Yarn processing technology

A processing technology and yarn technology, which is applied in the field of yarn processing, can solve problems such as large demand, increased production costs, and increased production processes, and achieve the effects of improving processing efficiency, enhancing strength, and reducing processing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

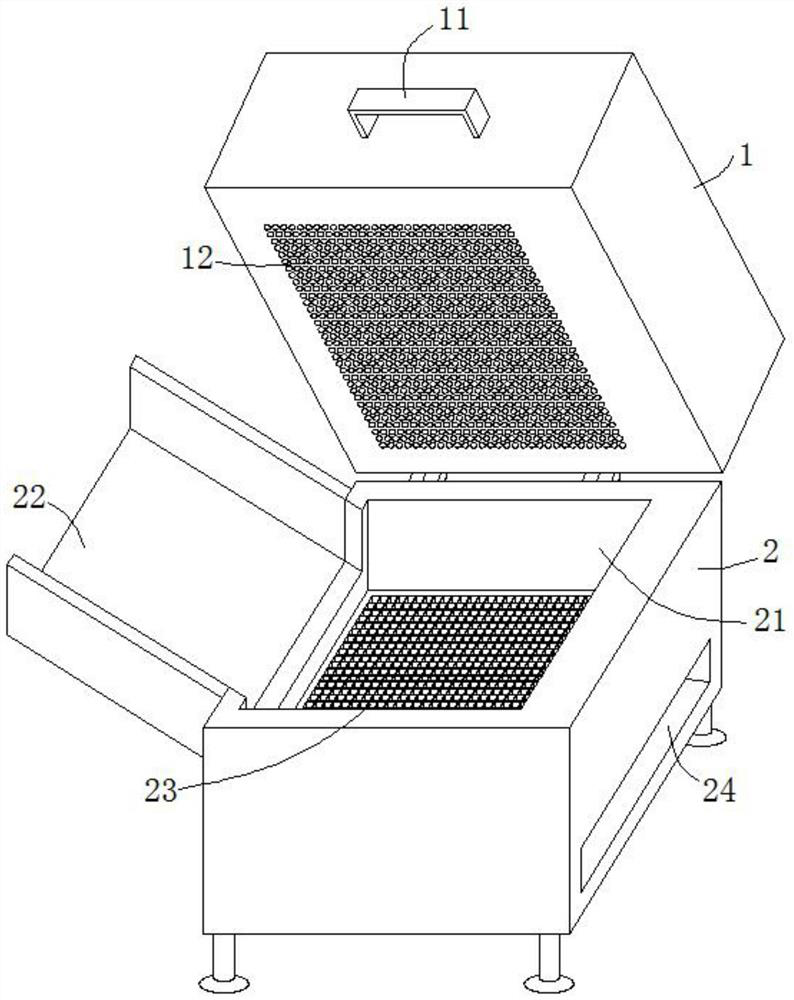

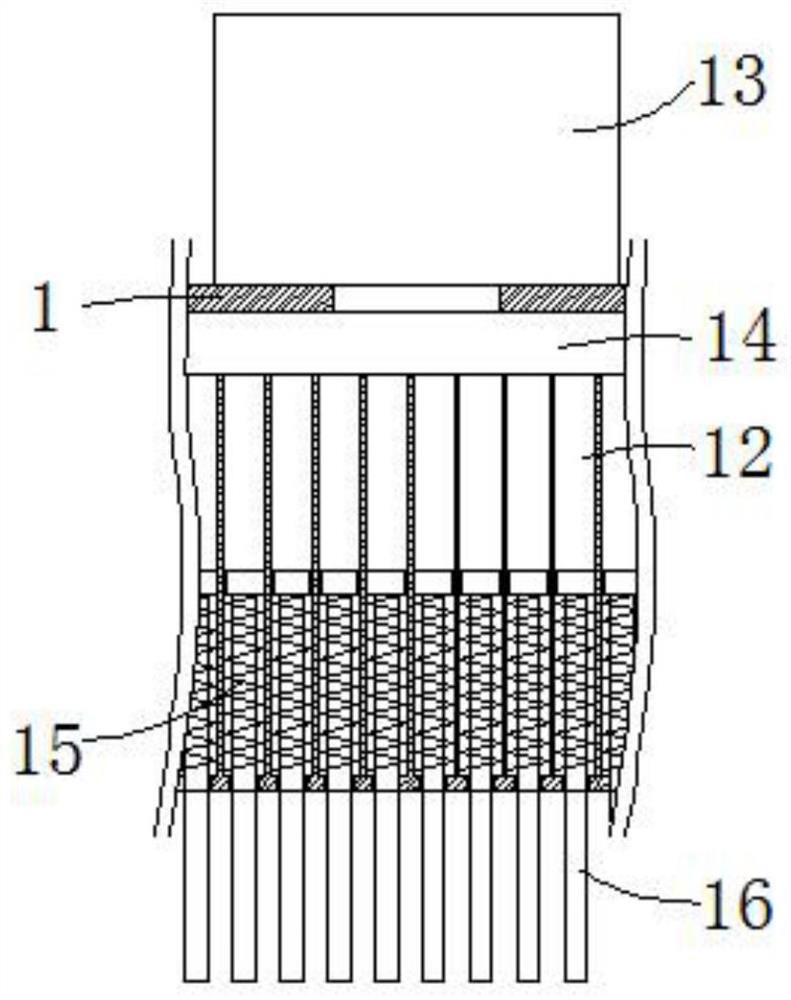

[0028] see Figure 1-3 , the present embodiment provides a kind of yarn processing technology, and the yarn processing steps are:

[0029] A. Cotton: The cotton is picked from the field, packed and transported to the workshop in cloth bags, which is convenient for production;

[0030] B. Separation of cottonseed and cotton: separate the cotton from the cottonseed. During the separation process, the cotton is drawn and stretched to enhance the strength of the yarn, reduce subsequent processing procedures, reduce production costs, and improve processing efficiency;

[0031] C. Carding: further remove the neps, impurities and fiber defects in the fiber, improve the cleanliness of the cotton, so as to ensure that the final produced yarn is relatively clean, decompose the cotton block into a single fiber state, and improve the straight and parallel state of the fiber;

[0032] D. Strip roll: combined and drafted to increase the degree of straightening of the fibers in the small ro...

Embodiment 2

[0044] see Figure 1-3 , further improvements have been made on the basis of Example 1:

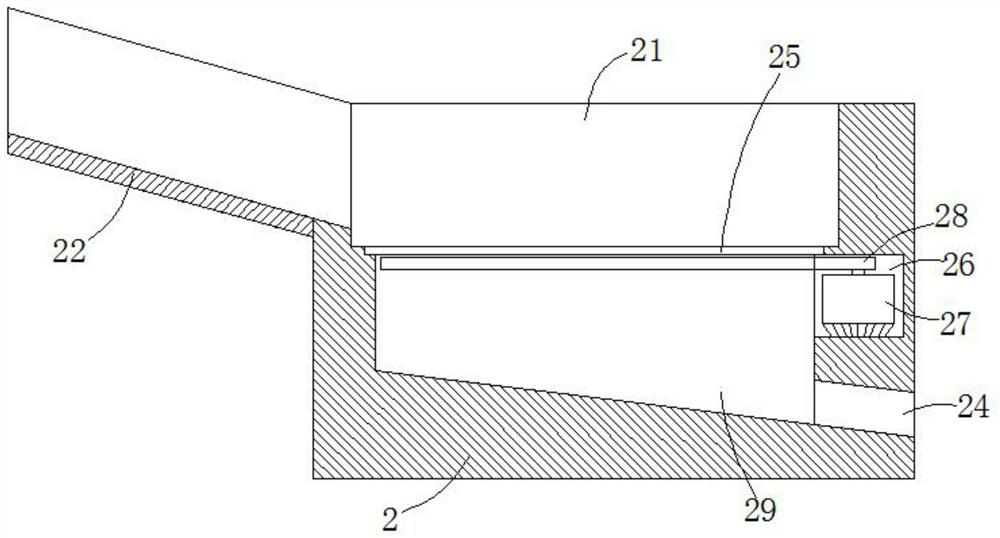

[0045] In order to solve the problem of how to avoid the unexported residual cotton inside the storage tank 29. The inner bottom end surface of the receiving groove 29 and the inner bottom end surface of the export port 24 are all distributed towards the outlet 24 opening below the 45° inclination angle, and the inclination angle of the storage groove 29 and the inner bottom end surface of the export port 24 is used to make the separated cotton. It is exported along the slope, without setting the transmission mechanism, saving production costs.

[0046] In order to solve the problem of how to increase enough space for the driving lever 28 to move back and forth. The length of driving lever 28 is 1 / 2nd of the interior front and rear span of mounting groove 26, and servomotor 27 is positioned at the interior midsection position of mounting groove 26, and the length of driving lever 28 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com