An injection molding processing method for forming orthogonal through-holes

A technology of injection molding processing and tiny holes, which is applied in the field of injection molding to achieve the effects of reducing energy consumption, quick replacement and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

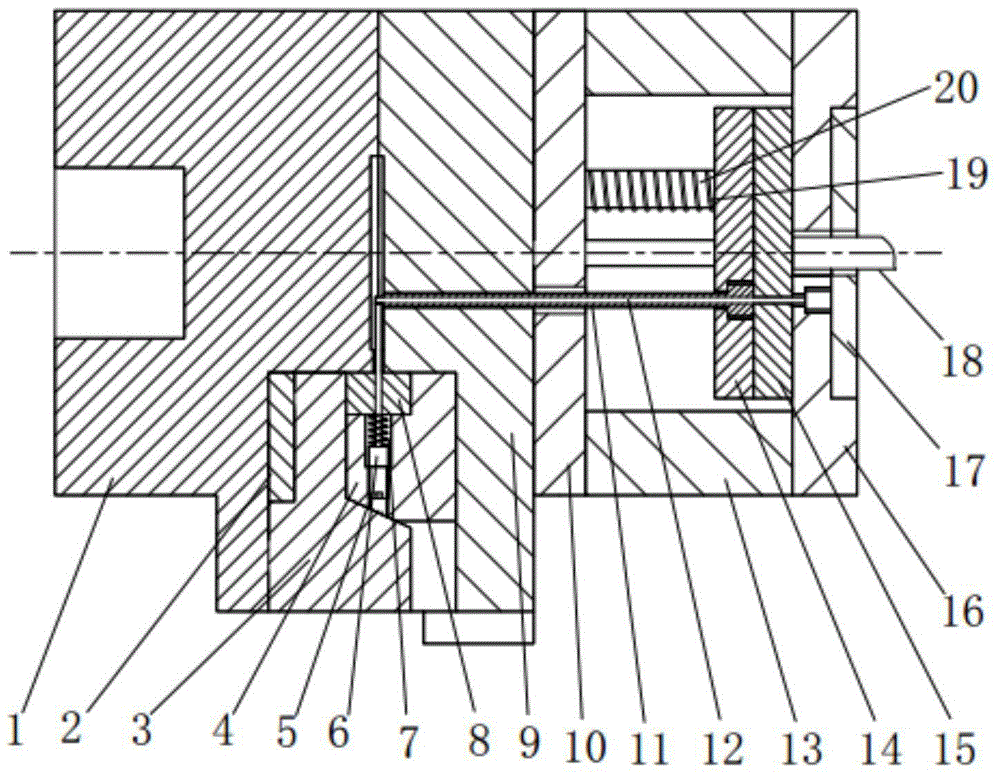

[0031] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions. Taking the use of a micro-injection mold device to make a microfluidic connector with orthogonal through micro-holes as an example, the specific implementation steps of the present invention are as follows:

[0032] 1. Assembly of fixed mold components: the inclined guide post 25 is installed on the wedge block 3, pressed with the inclined guide post pressure plate 2, and the wedge block 3 is installed and fixed on the fixed template 1 with an open groove structure to complete the fixed mold parts assembly, such as Figure 4 shown.

[0033] 2. Assembly of moving mold parts:

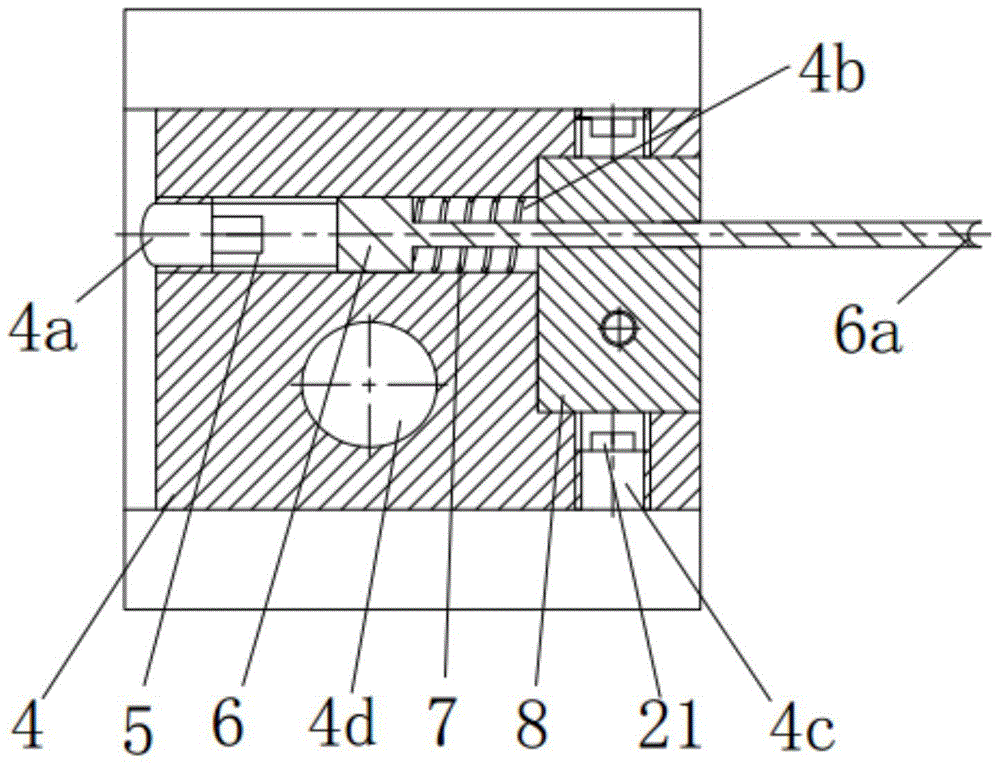

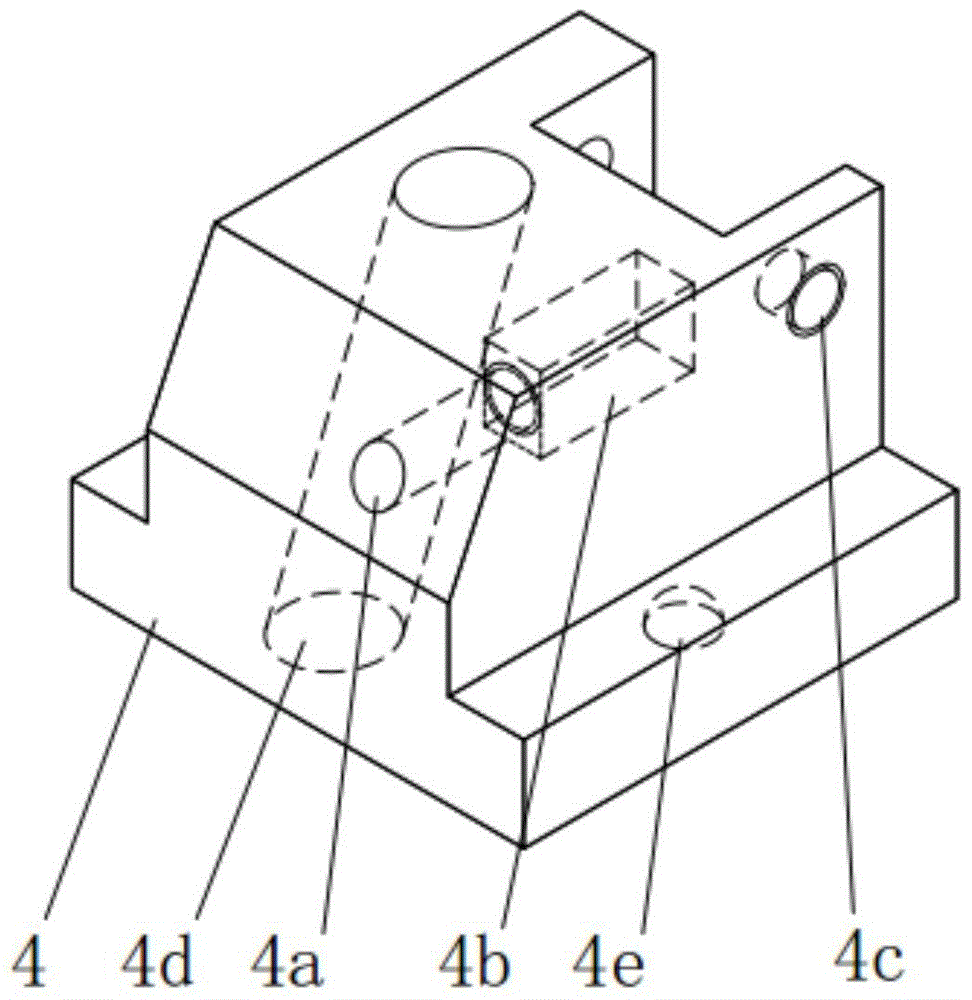

[0034] (1) Assembly of the fine-tuning side core-pulling mechanism: the side core-pulling 6 with the side core-pulling arc surface 6a at the rear end is installed on the side core-pulling fixing plate 8 through the compression spring 7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com