Multifunctional veterinary herbal medicine superfine crushing equipment

An ultra-fine pulverizing and multi-functional technology, which is applied in grain processing and other directions, can solve the problems of powder splashing around, affecting the pulverizing effect, and long pulverizing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

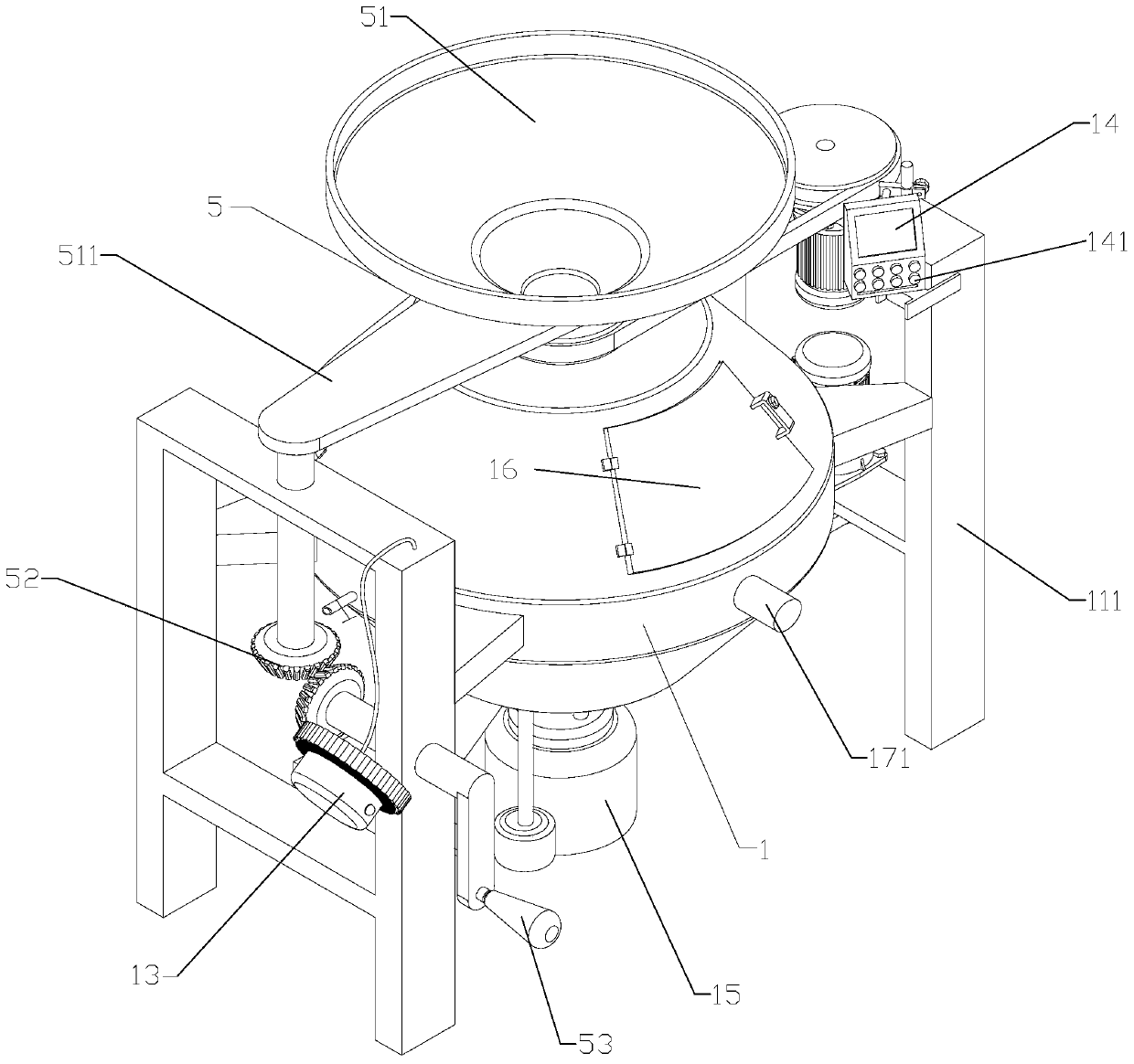

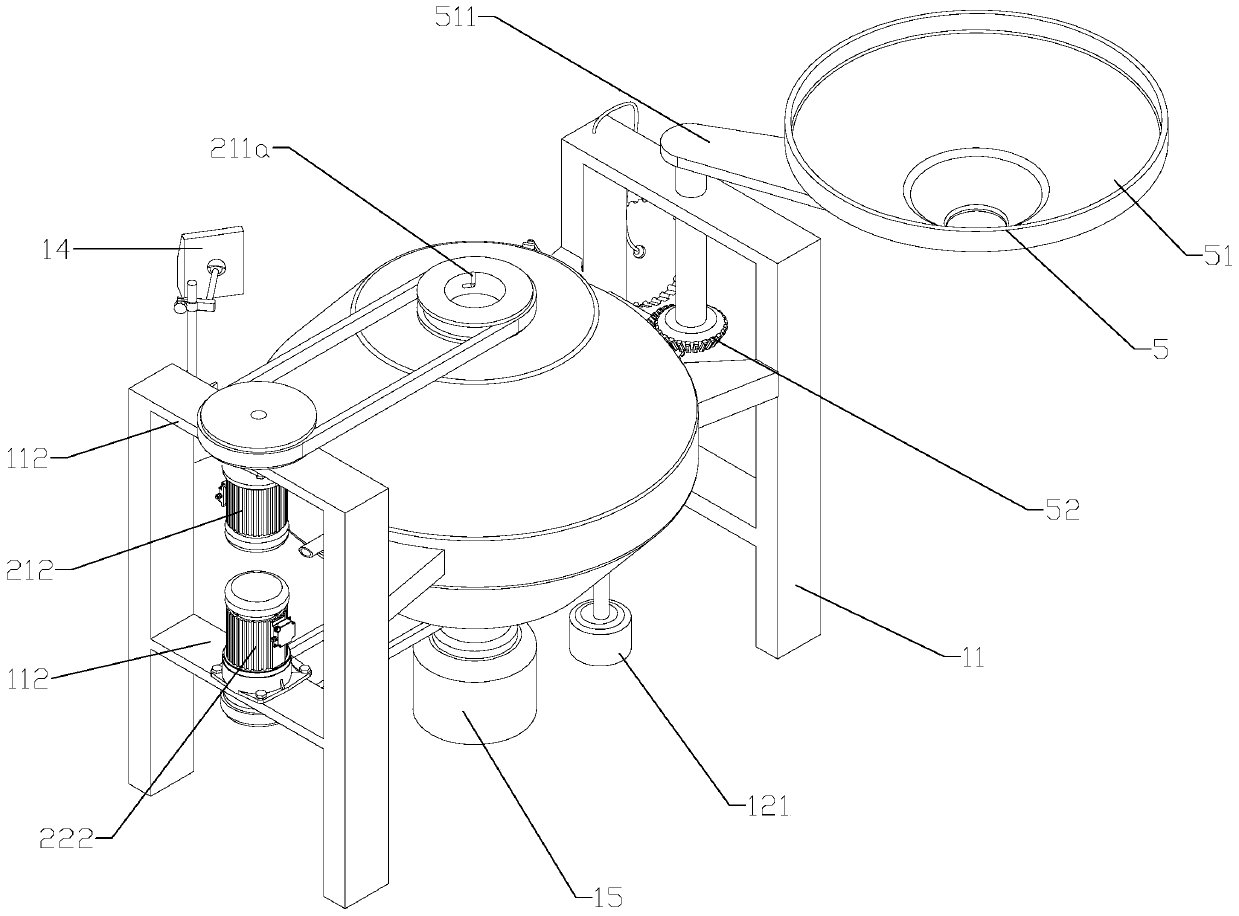

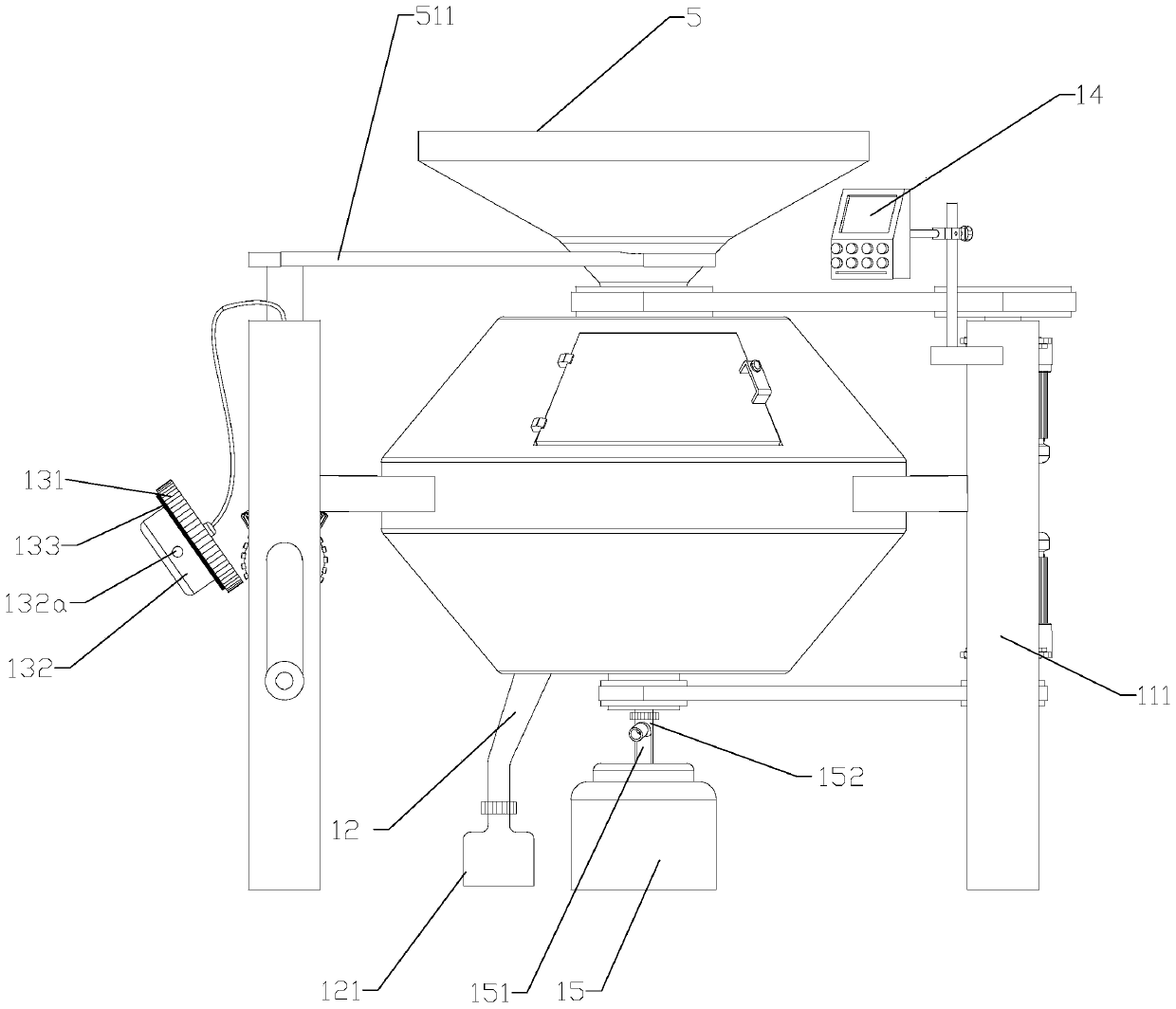

[0032] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

[0033] as attached figure 1 to attach Figure 11Shown Chinese veterinary medicine grinding equipment, it comprises housing 1, and housing 1 is fixed on a frame 11, and frame 11 comprises four upright posts 111 and the support plate 112 between connecting upright post 111. Grinding device 2 is arranged in housing 1, and grinding device 2 comprises upper grinding body 21 and lower grinding body 22, and upper grinding body 21 and lower grinding body 22 are all conical umbrella-shaped structures, and one is a conical protrusion, one It is a tapered groove cooperating with a tapered protrusion. The maximum distance between the upper grinding body 21 and the lower grinding body 22 is about 5-10 cm, and the surface of the upper grinding body 21 and the lower grinding body 22 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com