Double-layer fabric mingled with reinforced yarns and weaving method

A technology for sandwiching reinforced fabrics and fabric weave, applied in the direction of fabrics, multi-strand fabrics, textiles and papermaking, etc., can solve the problems of high labor intensity, stress fracture, large sewing equipment, etc., and achieve the effect of reducing processing procedures and simplifying manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

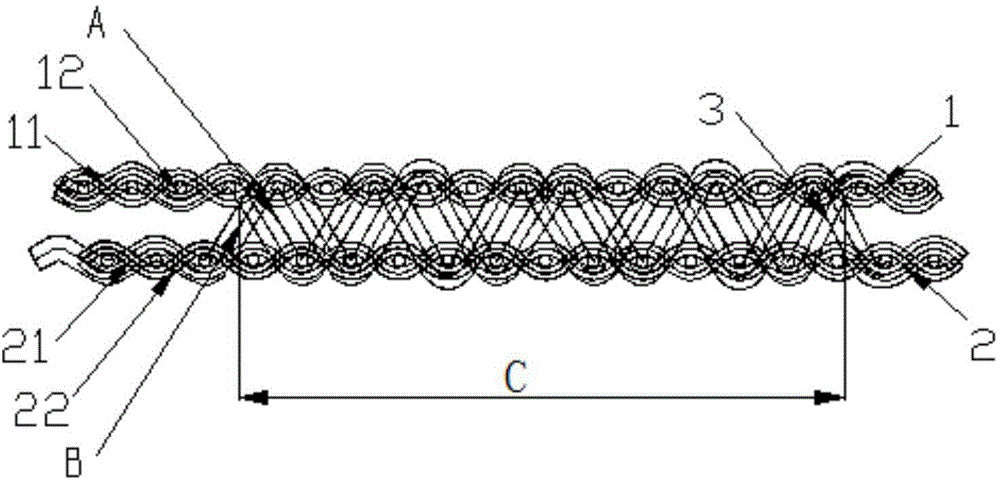

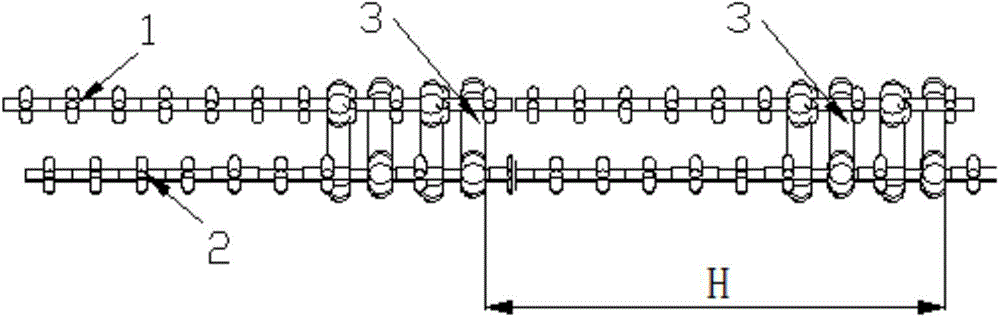

[0019] First, combine Figure 1 to Figure 2 The double-layer ribbed fabric of the present invention is specifically described, which includes upper and lower layers of fabric weaves, and ribbed yarns 3 are woven between the upper and lower layers of fabric weaves to connect the upper and lower layers of fabric weaves into one. Wherein, the rib yarn 3 is a warp yarn thicker than the warp yarn used in the upper and lower fabric weaves, and the rib yarn and the warp yarn are cross-woven with the weft yarn and woven into the upper fabric weave 1 and the lower fabric weave 2. to increase the tensile strength of the fabric. The upper and lower layers of fabric are woven in the middle of the upper fabric together with the upper warp yarn 11 and the upper weft yarn 12 within a certain length, and the lower rib yarn and the lower warp yarn 21 are woven together with the lower weft yarn 22 in the middle of the lower fabric within a certain length. After the next set length of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com