Patents

Literature

57results about How to "Reduce subsequent processing steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-thermal conductivity diamond/copper composite material applicable to wide temperature range and method

InactiveCN103184363AImprove thermal conductivityLow densityGearingCylindersThermal expansionInjection molding process

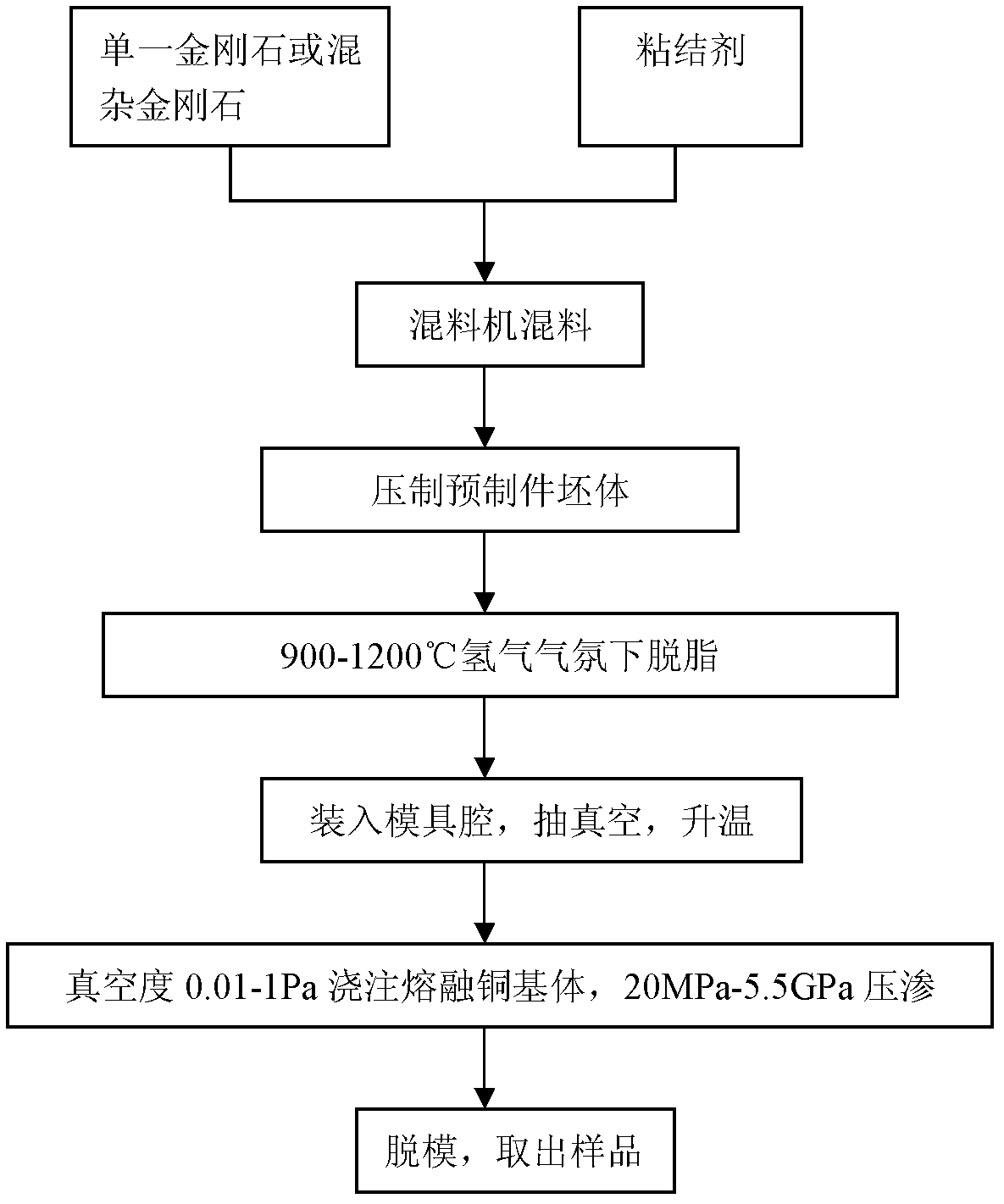

The invention relates to a high-thermal conductivity diamond / copper composite material applicable to a wide temperature range and a method, belonging to the technical field of preparation of thermal management materials. The copper-based composite material is prepared through the following steps: preparing a prefabricated reinforcement component from a reinforcement and a binder by using an injection molding process for a prefabricated component, wherein the reinforcement is prepared by mixing one or two different diamond particles; and casting fused copper liquid on the prefabricated reinforcement component and carrying out pressure infiltration, wherein a copper substrate is pure copper or copper alloy, and a volume ratio of a diamond to the copper substrate is 50-75%: 50-25%. The diamond / copper composite material prepared by using pressure infiltration is applicable to a wide temperature range of 40 to 350 K, has higher thermal conductivity compared with molybdenum-copper and tungsten-copper in the temperature range of 40 to 350 K, a low thermal expansion coefficient and small density and is a good option for a heat dissipation material used in a spatial refrigeration environment.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

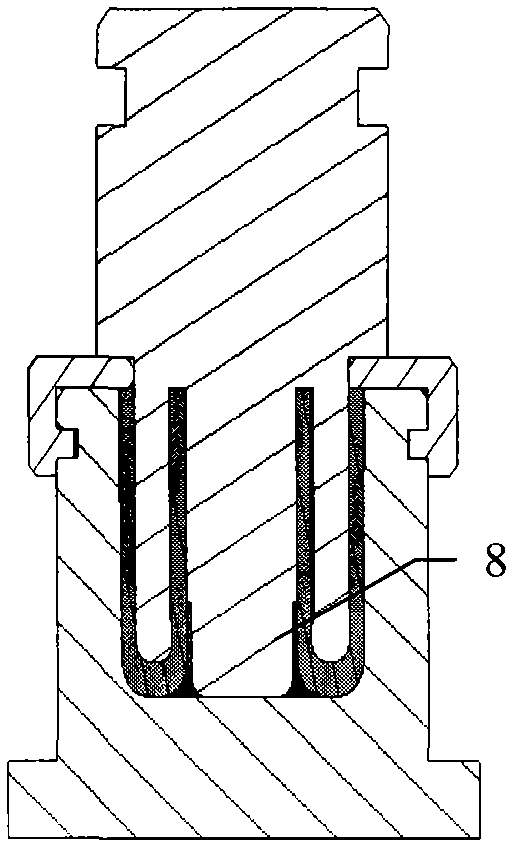

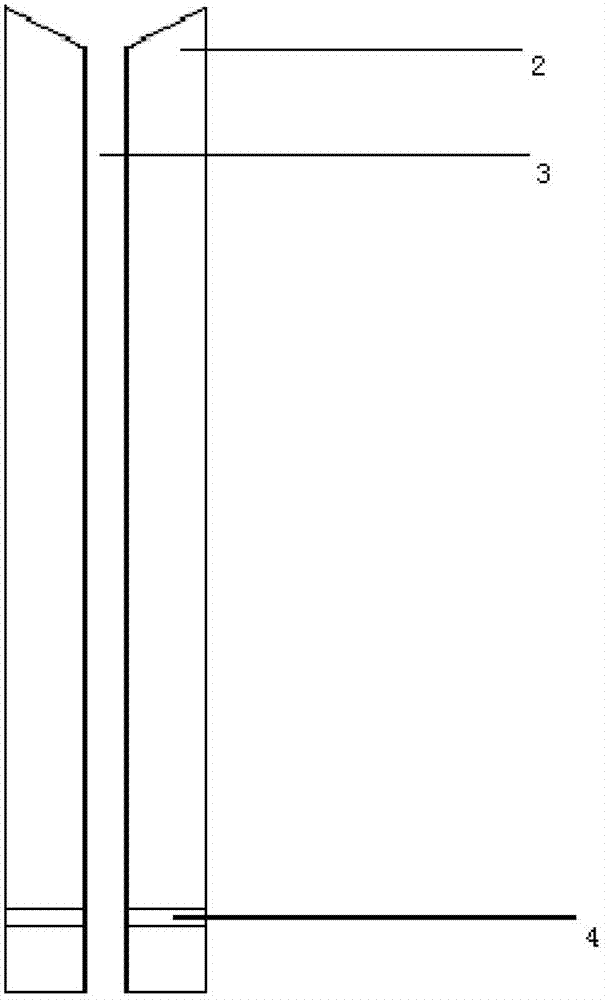

Two-way fine stamping die and two-way fine stamping part processing method

ActiveCN102806264AGood punching shear surface qualitySimple production processEngineeringMechanical engineering

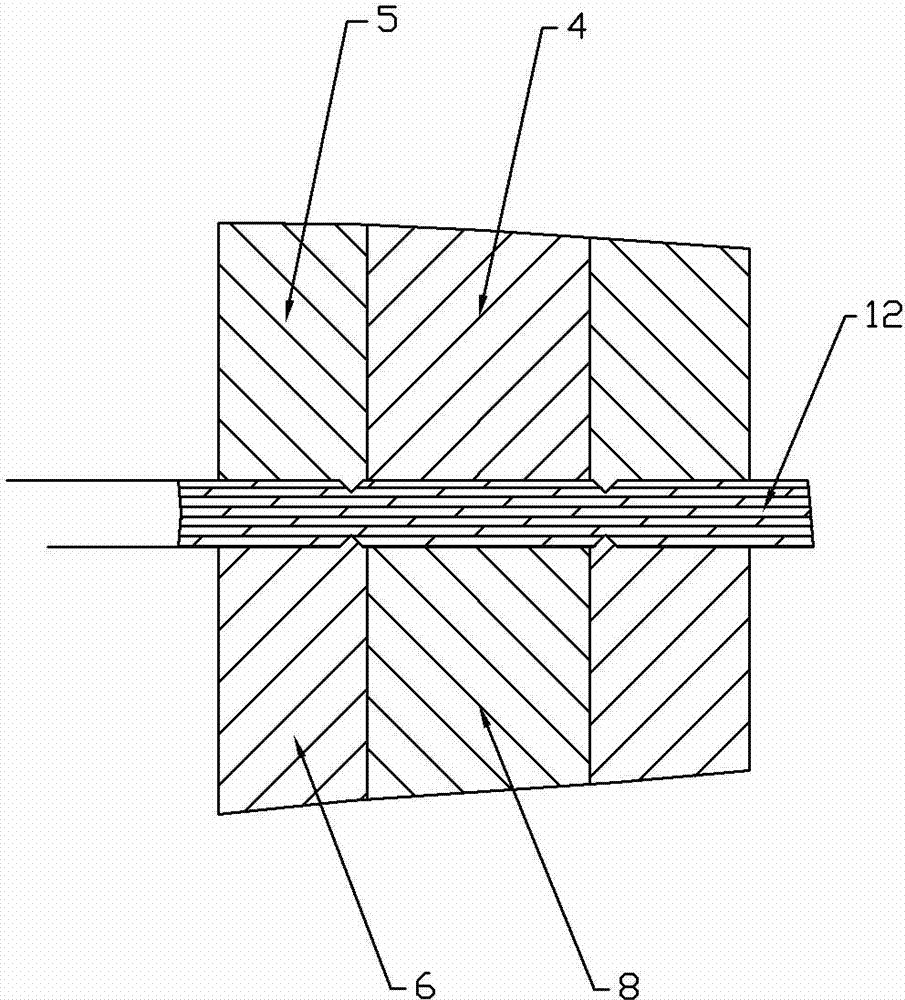

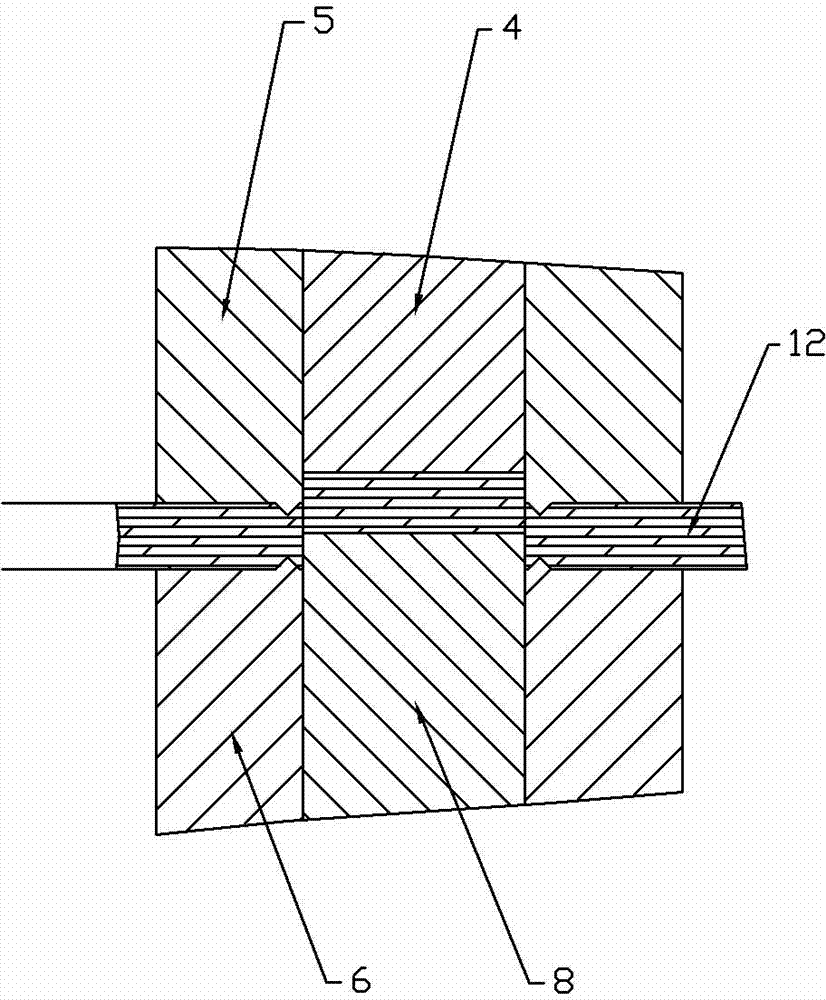

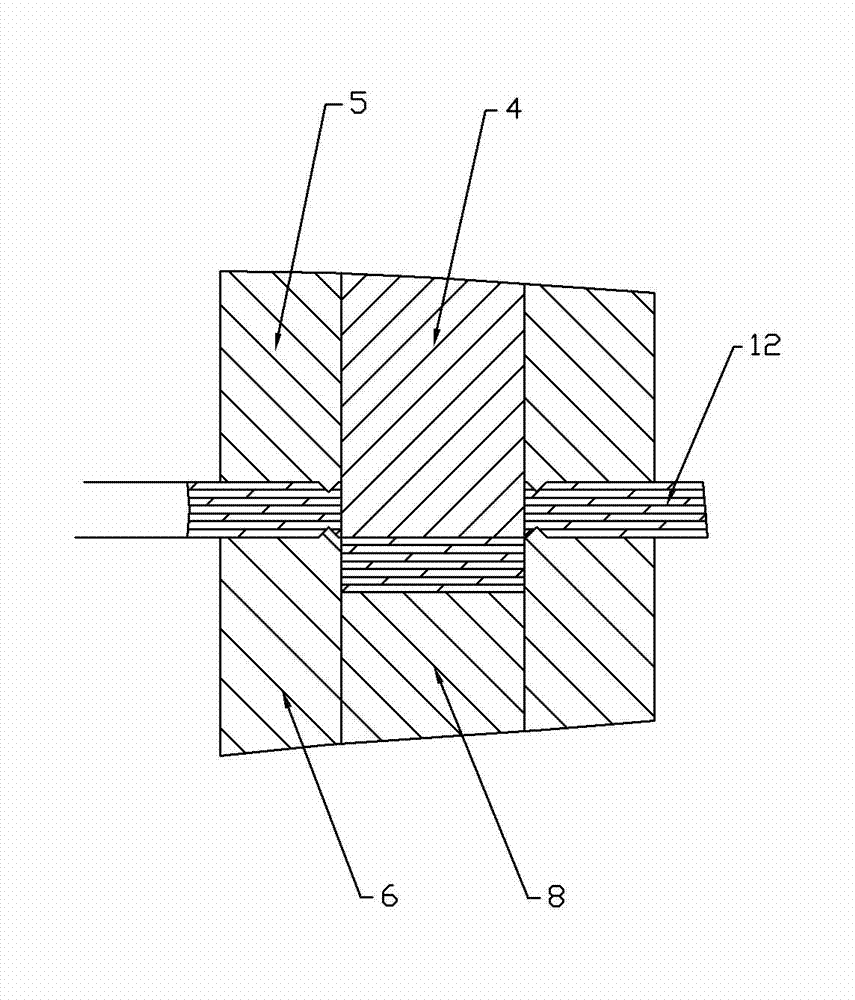

The invention relates to a fine stamping die and a two-way fine stamping part processing method. The two-way fine stamping die is characterized in that an upper die and a lower die respectively adopt a structure in which a concave die contains a convex die, an upper convex die is arranged in a cavity of an upper concave die, the upper concave die is arranged on an upper die base, a lower convex die is arranged in a cavity of a lower concave die, the lower concave die is fixed on a lower die base through a concave die fixing plate, and the upper convex die and the lower convex die slide in the concave die through the pressure transmitted by a fine stamping pressure machine. The two-way fine stamping part processing method comprises the following steps that: the lower die moves upwards, the upper die and the lower die press a material so that the material is in a pressed state, and the lower convex die continuously moves upwards to the position which is 1 / 3-1 / 2 of the thickness of the material; the upper convex die moves downwards, and the material is chopped under the material pressing force, chopping force and reserve pressure until the material is separated; and the lower die moves downwards, the upper die and the lower die are separated, and the lower convex die ejects a part from the lower concave die. According to the invention, the finely-stamped part product obtained by the two-way fine stamping part processing method is good in chopping quality, and can be directly used for mechanical assembly, so that the production efficiency can be greatly improved.

Owner:河南星光机械制造有限公司

Method for growing semispherical sapphire crystal with certain curvature

ActiveCN102703980AReduce subsequent processing stepsReduce consumptionPolycrystalline material growthBy pulling from meltEngineeringMachining process

The invention discloses a method for growing a semispherical sapphire crystal with a certain curvature. The method comprises the following steps of: forming a melt layer on the surface of a mold by adopting a mold guiding method; aligning a seed crystal with the mold; making a lifting rod slide vertically and a vertical bracket slide horizontally by adjusting the position of a lifting head along a horizontal direction; matching three moving tracks to form a geometrical spherical surface with a certain curvature; and guiding the crystal to grow into a semispherical shape with a certain curvature. In the method, the semispherical sapphire crystal grown with an improved mold guiding method has the advantages of high crystal growing speed and moulding at one time, subsequent machining processes of the semispherical sapphire crystal can be reduced, resource energy consumption in a crystal machining process is lowered, and the cost is saved.

Owner:通辽精工蓝宝石有限公司

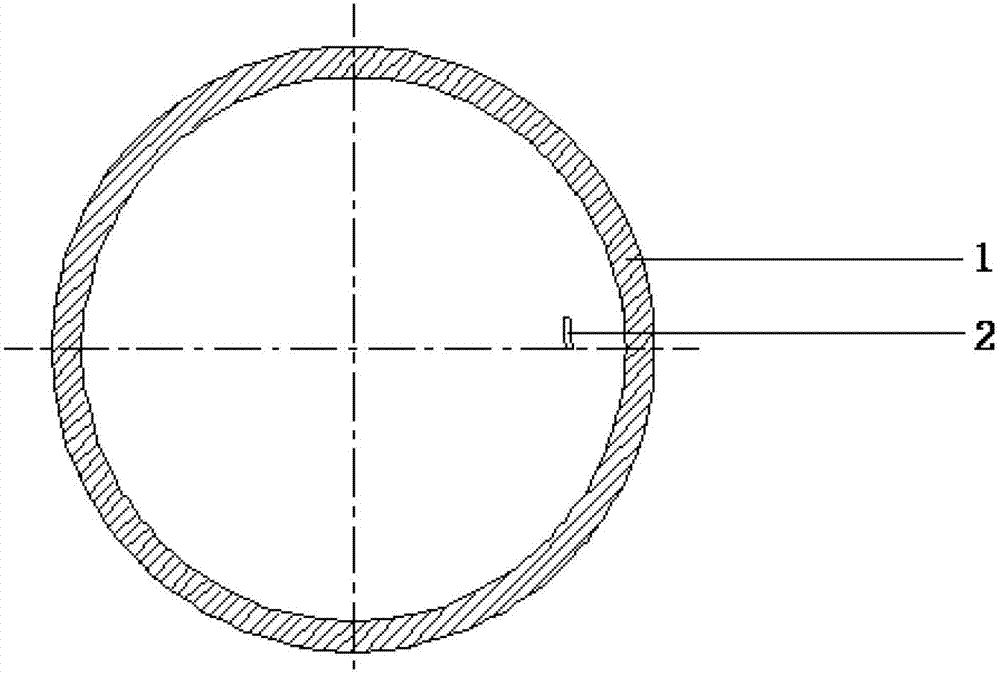

Opening reinforcement method and reinforcement sheet of fiber reinforcement resin composite material member

The invention discloses an opening reinforcement method and a reinforcement sheet of components of fiber-reinforced resin composites and relates to an opening reinforcement method and a reinforcement sheet used in the method. The invention solves the problems of the present reinforcement method such as difficult quality control, excessive subsequent working procedures, long time of occupying forming molds, and low working efficiency. The main steps of the method are as follows: preparing the reinforcement sheet; laying a fibrous presoaked band and the reinforcement sheet on a core mold for preparing the components of the fiber-strengthening resin composites and compacting fibrous presoaked band and the reinforcement sheet. The reinforcement sheet is annular with the thickness L2 of 2 to 4mm. The implementation of the reinforcement with the method can realize parallel production of a reinforcement section and composite bodies as well as the assembly type production of laying the composites, greatly improve the turnover utilization ratio of the mold, increase work efficiency, shorten the product molding cycle and lower the requirements of application periods of the resin body.

Owner:HARBIN FRP INST

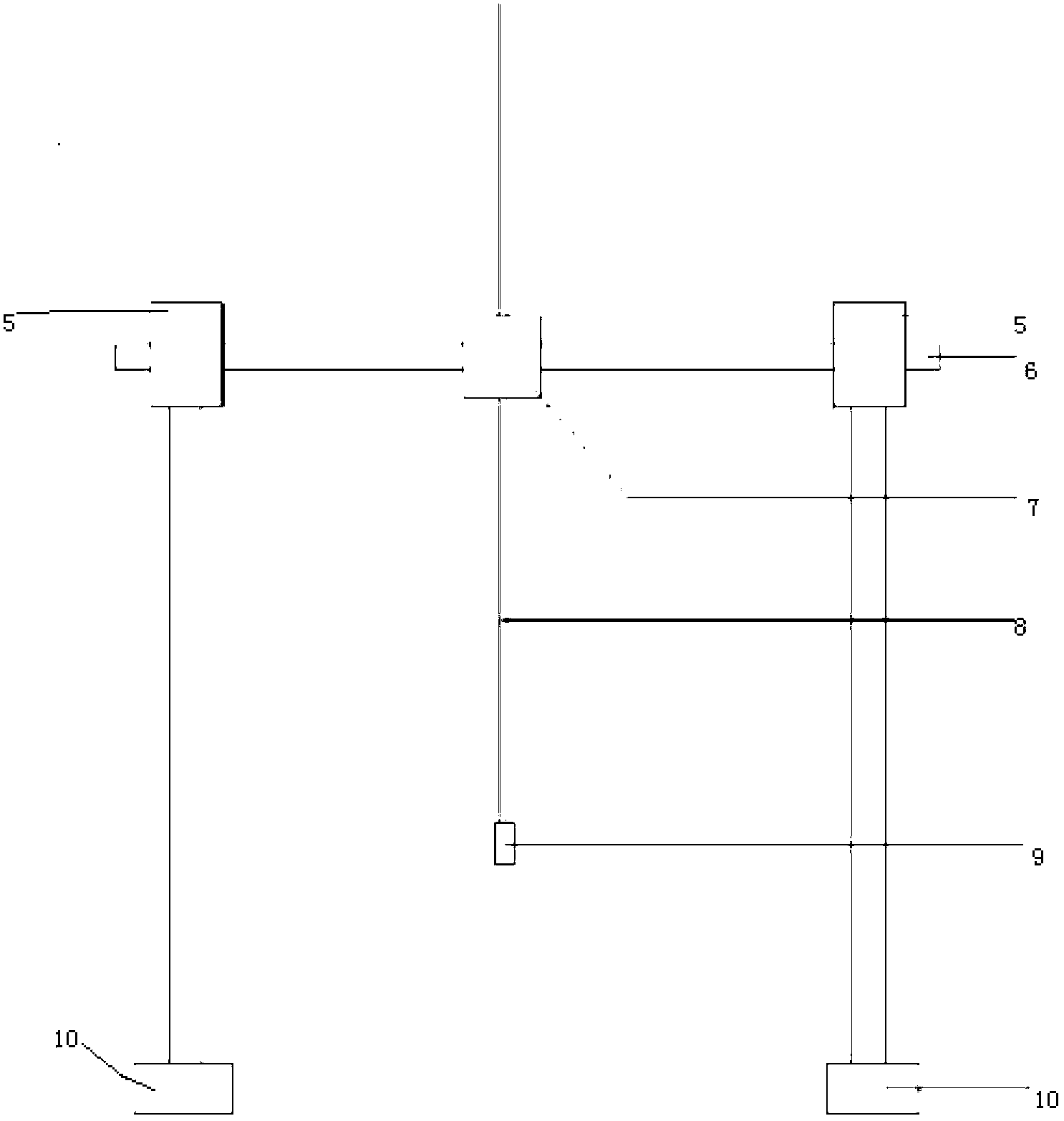

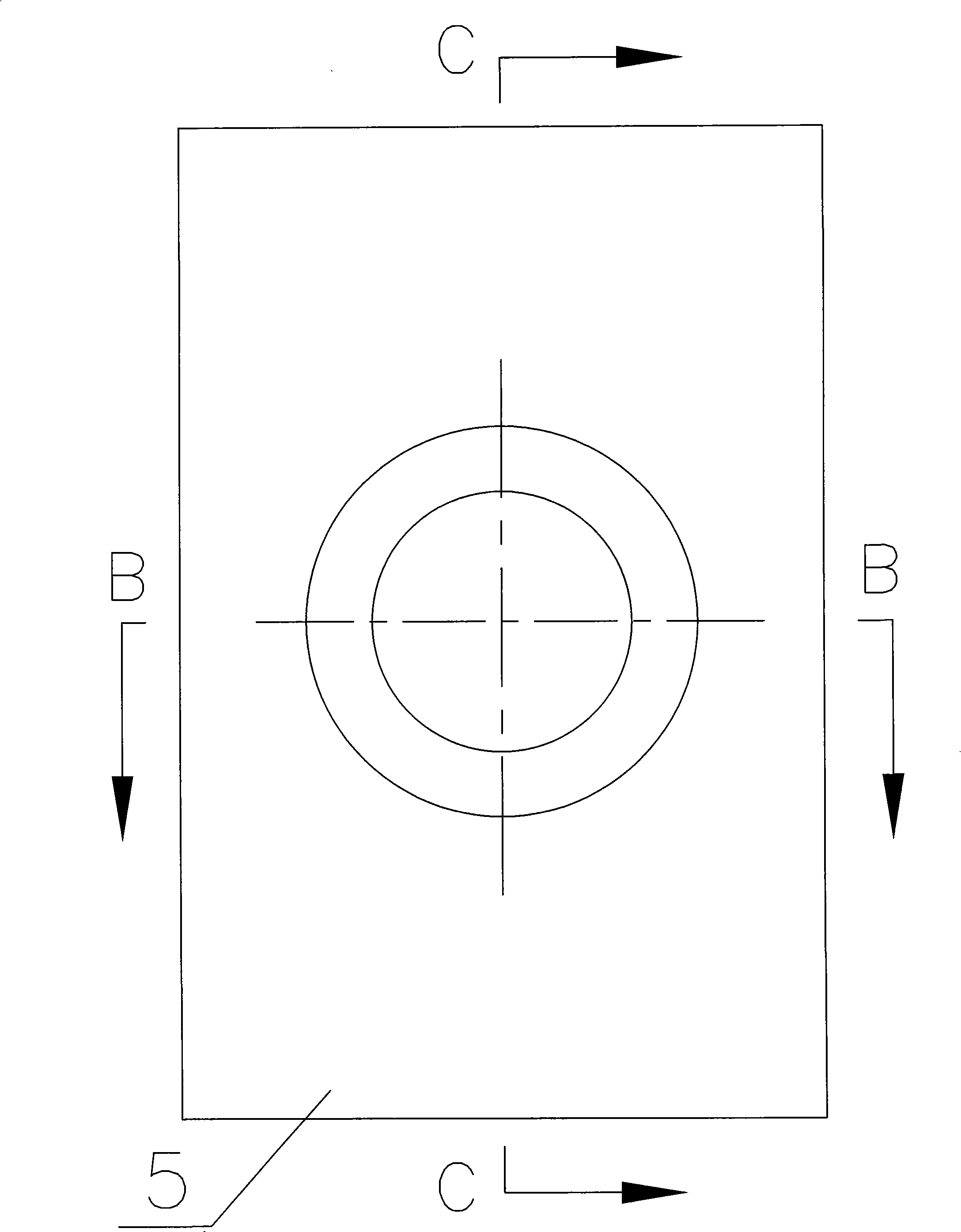

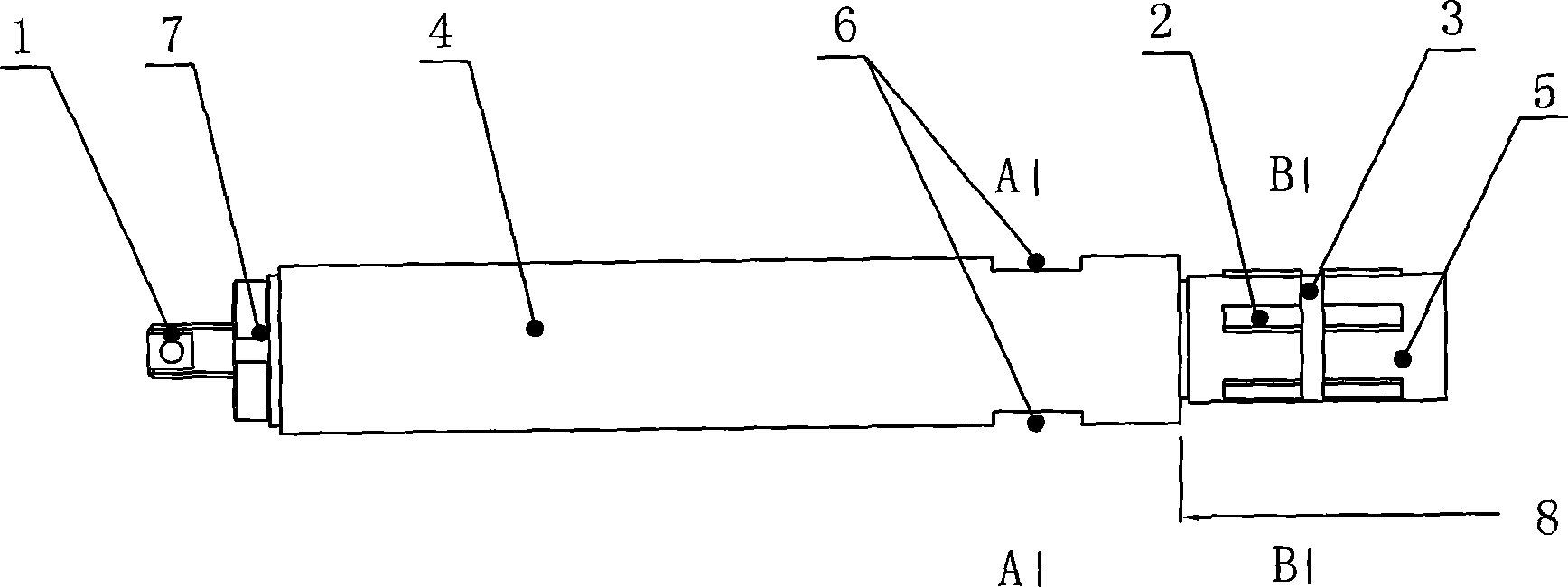

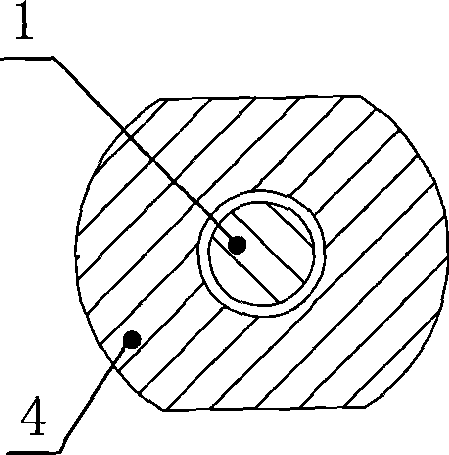

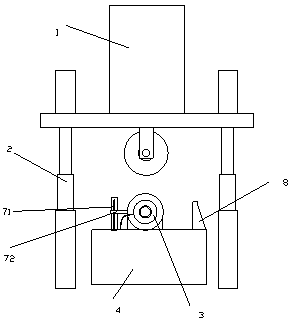

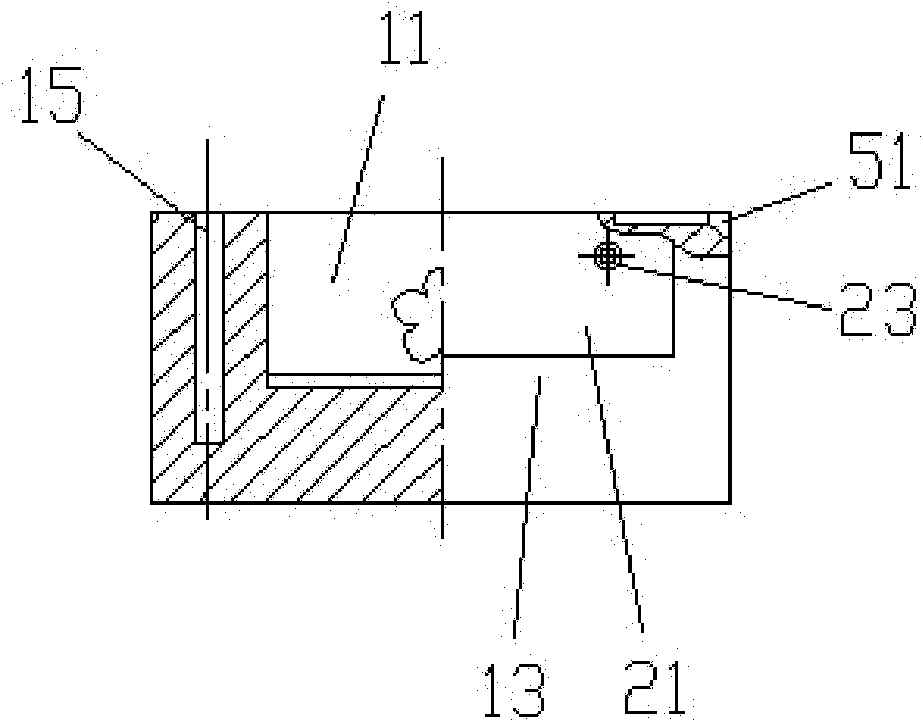

Improved inner expansion type tube extension device

InactiveCN101474645AReliable processingReduce subsequent processing stepsWork holdersEngineeringExpansion joint

The invention provides an improved internal expanded tube extender. The tube extender can greatly reduce tube process margin length in machining spiral finned tubes, reduce subsequent finned tube machining procedures, improve the work efficiency and lower the manufacturing cost. The tube extender comprises a sleeve, an internal draw bar, an expansion block and an elastic ferrule, the sleeve comprises a tube connecting part and an expansion joint part, the internal draw bar is sheathed inside the sleeve, the expansion joint part of the sleeve is provided with a sliding groove along a circumferential direction, the expansion block is embedded in the sliding groove, and the elastic ferrule is sheathed on the periphery of the expansion joint part of the sleeve.

Owner:WUXI HUAGUANG BOILER

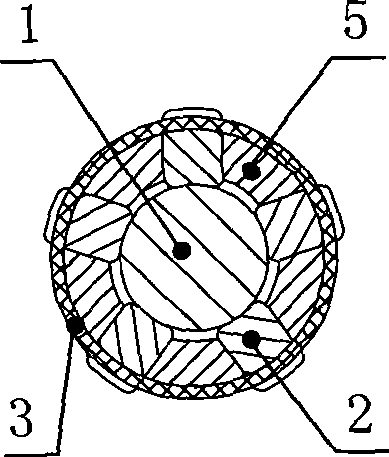

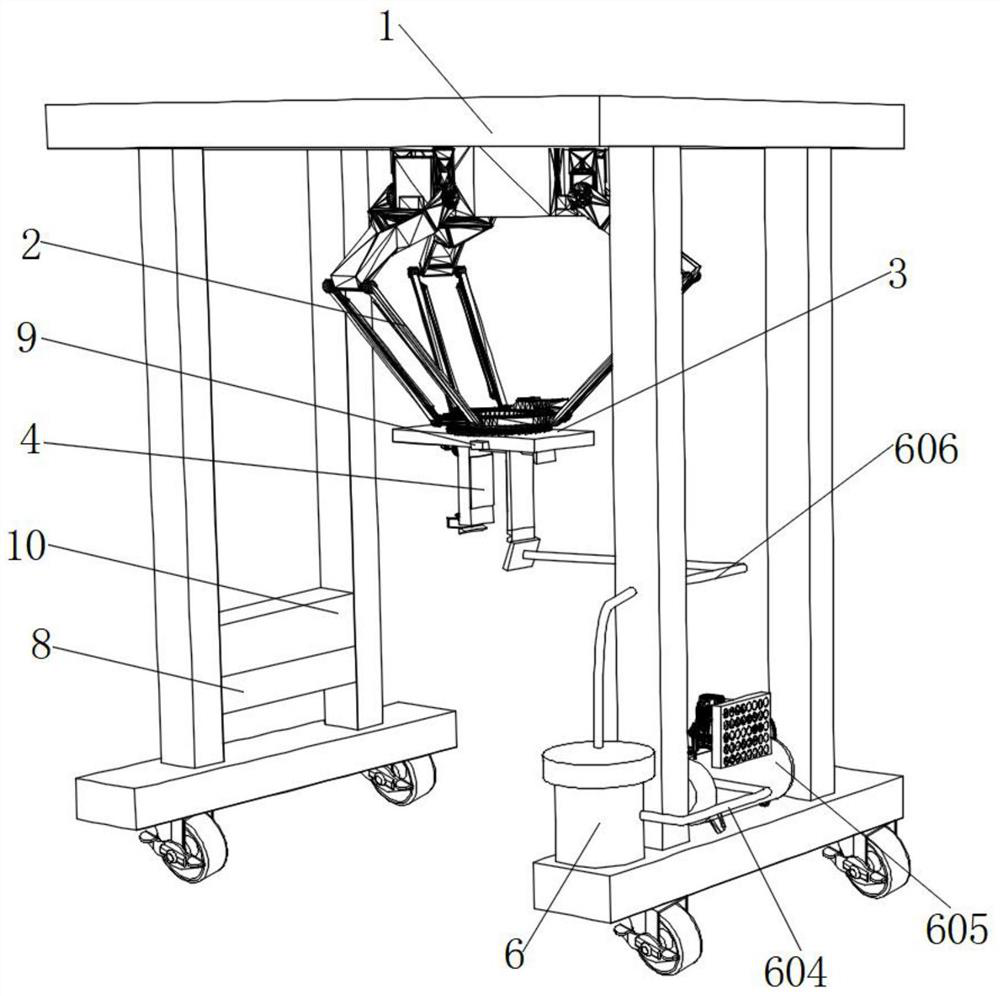

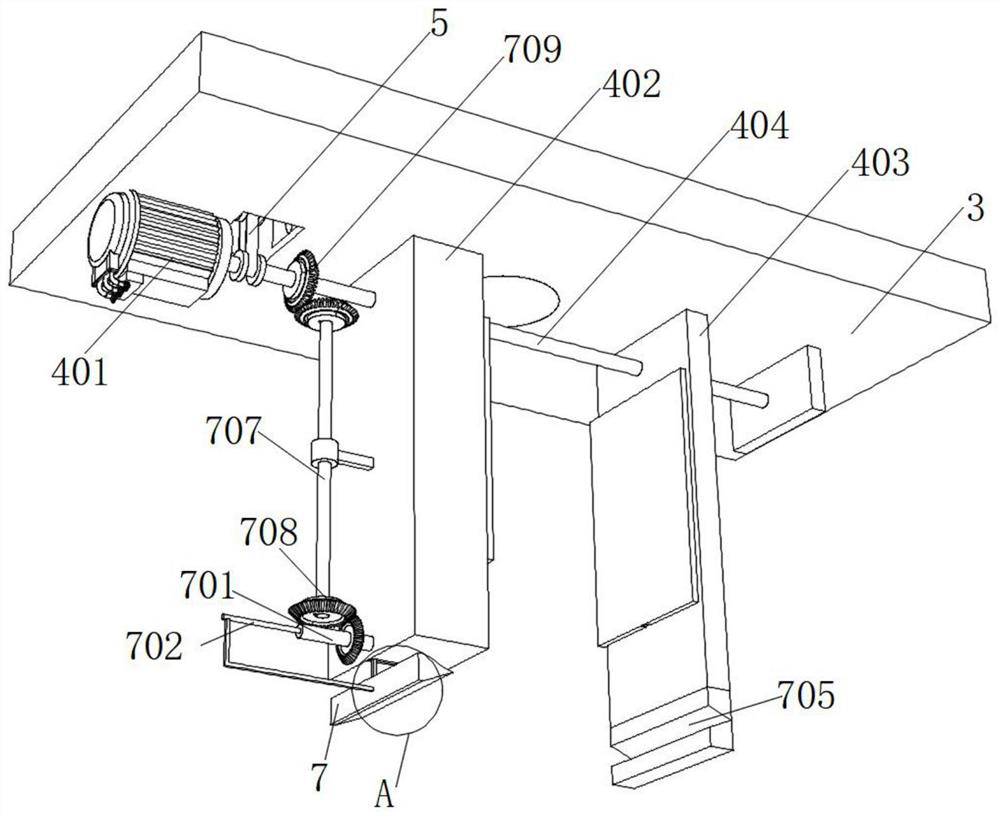

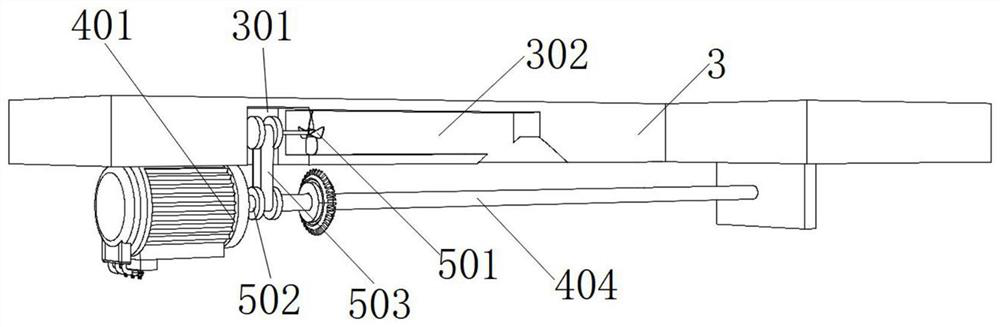

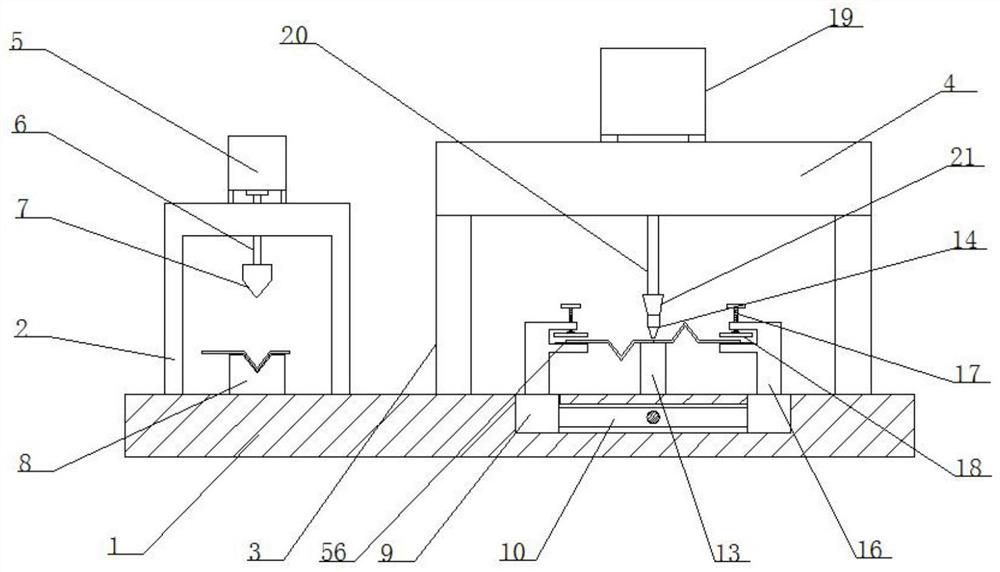

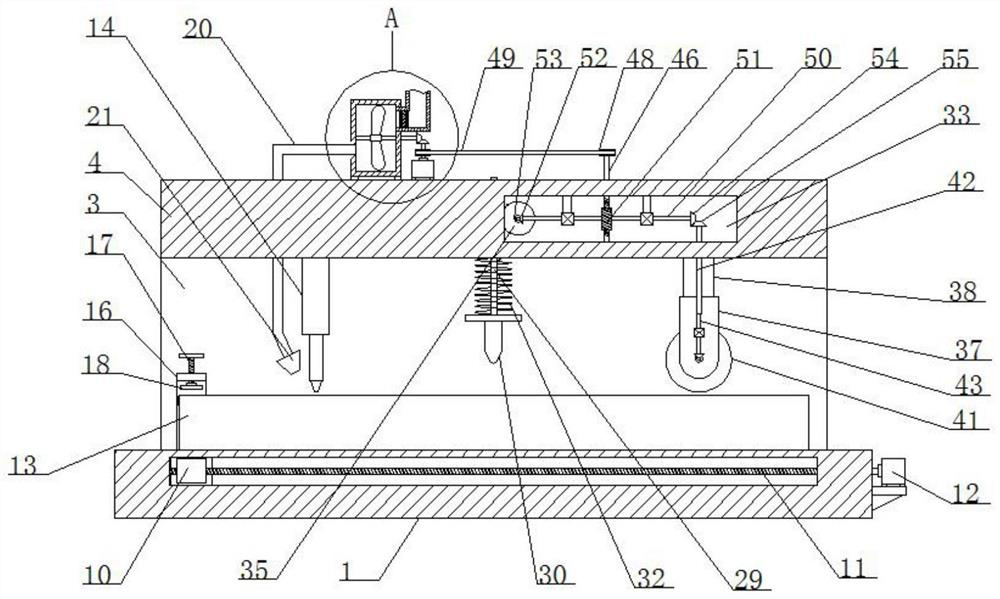

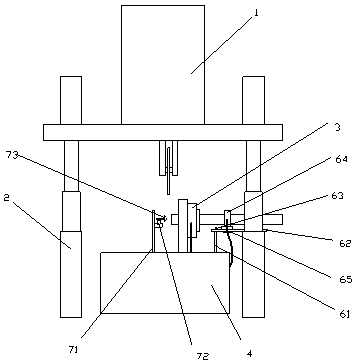

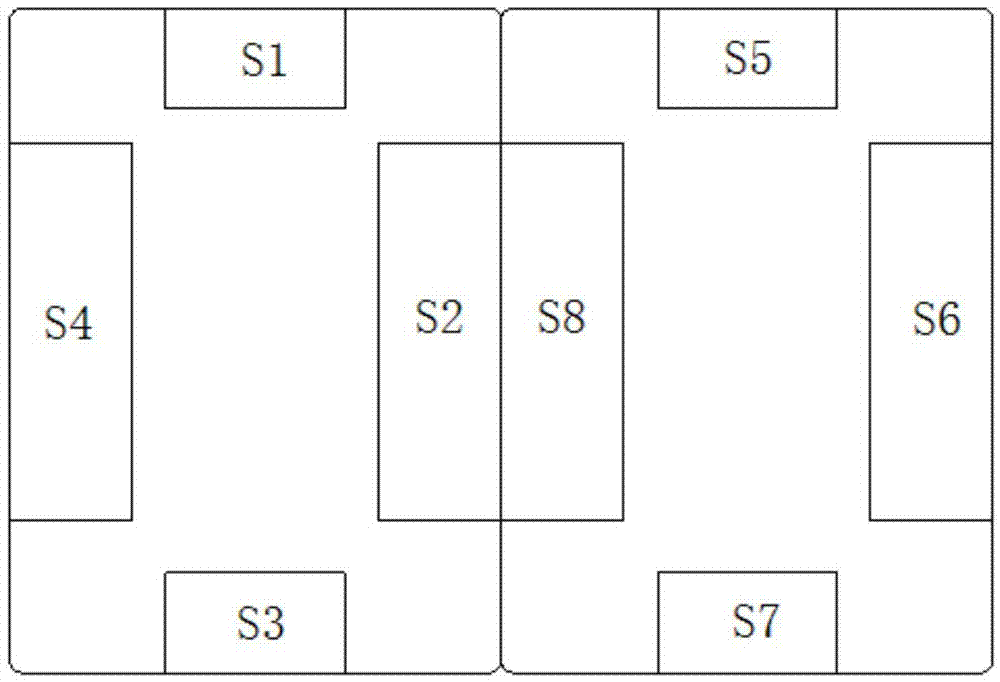

Intelligent tea picking robot capable of recognizing and simulating human hands through artificial intelligence

InactiveCN113519269AReduce subsequent processing stepsReduce labor intensityImage enhancementImage analysisRobot handMobile manipulator

The invention discloses an intelligent tea picking robot capable of recognizing and simulating human hands through artificial intelligence. The intelligent tea picking robot comprises a frame, a central control module and a camera; a four-axis parallel robot body is arranged on the inner top wall of the frame; a strip-shaped plate is fixedly connected to the bottom end of the four-axis parallel robot body; the camera is arranged on the lower edge of one side of the strip-shaped plate; a clamping structure is arranged at the bottom end of the strip-shaped plate; an auxiliary structure is arranged in the strip-shaped plate; a cutting structure is arranged on one side of the bottom end of the clamping structure; and a collecting structure is arranged at the other end of the bottom end of the clamping structure. Tea leaves to be picked are determined according to comparison of a video of the tea leaves shot by the camera and atlas, a mechanical arm is rapidly moved to automatically and accurately pick the tea leaves, meanwhile, the picked tea leaves are sucked into a storage container, and the quality of the tea leaves cannot be affected; and the picked tea leaves can be automatically collected and packaged, subsequent processing procedures are reduced, the labor intensity is reduced, and the production efficiency is improved.

Owner:石台县德馨农业科技有限公司 +1

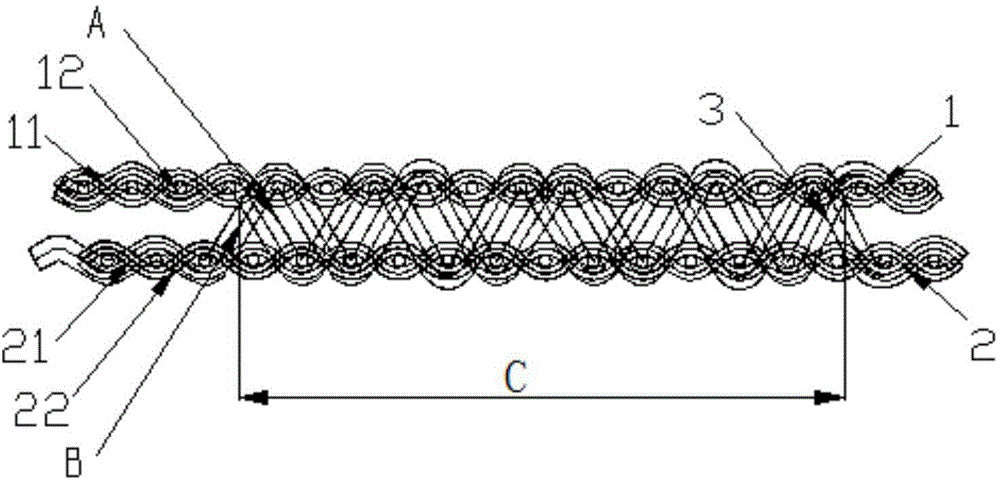

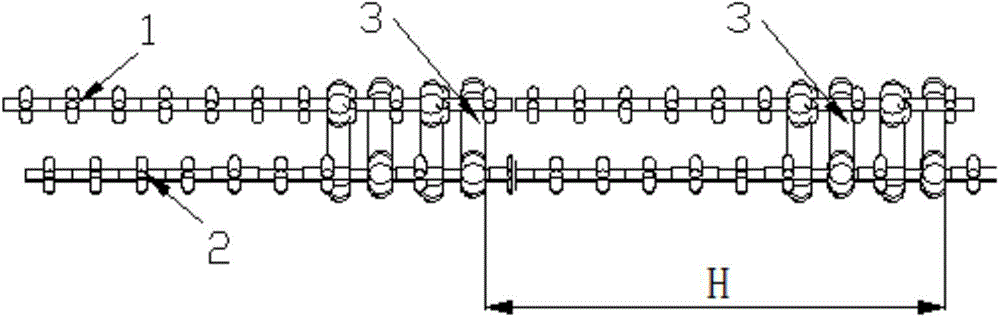

Double-layer fabric mingled with reinforced yarns and weaving method

InactiveCN103993403BStress structure is the sameReduce subsequent processing stepsMulti-ply fabricsYarnEngineering

The invention discloses double-layer fabric mingled with reinforced yarns and a weaving method. The double-layer fabric mingled with the reinforced yarns comprises an upper layer fabric structure and a lower layer fabric structure, and the reinforced yarns are woven between the upper layer fabric structure and the lower layer fabric structure and used for connecting the upper layer fabric structure with the lower layer fabric structure into a whole. In the weaving process, warp is divided into two sets, one set of warp is woven into the upper layer fabric structure, the other set of warp is woven into the lower layer fabric structure, in the weaving process, each set of warp and each set of weft are independently interwoven so that upper layer bottom cloth and lower layer bottom cloth can be formed, and in the warp yarn direction, the reinforced yarns are additionally arranged at certain intervals. According to the technical scheme, the upper layer fabric structure and the lower layer fabric structure are connected by weaving the reinforced yarns, it is guaranteed that stress structures of all reinforced warp structure points are the same, the follow-up processing procedures are reduced, and the manufacturing process is simplified.

Owner:HANGZHOU CHUANGXING WEAVING EQUIP TECH

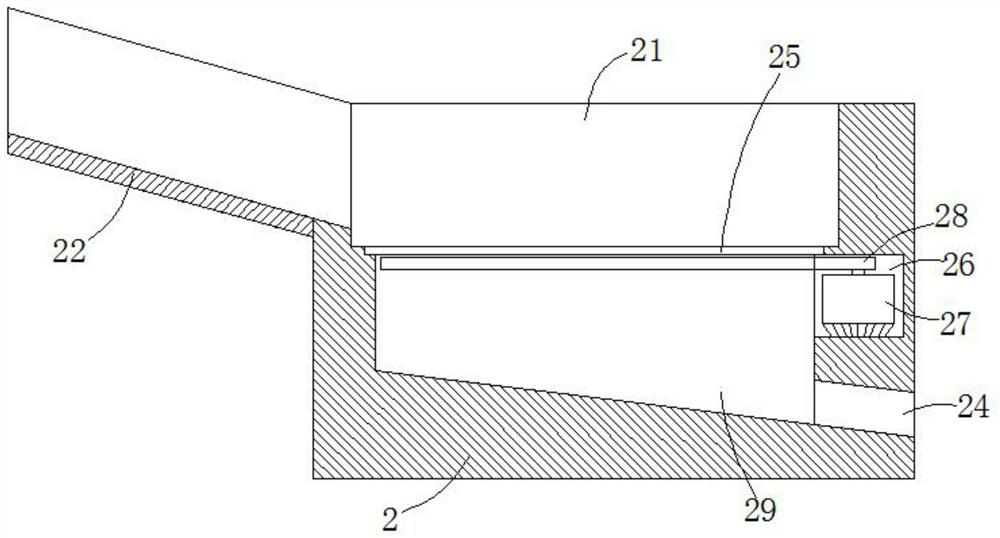

Stamping, bending and welding equipment

InactiveCN114029738AEffective extractionTap up and down quicklyDispersed particle separationWelding/cutting auxillary devicesSlag (welding)Structural engineering

The invention belongs to the field of hardware plate machining, particularly relates to stamping, bending and welding equipment, and aims to solve the problems that harmful gas is often generated when existing plates are welded, the body health of operators is damaged for a long time, a plurality of procedures such as deslagging and polishing need to be carried out on the plates by workers after welding, time and labor are wasted, and the production efficiency is poor. According to the technical scheme, the equipment comprises a bottom plate, the top of the bottom plate is fixedly connected with a U-shaped frame and two side plates, the tops of the two side plates are fixedly connected with the same top plate, the top of the U-shaped frame is fixedly provided with a hydraulic machine, and an output shaft of the hydraulic machine is provided with a telescopic rod. During use, harmful gas can be effectively filtered, purified and discharged, meanwhile, welding slag generated by welding can be continuously removed after welding is completed, finally, exposed welding seams are polished and ground, the machining procedures after welding are effectively reduced, and the machining efficiency is improved.

Owner:蔡瑞凡

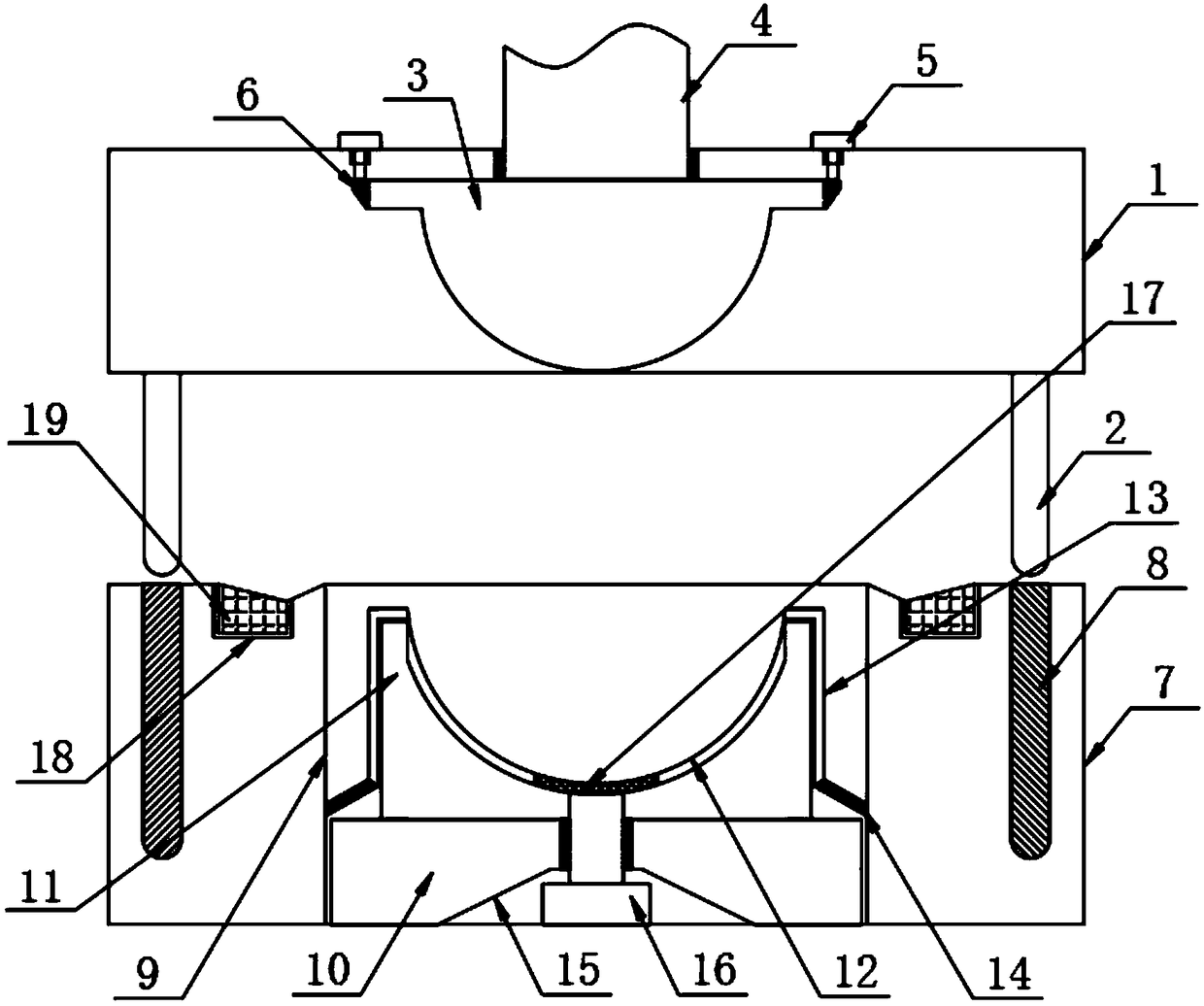

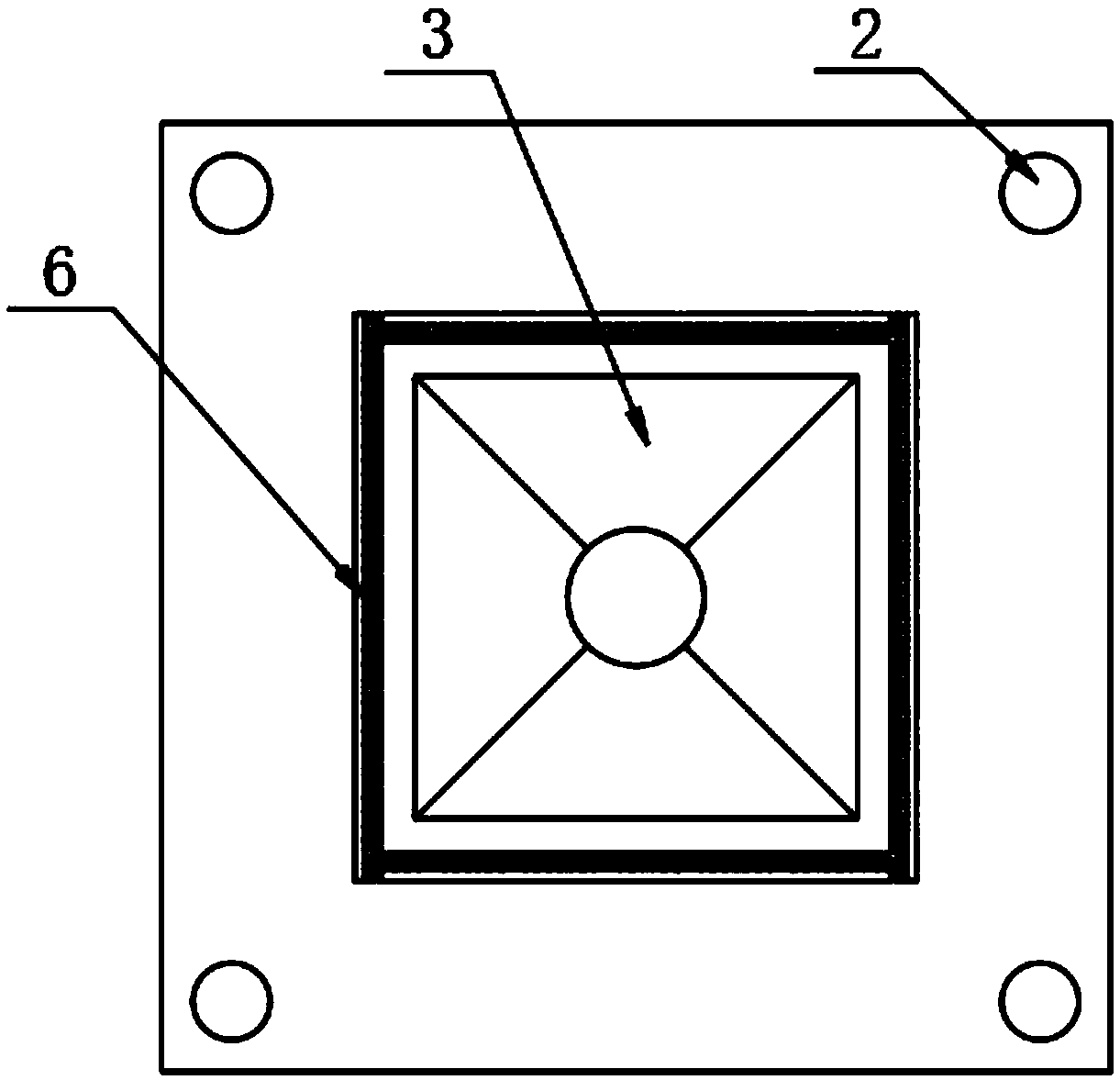

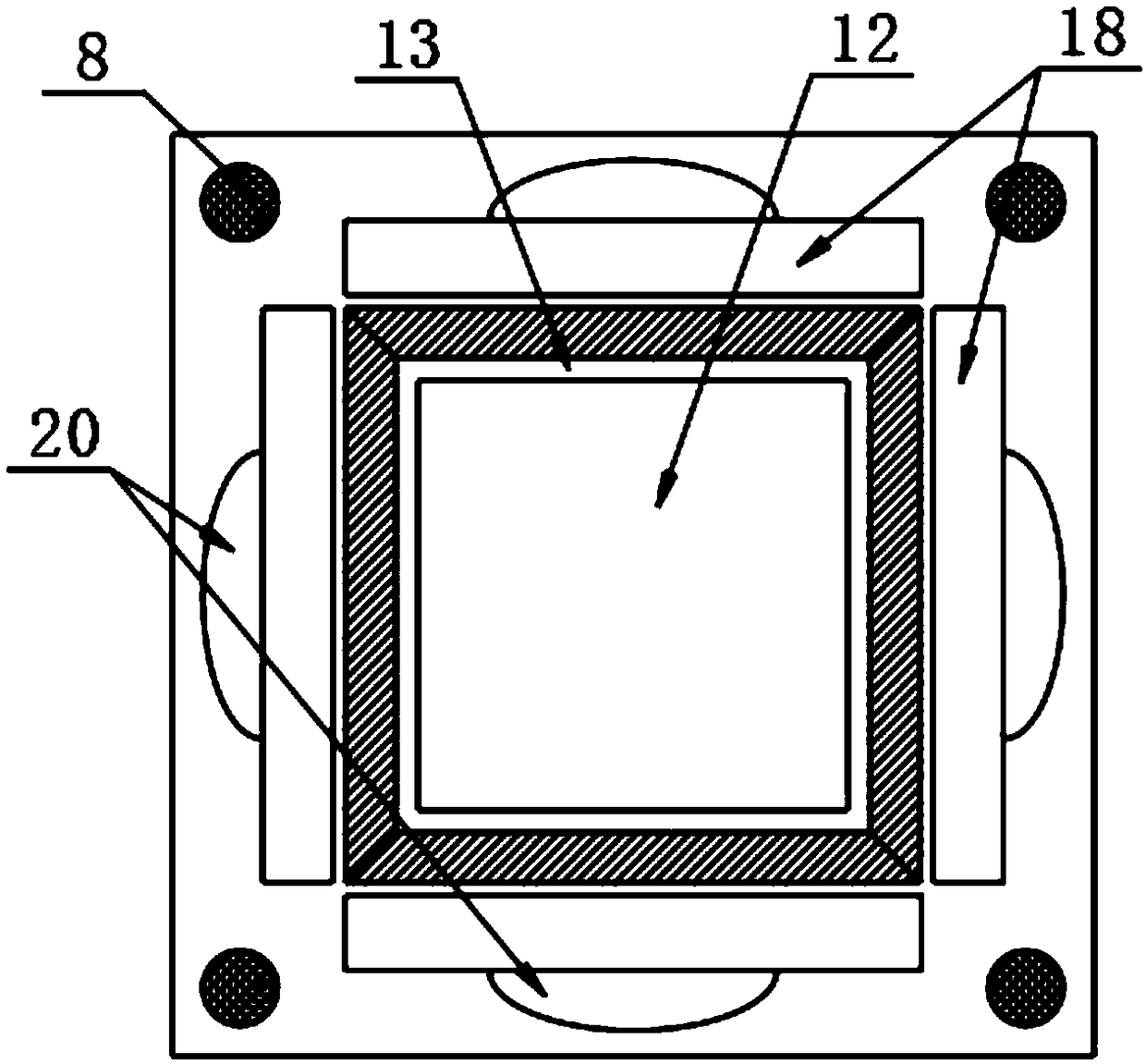

Lampshade stamping die

PendingCN109175108AGood for up and down movementImprove product qualityShaping toolsMetal-working feeding devicesHydraulic cylinderEngineering

The invention discloses a lampshade stamping die. The lampshade stamping die comprises an upper die. Limiting pillars are arranged at four corners of the bottom of the upper die correspondingly. A stamping die head is arranged in the center inside the upper die. A stamping rod is fixedly connected to the center of the top of the stamping die head. One end of the stamping rod penetrates the upper die. First hydraulic cylinders are arranged at the top of the upper die. A piston rod at the end of each first hydraulic cylinder penetrates the upper die. The end of the piston rod of each first hydraulic cylinder is fixedly connected with a cutter. A lower is arranged at the bottom of the upper die. Limiting holes are formed in four corners of the top of the lower die correspondingly. According to the lampshade stamping die, the cutters are arranged on the outer wall of the top end of the circumferential side of the stamping die head, the inner side walls of the cutters are arranged to be coplanar with the outer wall of a plate frame, and after stamping is completed, the cutters can be driven by the first hydraulic cylinders to move up and down conveniently so that leftover materials, generated after stamping is completed, of a plate can be cut away; and therefore, quality of a product obtained after stamping is completed is improved, and subsequent machining procedures are reduced.

Owner:大连函量科技发展有限公司

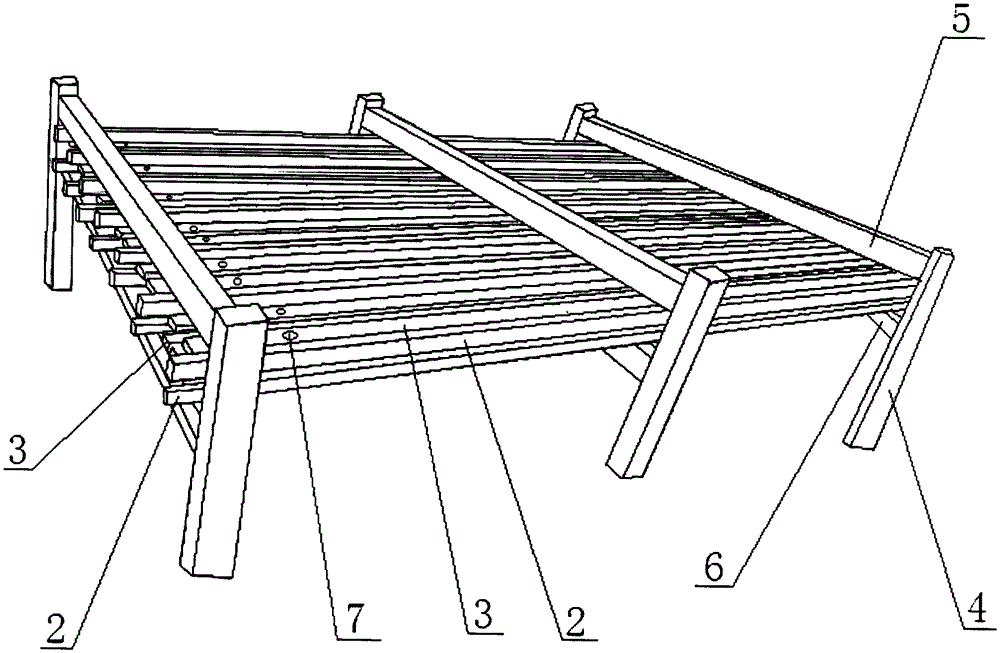

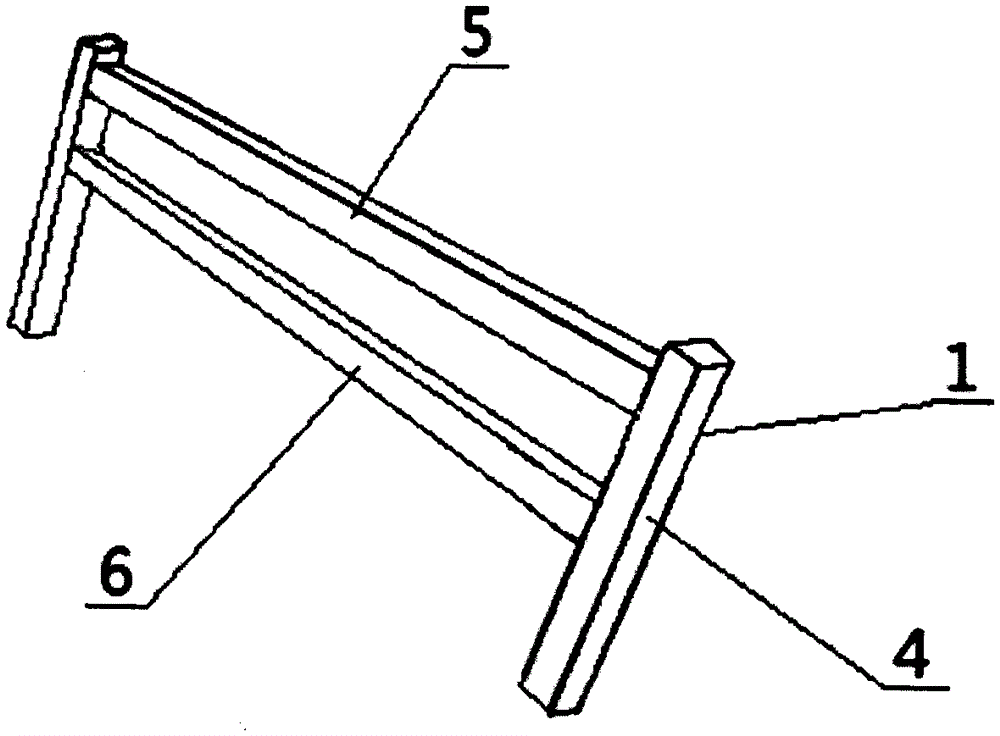

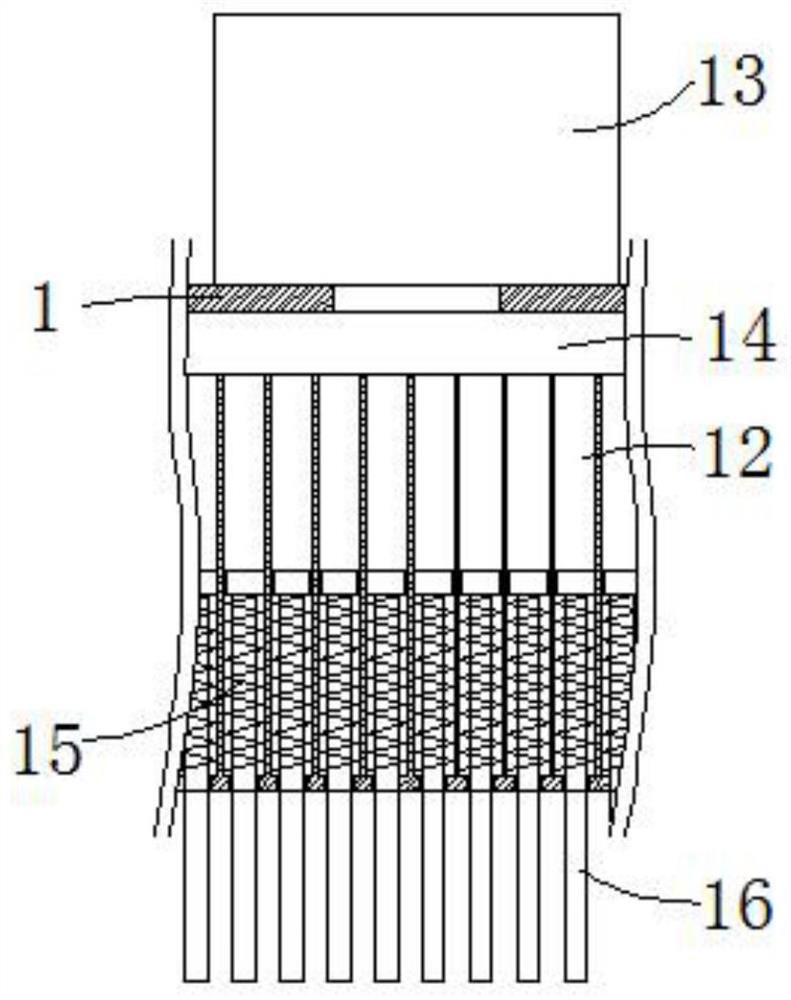

Splicing and drying integration device for integrated boards

InactiveCN105397878AScientific and reasonable structureObvious effectWood veneer joiningHeating arrangementFixed frameMachining process

A splicing and drying integration device for integrated boards is composed of frame bodies, board limiting pipe frames and heat supply pipelines. The board limiting pipe frames are fixed to upper fixing frames and lower fixing frames of the three frame bodies correspondingly, the heat supply pipelines are arranged among the upper fixing frames of the frame bodies, the lower fixing frames of the frame bodies and the board limiting pipe frames correspondingly, and therefore the whole device is formed. According to the device, the process of drying the boards or square timber and then splicing the boards or the square timber is eliminated, and drying and splicing are directly and synchronously realized on a machine; the board limiting pipe frames do not serve as heat supply pipelines of heat conduction carriers, and the movable heat supply pipelines without the limiting and forming effect are used for heating, drying and forming the boards side by side; when the board splicing machine splices the boards and carries out feeding, because the board limiting pipe frames are insusceptible to heat expansion and cold shrinkage and do not deform, the boards are insusceptible to the board limiting pipe frames and do not warp or deform accordingly; the number of the subsequent machining processes of the prepared boards is small, loss is reduced, and the quality is more stable.

Owner:GUANGXI NANNING QIAOSHENG WOOD

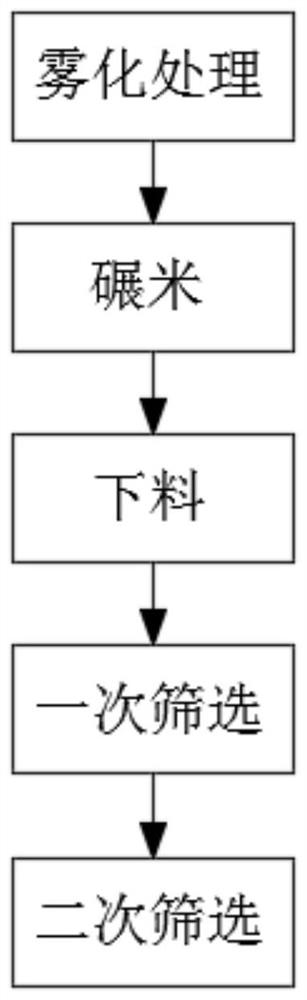

Rice whitening method

ActiveCN112156826AReduce subsequent processing stepsImprove quality and efficiencyGrain huskingGrain polishingBiotechnologyBroken rice

The invention discloses a rice whitening method. The rice whitening method comprises the following steps of (1) atomization treatment, namely soaking brown rice with a compound enzyme solution of cellulase, maltase and protease in a spraying manner; (2) rice milling, namely feeding the soaked brown rice in the step (1) into a rice milling device for rice milling; (3) discharging, namely conveyingmilled semi-polished rice from a rice milling box into a material distribution box; (4) primary screening, namely screening out large-grain rice and small-grain rice through a first filter screen; and(5) secondary screening, namely screening out the small-grain rice and impurity grains through a second filter screen. The invention relates to the technical field of rice processing. The method reduces the broken rice rate in the rice milling process, improves the rice milling quality and improves the rice processing efficiency.

Owner:和县金城米业有限责任公司

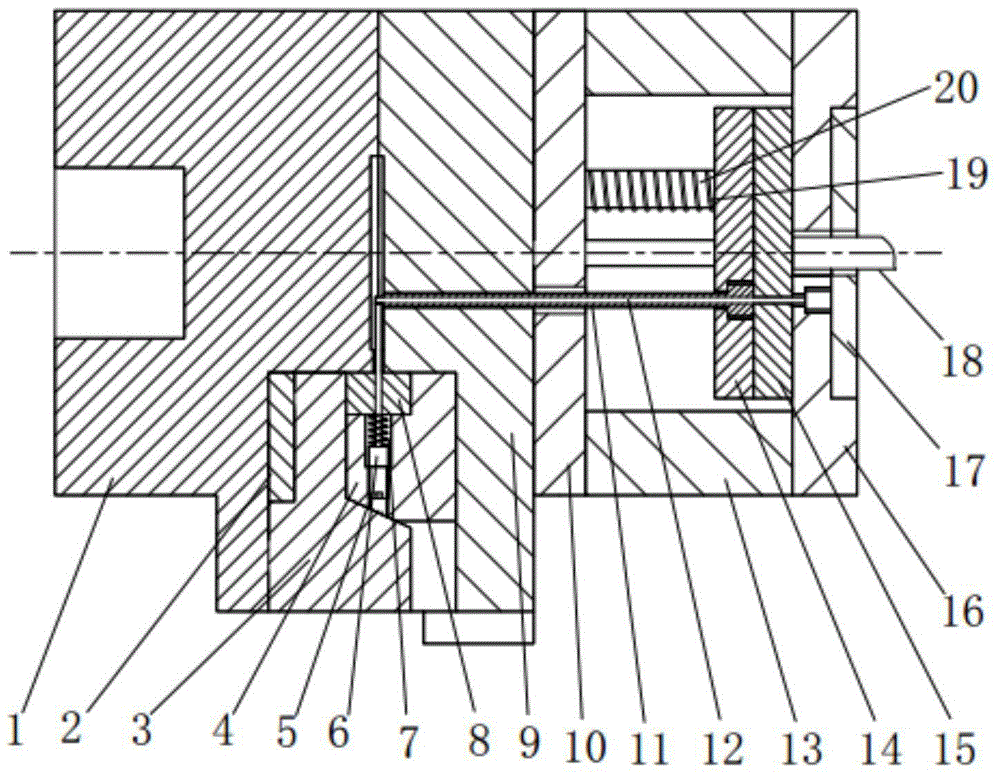

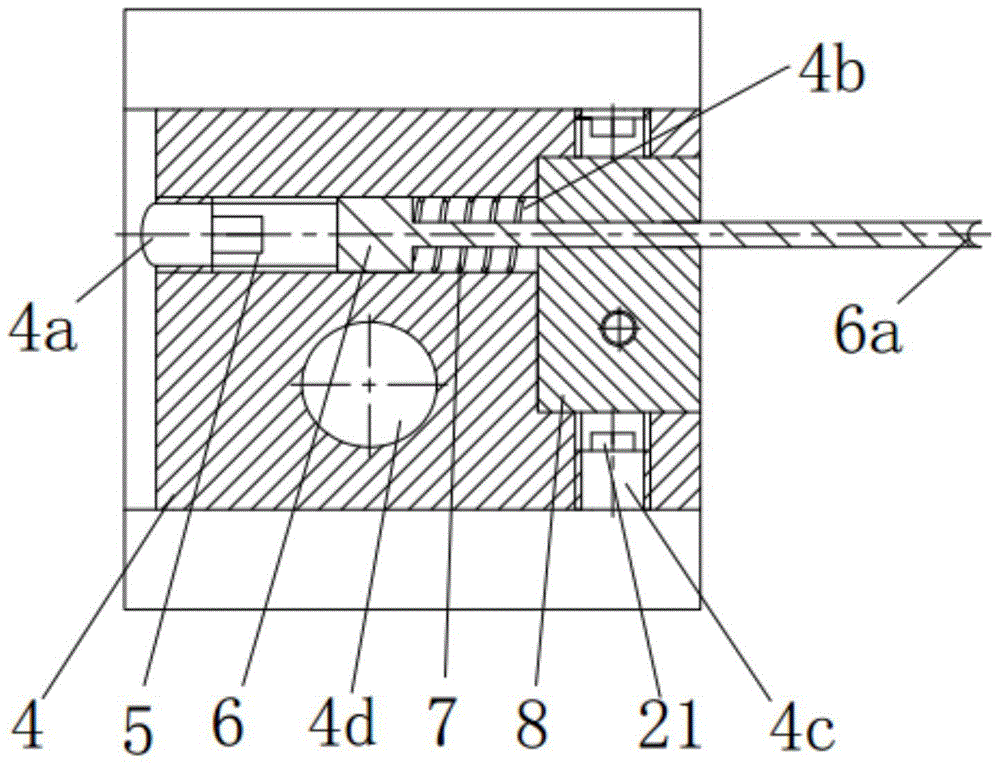

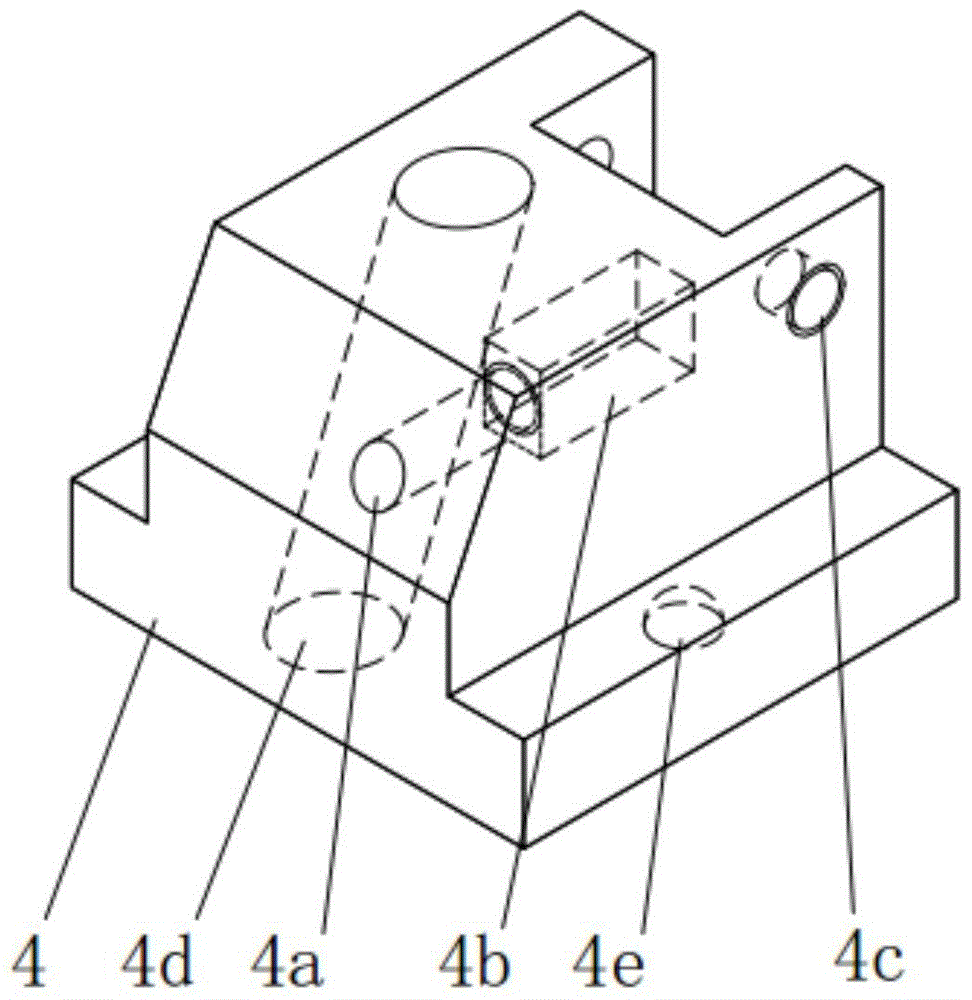

Injection molding processing method for forming orthogonal through micro-hole

The invention relates to an injection molding processing method for forming an orthogonal through micro-hole, belongs to the field of injection molding and relates to an injection mold processing method and device for forming the orthogonal through micro-hole. In the method, micro-adjustment is realized through side core-pulling movement of a micro-adjustable side core-pulling mechanism to complete accurate alignment of a horizontal arc surface with a vertical cylindrical surface. The implementation process of the injection mold processing method comprises steps of mold closing, pouring, mold opening and product ejection. The mold device adopted by the method consists of a fixed mold part, the micro-adjustable side core-pulling mechanism, an ejector sleeve / rod ejection mechanism and a movable mold part. By adopting the method, a micro-fluid connector with the orthogonal through micro-hole and a micro positioning through hole can be molded in one step, the subsequent process is reduced, the molding efficiency is high, the cost is decreased and the energy consumption is reduced; the relative position accuracy between the orthogonal through micro-hole and the micro positioning through hole can be guaranteed, a basic guarantee is provided for next step key bonding and encapsulation, and the quick replacement of a mold core is realized.

Owner:DALIAN UNIV OF TECH

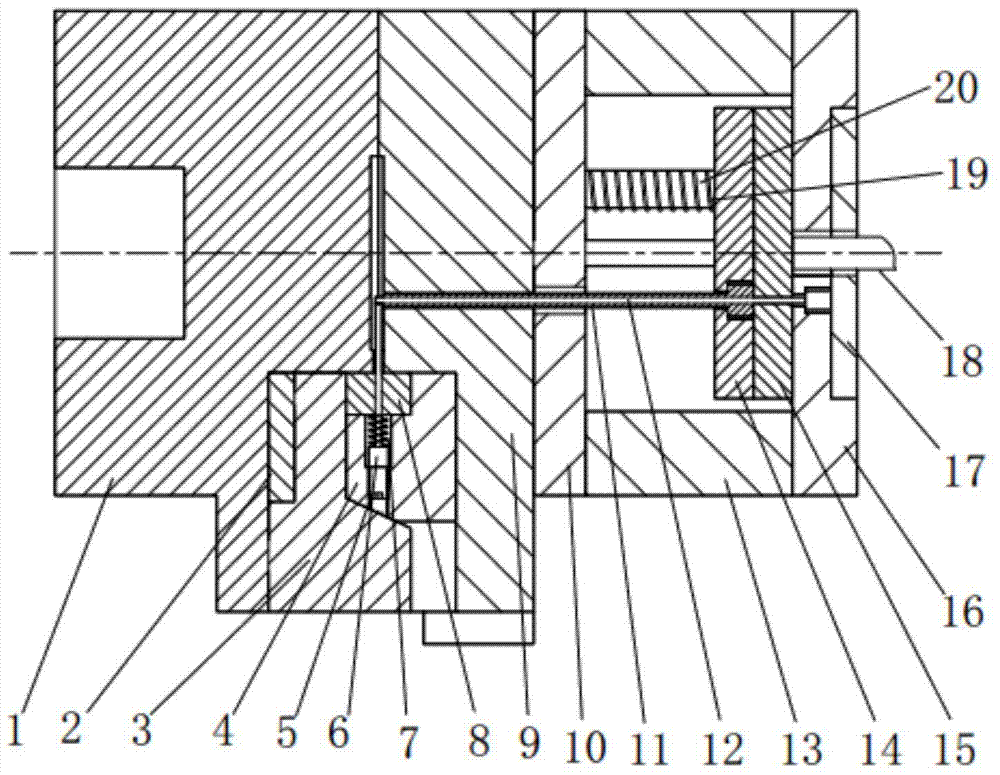

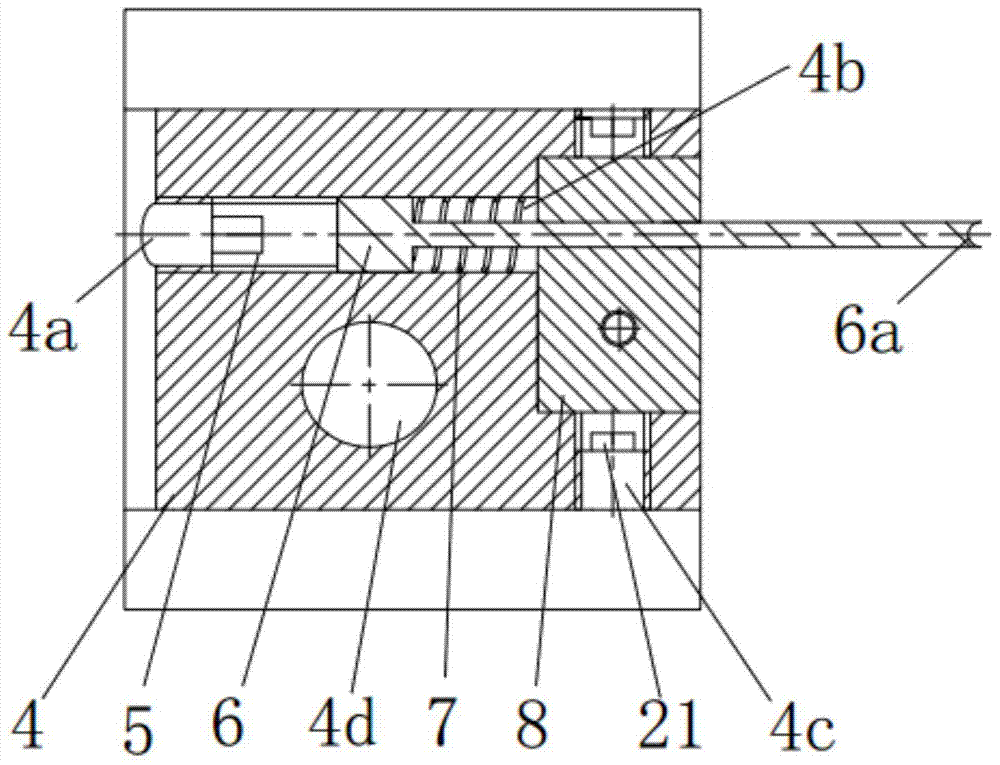

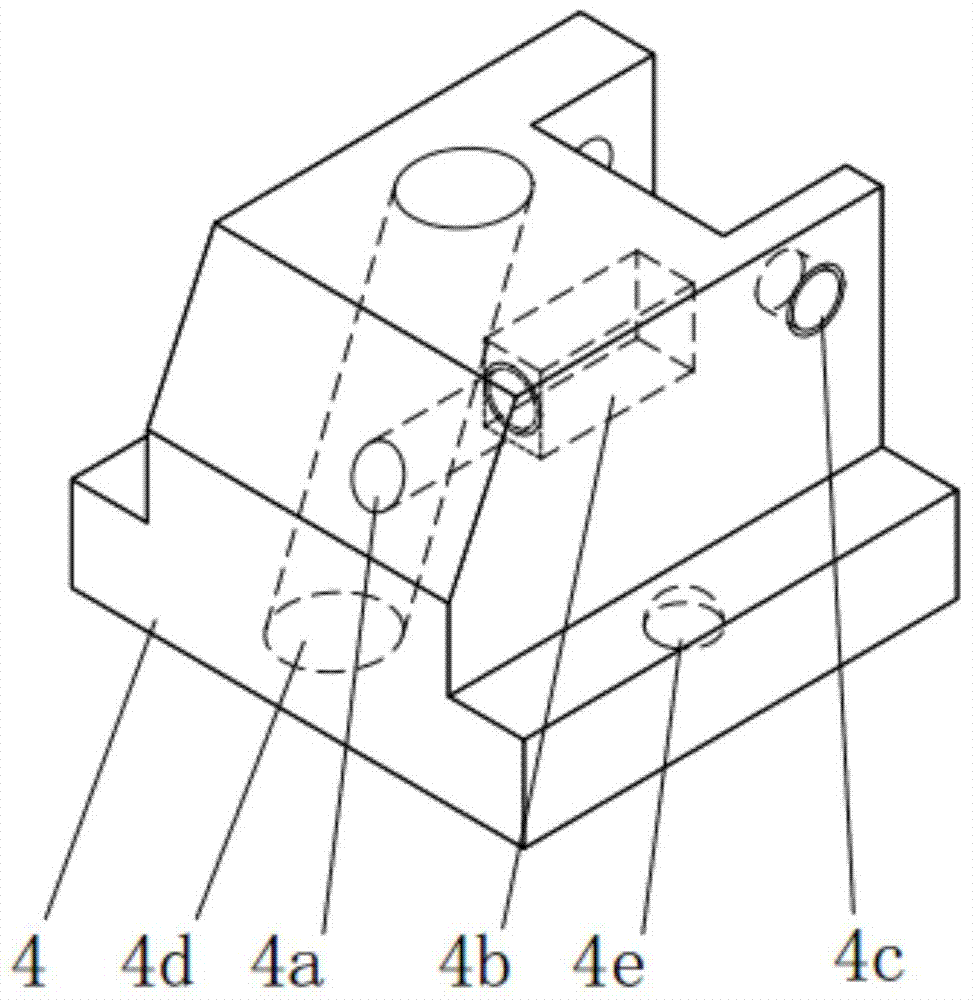

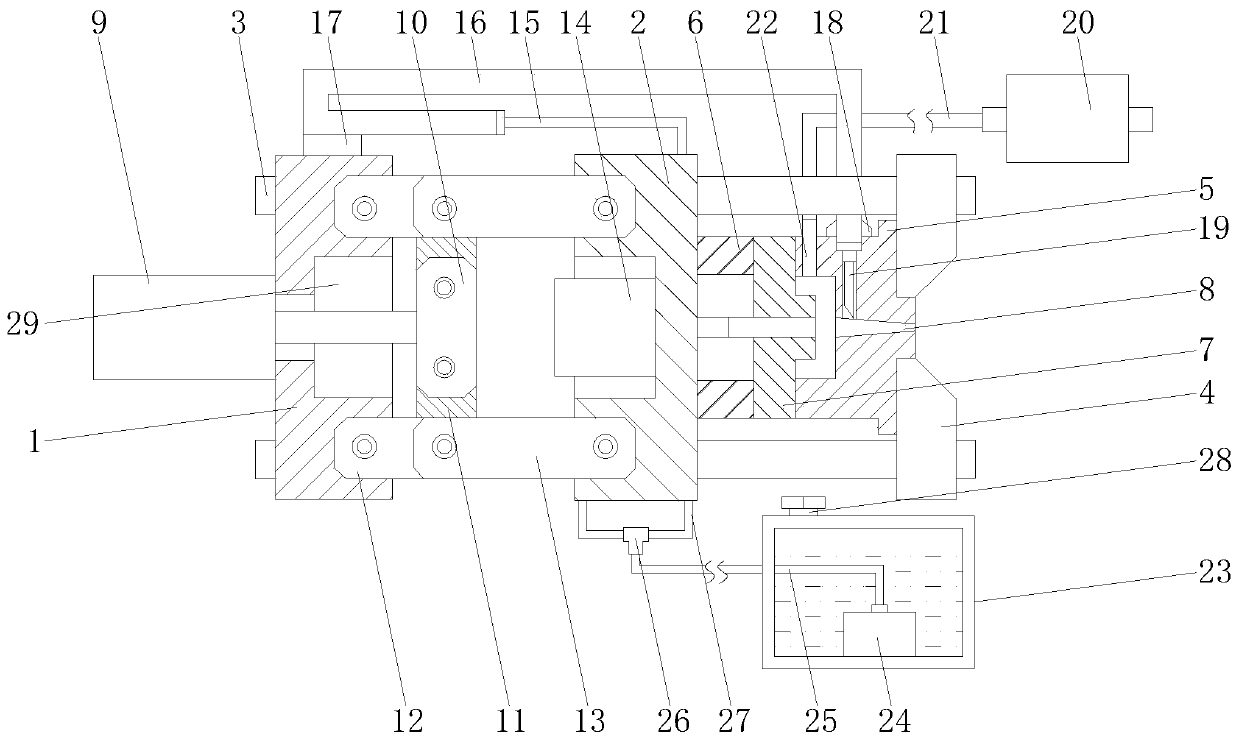

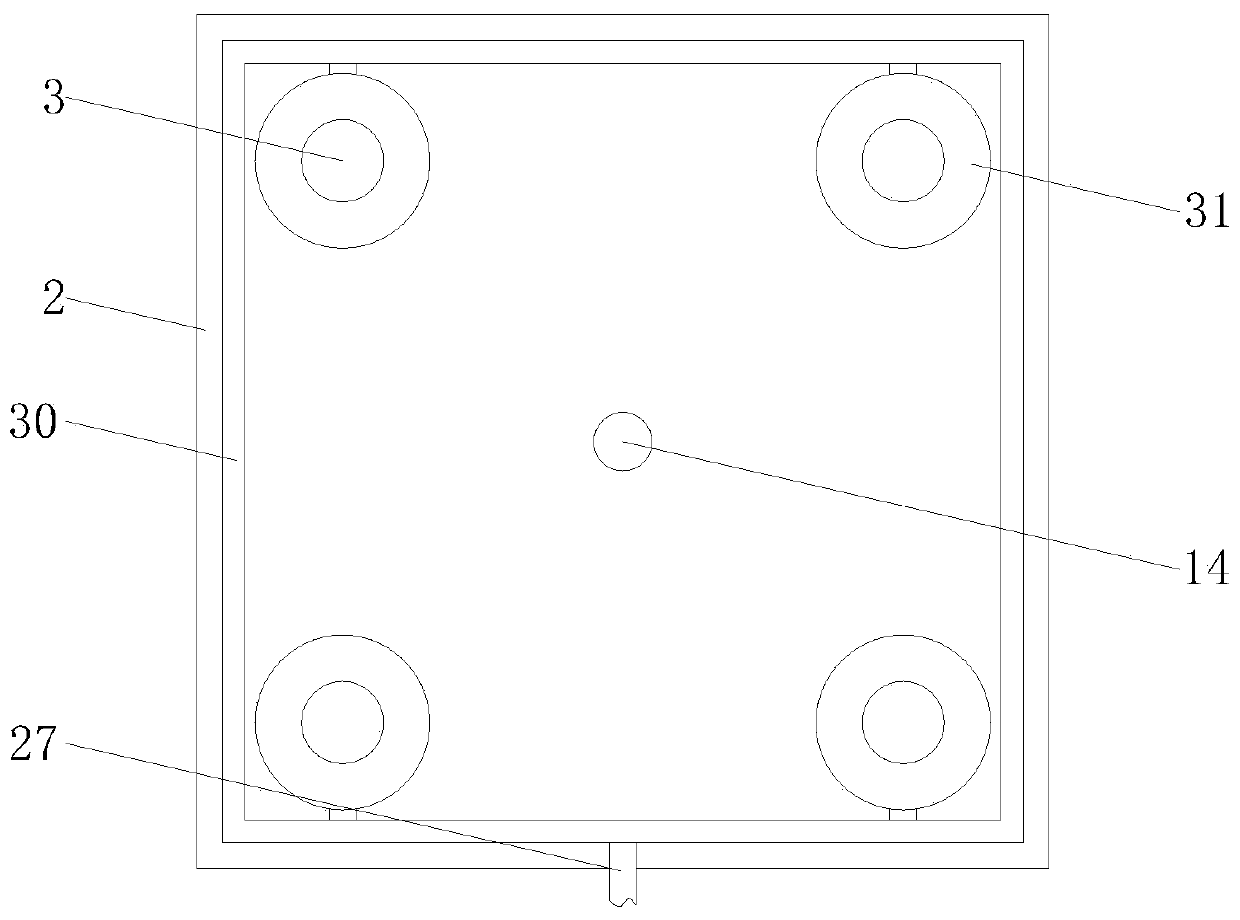

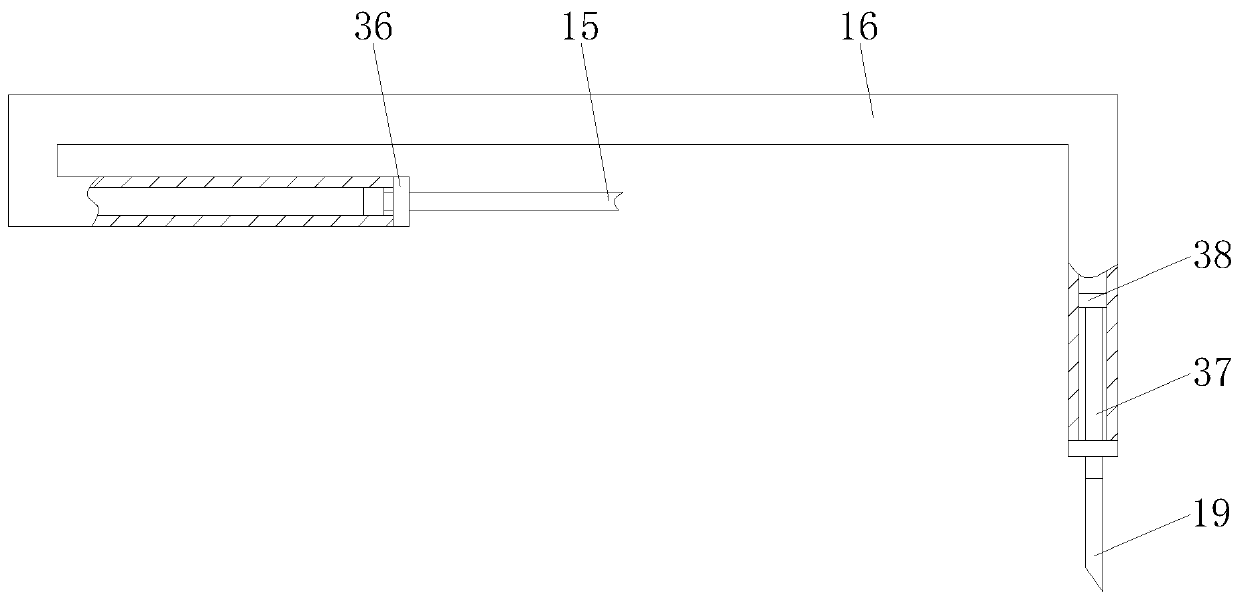

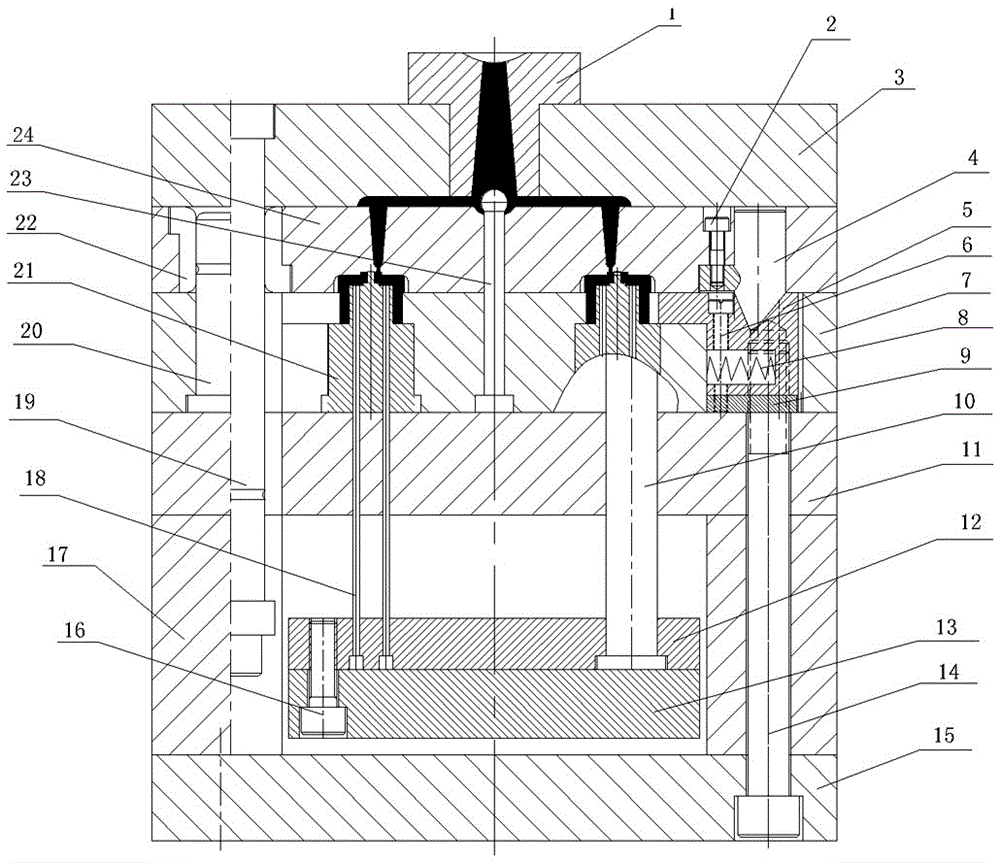

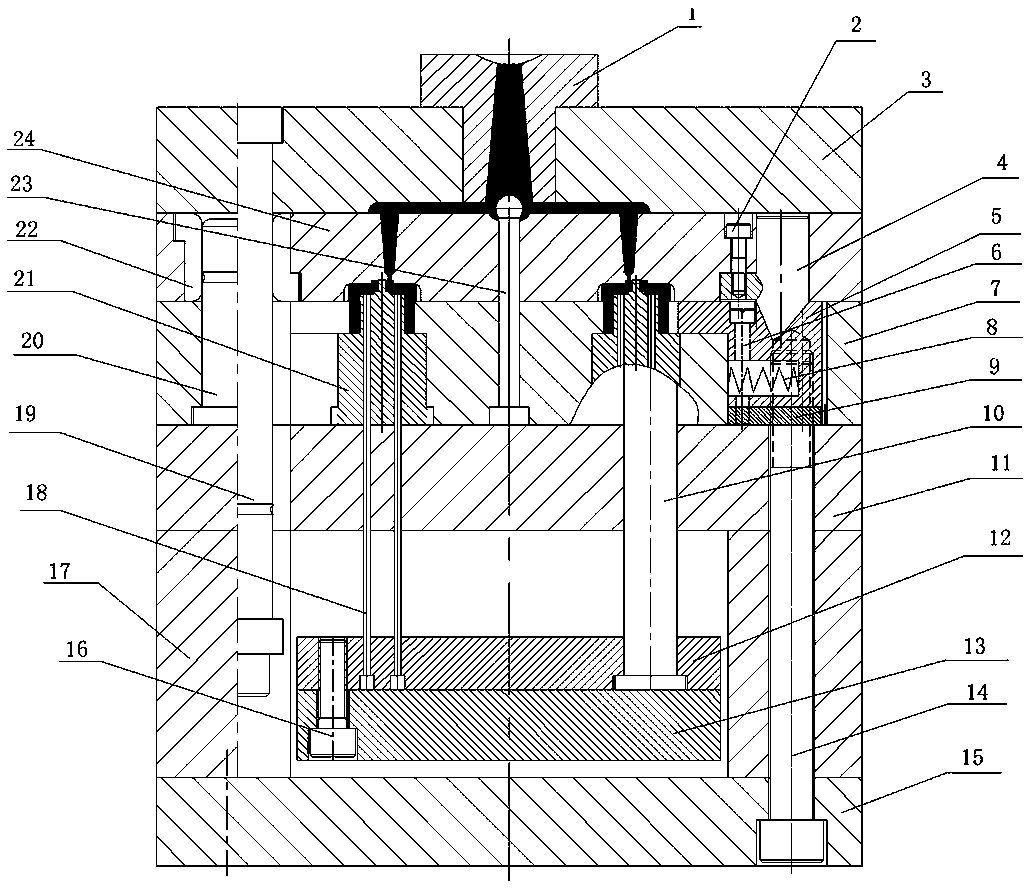

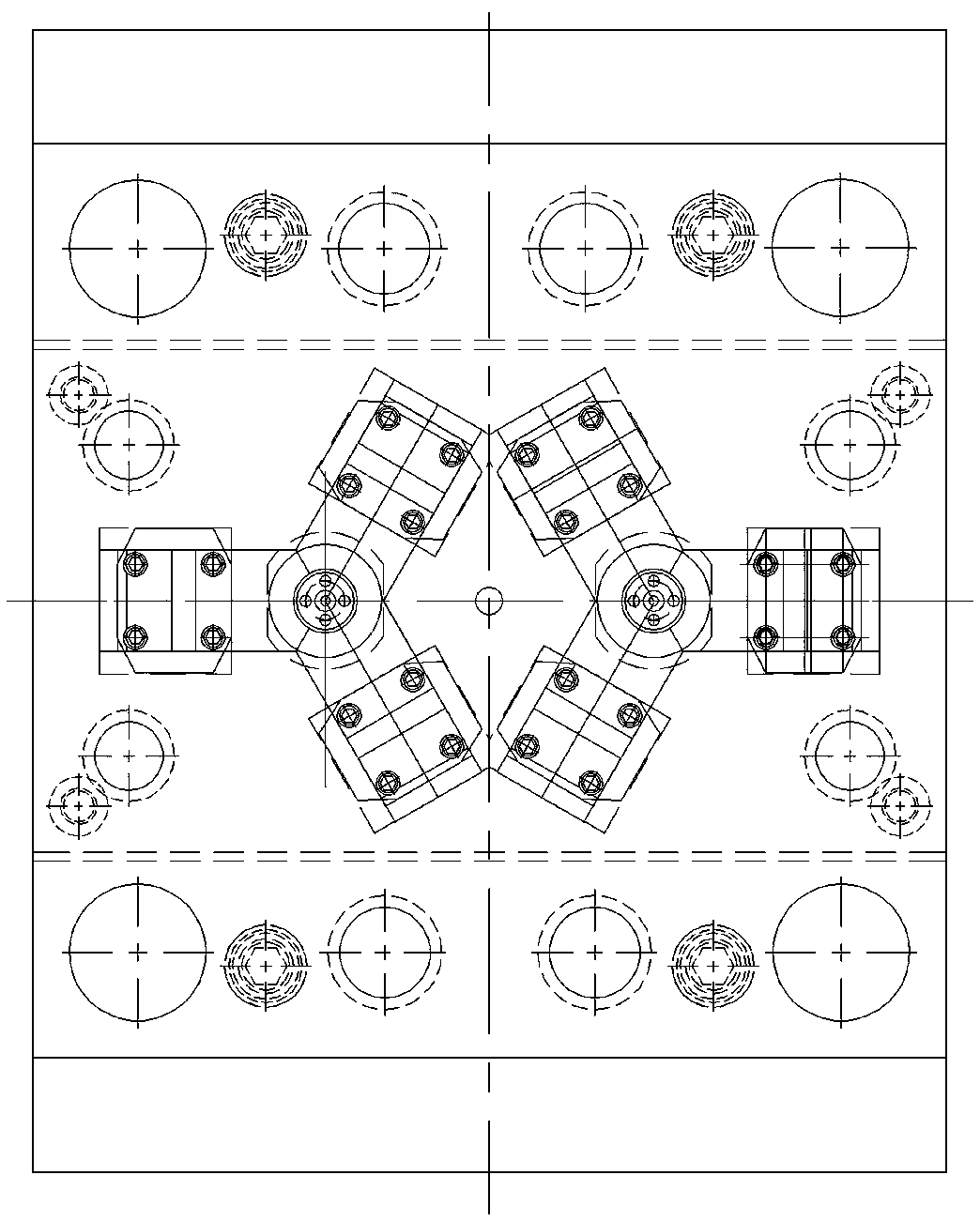

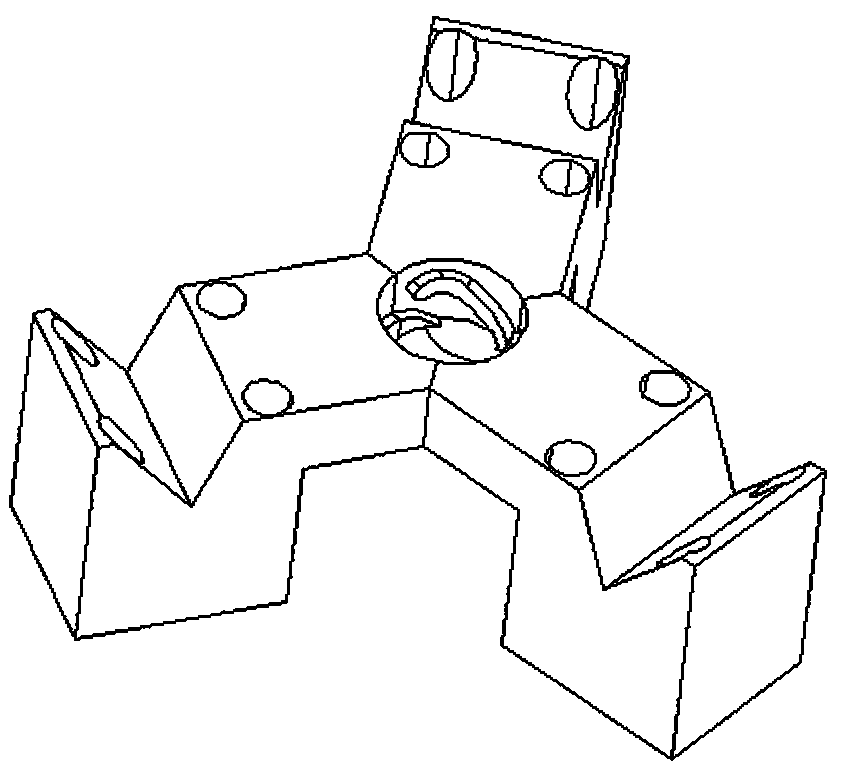

Connecting rod type mold closing type injection mold

InactiveCN110126198AReduce subsequent processing stepsImprove processing efficiencyMachining processVacuum pump

The invention discloses a connecting rod type mold closing type injection mold. The connecting rod type mold closing type injection mold comprises a fixed base, a sliding base, guiding rods, fixing blocks, a front mold, connecting blocks, a back mold, a pouring gate, a first air cylinder, a movable block, a first connecting rod, second connecting rods, third connecting rods, a second air cylinder,a first piston rod, an air inflator, a cushion plate, reinforcing rib plates, a cutter, a vacuum pump, a first connecting pipe, a straight pipe, an oil tank, an oil pump, an oil pipe, a three-way pipe, second connecting pipes, an oil filling port, a groove, an annular pipe, sponge rings, a circular hole, a spring, a piston rod, a limiting groove, a limiting ring, a second piston rod and a piston.According to the connecting rod type mold closing type injection mold, the structure is reasonable, a cutting structure is arranged, therefore, when the front mold and the back mold are separated, excess materials at the pouring gate can be automatically cut by means of force generated when the front mold and the back mold are separated, the subsequent machining process of injection molding partsis reduced, and the machining efficiency is improved.

Owner:戴琼英

LED road lamp module with plastic cooler and manufacture method thereof

PendingCN110375282AGood thermal radiation performanceDisperse quickly and evenlyMechanical apparatusLighting heating/cooling arrangementsCooling effectEngineering

The invention relates to the technical field of lighting equipment, in particular to an LED road lamp module with a plastic cooler and a manufacture method thereof. The LED road lamp module comprisesa lens and a plastic cooler. In the LED road lamp module with the plastic cooler and the manufacture method thereof, heat is produced by an LED bulb on a lamp panel, the bulb emits light and at the same time produces the heat, the temperature of the lamp panel is raised, an aluminum base plate on the back of the lamp panel is in contact with liquid in the plastic cooler, the heat is transferred into the liquid, dynamic circulating liquid heat convection is formed in the plastic cooler, the heat is uniformly and rapidly dispersed onto the surface of the plastic cooler, and a cooling process isfinished after heat exchange is carried out with surrounding air. The LED road lamp module has the advantages that although a difference between the temperature of the bulb and the surface temperatureof the cooler is small, a difference between the surface of the cooler and the temperature of the surrounding air is large, the heat radiation capability of plastics is great, and therefore, the whole cooling effect is great; and the material cost of the plastic cooler is low, the following processing procedures are few, the production efficiency is high, a cooling system is simple and easy, andthe popularization property is strong.

Owner:广州融捷照明科技有限公司

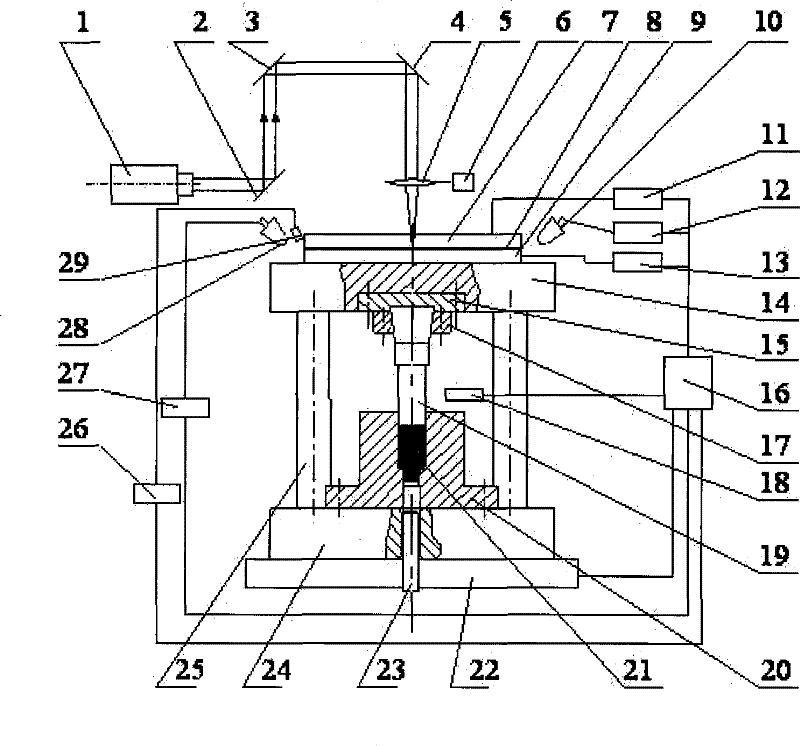

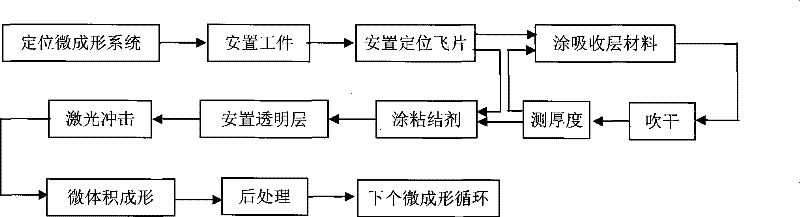

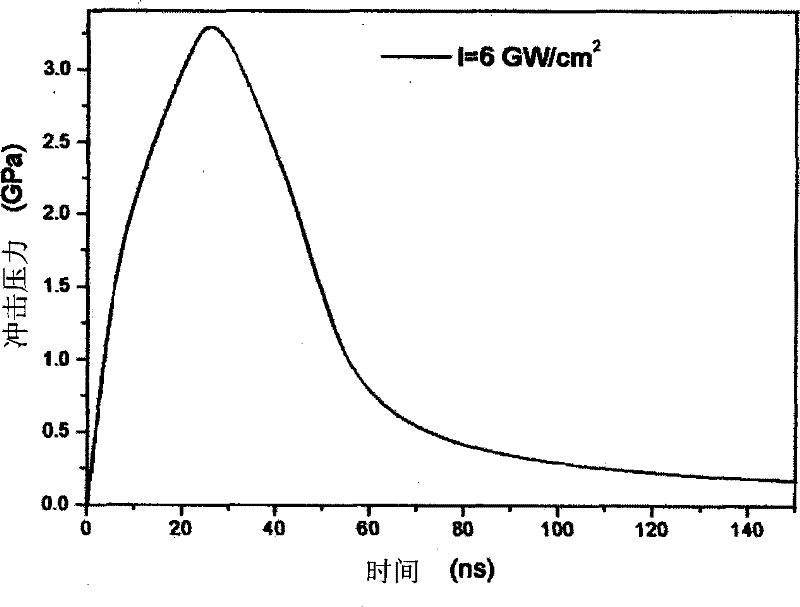

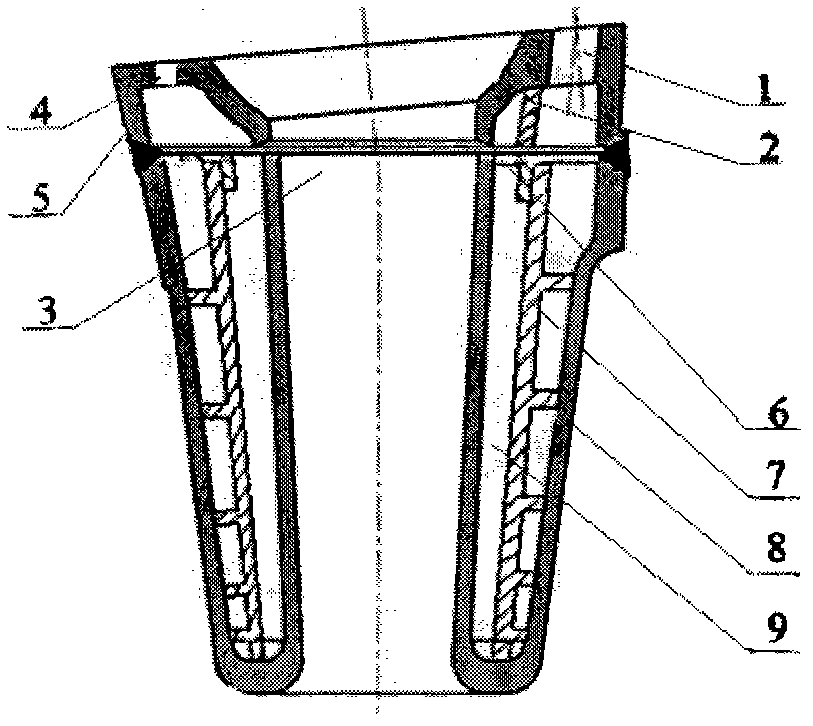

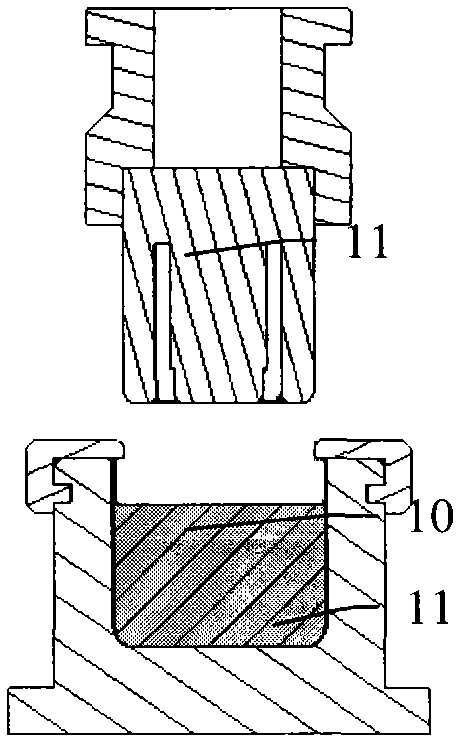

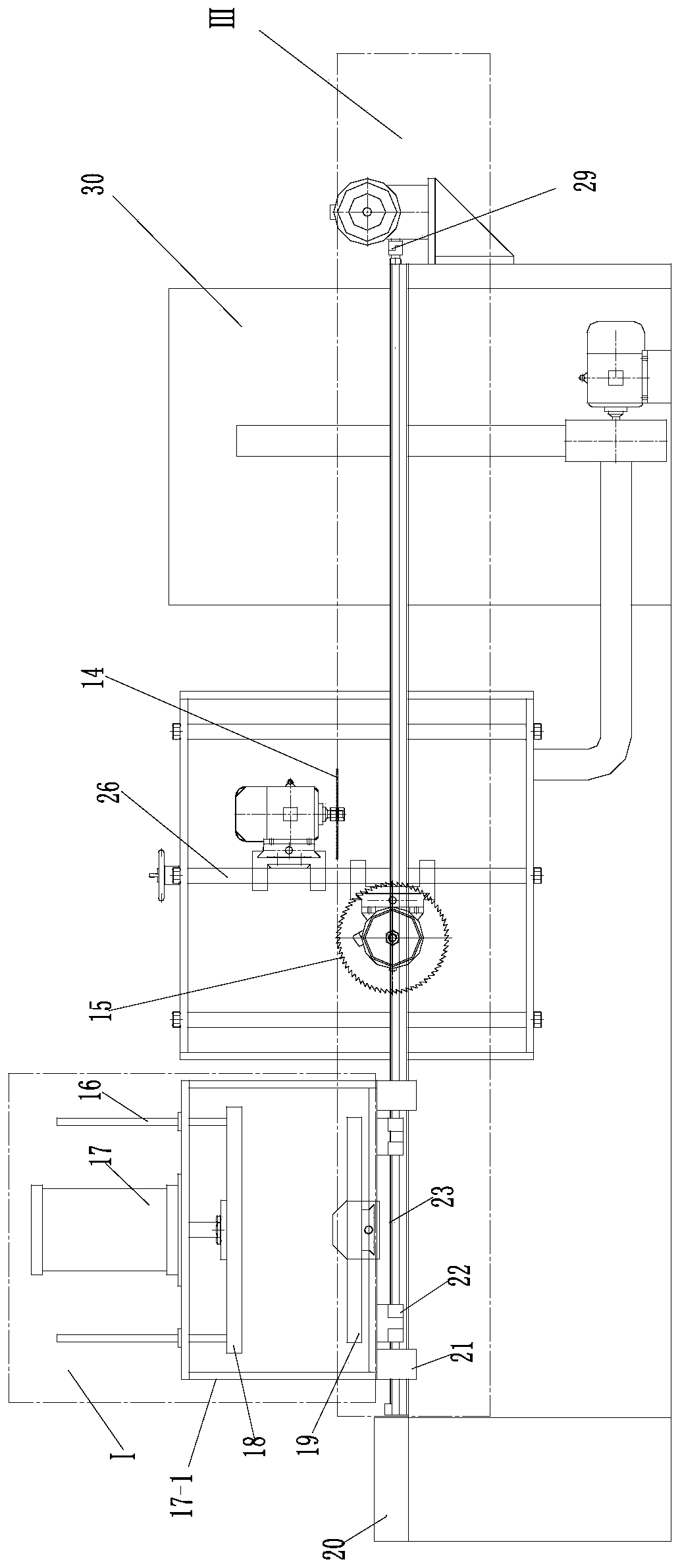

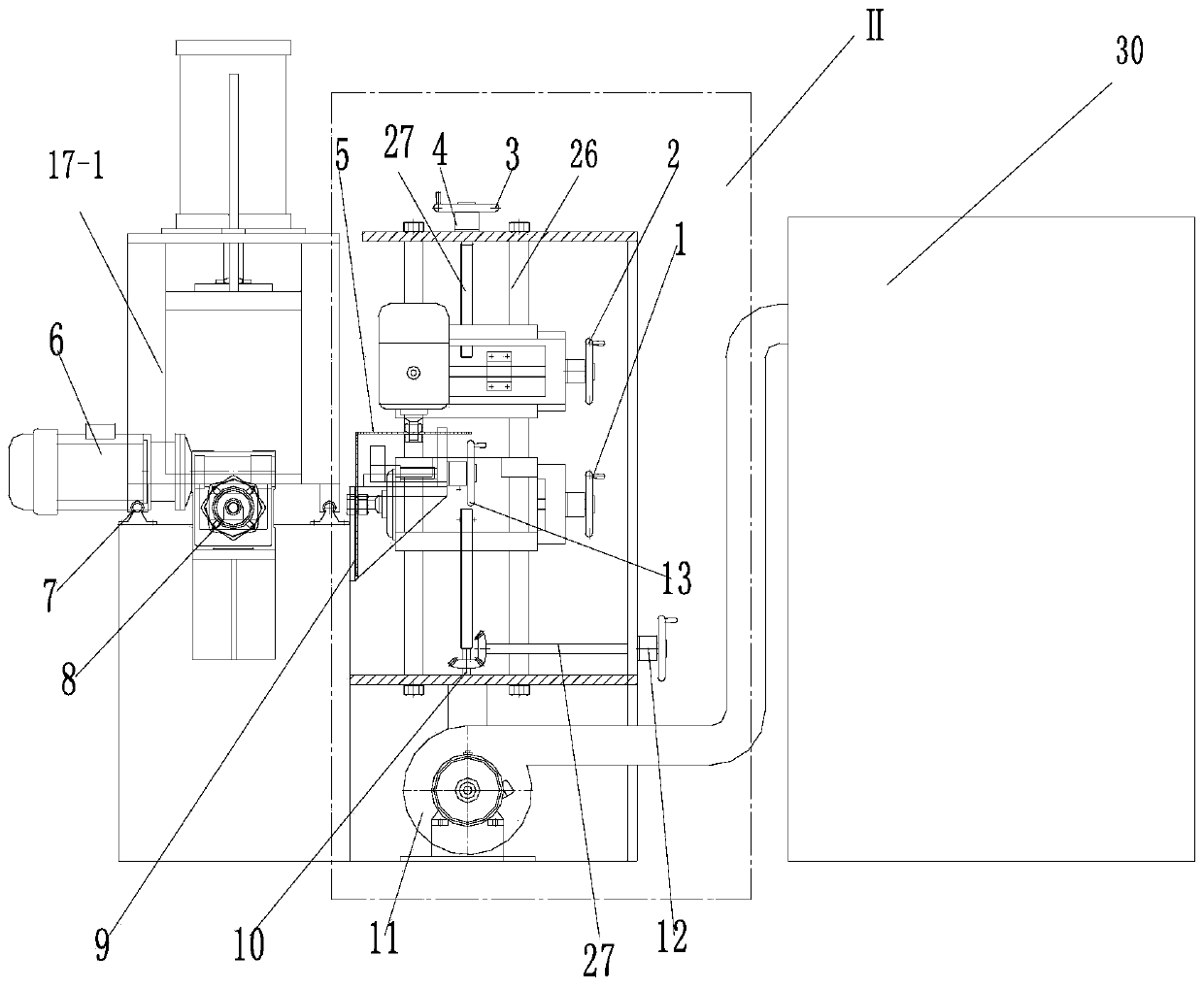

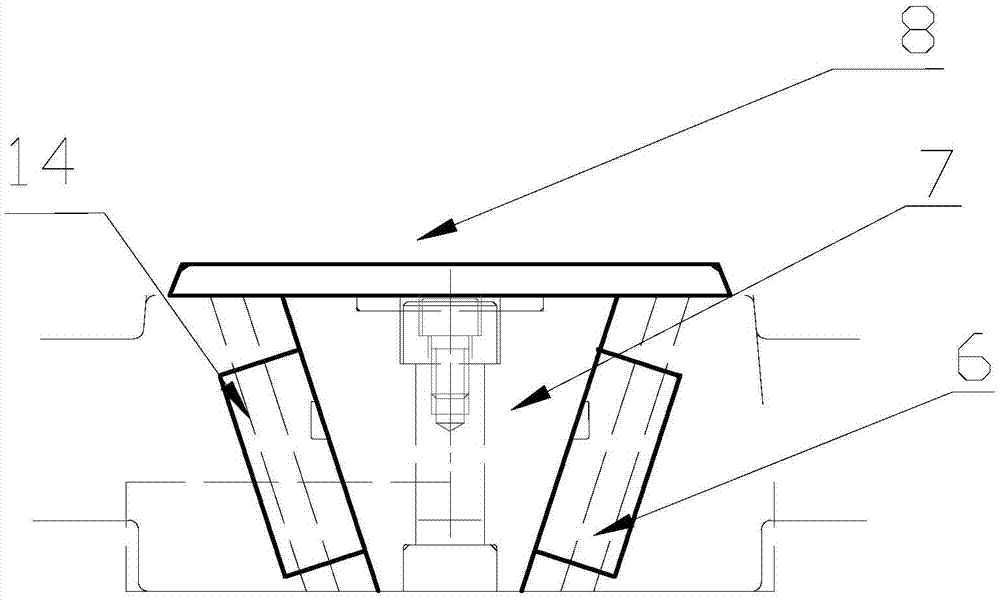

Laser impact tiny bulk forming method and apparatus for tiny apparatus

InactiveCN101269440BImprove efficiencyHigh precisionLaser beam welding apparatusSurface layerMicro devices

The invention provides a laser impulse micro-bulk forming method and a device thereof, being suitable for the micro-bulk forming of a planchet and belonging to the laser micro-processing field and micro-bulk forming field. The forming method is as follows: impulse wave induced by laser is used as a forming force source for micro-device micro-bulk forming; laser burst generated by a laser generator according to requirements is irradiated at a flying-piece surface layer passing through a transparent restraint layer through an external light path system; a high temperature and high pressure plasma body is generated and the impulse wave is formed; overhigh pressure of the impulse wave is used for driving the flying-piece and a micro-plastic forming system connected with a flying piece; a micro-workpiece is pressed; the micro-bulk forming of the workpiece is finished. The device applied to the method comprises six parts of the laser generator, an external light path system, an induction impulse wave generation system, a micro-plastic forming system, a control system and an operating platform. The laser impulse micro-bulk forming method can be used for realizing the micro-bulk forming of any complex shaped micro-devices, and can be repeatedly impacted and loaded on, and has good repeatability and easy realization of automatic production.

Owner:JIANGSU UNIV

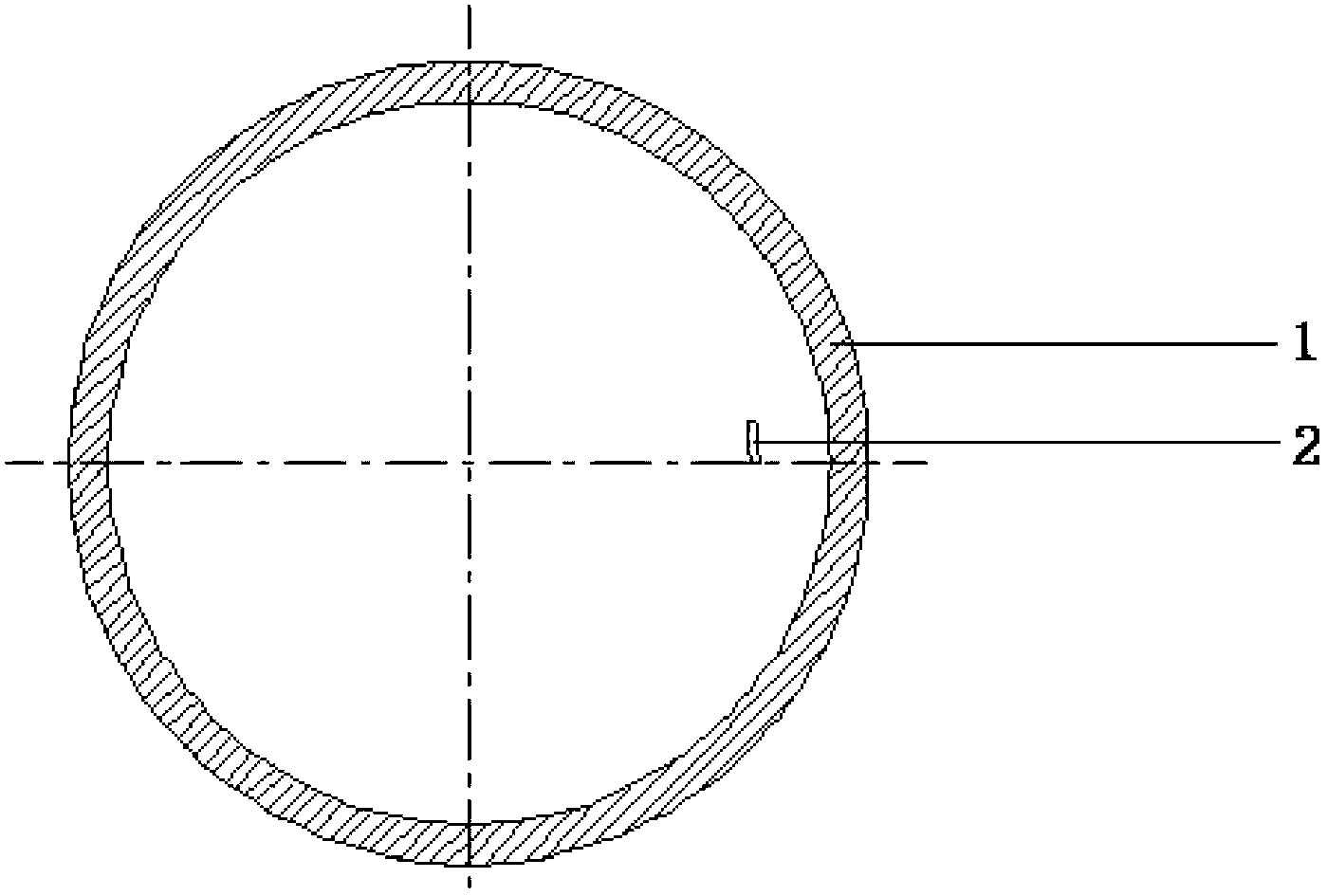

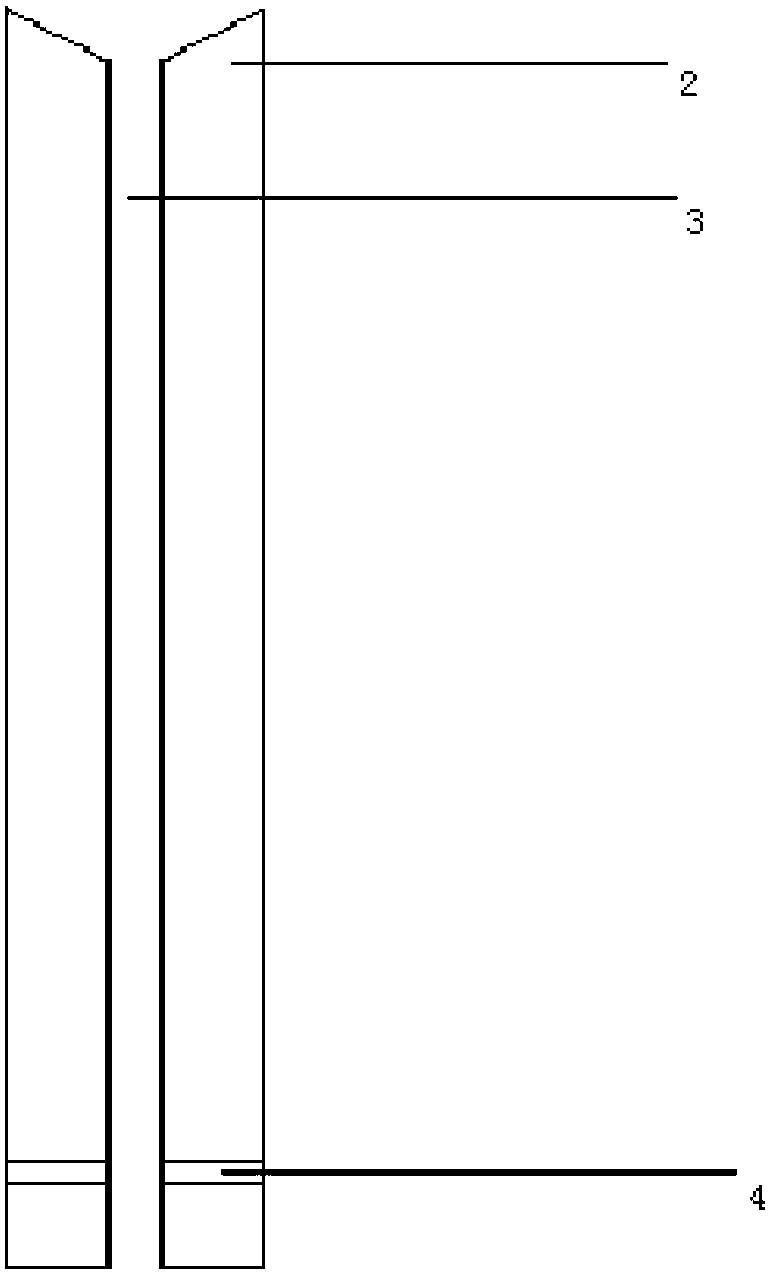

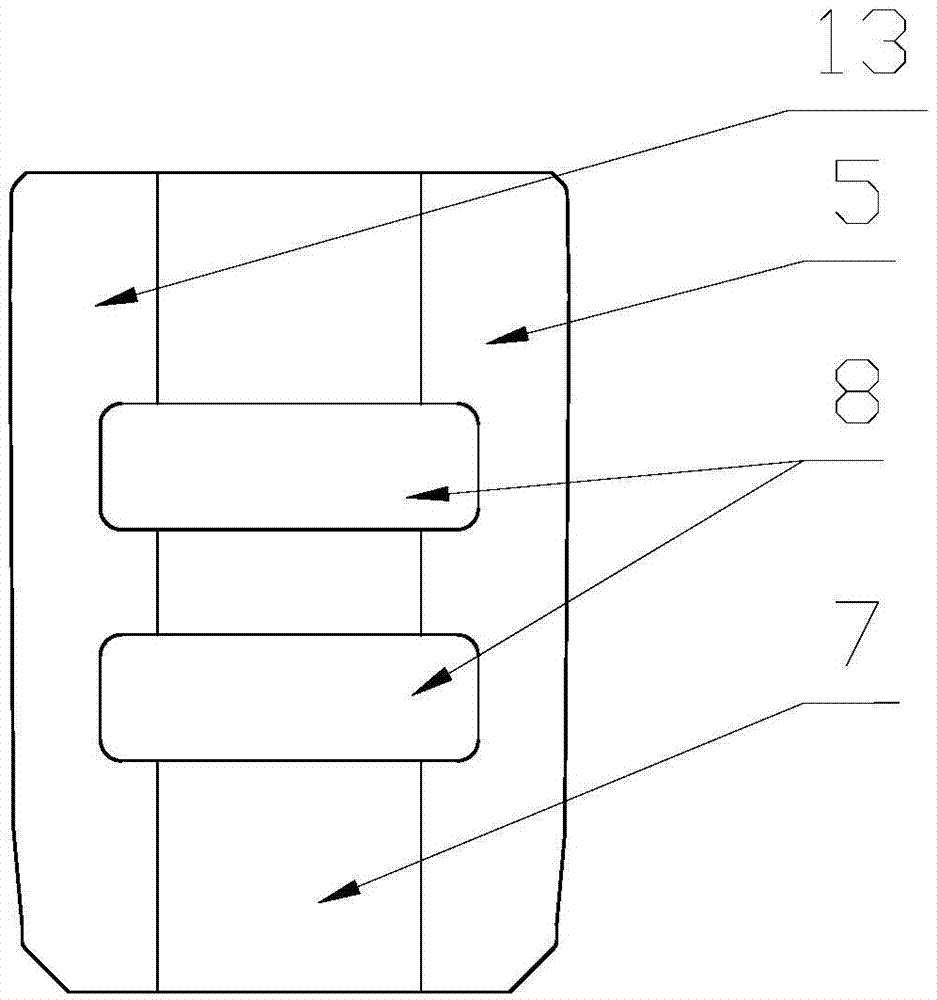

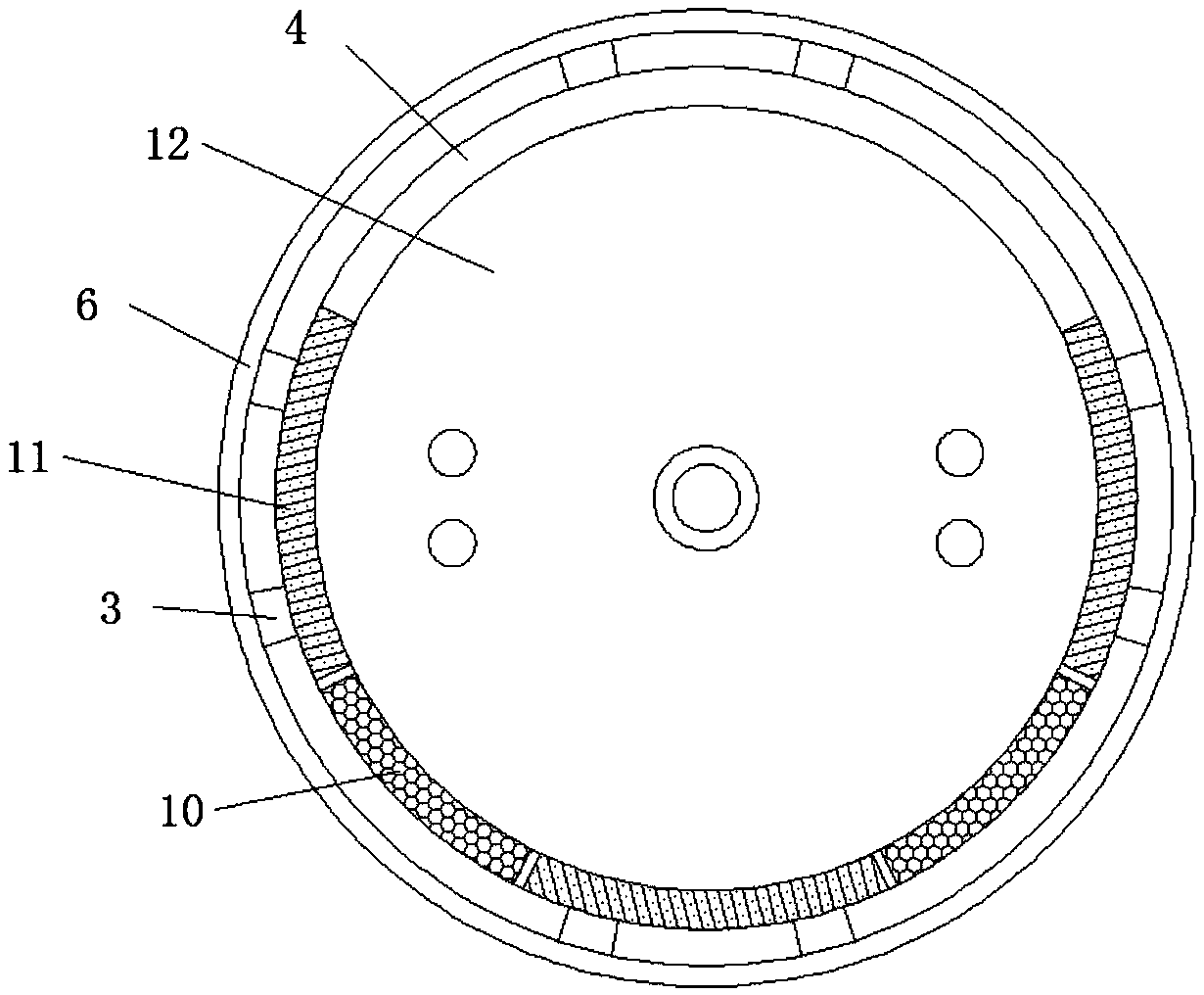

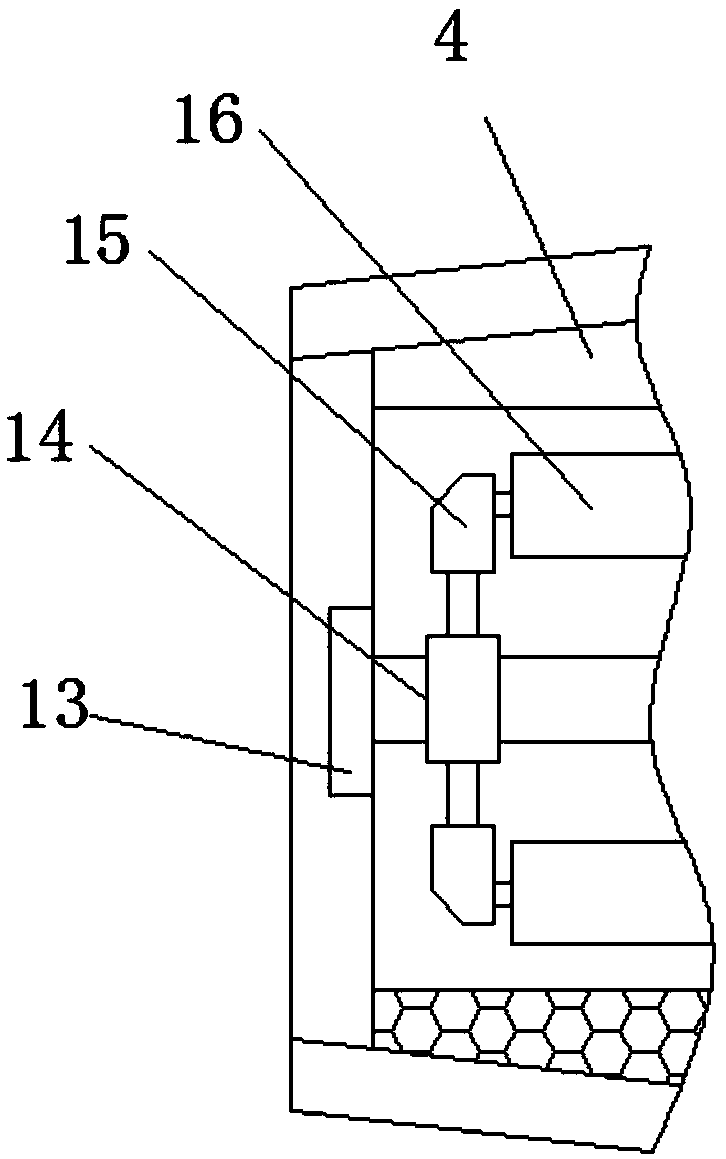

Blast furnace tuyere small sleeve

InactiveCN102978314ASolve the problem of small deformationExtend your lifeTuyeresMaterials scienceBlast furnace

The present invention provides a blast furnace tuyere small sleeve and a manufacturing method thereof. The blast furnace tuyere small sleeve comprises a tuyere body having a hot air center channel entrance, a water inlet hole and a water drainage hole, wherein a pure copper hollow annular tuyere wall manufactured by adopting hot extrusion molding is adopted, the tuyere body and the tuyere wall are subjected to welding connection, and the tuyere wall has a long wall n shape. With the blast furnace tuyere small sleeve, disadvantages of short service life, low production efficiency and high production cost of the existing tuyere structure can be overcome.

Owner:XIAMEN LOTA INT CO LTD

A kind of colored polyurethane emulsion for waterproof coating and preparation method thereof

ActiveCN104193952BGood emulsifying effectHigh molecular weightPolyurea/polyurethane coatingsPolymer sciencePolymer chemistry

Owner:佛山市顺德区巴德富实业有限公司

Hydraulic pipe cutter

InactiveCN108115191ASimple structureLow costTube shearing machinesShearing machine accessoriesHydraulic cylinderDisplay device

The invention discloses a hydraulic pipe cutter which comprises a cutter head, a hydraulic cutting bracket, a pneumatic positioning chuck, a feeding mechanism, a deburring mechanism and a pressure detection system, wherein the hydraulic cutting bracket adopts a multi-stage hydraulic telescopic pole; a cutting table is arranged at the bottom of the hydraulic cutting bracket; a hydraulic cylinder and a pneumatic cylinder, which are connected with the multi-stage hydraulic telescopic pole, are arranged at the bottom of the cutting table; and the cutter head is fixedly hung at the top of the hydraulic cutting bracket. The device structure is simple, and the equipment cost is low; a vertical up-down cutting way is adopted, and the cutting is performed by self gravity of the cutter head; a pressure sensor and a display facilitate reducing negative effects in the cutting process; by the adoption of a travel switch and a feeding pneumatic chuck, error accumulation caused by complicated transmission links is avoided, and the machining precision is improved; and after cutting is completed, the deburring mechanism is used for polishing a fracture to reduce the subsequent manufacturing procedure.

Owner:丹阳市超宇五金磨具有限公司

Method for growing hemispherical sapphire crystal with certain curvature

ActiveCN102703980BReduce subsequent processing stepsReduce consumptionPolycrystalline material growthBy pulling from meltEngineeringMachining process

The invention discloses a method for growing a semispherical sapphire crystal with a certain curvature. The method comprises the following steps of: forming a melt layer on the surface of a mold by adopting a mold guiding method; aligning a seed crystal with the mold; making a lifting rod slide vertically and a vertical bracket slide horizontally by adjusting the position of a lifting head along a horizontal direction; matching three moving tracks to form a geometrical spherical surface with a certain curvature; and guiding the crystal to grow into a semispherical shape with a certain curvature. In the method, the semispherical sapphire crystal grown with an improved mold guiding method has the advantages of high crystal growing speed and moulding at one time, subsequent machining processes of the semispherical sapphire crystal can be reduced, resource energy consumption in a crystal machining process is lowered, and the cost is saved.

Owner:通辽精工蓝宝石有限公司

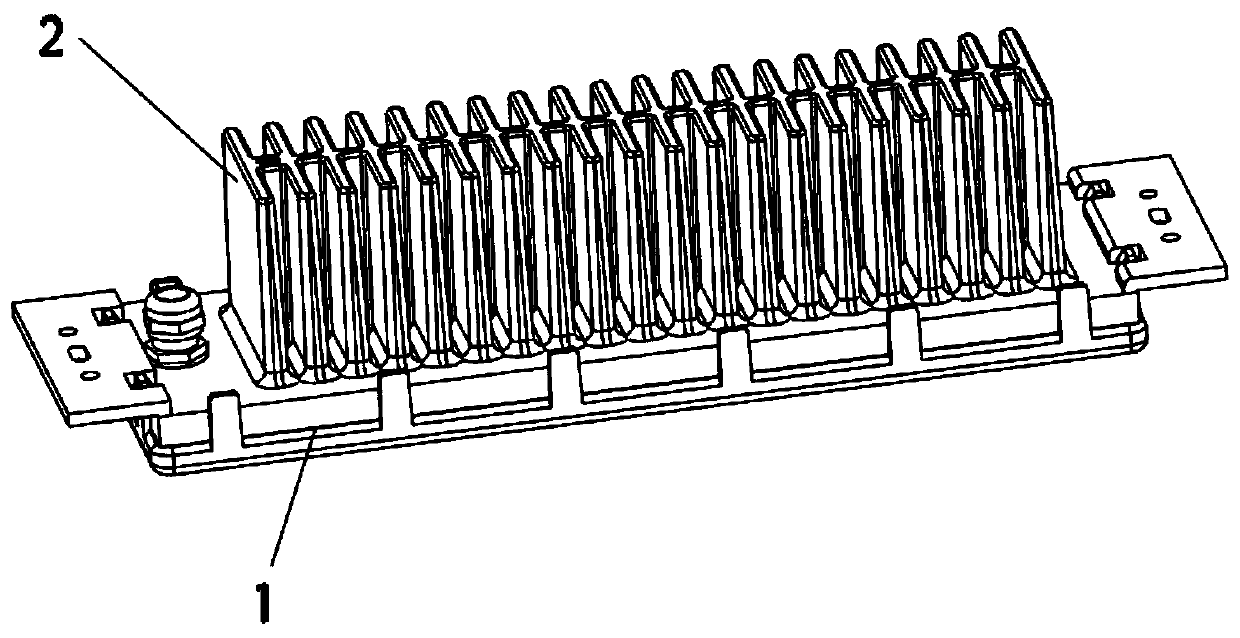

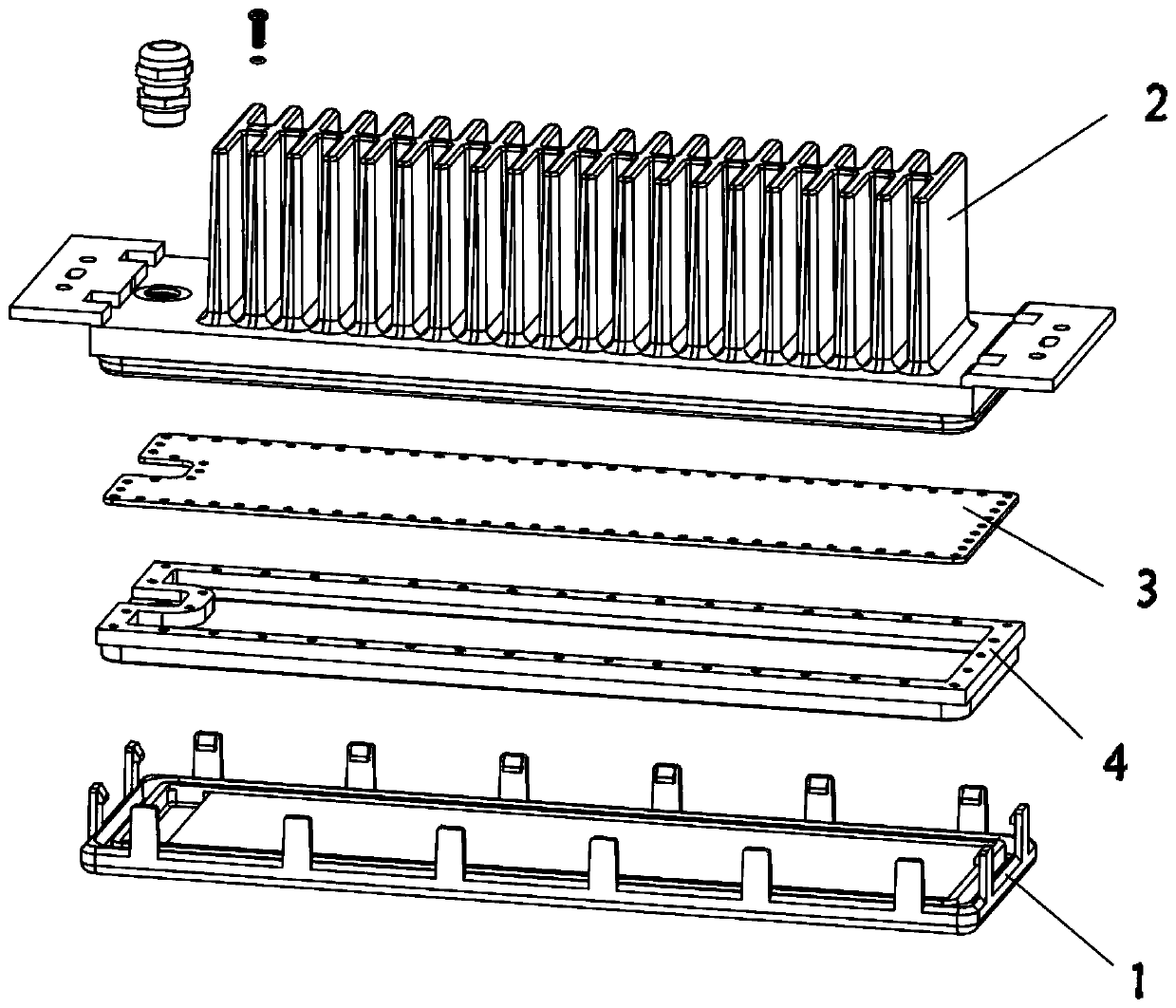

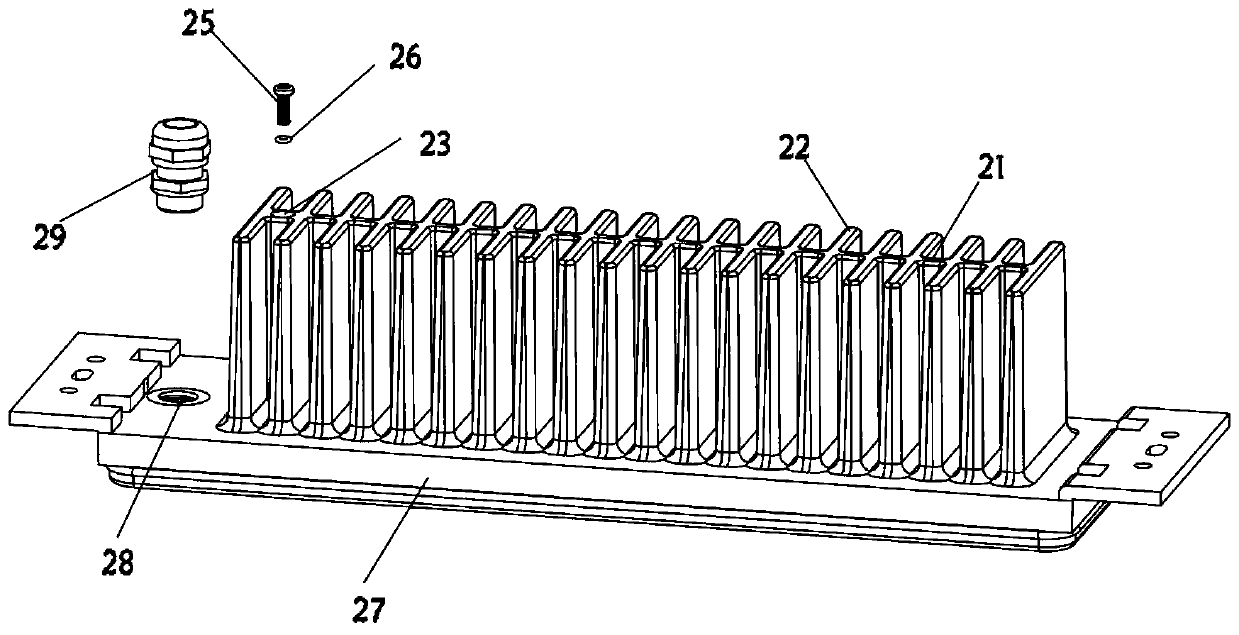

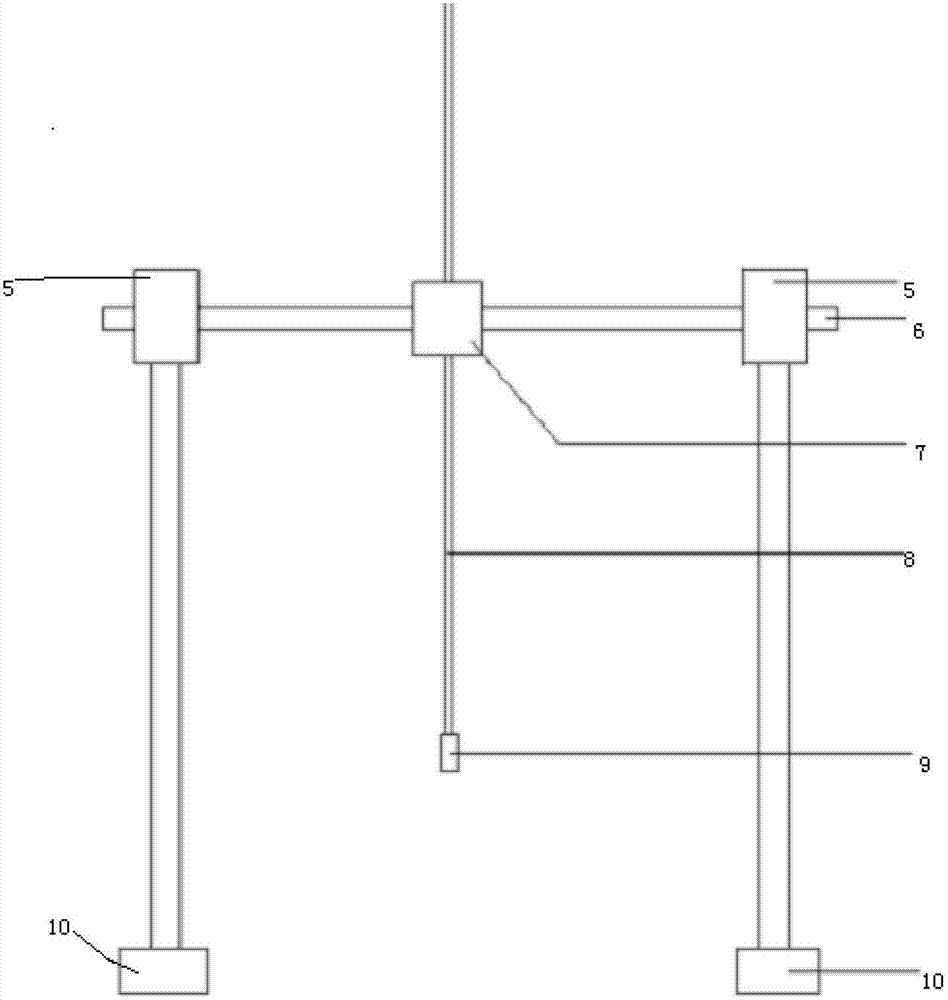

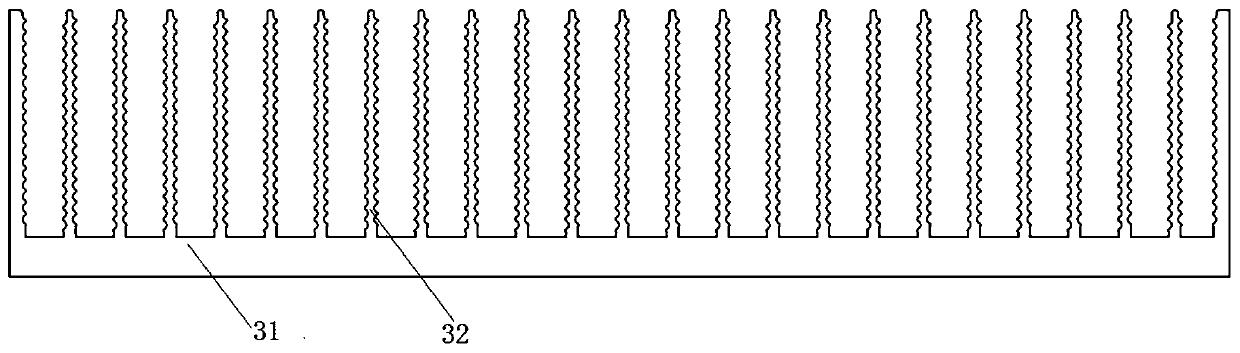

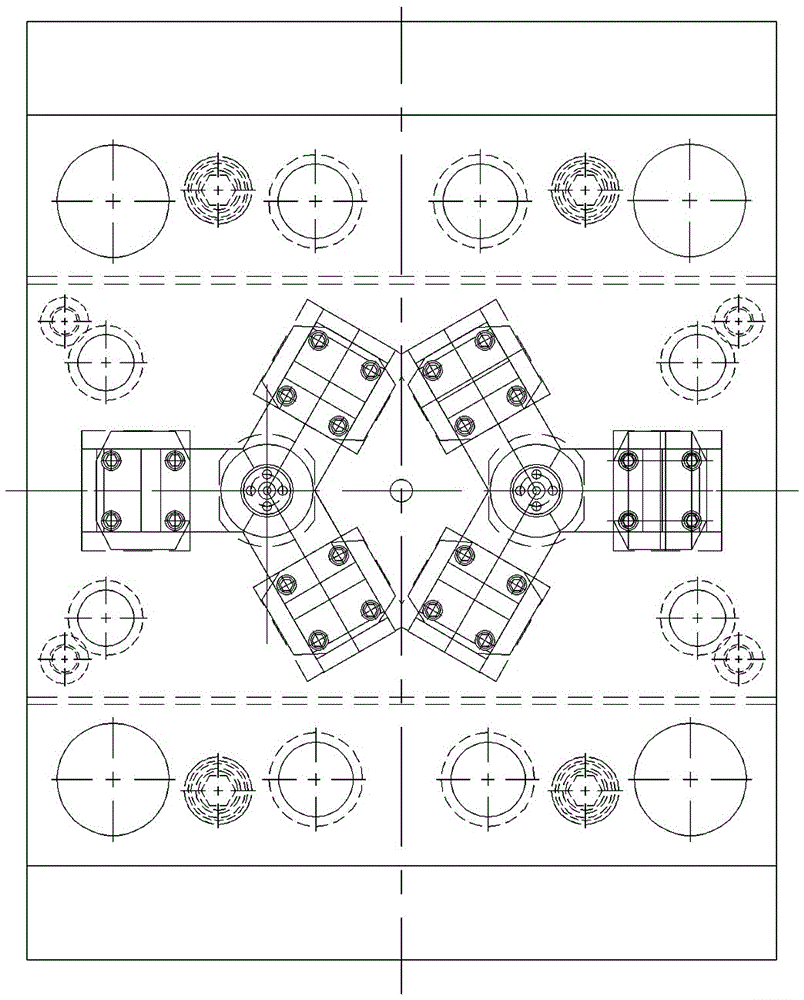

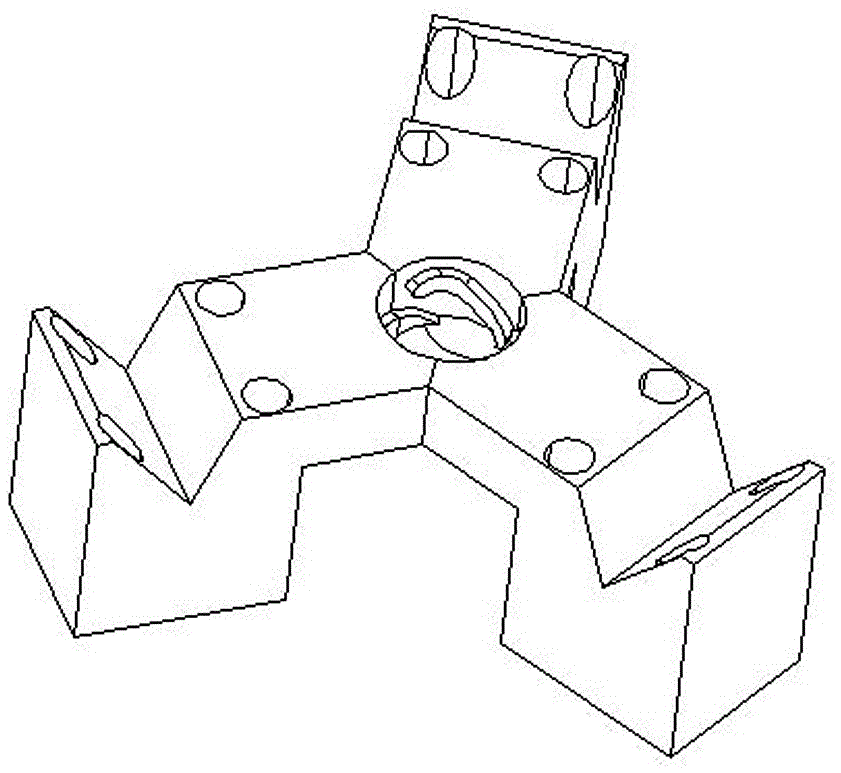

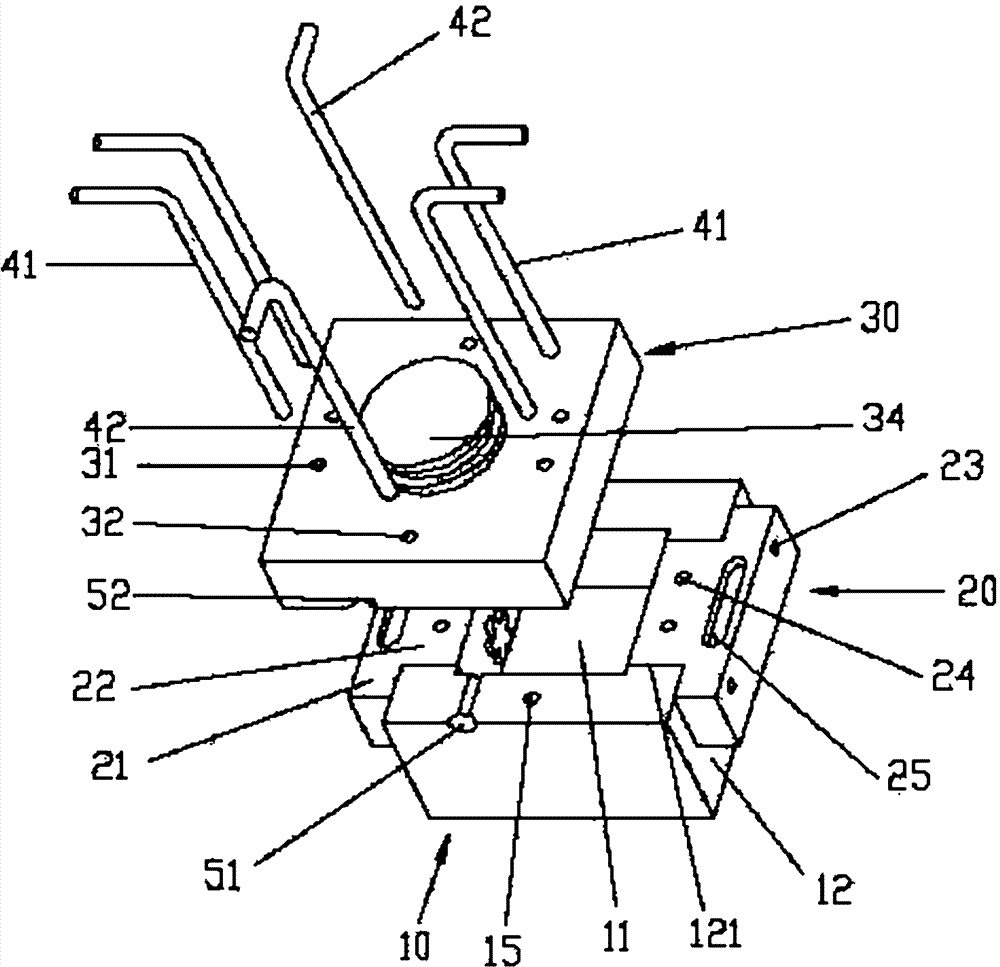

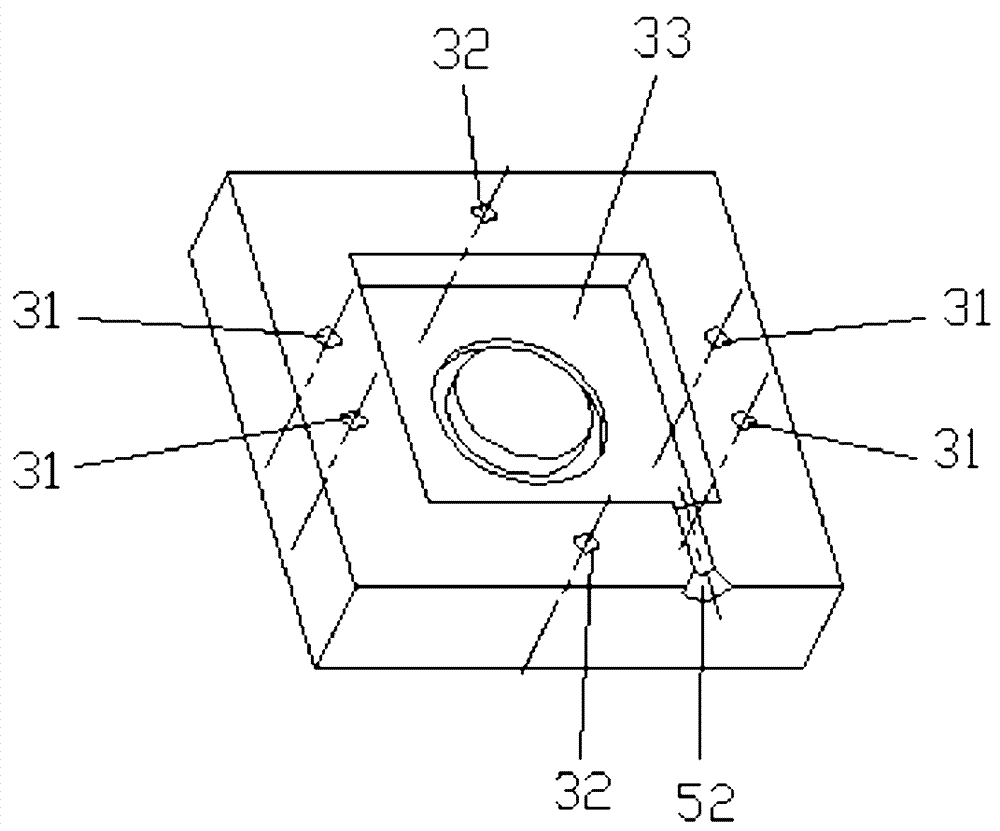

Saw cutting device for fin removing of interface of fin type radiator

PendingCN109954925AAvoid deformationImprove accuracyMetal sawing devicesMetal sawing accessoriesEngineeringMechanical engineering

The invention relates to a saw cutting device for fin removing of the interface of a fin type radiator. The saw cutting device is characterized by including a workpiece clamping mechanism, an interface saw cutting mechanism and a workpiece moving mechanism, the workpiece clamping mechanism is connected with the workpiece moving mechanism and reciprocates along a working table longitudinally, the interface saw cutting mechanism includes a horizontal saw blade, a longitudinal regulating mechanism of the horizontal saw blade, a horizontal regulating mechanism of the horizontal saw blade, a vertical saw blade, a longitudinal regulating mechanism of the vertical saw blade and a horizontal regulating mechanism of the vertical saw blade, and the horizontal saw blade and the vertical saw blade areperpendicular to each other in the axis direction of the cutting edges of the horizontal saw blade and the vertical saw blade, and constitute the simultaneous cutting structure of the horizontal sawblade and the vertical saw blade. The saw cutting device for fin removing of the interface of the fin type radiator has the beneficial effects that the high accuracy of fin removing is ensured, deformation of fins during saw cutting is avoided, and saw cutting is completed for one time.

Owner:中色(天津)特种材料有限公司

Die-casting die and interior drawing sliding block device and die casting method thereof

The invention discloses a die-casting die and an interior drawing sliding block device and die casting method thereof. The sliding block device comprises a compressing part, at least two driven parts and at least two sliding mechanisms. The sliding mechanisms are connected to the compressing part through the driven parts respectively. The driven parts can convert displacement of the compressing part in the first direction into displacement of the sliding mechanism in the second direction. The die-casting die can achieve that products are taken out of die cavities at the same time under the production condition of one die and the multiple cavities, so that reliability of the process and continuity of the whole production assembly line are ensured. On the premise of ensuring the production stability, the yield is improved. To-be-machined products on the inner sides of adjacent die cores can directly form molded grooves, so that the subsequent machining procedures are reduced, and the cost is reduced. As the to-be-machined products can directly form the molded grooves in an interior drawing mode, the interior quality of the products is improved, local thickness of the products is reduced, and the phenomena of pores and poor shrinkage cavities caused by thermal expansion and cold contraction of to-be-machined alloy materials are avoided.

Owner:MINO PRECISION DIE CASTING SHANGHAI CO LTD

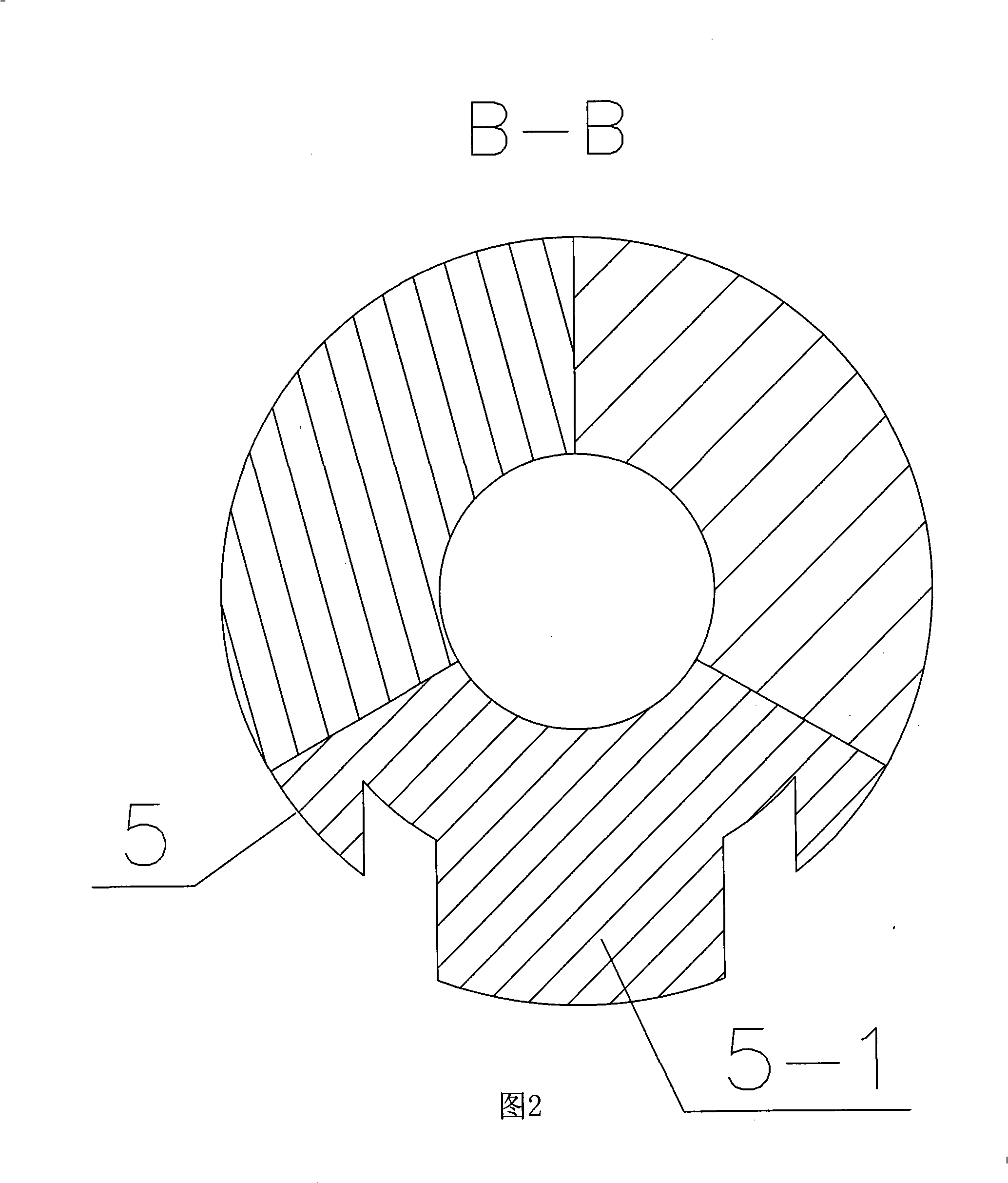

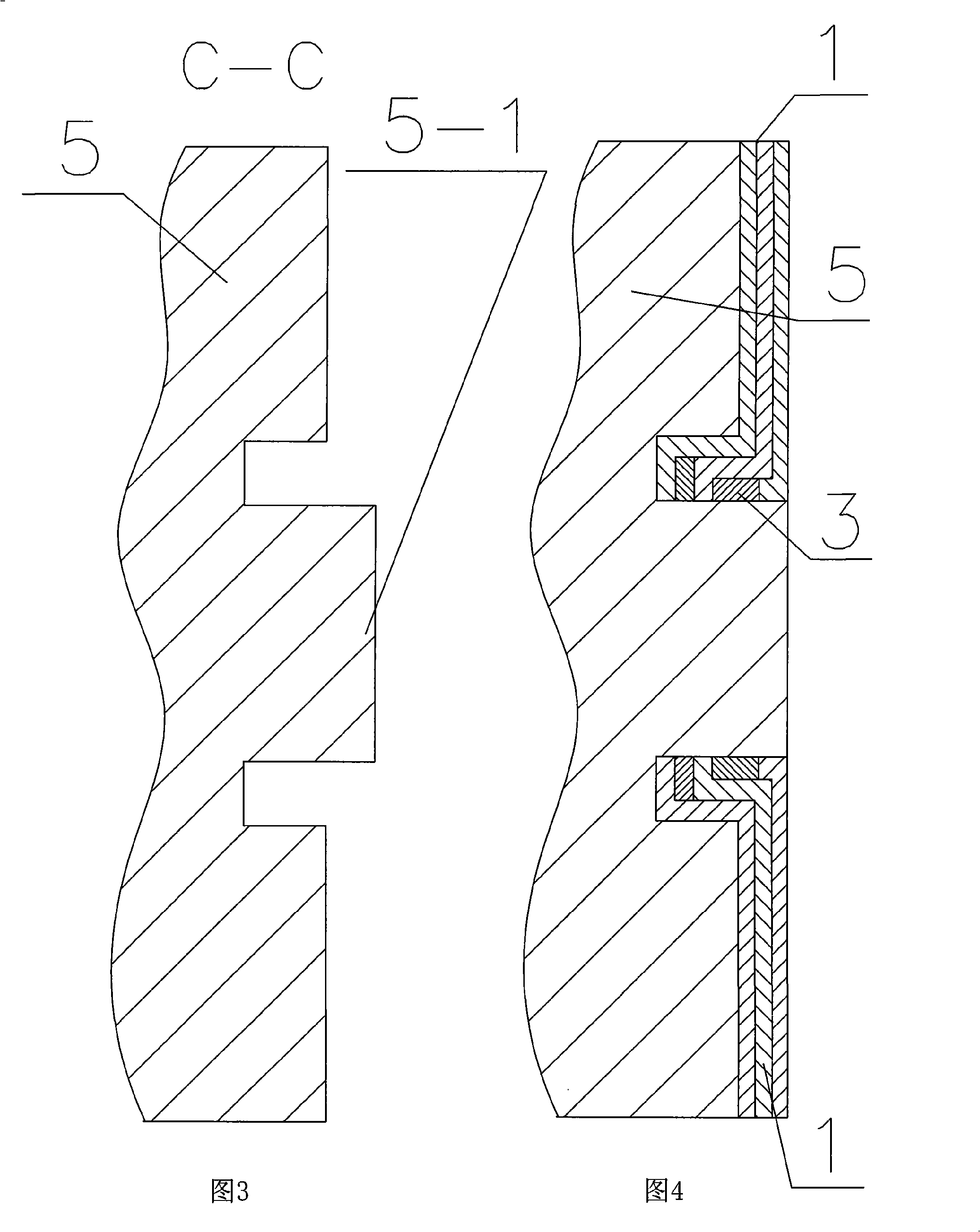

Plastic forming die for cylinder and irregular three-head spiral groove on side surface thereof

The invention provides a plastic forming die for a cylinder and an irregular three-head spiral groove in the side surface thereof. The plastic forming die comprises a fixed die and a moving die in folding with the fixed die; the fixed die comprises an upper die seat and a fixed cavity plate, the upper die seat is connected with molding equipment, and the upper die seat is parallel to the fixed cavity plate and connected with the fixed cavity plate through a pull plate guide post; a slider angle pin, a pouring gate and two vertically arranged shaping cavities are arranged on the fixed cavity plate; the moving die comprises a lower die seat, a moving cavity plate, a supporting plate and an ejecting mechanism, the lower die seat is connected with the moving plate of the molding equipment, the lower die seat is parallel to the upper die seat, and the moving cavity plate and the fixed cavity plate are arranged in a matched manner; a movable mold core, a sliding block and a sprue puller are arranged on the moving cavity plate, and the sliding block, the movable mold core and the shaping cavities together form a cavity for workpiece injection molding. By changing the structure of the sliding block and adopting a pin-point gate, one die for two pieces is achieved, the structure is simple, the operation is convenient, product accuracy can be ensured easily, the appearance quality is good, the manual labor intensity is lowered, the work efficiency is improved, and an industrial application prospect is achieved.

Owner:中壹发展八五零电子有限公司

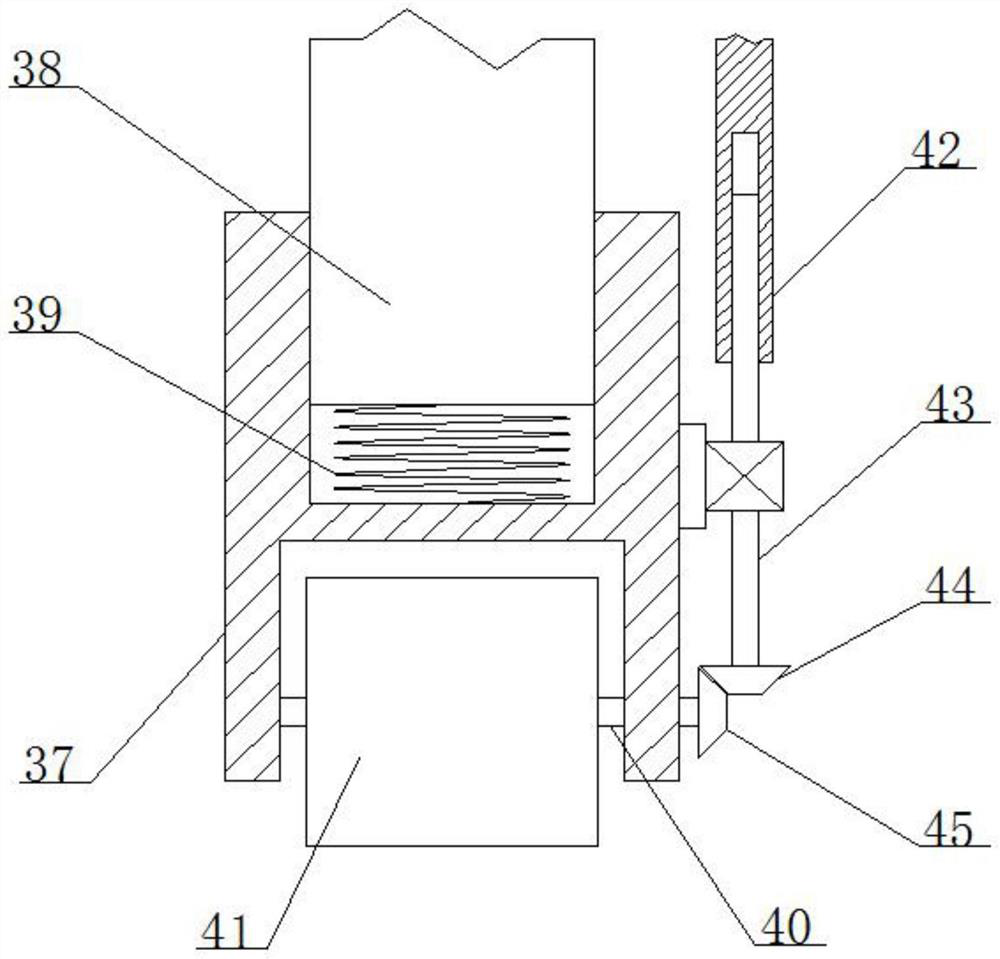

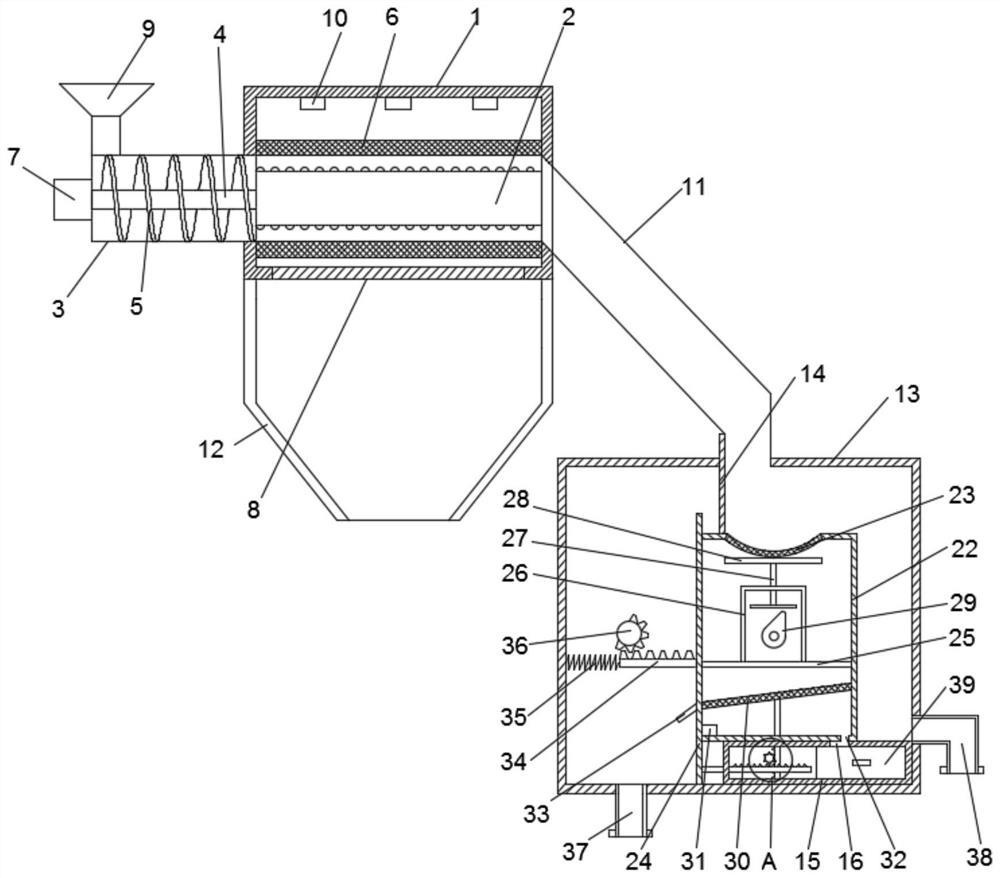

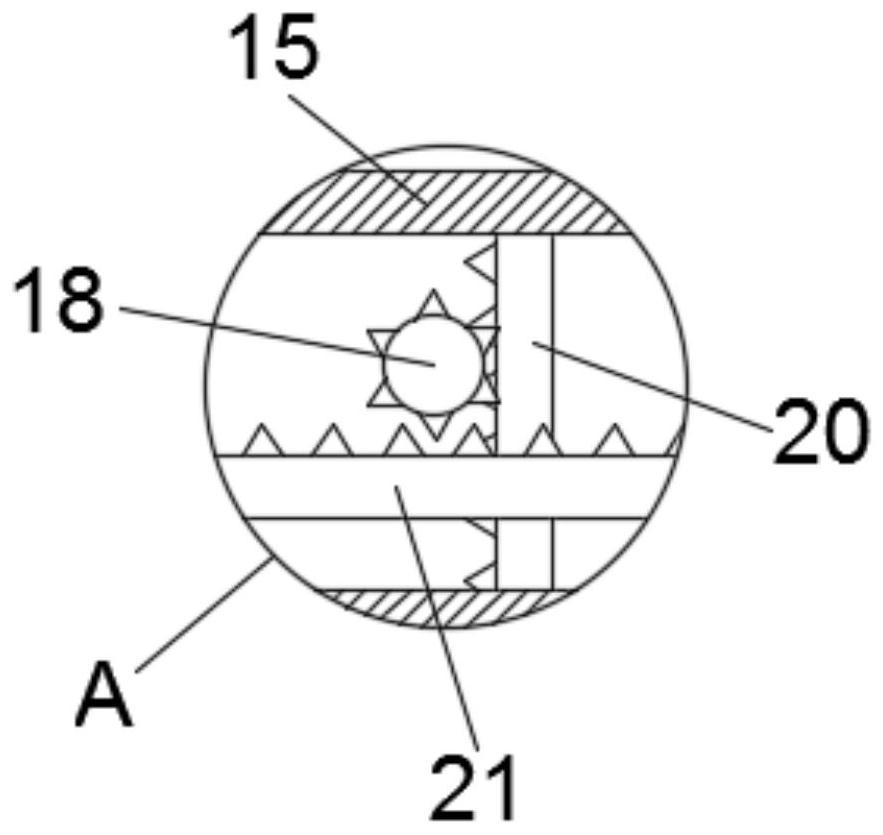

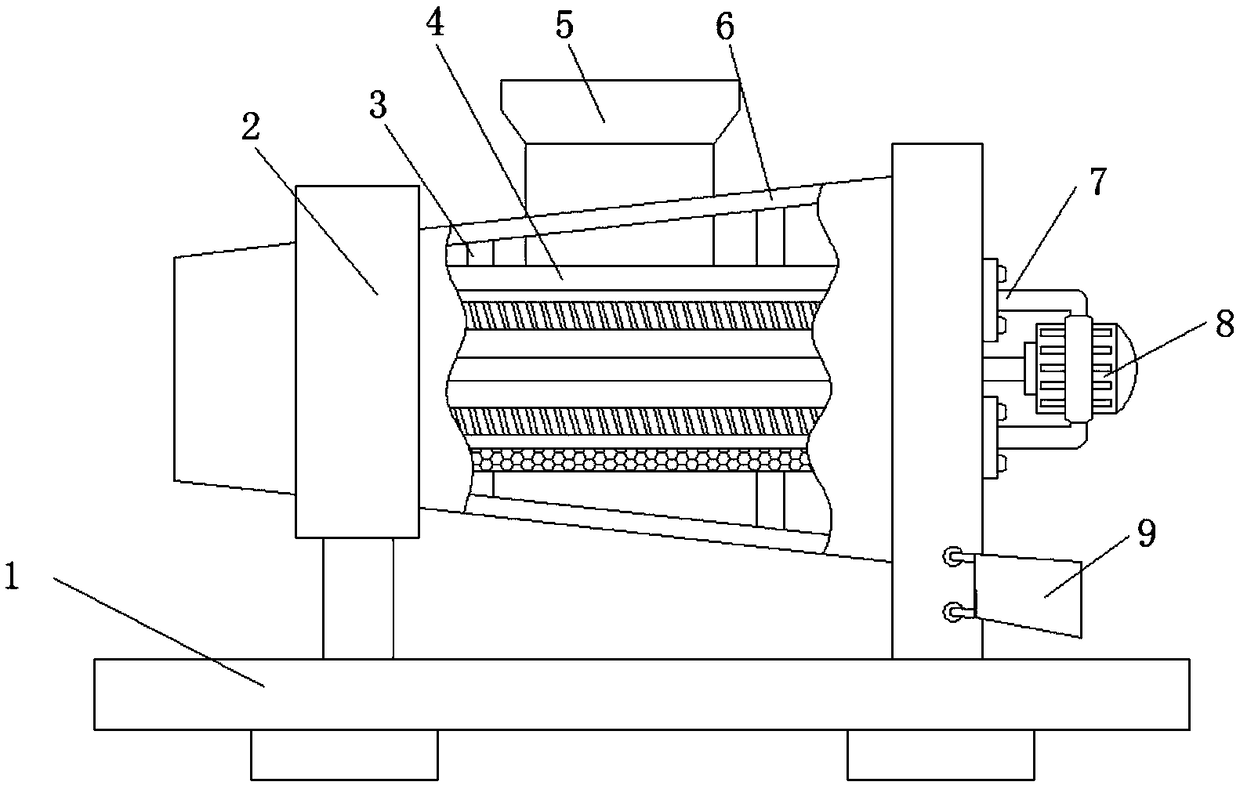

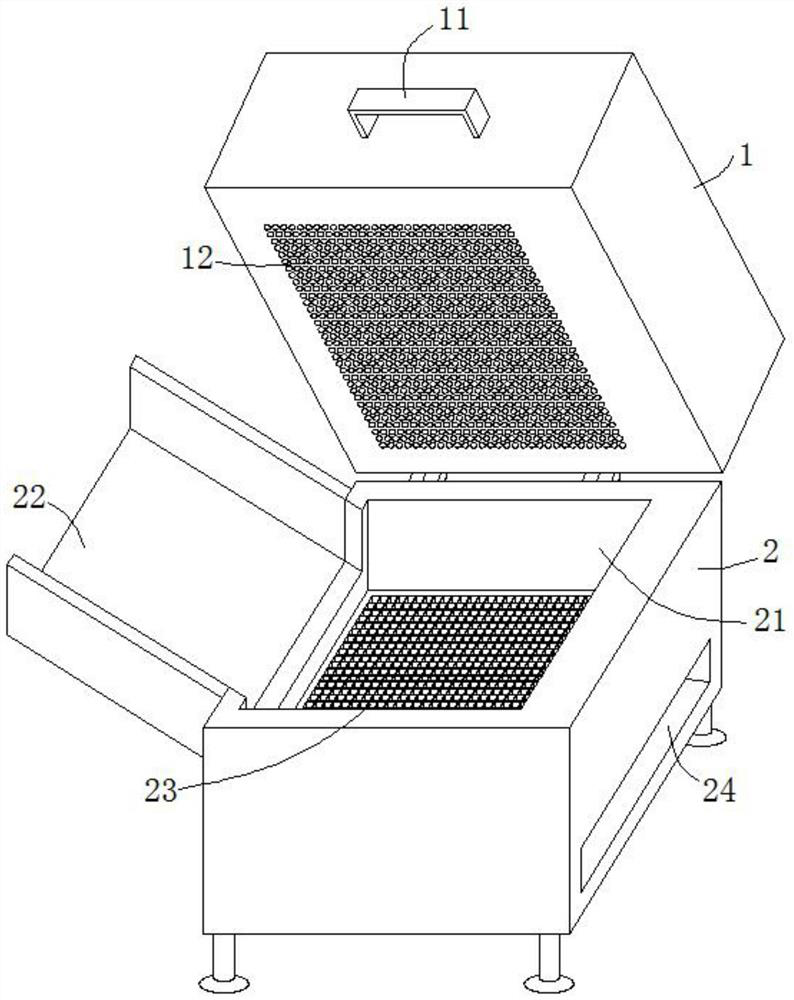

Circulating grinding and screening device for Chinese herbal medicines

InactiveCN108816366AImprove grinding efficiencyReduce subsequent processing stepsGrain treatmentsChinese herbsAerospace engineering

The invention discloses a circulating grinding and screening device for Chinese herbal medicines. The device comprises a fixed base plate, a grinder body is fixed above the fixed base plate through afixed support, a feeding hopper is welded at the top of the grinder body, a grinder inner cylinder is welded to the inner wall of the grinder body through fixed rods, a grinder seal plate is fixed atone end of the grinder body by a bolt, a servo motor is fixed to the outside center of the grinder seal plate through a motor fixed mount, the output shaft of the servo motor runs through the grinderseal plate and extends into the grinder inner cylinder. According to the invention, three grinding plates are equidistantly embedded on the inner wall of the grinder inner cylinder in the grinder body, the interaction of the grinding plates and grinding roll shafts can enhance the grinding efficiency of the grinder body, at the same time filter plates are disposed between two adjacent grinding plates, so that the grinder body can achieve screening and discharging of ground Chinese herbal medicines at the same time of grinding, thus reducing the subsequent processing procedures of Chinese herbal medicines.

Owner:韩芹

Casting mold

ActiveCN102125992BSolve the problem of inconvenient mold openingReduce subsequent processing stepsFoundry mouldsFoundry coresEngineeringCasting mold

The invention discloses a mold used in the casting field. The mold comprises a lower mold, a sliding block positioned on the lower mold, an upper mold, a lower mold pouring port positioned on the lower mold and an upper mold pouring port positioned on the upper mold, wherein the lower mold comprises a lower mold cavity which is sunk inwards and the side wall around the lower mold cavity, a gap penetrating through the side wall is arranged on the side wall of the lower mold, the sliding block comprises a first body positioned on the outer side of the side wall and a second body which is matched with the size of the gap and inserted in the gap, and the size of the first body is larger than that of the second body; and the upper mold comprises an upper mold cavity which is sunk inwards, and convex or sunk patterns are arranged on the bottom surface of the upper mold cavity and the surface facing the lower mold cavity of the second body.

Owner:WUJIANG SENTAI MACHINERY MFG

Temperature-controlling, mold-casting and continuous casting direct molding technology of copper alloy special-shaped strip

The invention discloses a temperature-controlling, mold-casting and continuous casting direct molding technology of a copper alloy special-shaped strip. The direct molding technology comprises the following steps that proportioning is carried out, and specifically oxygen-free copper, silicon, manganese, tin, zinc, titanium, molybdenum, cobalt, tungsten, yttrium, nano wear-resistant particles and transition metal are weighed and mixed to obtain mixed proportioned materials; a three-dimensional geometric model comprising a smelting crucible, a casting mold, a special-shaped strip and a water-cooled copper sleeve is established by adopting ProE software, and by adopting ProCast software, grid division is carried out on the model and simulation calculation is carried out on the continuous casting steady-state temperature field of the special-shaped strip; and the copper alloy special-shaped strip is prepared by adopting the temperature-controlling, mold-casting and continuous casting technology, and the temperature gradient, the solidification speed, the continuous casting speed and the mold casting temperature in the continuous casting process are controlled to regulate the tissue structure and the surface quality. According to the direct molding technology, the technological process is short, the production cost is low, the product surface quality is good, and the performance isexcellent.

Owner:WUXI YIMING PRECISION COPPERBELT

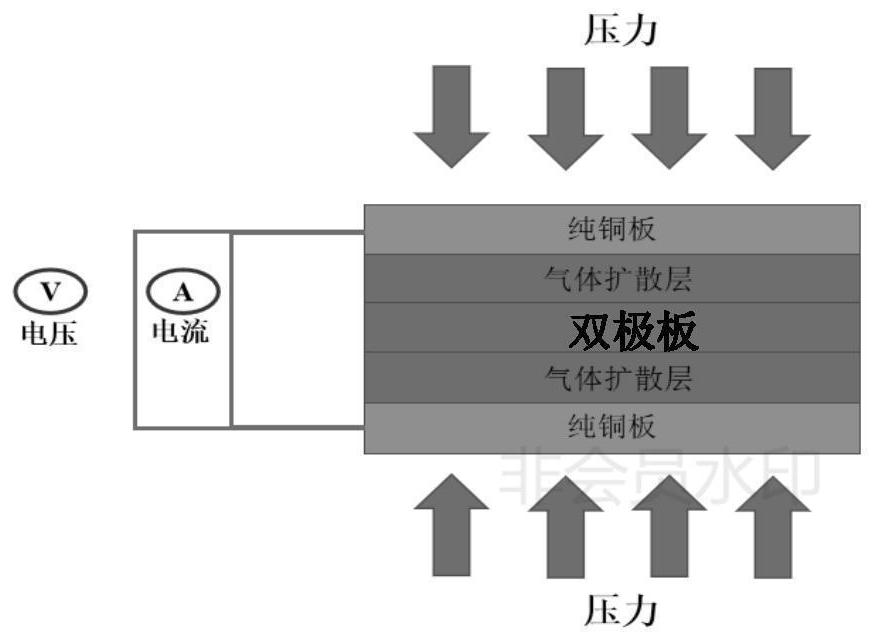

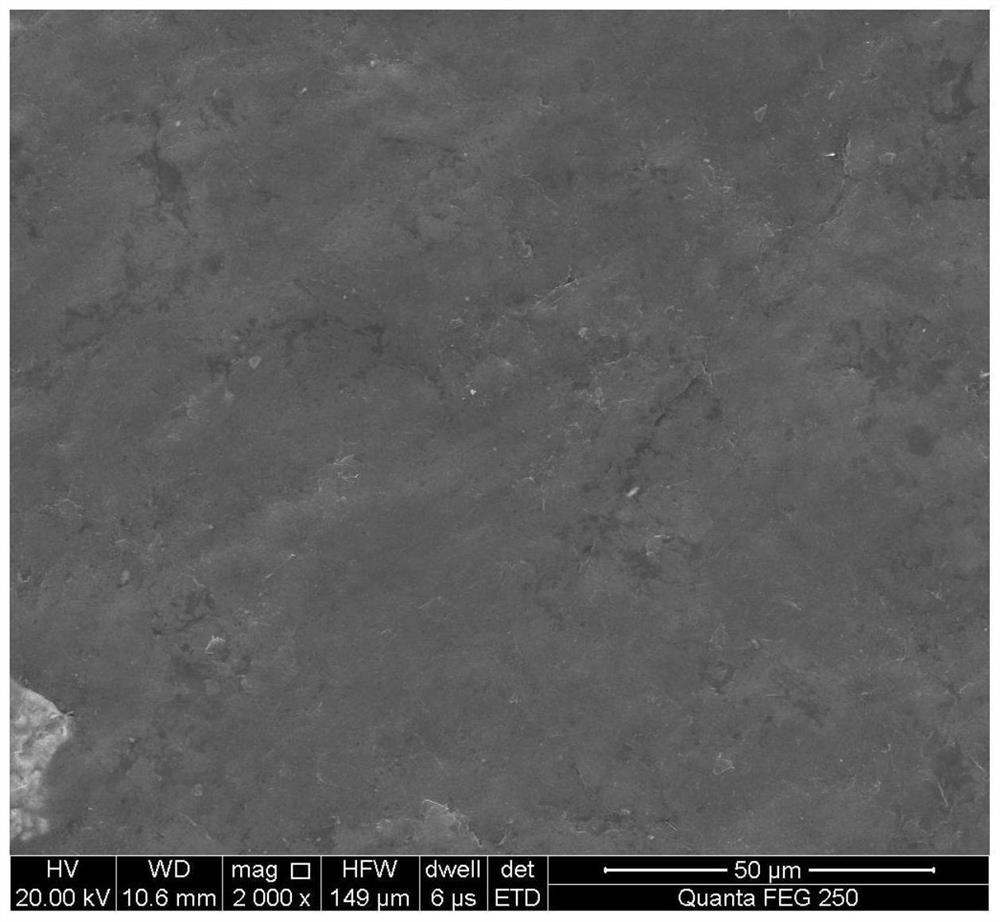

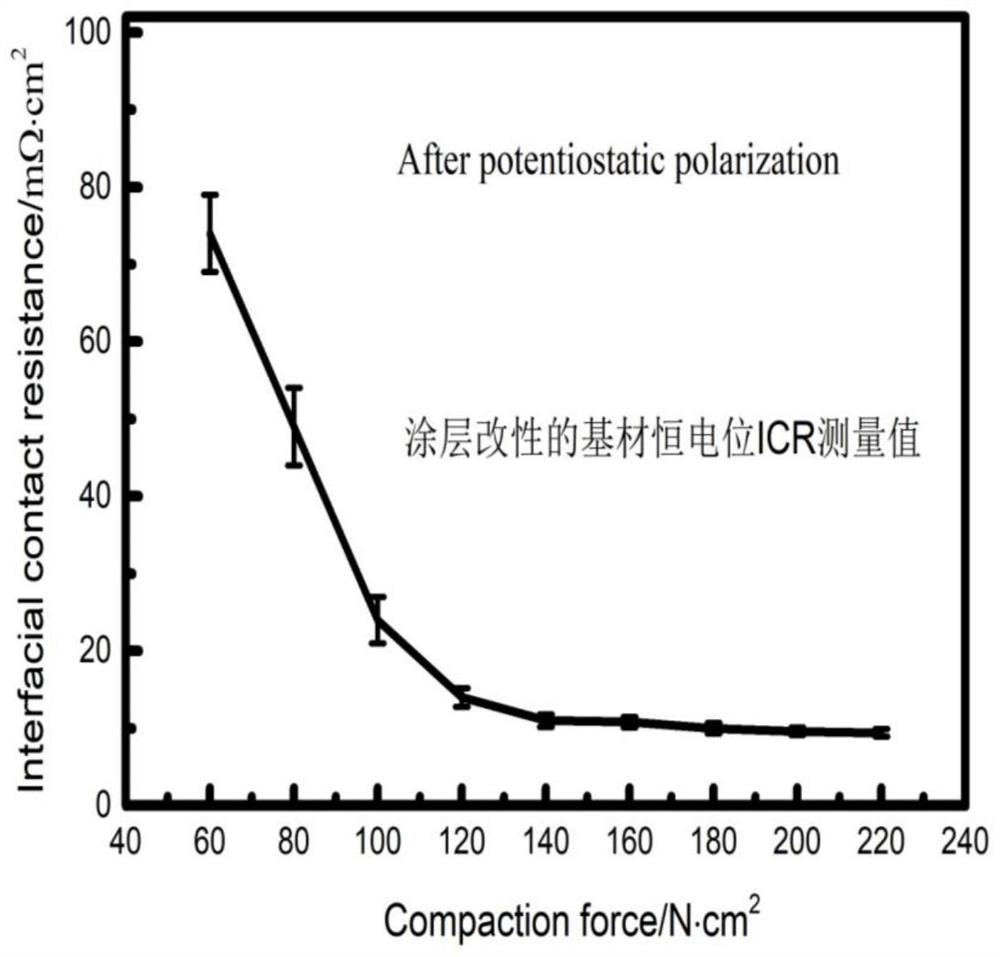

A kind of preparation method of titanium-aluminum alloy material and titanium-aluminum alloy material and its application

ActiveCN111318685BReduce deformation and other problemsImprove corrosion resistanceAnodisationTransportation and packagingMicro arc oxidationProton exchange membrane fuel cell

The invention discloses a preparation method of a titanium-aluminum alloy material, the titanium-aluminum alloy material and its application, comprising: taking commercial 6061 aluminum alloy powder, the particle size of the alloy powder is 180-200 mesh; pure titanium powder, the particle size is 180 mesh ~200 meshes; take aluminum-titanium powder according to the mass ratio of 7:3 to form aluminum-titanium powder I; take aluminum-titanium powder according to the mass ratio of 5:5 to form aluminum-titanium powder II; take aluminum-titanium powder according to the mass ratio of 3:7 to form aluminum-titanium powder Ⅲ; ball milling pretreatment; molding; preparation of titanium-aluminum alloy material matrix; micro-arc oxidation treatment on the surface of the bipolar plate matrix to obtain a surface with nanoporous structure; preparation of titanium-aluminum alloy material. The invention provides a titanium-aluminum alloy material. The bipolar plate of a proton exchange membrane fuel cell is directly pressed into shape, and flow channels are directly prepared during the forming process, which reduces subsequent processing procedures and further improves the corrosion resistance and performance of the titanium-aluminum alloy material. Stability in PEMFCs working environment.

Owner:HUNAN INSTITUTE OF ENGINEERING

Yarn processing technology

PendingCN113201829AHigh strengthReduce subsequent processing stepsVegetable fibre separation from seedsYarnYarnCarding

The invention discloses a yarn processing technology, and relates to the technical field of yarn processing. The yarn processing technology comprises the following steps of A, cotton obtaining; B, cotton seed and cotton separation; C, cotton carding; D, sliver coiling; E, drawing; and F, twisting. According to the yarn processing technology, the cotton and cotton seeds are separated, and in the separation process, the cotton is lengthened and stretched at the same time, so that the strength of yarn is enhanced, the subsequent processing procedures are reduced, the production cost is reduced, and the processing efficiency is improved.

Owner:安徽杰达纺织科技有限公司

A Direct Forming Technology of Copper Alloy Special-Shaped Strip by Temperature-controlled Casting Continuous Casting

The invention discloses a temperature-controlling, mold-casting and continuous casting direct molding technology of a copper alloy special-shaped strip. The direct molding technology comprises the following steps that proportioning is carried out, and specifically oxygen-free copper, silicon, manganese, tin, zinc, titanium, molybdenum, cobalt, tungsten, yttrium, nano wear-resistant particles and transition metal are weighed and mixed to obtain mixed proportioned materials; a three-dimensional geometric model comprising a smelting crucible, a casting mold, a special-shaped strip and a water-cooled copper sleeve is established by adopting ProE software, and by adopting ProCast software, grid division is carried out on the model and simulation calculation is carried out on the continuous casting steady-state temperature field of the special-shaped strip; and the copper alloy special-shaped strip is prepared by adopting the temperature-controlling, mold-casting and continuous casting technology, and the temperature gradient, the solidification speed, the continuous casting speed and the mold casting temperature in the continuous casting process are controlled to regulate the tissue structure and the surface quality. According to the direct molding technology, the technological process is short, the production cost is low, the product surface quality is good, and the performance isexcellent.

Owner:WUXI YIMING PRECISION COPPERBELT

A plastic molding mold for a cylinder and its side irregular three-headed spiral groove

The invention provides a plastic forming die for a cylinder and an irregular three-head spiral groove in the side surface thereof. The plastic forming die comprises a fixed die and a moving die in folding with the fixed die; the fixed die comprises an upper die seat and a fixed cavity plate, the upper die seat is connected with molding equipment, and the upper die seat is parallel to the fixed cavity plate and connected with the fixed cavity plate through a pull plate guide post; a slider angle pin, a pouring gate and two vertically arranged shaping cavities are arranged on the fixed cavity plate; the moving die comprises a lower die seat, a moving cavity plate, a supporting plate and an ejecting mechanism, the lower die seat is connected with the moving plate of the molding equipment, the lower die seat is parallel to the upper die seat, and the moving cavity plate and the fixed cavity plate are arranged in a matched manner; a movable mold core, a sliding block and a sprue puller are arranged on the moving cavity plate, and the sliding block, the movable mold core and the shaping cavities together form a cavity for workpiece injection molding. By changing the structure of the sliding block and adopting a pin-point gate, one die for two pieces is achieved, the structure is simple, the operation is convenient, product accuracy can be ensured easily, the appearance quality is good, the manual labor intensity is lowered, the work efficiency is improved, and an industrial application prospect is achieved.

Owner:中壹发展八五零电子有限公司

An injection molding processing method for forming orthogonal through-holes

The invention relates to an injection molding processing method for forming an orthogonal through micro-hole, belongs to the field of injection molding and relates to an injection mold processing method and device for forming the orthogonal through micro-hole. In the method, micro-adjustment is realized through side core-pulling movement of a micro-adjustable side core-pulling mechanism to complete accurate alignment of a horizontal arc surface with a vertical cylindrical surface. The implementation process of the injection mold processing method comprises steps of mold closing, pouring, mold opening and product ejection. The mold device adopted by the method consists of a fixed mold part, the micro-adjustable side core-pulling mechanism, an ejector sleeve / rod ejection mechanism and a movable mold part. By adopting the method, a micro-fluid connector with the orthogonal through micro-hole and a micro positioning through hole can be molded in one step, the subsequent process is reduced, the molding efficiency is high, the cost is decreased and the energy consumption is reduced; the relative position accuracy between the orthogonal through micro-hole and the micro positioning through hole can be guaranteed, a basic guarantee is provided for next step key bonding and encapsulation, and the quick replacement of a mold core is realized.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com