Rice whitening method

A rice whitening technology, which is applied in grain milling, grain degerming, grain processing, etc., can solve the problems of increasing screening work, not being able to separate impurity particles of different sizes of rice grains, and breaking of rice grains, so as to reduce subsequent processing procedures , Improve the effect of processing quality and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

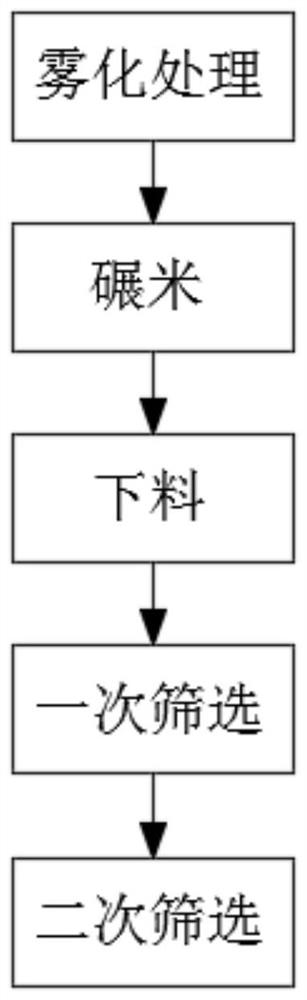

[0034] Embodiment 1: see figure 1 , a method for whitening rice, comprising the steps of:

[0035] (1) Atomization treatment: first use the compound enzyme liquid of cellulase, maltase and protease to infiltrate brown rice by spraying;

[0036] (2) Rice milling: the brown rice after soaking treatment in step (1) is sent in the rice milling device to carry out rice milling process;

[0037] (3) Blanking: transport the semi-polished rice after rice milling from the rice milling box to the distribution box;

[0038] (4) primary screening: large-grain rice and small-grain rice are screened out by the first filter screen;

[0039] (5) Secondary screening: small-grained rice and impurity particles are screened out through the second filter screen.

[0040] Preferably, in the compound enzyme liquid: cellulase is 50wt%, maltase is 10wt%, and protease is 8wt%.

[0041] Preferably, the temperature of the atomization treatment is 30°C, and the enzymolysis time is 0.5h.

[0042] Use ...

Embodiment 2

[0043] Embodiment 2: The same as embodiment 1 will not be repeated, and the difference with embodiment 1 is:

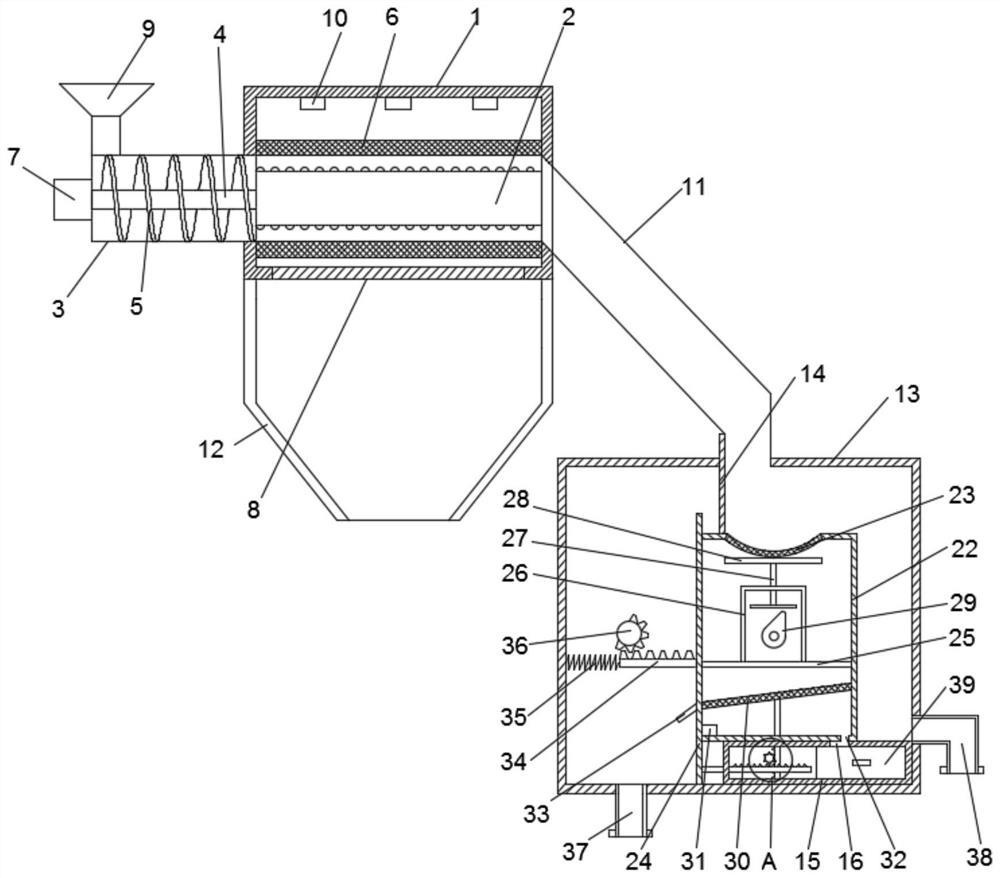

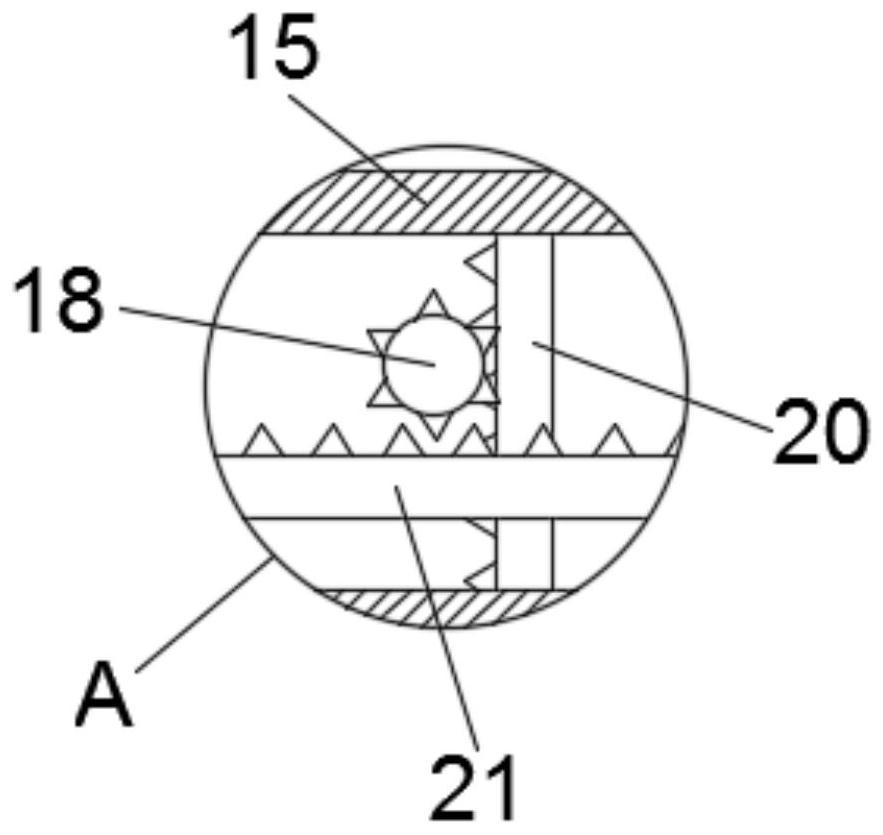

[0044] see Figure 2-4 , the rice milling device includes a rice milling box, the middle part of the rice milling box is rotatably equipped with rolling rollers, the top of the rice milling box is provided with several sets of first air blowers, and the left side of the rice milling box is fixedly equipped with a delivery box A transmission shaft is fixedly installed in the middle of the delivery box, the transmission shaft is fixedly connected with the rolling roller and has a concentric structure, and a helical blade is fixedly installed on the outside of the transmission shaft, and the rice in the delivery box is transported to the mill through the helical blade. Rice milling in the rice box;

[0045] The top of the left side of the delivery box is fixedly equipped with a rice feeding bucket, the inside of the delivery box is connected with the rice milling box, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com