recoveryFiberThermodynamics

The invention discloses a garment waste leftover material collecting and treating device. The garment waste leftover material collecting and treating device comprises a rack, a water tank and a low-temperature freezing device are fixedly installed on the rack, a conveying device is fixedly installed on one side of the low-temperature freezing device, and an opening and closing door is arranged atthe position, corresponding to the discharging end of the conveying device, of the low-temperature freezing device; and a screening device is further fixedly mounted on the rack, and the screening device is connected with the low-temperature freezing device through a feeding device. According to the garment waste leftover material collecting and treating device, leftover materials are frozen, hardened and then smashed, cooling is conducted in the smashing process so as to avoid rapid melting of moisture absorbed by the leftover materials, entanglement of fibers in the smashing process is avoided, and the smashing difficulty is reduced; and in addition, the screening device in the garment waste leftover material collecting and treating device can achieve continuous feeding and continuous discharging, and the garment waste leftover material collecting and treating device is suitable for industrial continuous production and improves the treatment efficiency.

Owner:ANHUI HENGYI TEXTILE TECH CO LTD

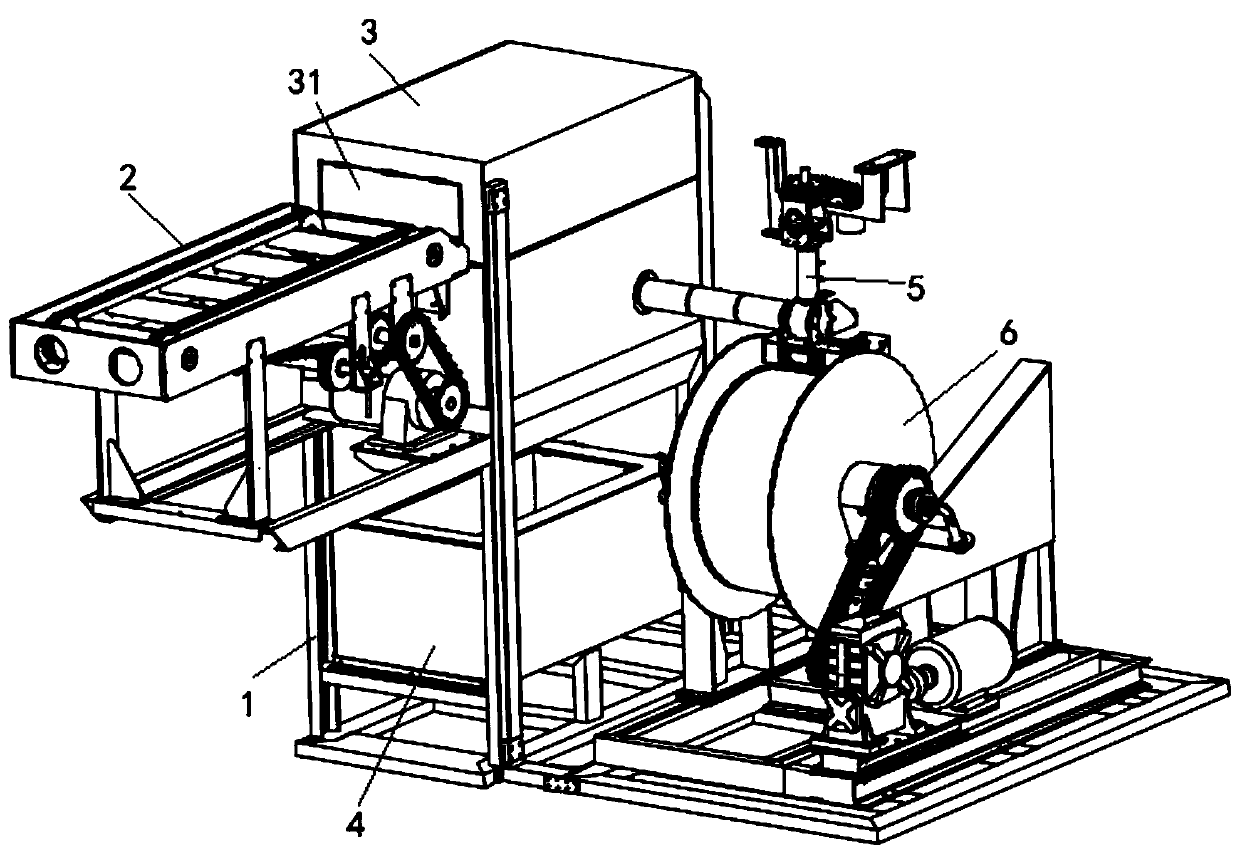

Vertical double-shaft coal crushing machine

ActiveCN103861690AIncrease crushing powerReduce crushing timeGrain treatmentsEngineeringMechanical engineering

The present invention relates to a vertical double-shaft cola crushing machine, which comprises a machine body, wherein one side on the upper end of the machine body is provided with a material inlet, the one side on the lower end of the machine body is provided with a material outlet, rotation shafts with rotation driven respectively by a motor are arranged in the machine body in an insertion manner, each rotation shaft is provided with a plurality of hammers, a horizontally-arranged material receiving plate is inserted in the machine body, material receiving plate supporting frames are arranged on both sides inside the machine body and the lower end of the material receiving plate, the position on one side of the machine body and corresponding to the material receiving plate in a parallel manner is provided with an opening door for pulling into / pulling out the material receiving plate, the middle of the material receiving plate is provided with a slot, each rotation shaft is arranged in a manner of penetrating-through of the slot, a plurality of rolling balls are respectively arranged on the two material receiving plate supporting frames, the material receiving plate moves on the rolling balls, and one end of the material receiving plate is further provided with a handle. According to the present invention, the structure is simple, the design is reasonable, the crushing efficiency per unit of time can be effectively improved, the crushing is uniform, and the crushing difficulty is relatively reduced.

Owner:蒋小华

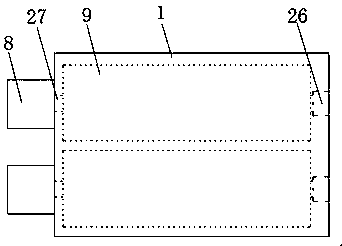

Grinding equipment for leftover materials of carton production

InactiveCN109078718AImprove crushing qualityReduce the difficulty of crushingGrain treatmentsMetal working apparatusMotor driveDrive shaft

The invention discloses grinding equipment for leftover materials of carton production. The grinding equipment comprises a grinding chamber, a feeding bin, first motors, rotating rollers, a second motor, grinding rods, a third motor, a first rotating shaft, a fourth motor and a second rotating shaft. The leftover material grinding equipment is characterized in that the grinding chamber is disposedon a bracket, the feeding bin is disposed at the top of the grinding chamber, the second motor is disposed at the top, between falling tubes, of the grinding chamber, and the grinding rod is arrangedon a second transmission shaft. According to the grinding equipment for the leftover materials of carton production, the bottoms of first grinding discs are connected with the tops of second grindingdiscs, the first grinding discs and the second grinding discs are arranged alternately, the third motor drives the first rotating shaft and the first grinding discs on the first rotating shaft to rotate, and the fourth motor drives the second rotating shaft and the second grinding discs on the second rotating shaft to rotate; and carton leftover materials after being ground by the grinding rods fall between the first grinding discs and the second grinding discs, the first grinding discs and the second grinding discs perform grinding on the carton leftover materials after being ground by the grinding rods, and the grinding quality of the carton leftover materials is further improved.

Owner:芜湖三华包装科技有限公司

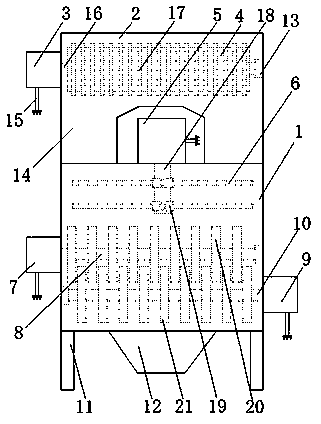

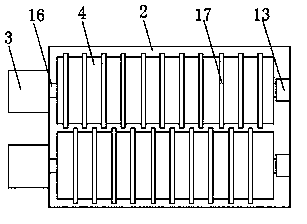

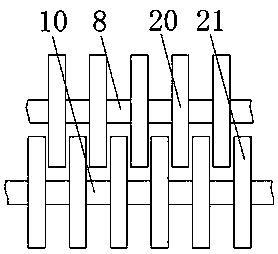

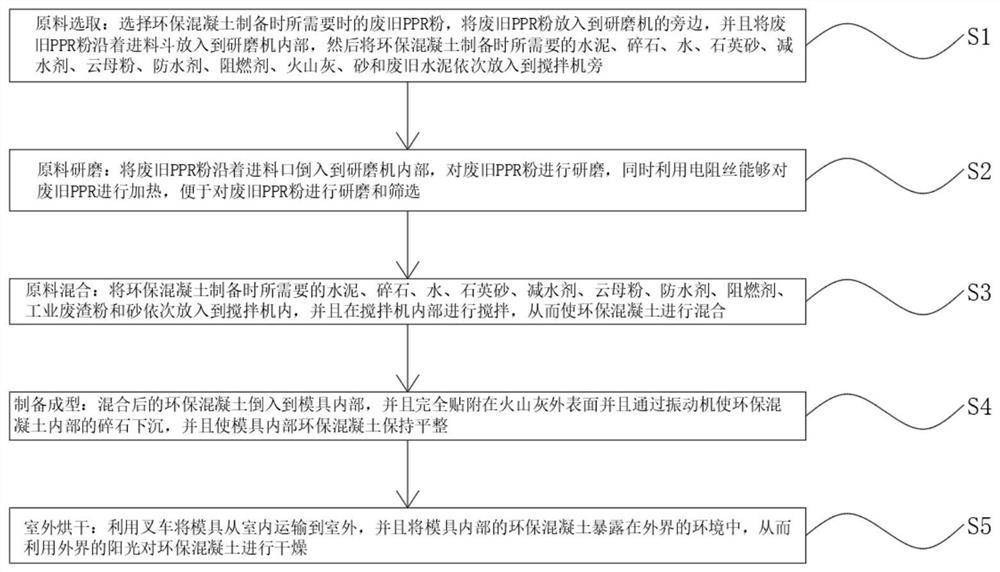

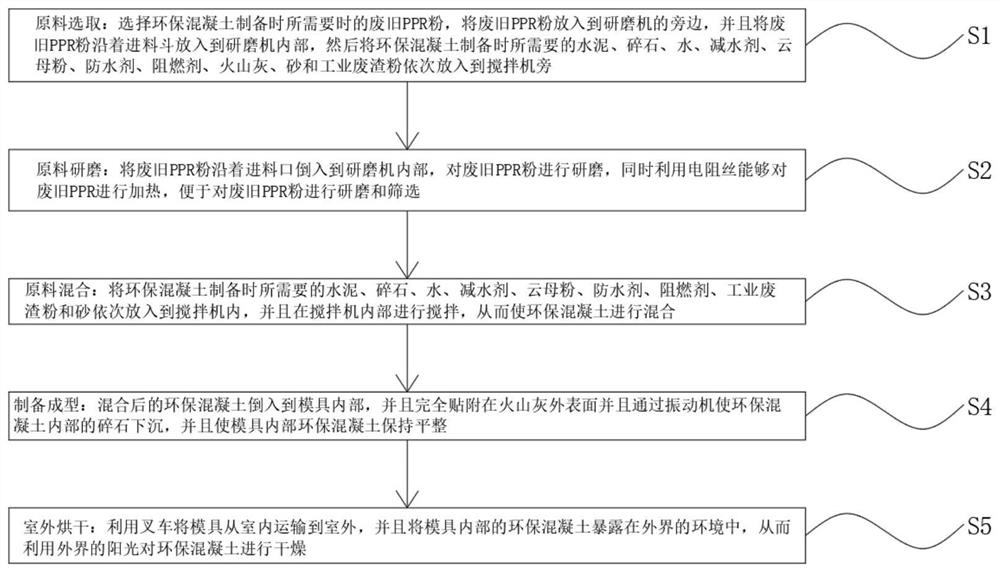

Processing method for high-strength environment-friendly concrete

ActiveCN111822080AReduce usageHigh hardnessSolid waste managementCeramic shaping apparatusSlagCompressive strength

The invention discloses a processing method for high-strength environment-friendly concrete. The environment-friendly concrete consists of the following components in parts by weight: 100-200 parts ofcement, 40-130 parts of water, 23.8-59 parts of quartz sand, 46.2-82.4 parts of broken stones, 1-2 parts of a water reducer, 10-30 parts of mica powder, 5-30 parts of a waterproof agent, 0.5-2 part of a flame retardant, 40-80 parts of cinerite, 10-30 parts of waste PPR powder, 245-490 parts of sand, 60-120 parts of an adhesive and 60-80 parts of industrial waste slag powder. Waste PPR powder andindustrial waste residue powder, which are added into concrete, are poured into a stirrer to stir, so that use amount of cement is reduced, and production cost is reduced; mica powder, quartz sand andcinerite are added, so that hardness, pressure resistance and water seepage resistance of concrete can be improved; and meanwhile, a heat conduction rate of the concrete is reduced, so that the concrete has highest hardness, highest compressive strength, low heat conduction rate and strong water seepage resistance; and meanwhile, production cost is reduced, waste PPR powder and industrial waste residue powder are recycled, so that the environment-friendly purpose is achieved.

Owner:舟山恒尊预拌混凝土有限公司

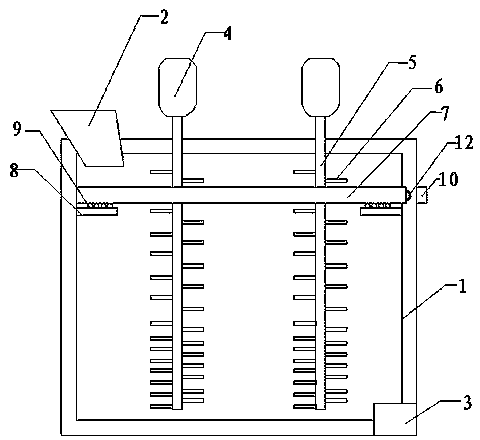

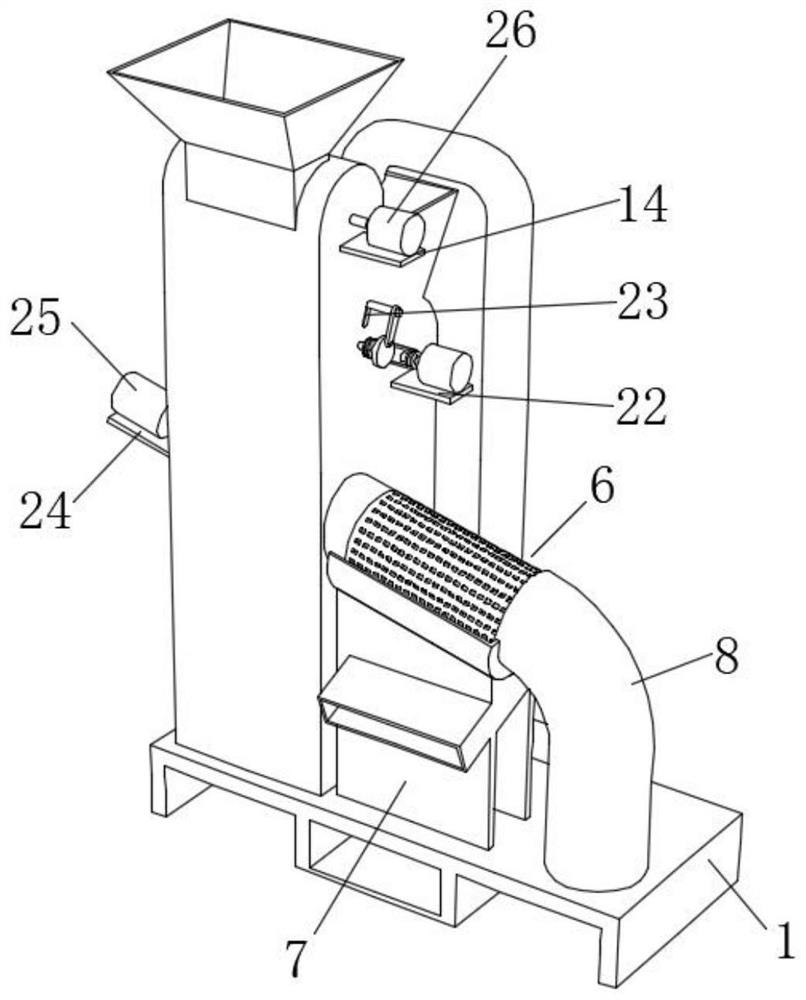

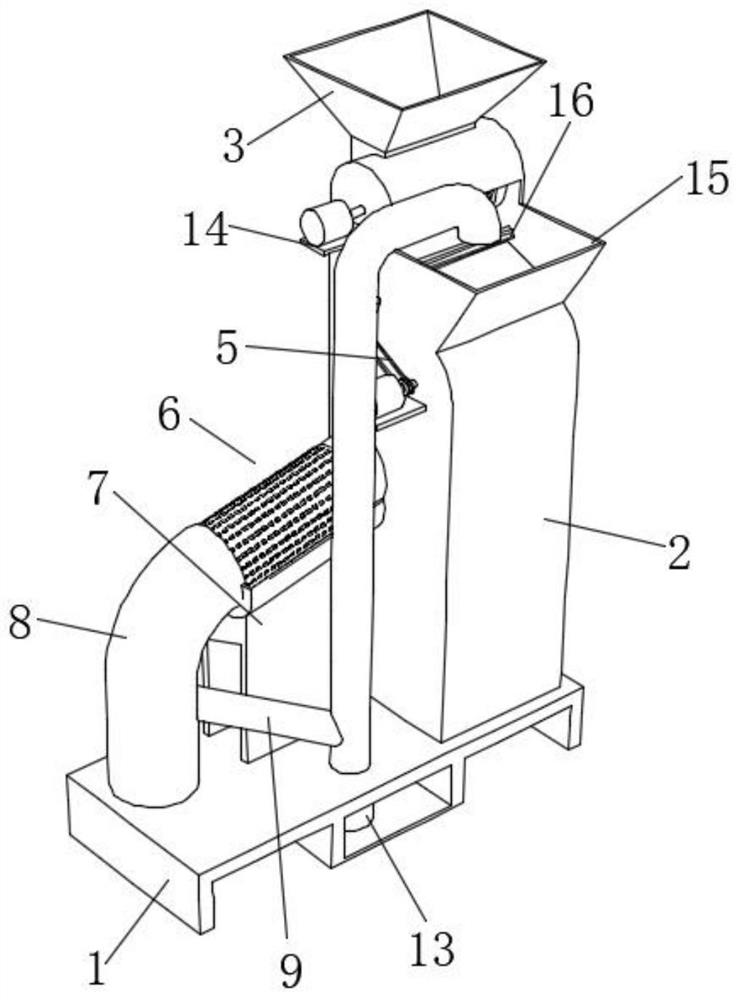

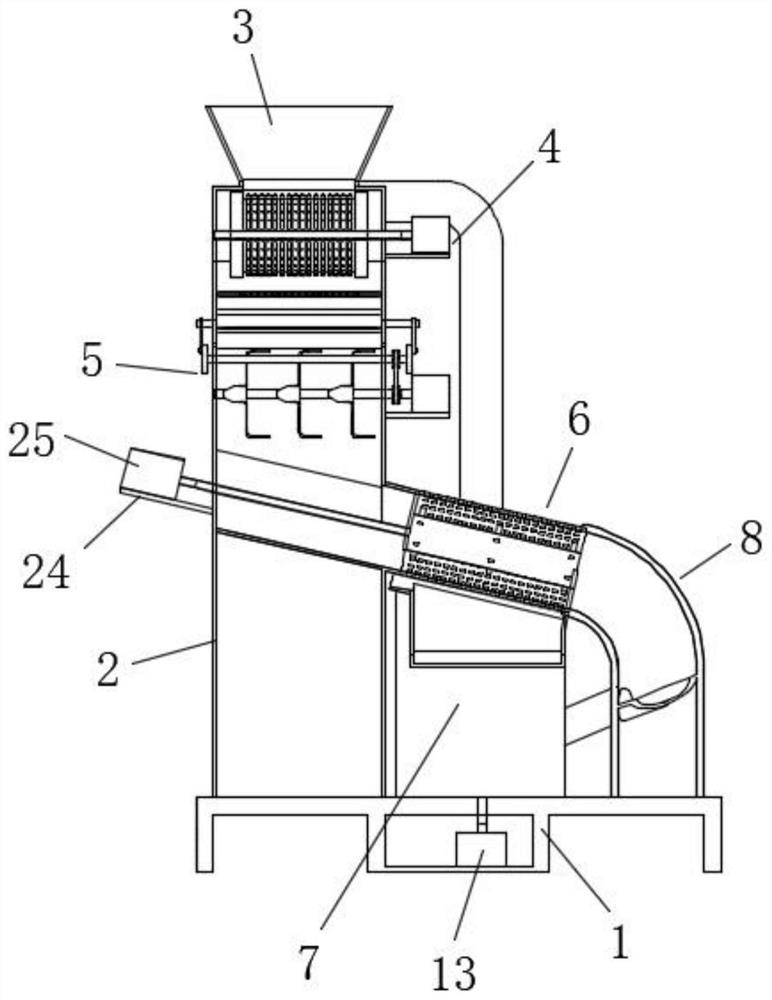

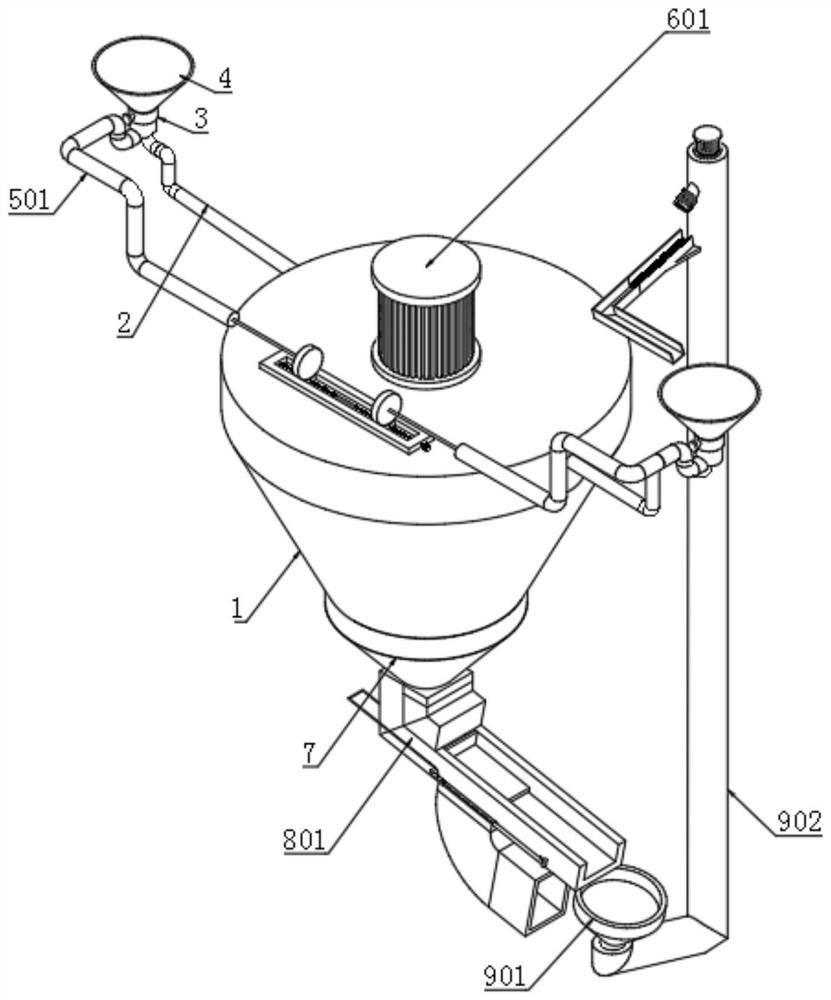

Self-cleaning pulverizing device for pueraria lobata

InactiveCN109331958AReduce the difficulty of crushingIncrease productivityCleaning using liquidsGrain treatmentsLobataWater storage tank

The invention discloses a self-cleaning crushing device for pueraria lobata. The self-cleaning crushing device comprises a machine case, a cutting mechanism, a crushing mechanism, a spraying mechanism, a screen mechanism and a storage box. The cutting mechanism comprises a driving motor I, a rotating shaft I, a rotating shaft II, a blade group I and a blade group II, wherein the blade group I andthe blade group II are welded to the rotating shaft I and the rotating shaft II and are composed of blades, and the blades are welded to the rotating shaft I and rotating shaft II correspondingly. Fixed gaps are arranged between adjacent blades. The outer circumferences of the blades are provided with equally divided notches. The crushing mechanism comprises a plurality of driving motors II, rolling shafts and rolling rollers, wherein the rolling rollers are fixedly connected to the rolling shafts. The spraying mechanism comprises a water storage tank, a water outlet pipe and a spray head arranged on the end portion of the water outlet pipe. The screen mechanism comprises an installation plate, a spring, a connecting column, a metal screen and vibration motors symmetrically arranged at twosides of the bottom of the metal screen, wherein the metal screen is welded to the bottom of the connecting column. By means of the self-cleaning crushing device, the powder yield of the pueraria lobata can be improved, and the equipment service life can be ensured as well.

Owner:霍山县宝康食品厂

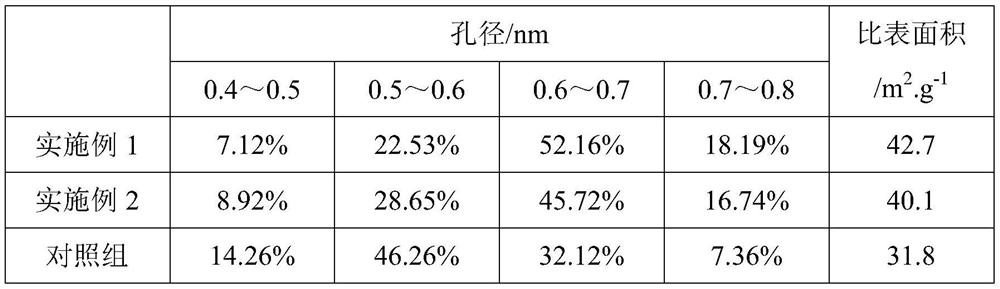

Method for preparing porous-structure tire rubber powder by wet crushing

PendingCN111730786ALower glass transition temperatureReduce difficulty and costPlastic recyclingMechanical material recoveryWaste tiresComposite material

The invention discloses a method for preparing porous-structure tire rubber powder by wet crushing. The method comprises the following steps that swelling treatment is carried out on waste tire blockssubjected to coarsely crushing by using an organic solvent at normal temperature, meanwhile, active treatment is carried out under the action of ultrasonic waves, then low-temperature crushing treatment is carried out on the waste tire blocks subjected to precooling to obtain the porous-structure tire rubber powder. The waste tire blocks are soaked and swelled in the organic solvent, small molecules of the solvent are diffused to gaps of rubber macromolecules, and a three-dimensional cross-linked network of the rubber macromolecules is gradually expanded, so that the glass transition temperature of the tire rubber is reduced, the waste tire particles can be converted into a brittle state in a short time, the crushing difficulty is reduced, and the production efficiency of fine rubber powder is improved; and after the solvent is volatilized, abundant pore structures are formed on the surface and inside the rubber powder, the specific surface area is large, and the performance of the rubber powder is improved.

Owner:安徽克林泰尔环保科技有限公司

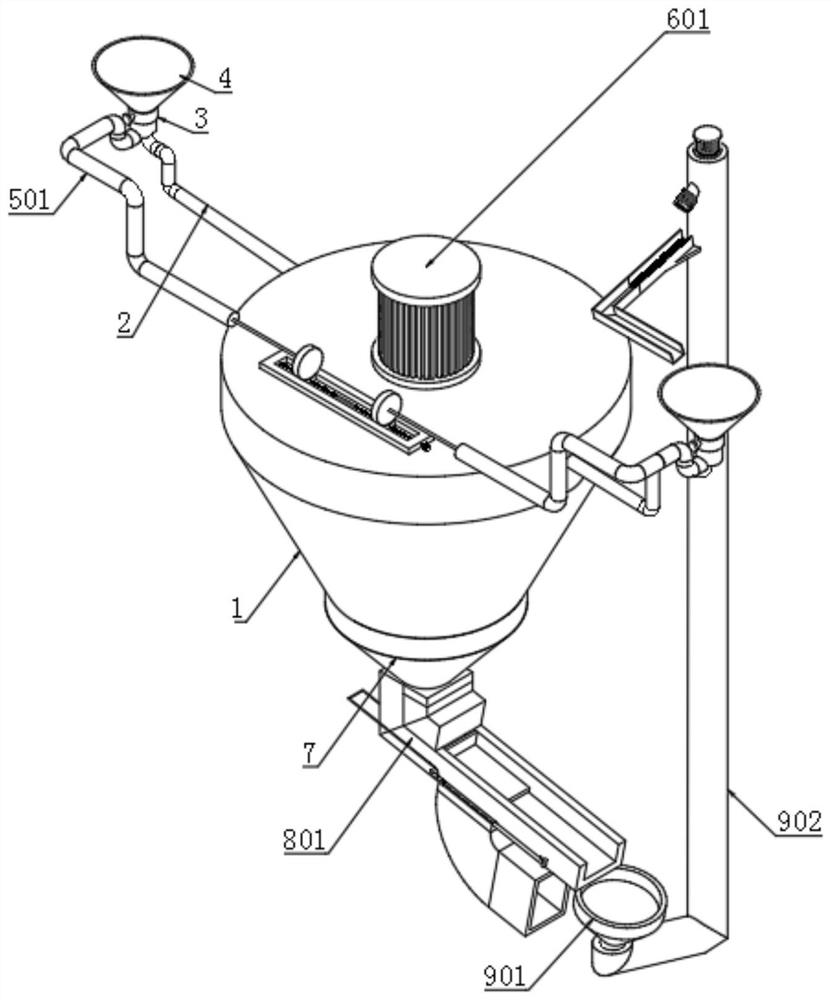

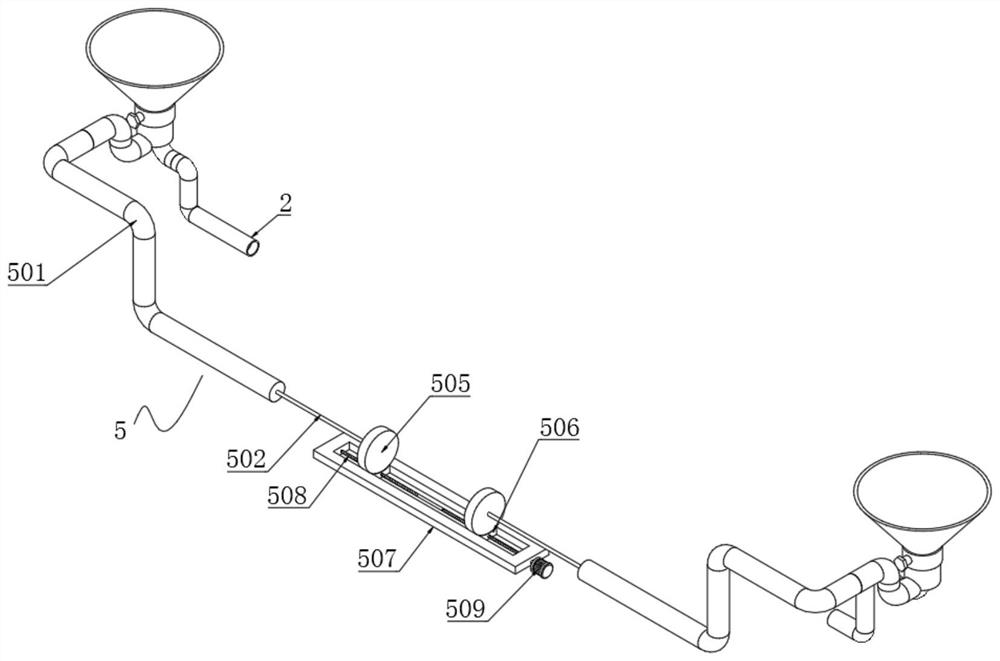

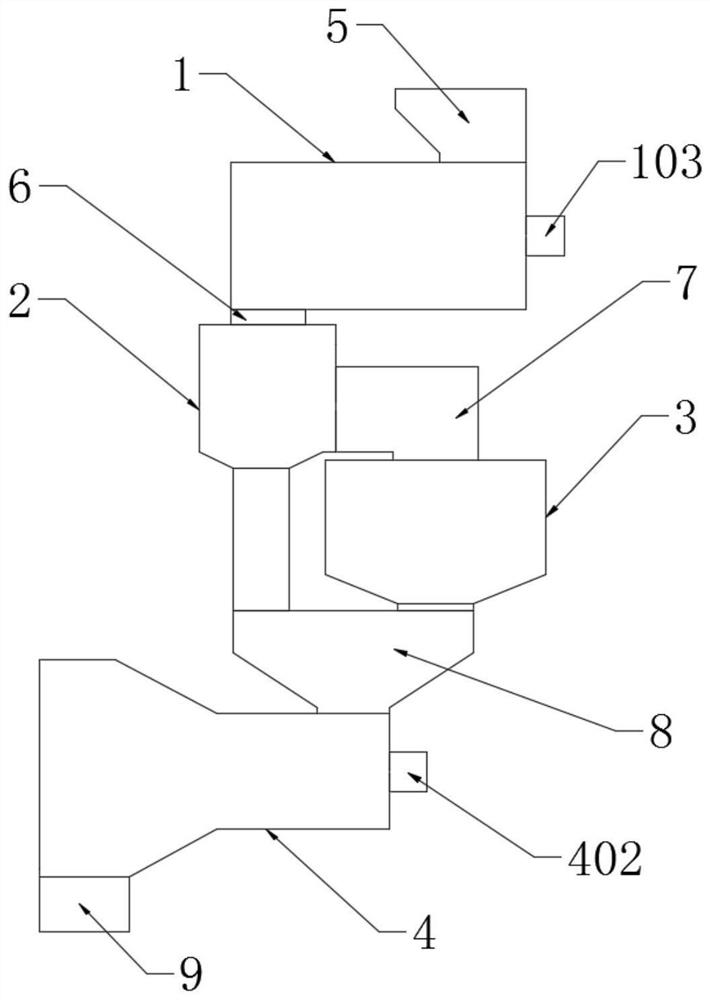

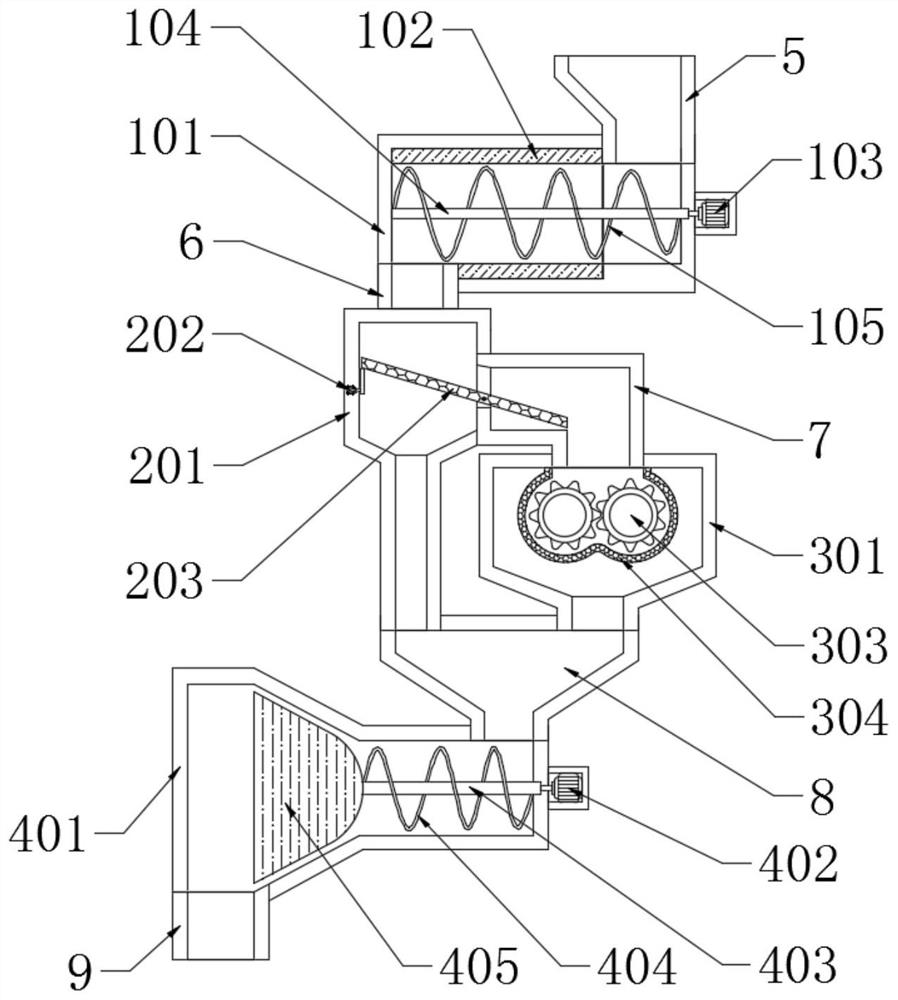

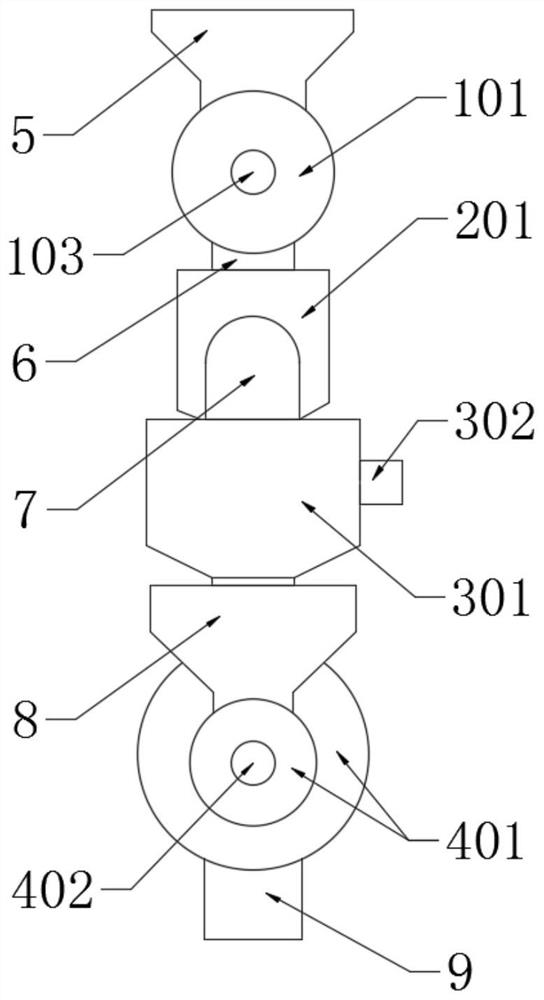

Production equipment for casting residue superfine slag powder and production method based on equipment

ActiveCN113578442AImprove drying effectReduce the difficulty of crushingSievingSolid waste managementSlagProcess engineering

The invention discloses production equipment for casting residue superfine slag powder and a production method based on the equipment. The production equipment comprises a drying mechanism, wherein a feeding hopper is arranged at the top end of the drying mechanism; a material guiding pipe is arranged at the end, away from the feeding hopper, of the drying mechanism; a screening mechanism is arranged on the side, away from the drying mechanism, of the material guiding pipe; a conveying pipe is arranged on the side wall of the screening mechanism; a smashing mechanism is arranged on the side, away from the screening mechanism, of the conveying pipe; a mixing tank is arranged on the side, away from the conveying pipe, of the smashing mechanism; and the mixing tank is connected with the bottom end of the screening mechanism. The production equipment for the casting residue superfine slag powder provided by the invention is novel in structure, high in automation degree, low in required labor intensity, good in grinding effect and high in working efficiency, the whole production process is simple and practical, casting residue slag drying and grinding are effectively integrated, and automatic production is achieved.

Owner:广东韶钢嘉羊新型材料有限公司

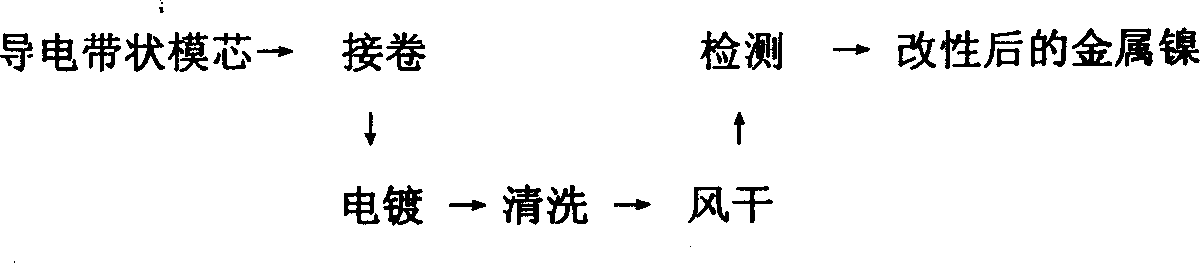

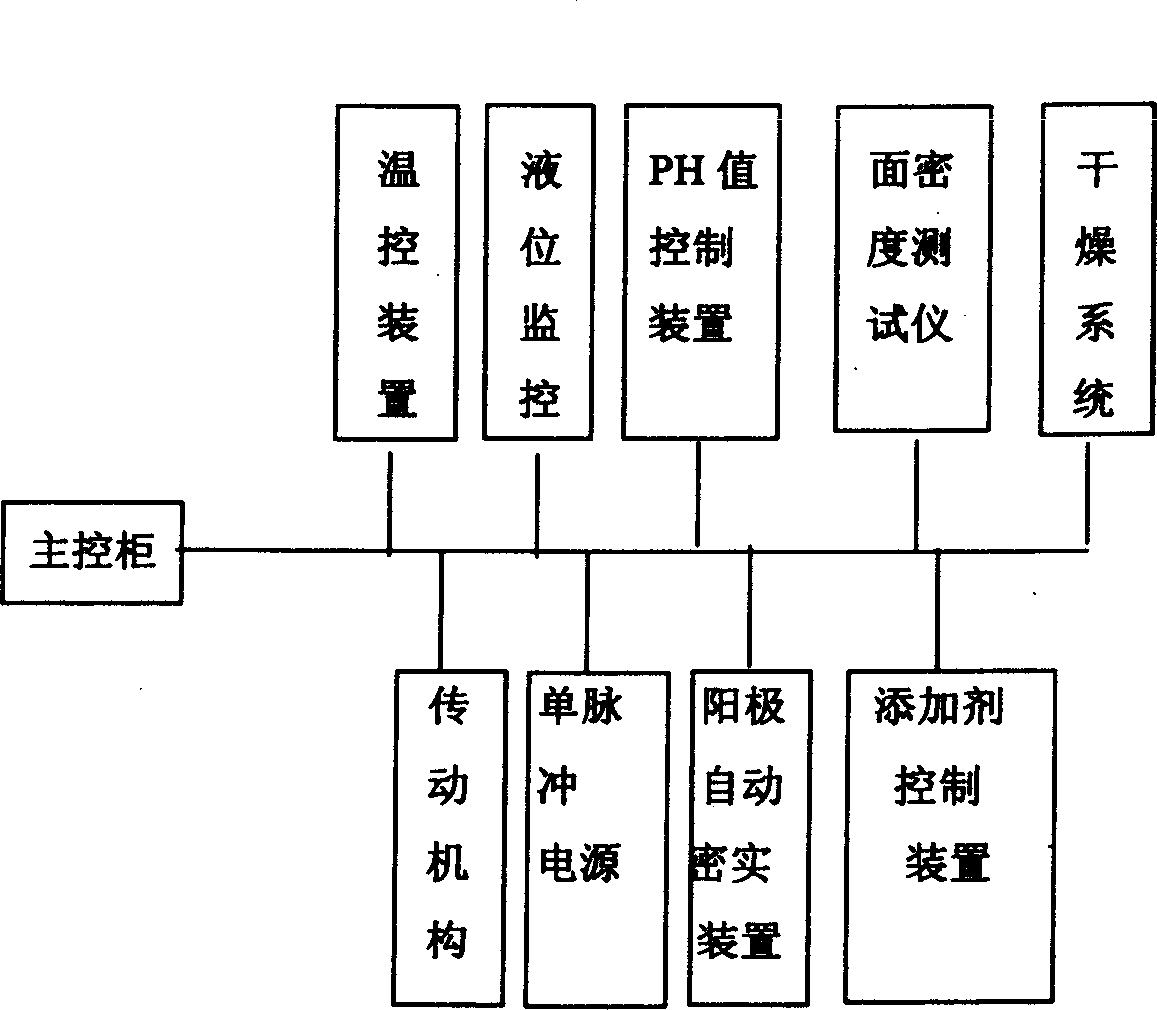

Production of nickel-powder by electromechanical modification self-formative process

InactiveCN1895821AImprove protectionShort processElectroforming processesSelf formingPollutant emissions

An electrochemical modifying and self-forming process for preparing nickel powder includes such steps as making the mould core to be electrically conductive, electrochemical modifying of Ni, thermodecomposing, oxidizing, pulverizing, sieving, reducing, and sieving.

Owner:HEZE TIANYU TECH DEV CO LTD

Microwave-assisted preparation process of tuna bone meal

InactiveCN109892475ADestroy surface integrityImprove crushing effectAnimal feeding stuffAccessory food factorsNeutral proteaseLiquid ratio

The invention discloses a microwave-assisted preparation process of tuna bone meal. The preparation process comprises the following steps: mixing every 120 g of tuna bone and distilled water in a material-to-liquid ratio of 1:1 to obtain a mixed solution a1, adding trypsin and neutral protease to the mixed solution a1 for enzymolysis, boiling the tuna bone to inactivate enzyme, and performing microwave heating treatment at a microwave power of 400-1200 W for 30-150 minutes; finally, grinding the tuna bone by a grinder to obtain the finished bone meal. The preparation process can effectively increase the utilization rate and use effect of the tuna bone meal.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

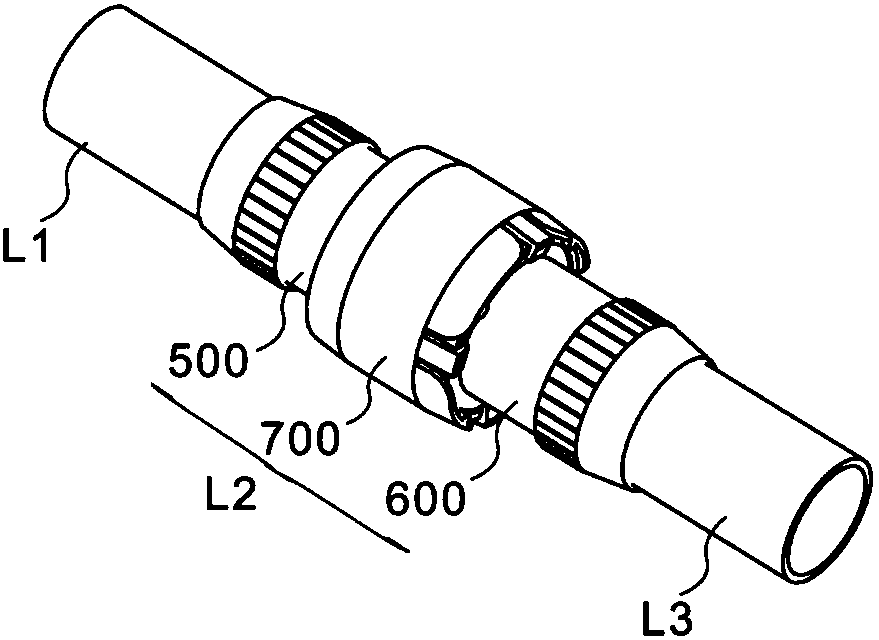

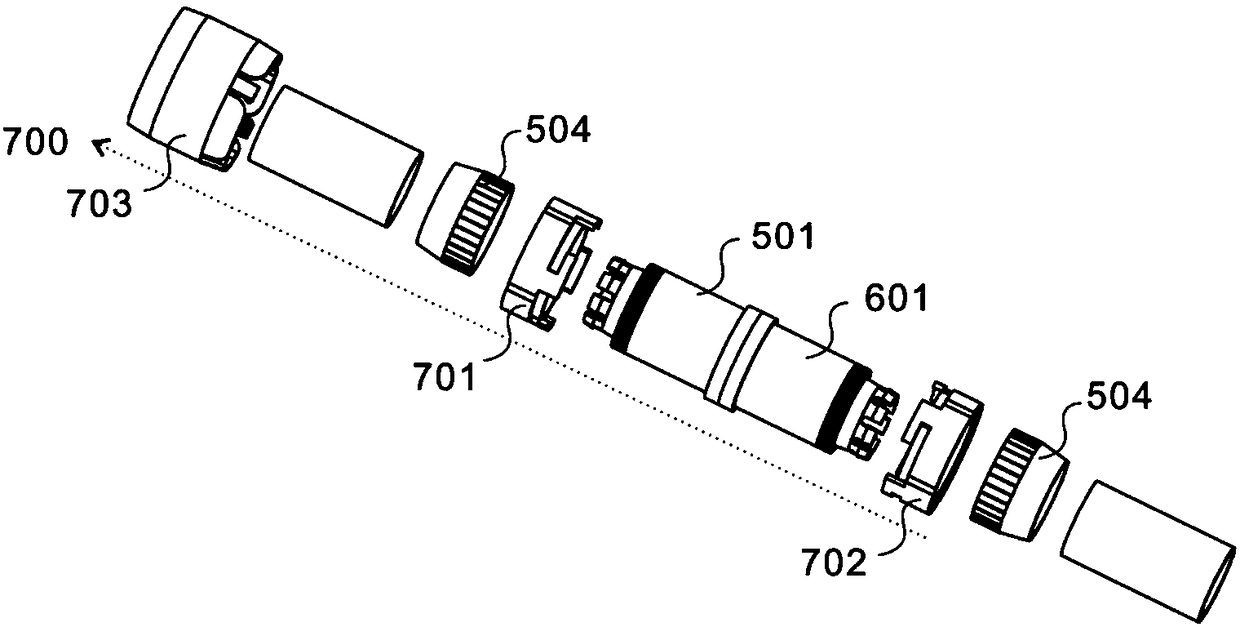

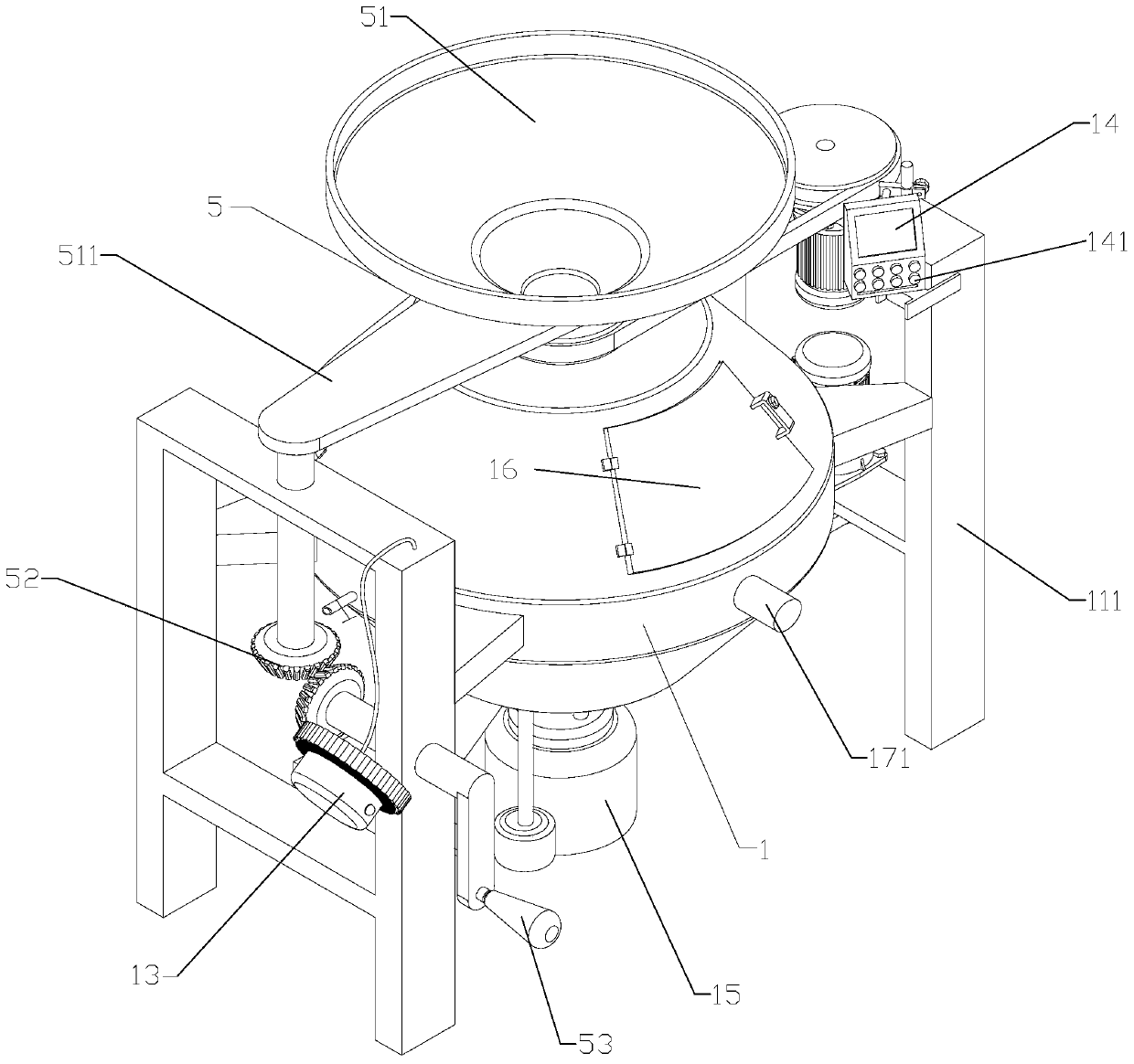

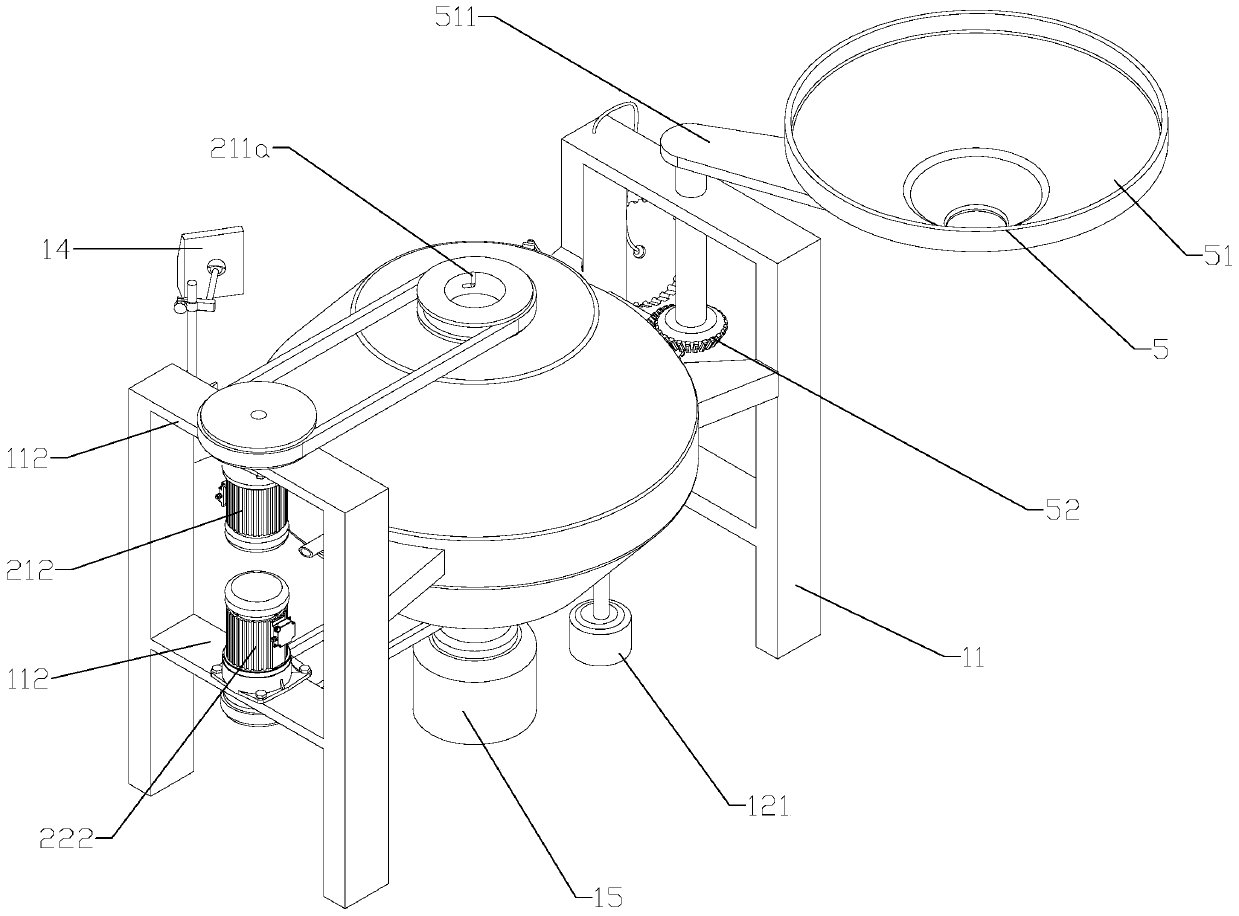

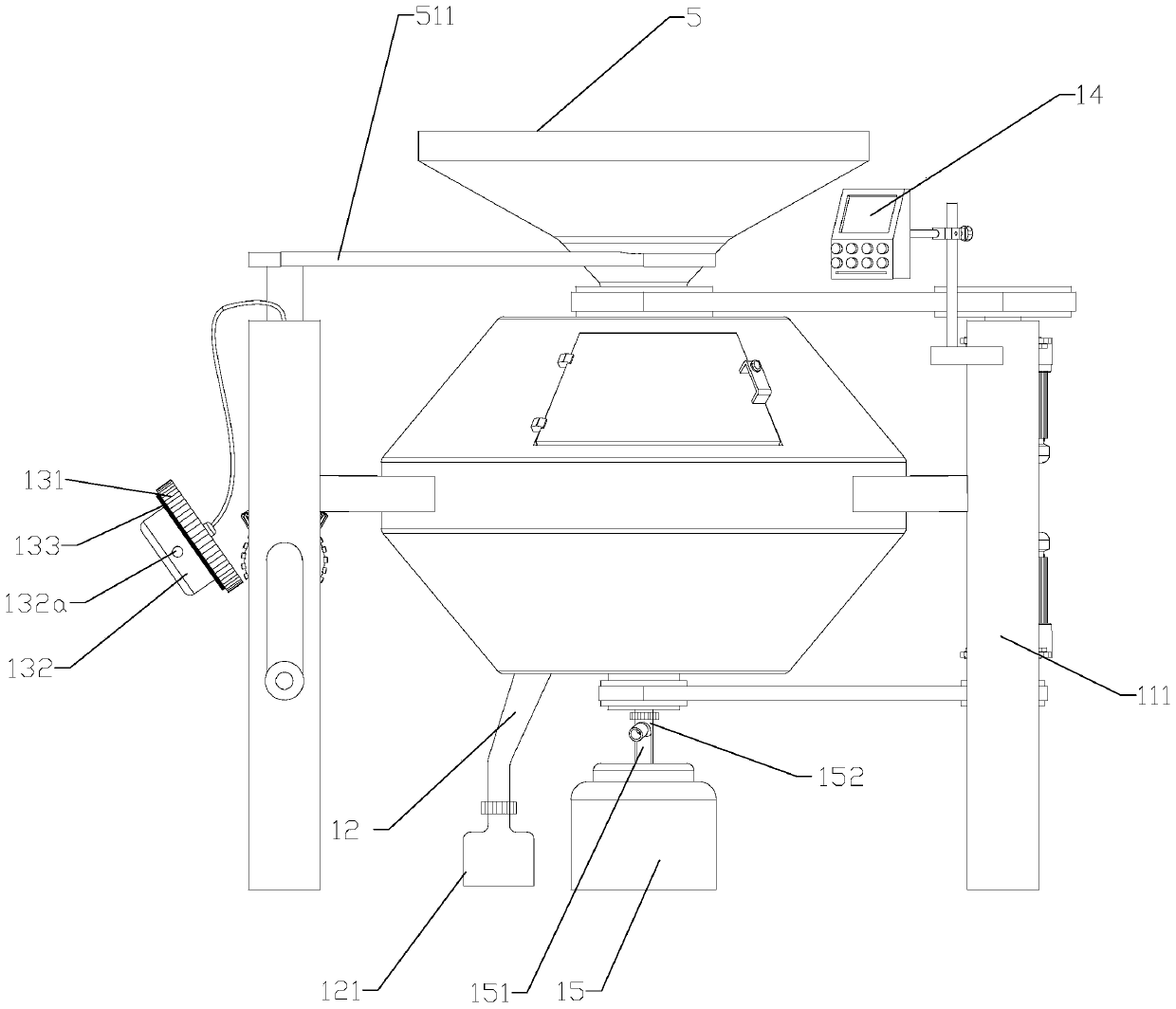

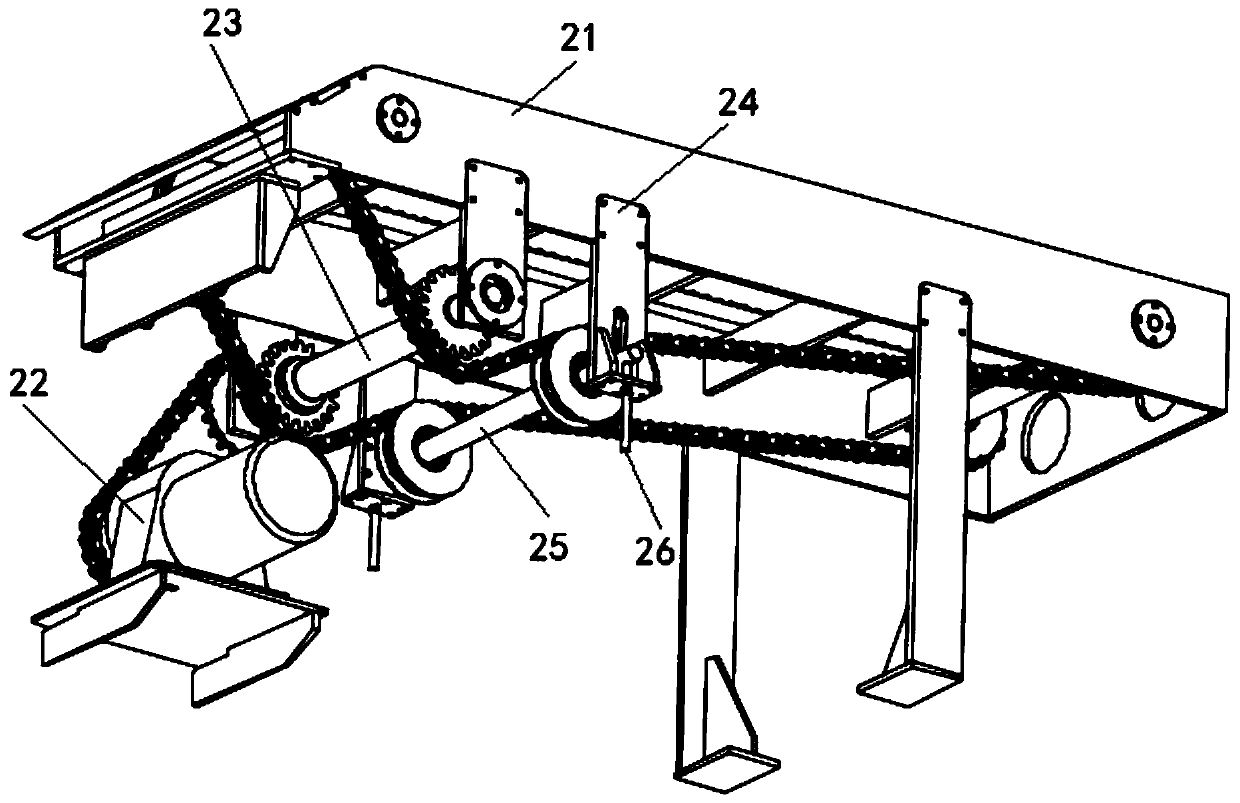

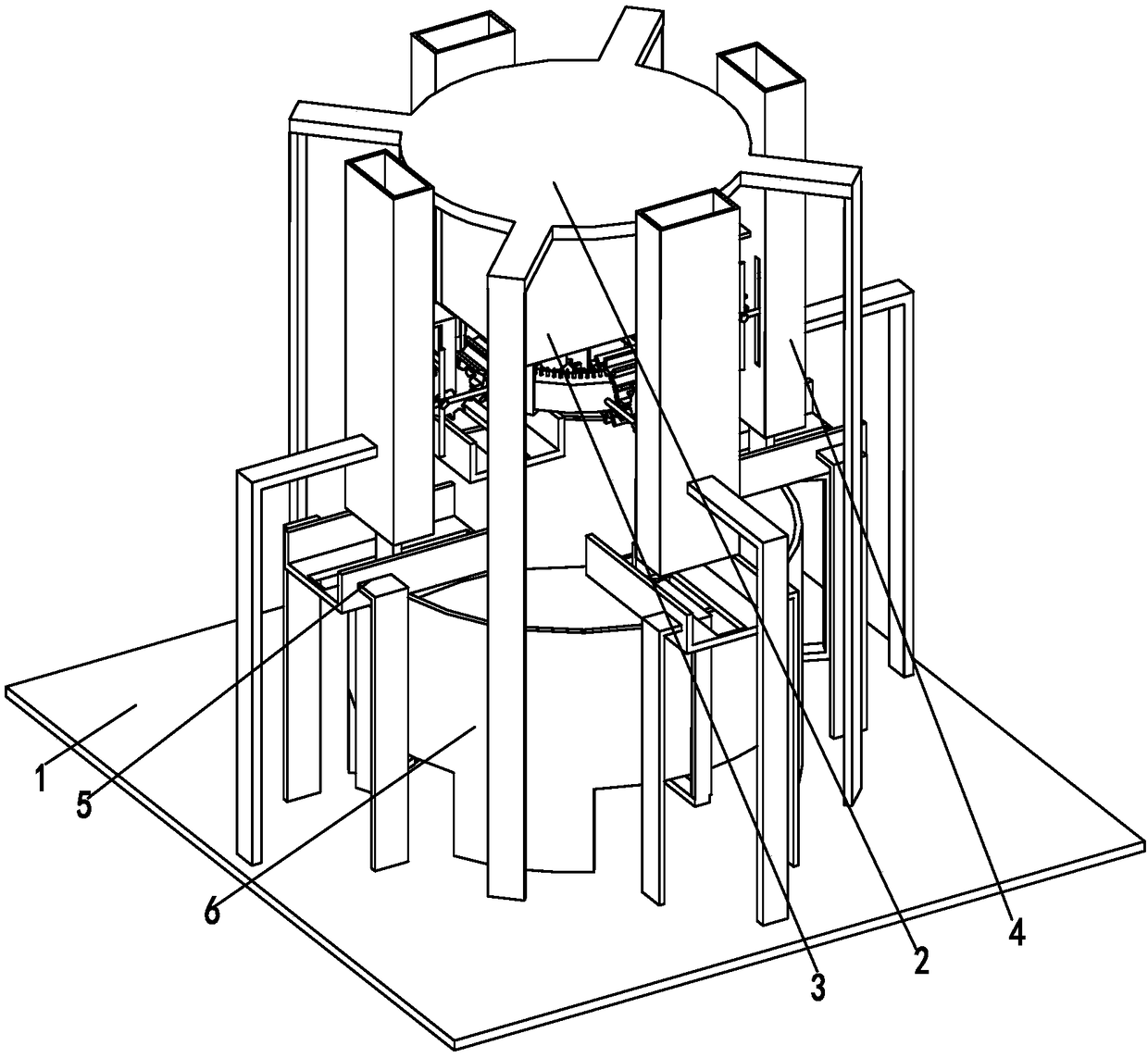

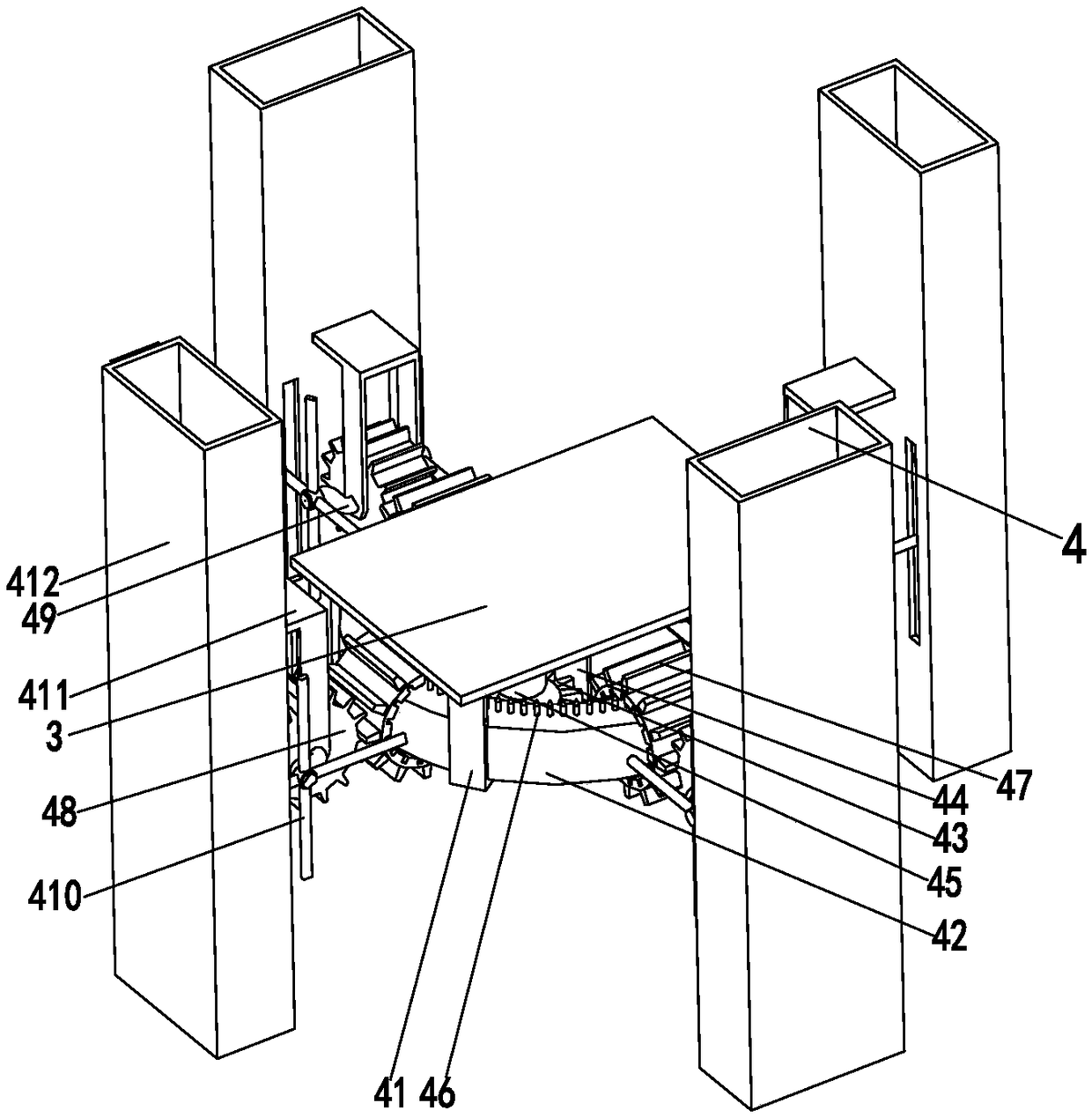

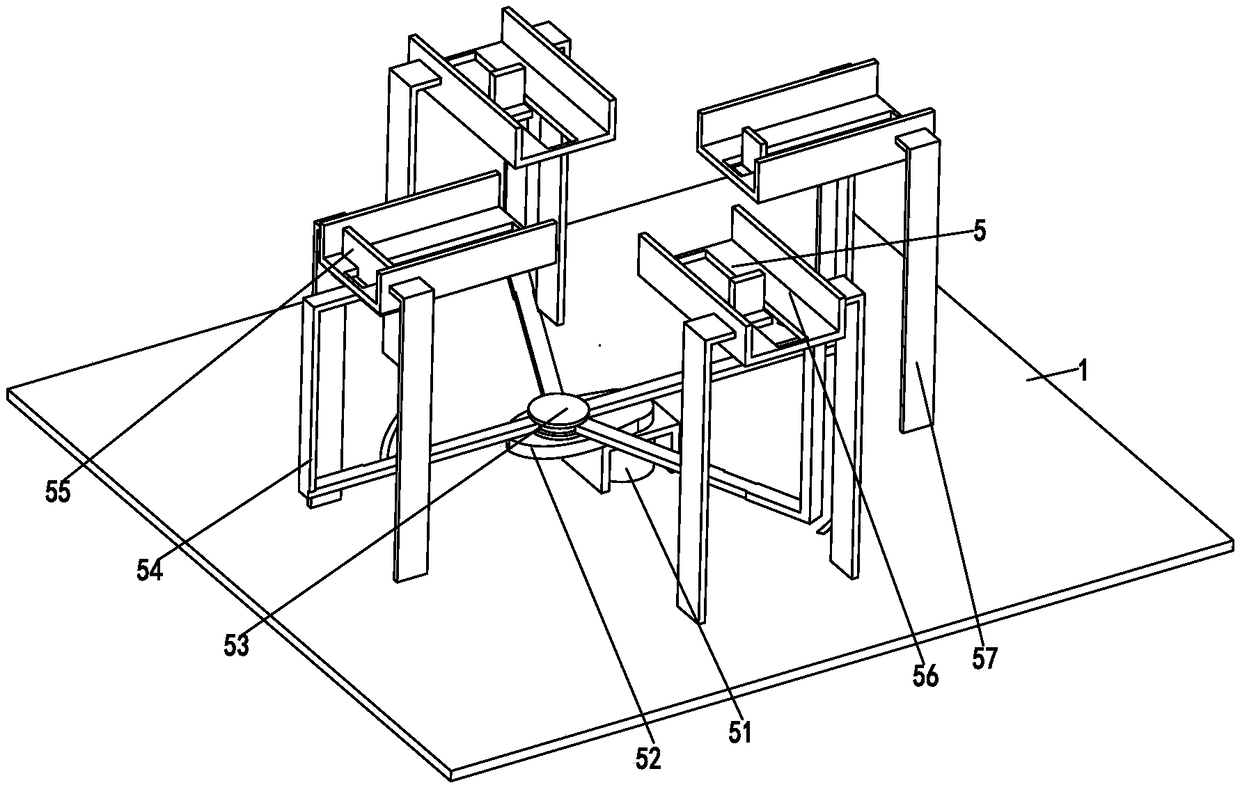

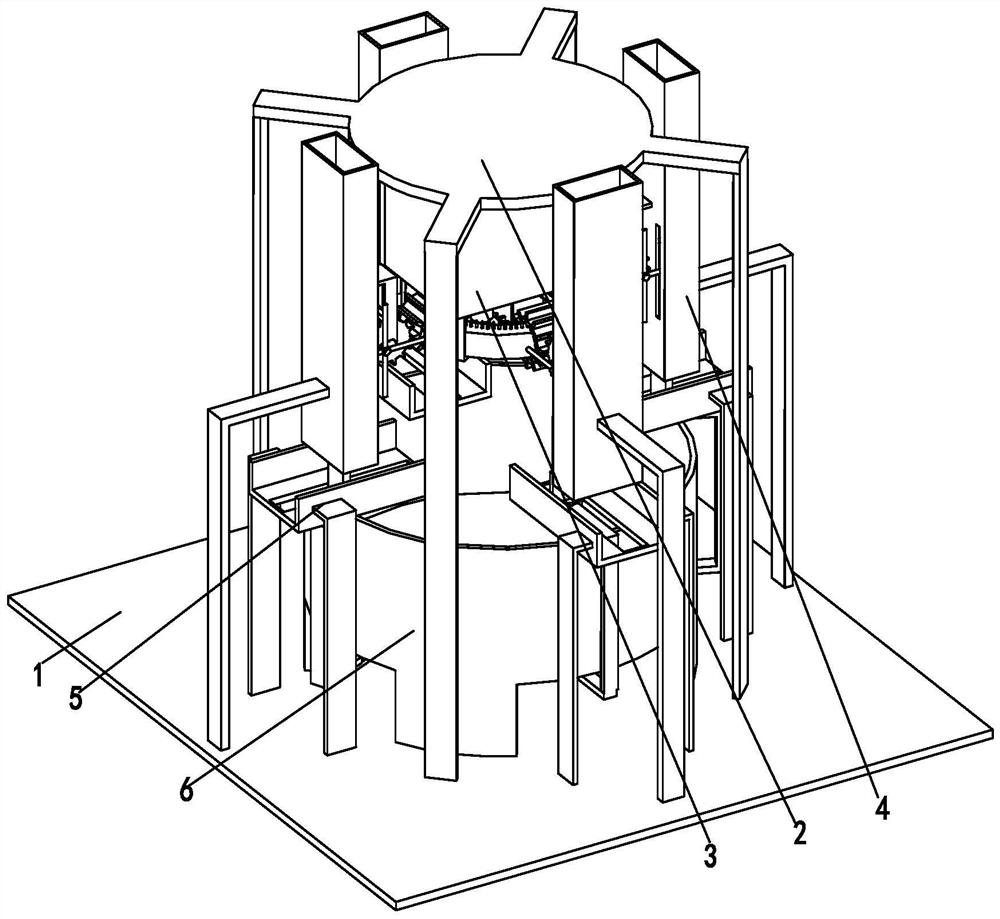

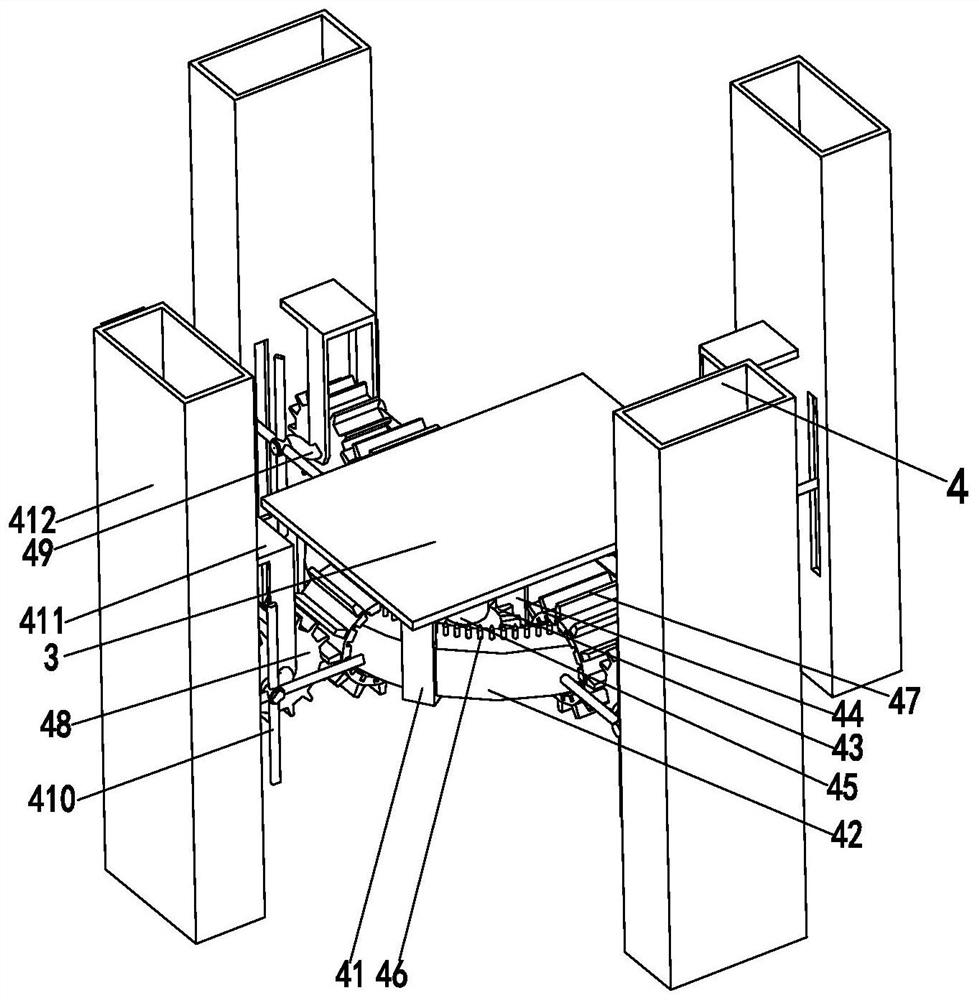

Automatic continuous feeder for PVC (Polyvinyl Chloride) pipe processing

ActiveCN109228025AImprove securityReduce the difficulty of crushingPlastic recyclingGrain treatmentsPulverizerEngineering

The invention relates to an automatic continuous feeder for PVC (Polyvinyl Chloride) pipe processing. The automatic continuous feeder comprises a bottom plate, a mounting rack, a connecting bracket, afeeding device, a push device and a grinder, wherein the mounting rack is arranged on the bottom plate; the connecting bracket is arranged at the lower end of the mounting rack; the side wall of theconnecting bracket is connected with the feeding device; the push device is arranged at the lower end of the feeding device; the grinder is arranged at the lower end of the push device; the feeding device, the push device and the grinder are all arranged on the bottom plate; and the feeding device comprises a support frame, a rotary gear ring, a rotating gear, a mounting bracket, a rotating motor,a cone column, a rotary gear, a driven gear, a feeding shaft, a feeding rack, a connecting rack and a feed box. According to the automatic continuous feeder disclosed by the invention, the problems existing in the conventional PVC pipe recovering and grinding process that manual continuous feeding is needed, potential safety hazards exist, the grinding difficulty is high, the grinding effect is poor and the like can be solved, and the continuous feeding function in the PVC pipe grinding process can be realized.

Owner:安徽红叶塑胶有限公司

Multistage smashing device for plastic product recycling

InactiveCN111660462AFully contactedFast cutting speedPlastic recyclingMechanical material recoveryAugerStructural engineering

The invention discloses a multistage smashing device for plastic product recycling, and relates to the technical field of waste recycling. The device includes a screening drum, a spiral packing augerand a smashing box, a fine smashing mechanism and a rough smashing mechanism are arranged in the smashing box, the rough smashing mechanism includes a smashing drum and a cutting plate, taper nails are fixedly arranged on the circumferential side face of the smashing drum, and a plurality of triangular blades are fixedly arranged on the surface of a cutting plate I. The fine smashing mechanism includes a second round rod, a cam, a single blade, and a connecting block, a plurality of cross-shaped blades are fixedly arranged on the circumferential side face of the second round rod, a long shaftand a short shaft are fixedly arranged on two sides of the single blade respectively, and the long shaft and the short shaft are separately connected with the connecting block in a rotating mode. According to the device, the rough smashing mechanism, fine smashing mechanism, the screening drum and the spiral packing auger are arranged, unqualified plastic bottle pieces are screened and broken again until pieces are qualified by multiple smashing of plastic bottle pieces with different volume, the problem that the slow speed and the poor effect of smashing plastic bottles by an existing smashing device is solved.

Owner:芜湖青悠静谧环保科技有限公司

A method for recycling waste tires through ammonia low-temperature desulfurization

ActiveCN105399075BImprove crispnessReduce the difficulty of crushingCarbon preparation/purificationBond energyFluidized bed

The invention relates to the technical field of comprehensive utilization of resources and particularly relates to a method for recycling waste tires through ammonia-process low-temperature desulfurization. According to the method, the waste tires are placed at low temperature and are ground, so that the frangibility of the waste tires is improved, and the grinding difficulty of the waste tires is reduced; the waste tires are mixed with a low-temperature ammonia water solution and are subjected to microwave radiation treatment, so that bond energies of S-S bonds and S-C bonds in the waste tires are damaged, and the bond energy of C-C bonds in the waste tires is protected; by adding a desulfurization agent and carrying out ultrasonic catalysis, the sulfur-containing rate in the waste tires is decreased; by virtue of high-temperature steam treatment in a circulating fluidized bed, the splitting of the waste tires is relatively thorough, and the quality of a prepared carbon black product is improved; particularly, by mixing a secondary desulfurization agent, the sulfur content in carbon black is relatively low, the wide application of the carbon black product in the chemical engineering field is promoted, and the addition value of the recycle of the waste tires is increased.

Owner:贵州华宇橡胶科技有限公司

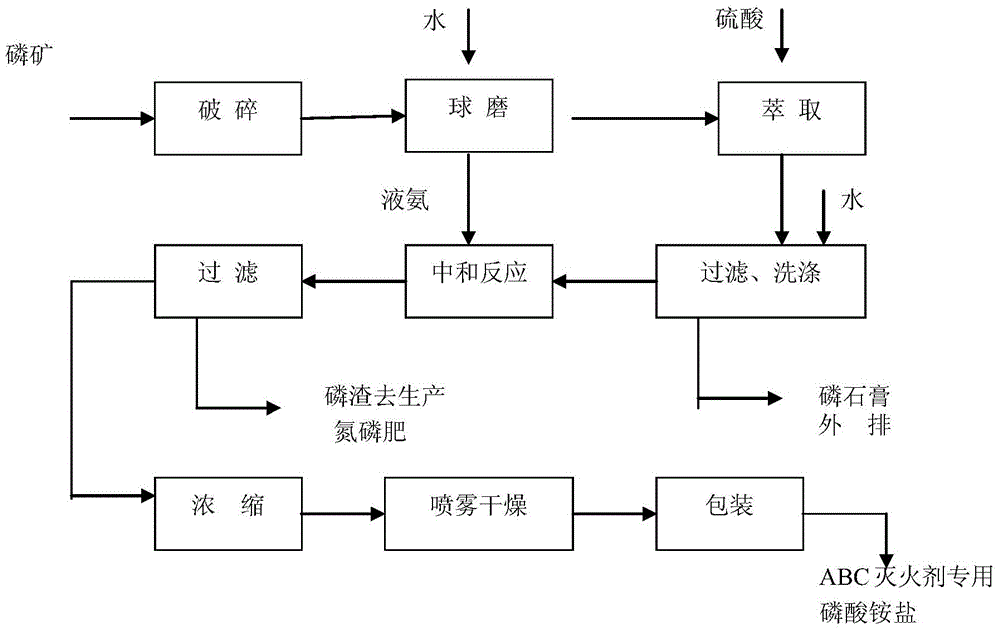

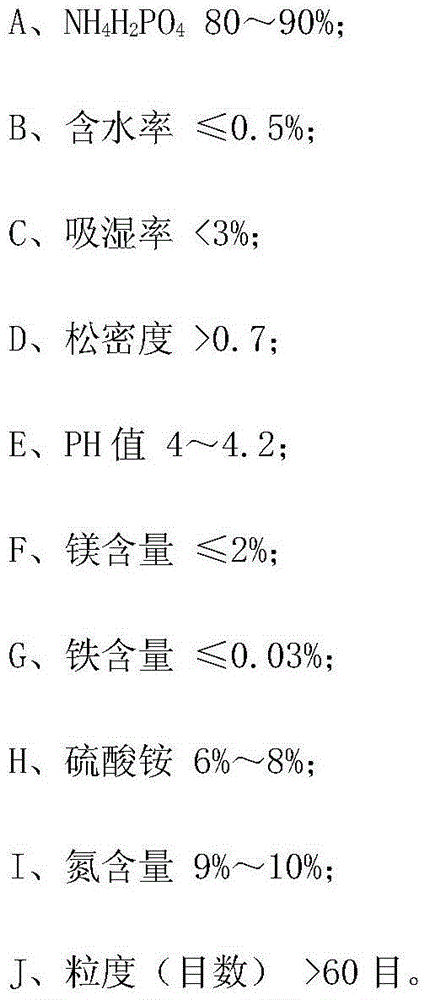

Special ammonium phosphate salt for abc dry powder fire extinguishing agent and production method thereof

InactiveCN103964407BEasy to crushEasy to dryPhosphatesFire extinguisherPhosphoric acidMoisture absorption

The invention discloses ammonium phosphate special for an ABC dry powder fire-extinguishing agent and a production method of ammonium phosphate. The production method comprises the steps of crushing phosphate ores, adding water, performing ball-milling, adding concentrated sulfuric acid for extracting, filtering by adding water, and washing to obtain wet-process phosphoric acid; then adding liquid ammonia for neutralizing until the nitrogen content reaches 9-10% and the PH value is 4-4.2; finally concentrating, and performing spray-drying to obtain ammonium phosphate, wherein the quality standards are as follows: the NH4H2PO4 content is 80-90%; the moisture content is less than or equal to 0.5%; the moisture absorption rate is less than 3%; the bulk density is more than 0.7; the pH value is 4-4.2; the magnesium content is less than or equal to 2%; the iron content is less than or equal to 0.03%; the ammonium sulfate content is 6-8%; the nitrogen content is 9-10%; the granularity (mesh number) is more than or equal to 60 meshes. The ABC dry powder fire-extinguishing agent produced by using the method can be used for improving the quality and reducing the production cost.

Owner:钟敏

An automatic continuous feeder for pvc pipe processing

ActiveCN109228025BManual continuous feeding withoutReduce the difficulty of crushingPlastic recyclingGrain treatmentsGear wheelPolyvinyl chloride

Owner:安徽红叶塑胶有限公司

A preparation method of steam-free aerated brick based on industrial, agricultural and construction waste

ActiveCN106477983BSmall particlesReduce the difficulty of crushingCeramicwareLiquid wasteSodium bicarbonate

The invention discloses a non-autoclaved aerated brick based on industrial, agricultural and construction waste. A specific preparation method comprises the following steps of: mixing concrete and brick slag with polystyrene foaming particles, smashing twice and heating and stirring to obtain modified construction waste; drying and levigating sludge and mixing with straw ash, rice ash and soybean residue, and grinding to obtain modified agricultural waste; mixing the modified construction waste and the modified agricultural waste, and performing dry stirring; adding cement, lime, fly ash, mineral slag, paper pulp waste liquid, NF aliphatic water reducing agent, sodium carbonate, sodium bicarbonate and polypropylene fiber, and mixing; adding water and stirring; and pouring into a mould; and pressing, heating and maintaining to obtain a product. In the invention, the prepared non-autoclaved aerated brick based on industrial, agricultural and construction waste has good heat retaining property; through comprehensive utilization of multiple modified wastes, the non-autoclaved aerated brick has high economy and is green and environment-friendly.

Owner:江西中态环保科技有限公司

A kind of processing method of high-strength environment-friendly concrete

ActiveCN111822080BReduce usageHigh hardnessSolid waste managementCeramic shaping apparatusCompressive resistanceCrushed stone

The invention discloses a processing method of high-strength environment-friendly concrete. The environment-friendly concrete is composed of the following components in parts by weight: 100-200 parts of cement, 40-130 parts of water, 46.2-82.4 parts of gravel, and a water reducer 1‑2 parts, 10‑30 parts of mica powder, 5‑30 parts of waterproofing agent, 0.5‑2 parts of flame retardant, 40‑80 parts of volcanic ash, 10‑30 parts of waste PPR powder, 245‑490 parts of sand and industrial waste powder 60‑80 parts, the waste PPR powder and industrial waste powder added to the concrete are poured into the mixer for mixing, thereby reducing the amount of cement used, thereby saving production costs, and adding mica powder and pozzolan to the interior can increase The hardness, compression resistance and water seepage resistance of concrete reduce the thermal conductivity of the concrete at the same time, so that the concrete has the characteristics of the highest hardness, the highest compressive strength, low thermal conductivity and strong water seepage resistance, and saves production costs at the same time. In addition, waste PPR powder and industrial waste powder are recycled to achieve the purpose of environmental protection.

Owner:舟山恒尊预拌混凝土有限公司

Walnut oil curing squeezing method

InactiveCN107557141AImprove brittlenessEvenly heatedFatty-oils/fats refiningFatty-oils/fats productionEconomic benefitsMoisture

The invention relates to walnut oil curing squeezing method which specifically comprises the following steps: (1) purchasing and crushing high-quality walnut kernels; (2) performing curing treatment on walnut kernels; and (3) removing impurities of walnut oil. Tests show that by adopting the walnut oil curing squeezing method provided by the invention, moisture and impurities such as coked walnutkernels generated in the curing squeezing process are reduced, the content of impurities in crude oil is reduced to be less than 1.0% from 2.1% of the prior art, meanwhile the oil yield of the walnutkernels is increased to be 39.9% or greater from 38.5% of the prior art, and thus the economic benefits of companies are greatly increased.

Owner:界首市致富家庭农场

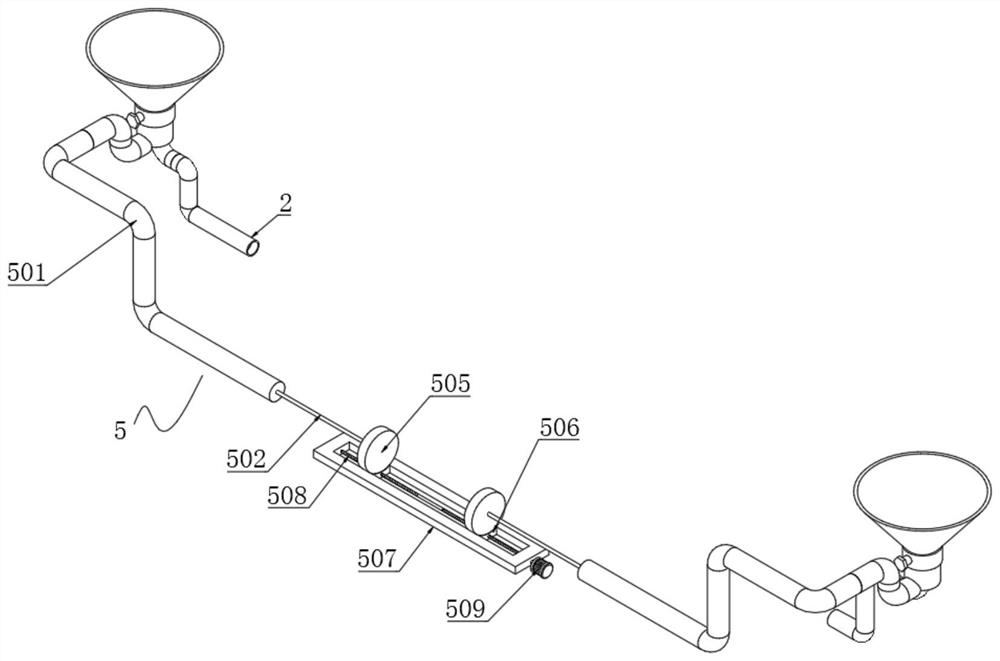

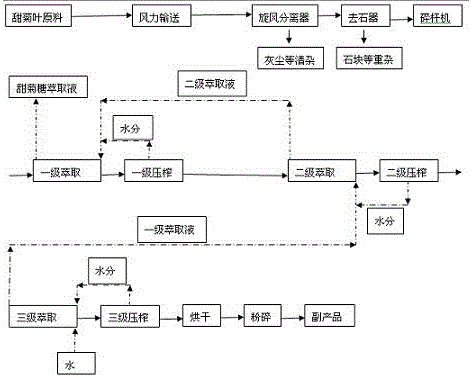

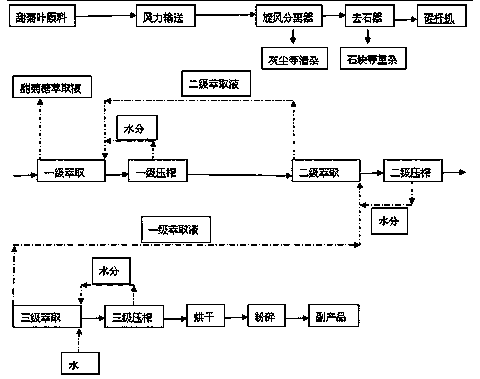

Counter-current extraction method for stevia rebaudian

ActiveCN106146575AReduce consumptionSubsequent production process is stableSugar derivativesSugar derivatives preparationSolventPre treatment

The invention discloses a counter-current extraction method for stevia rebaudian, which comprises the following steps: (1) using a cyclone separator for separating and removing light impurities from stevia rebaudian, using a wind power stone remover for removing heavy impurities, crushing stems and then performing multi-level counter-current extraction; (2) in a multi-level counter-current extraction process, extracting the materials at each level and then squeezing water; performing next level of extracting and squeezing on the squeezed material, returning the water squeezed at each level and extracting at the level; (3) in the multi-level counter-current extraction process, using new solvents as all the extraction agents for the latest level extraction; taking extract liquor generated from each level of extraction as the extract liquor for the superior extraction; obtaining the extraction liquor generated from level-1 extraction as final extraction liquor of stevia rebaudian. According to the invention, the pretreatment operation is performed for ensuring the basic constant characters of the materials for extraction and ensuring the stability of the subsequent production. Meanwhile, a multi-level squeezing system is added in the multi-level counter-current extraction system, so that the water consumption is reduced, energy consumption is reduced and the yield of the products is increased.

Owner:CHENGUANG BIOTECH GRP CO LTD

Ore crushing and screening machine

ActiveCN112844554AReduce the difficulty of crushingImprove crushing effectCocoaGrain treatmentsPhysicsElectric machinery

The invention discloses an ore crushing and screening machine, and particularly relates to the technical field of ore processing. The ore crushing and screening machine comprises a machine body, wherein a rotating mechanism is arranged in the middle of the machine body; the rotating mechanism comprises an outer rotating cylinder; an inner waveform sliding groove is formed in the inner side wall of the outer rotating cylinder; an inner rotating cylinder is arranged in the middle of the inner side of the outer rotating cylinder; an outer waveform sliding groove is formed in the outer side wall of the inner rotating cylinder; a U-shaped frame is arranged between the outer rotating cylinder and the inner rotating cylinder; and the two sides of the U-shaped frame are movably sleeved with sliding sleeves. According to the ore crushing and screening machine provided by the invention, through the arrangement of the machine body, the rotating mechanism, a crushing cone, a lower shearing disc, an upper shearing disc, a sieve plate and a motor, in the rotating process of the outer rotating cylinder, the inner rotating cylinder, the crushing cone and the upper shearing disc, large ores can be sheared, the crushing difficulty is reduced, the ores can be crushed twice, and the crushing effect is improved; and meanwhile, the sieve plate is driven to move up and down through the sliding sleeves and connecting rods, so that ore screening can be accelerated, and efficiency is improved.

Owner:TANGSHAN SENPU MINING EQUIP CO LTD

A kind of ore crushing and screening machine

ActiveCN112844554BSpeed up sievingReduce the difficulty of crushingCocoaGrain treatmentsMining engineeringElectric machinery

Owner:TANGSHAN SENPU MINING EQUIP CO LTD

Raw material crushing equipment for production of traditional Chinese medicines

InactiveCN111841778AImprove crushing efficiencyReduce the difficulty of crushingGrain treatmentsMedicinal herbsMechanical engineering

The invention discloses raw material crushing equipment for production of traditional Chinese medicines, and relates to the technical field of production equipment of medicinal materials. The raw material crushing equipment for the production of the traditional Chinese medicines comprises a base; a crushing chamber is fixedly installed on the base; an air cylinder is fixedly installed on the top end of the crushing chamber; a movable end of the air cylinder is fixedly connected with a moving bar; the lower end of the moving bar is fixedly connected with a triangle plate; the left side of the triangle plate is provided with a first moving block, and the right side of the triangle plate is provided with a second moving block; mounting plates are fixedly installed on the outer sides of the first moving block and the second moving block; cutters are fixedly installed on the mounting plates; a first rotating shaft and a second rotating shaft are further arranged inside the crushing chamber;a stirring knife is fixedly installed on the first rotating shaft and a grinding roller is fixedly installed on the second rotating shaft; a grinding plate is further fixedly installed inside the crushing chamber; and a plurality of sieve holes are arranged on the grinding plate. According to the raw material crushing equipment for the production of the traditional Chinese medicines provided by the invention, the crushing effect of the traditional Chinese materials can be better, and the crushing efficiency is higher.

Owner:陈扬

A kind of countercurrent extraction method of stevia leaf

ActiveCN106146575BReduce consumptionSubsequent production process is stableSugar derivativesSugar derivatives preparationPre treatmentSolvent

The invention discloses a counter-current extraction method for stevia rebaudian, which comprises the following steps: (1) using a cyclone separator for separating and removing light impurities from stevia rebaudian, using a wind power stone remover for removing heavy impurities, crushing stems and then performing multi-level counter-current extraction; (2) in a multi-level counter-current extraction process, extracting the materials at each level and then squeezing water; performing next level of extracting and squeezing on the squeezed material, returning the water squeezed at each level and extracting at the level; (3) in the multi-level counter-current extraction process, using new solvents as all the extraction agents for the latest level extraction; taking extract liquor generated from each level of extraction as the extract liquor for the superior extraction; obtaining the extraction liquor generated from level-1 extraction as final extraction liquor of stevia rebaudian. According to the invention, the pretreatment operation is performed for ensuring the basic constant characters of the materials for extraction and ensuring the stability of the subsequent production. Meanwhile, a multi-level squeezing system is added in the multi-level counter-current extraction system, so that the water consumption is reduced, energy consumption is reduced and the yield of the products is increased.

Owner:CHENGUANG BIOTECH GRP CO LTD

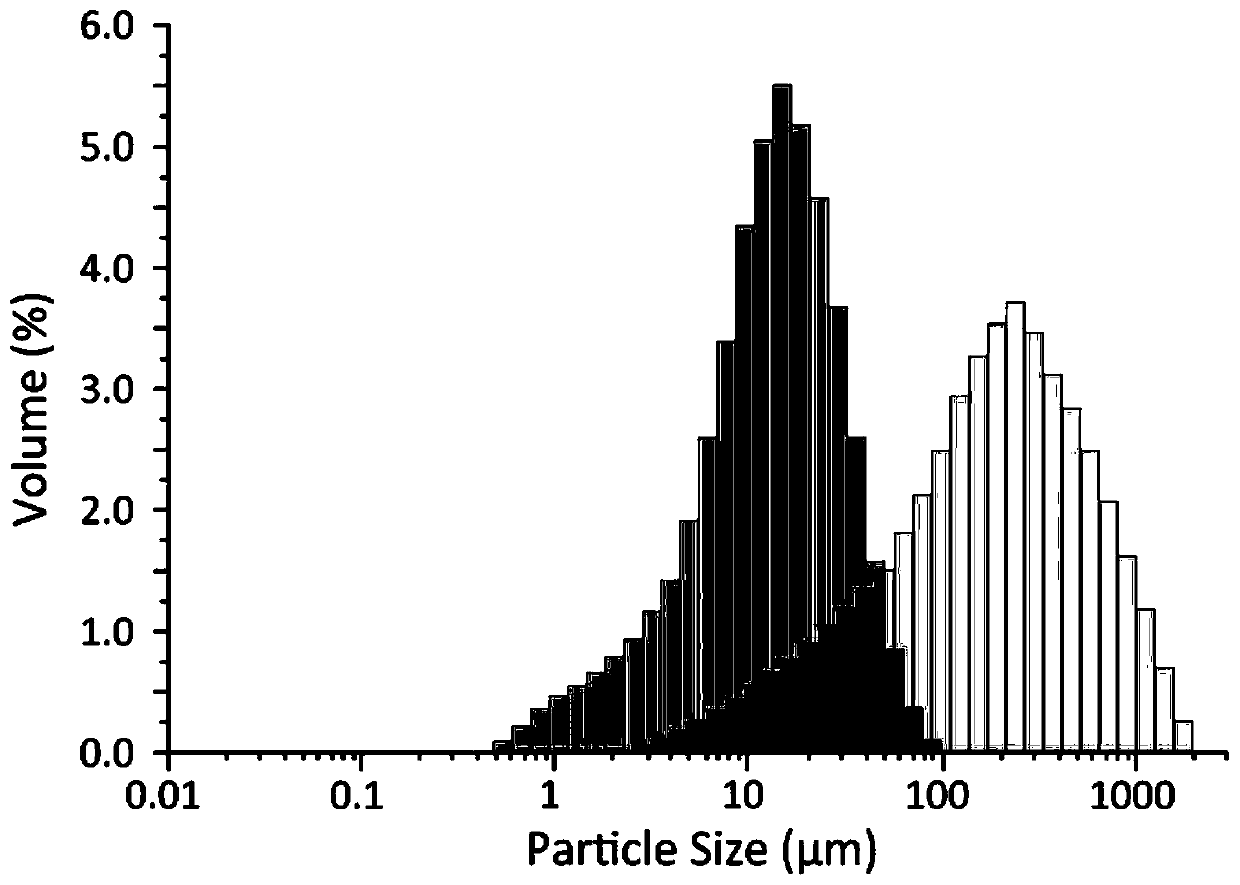

A kind of superfine powder of Hetian jade and preparation method thereof

The invention provides Hetian jade ultrafine powder and a preparation method thereof. Hetian jade leftover materials are fully utilized, and waste is avoided. The preparation method comprises the steps that the Hetian jade leftover materials are firstly mechanically smashed into Hetian jade coarse powder, then, the Hetian jade coarse powder is added into a treating agent, vacuum freeze drying andairflow smashing are carried out, micron-sized Hetian jade medium coarse powder is prepared, and finally, Hetian jade ultrafine powder of which the particle size is 10 nm or below is obtained throughwet grinding under the action of nano zinc oxide with positive charge. According to the Hetian jade ultrafine powder, the particle size is relatively small, besides, the surface of the Hetian jade ultrafine powder has positive charge, agglomeration is avoided, and fluidity is good.

Owner:广州东芳沁玉生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com