Splicing and drying integration device for integrated boards

A technology for plates and heating devices, applied in heating devices, drying, dryers, etc., can solve the problems of wasting materials and increasing the difficulty of work in the sand leveling process, so as to achieve the advantages of reducing loss, fewer processing steps and significant effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0029] The invention is composed of a frame body (1), a plate limiting pipe frame (2), and a heating pipeline (3).

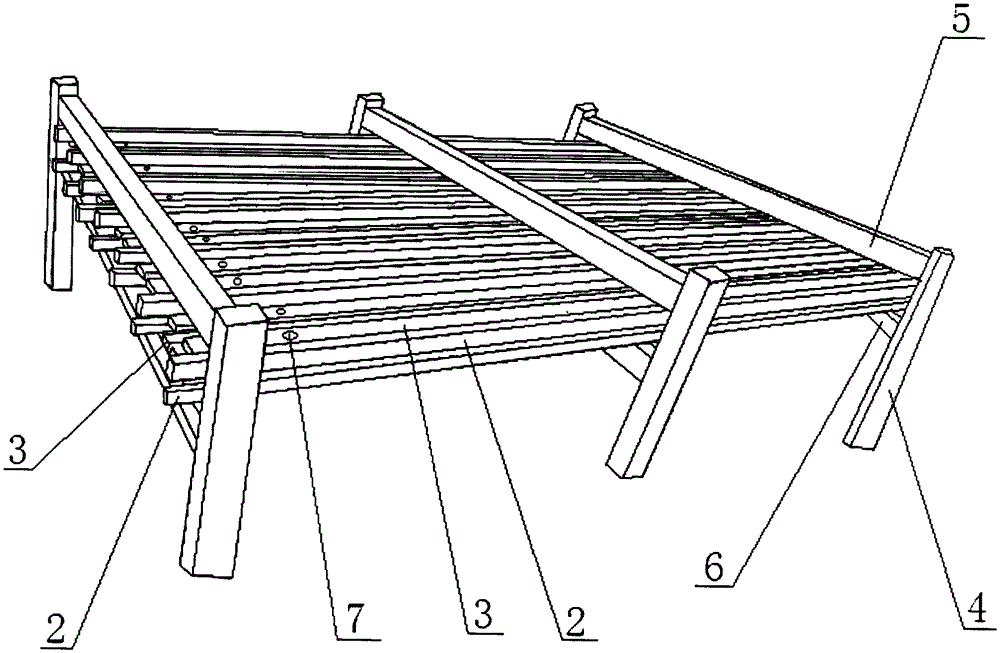

[0030] figure 1 Shown is the structural representation of the present invention. Among them, 2 is the plate limit pipe frame (2), 3 is the heating pipe (3), 4 is the frame foot (4), 5 is the upper fixing frame (5) of the frame body, and 6 is the frame body Lower fixed mount (6), 7 is the air inlet hole (7) that is provided with on the top of heating pipeline.

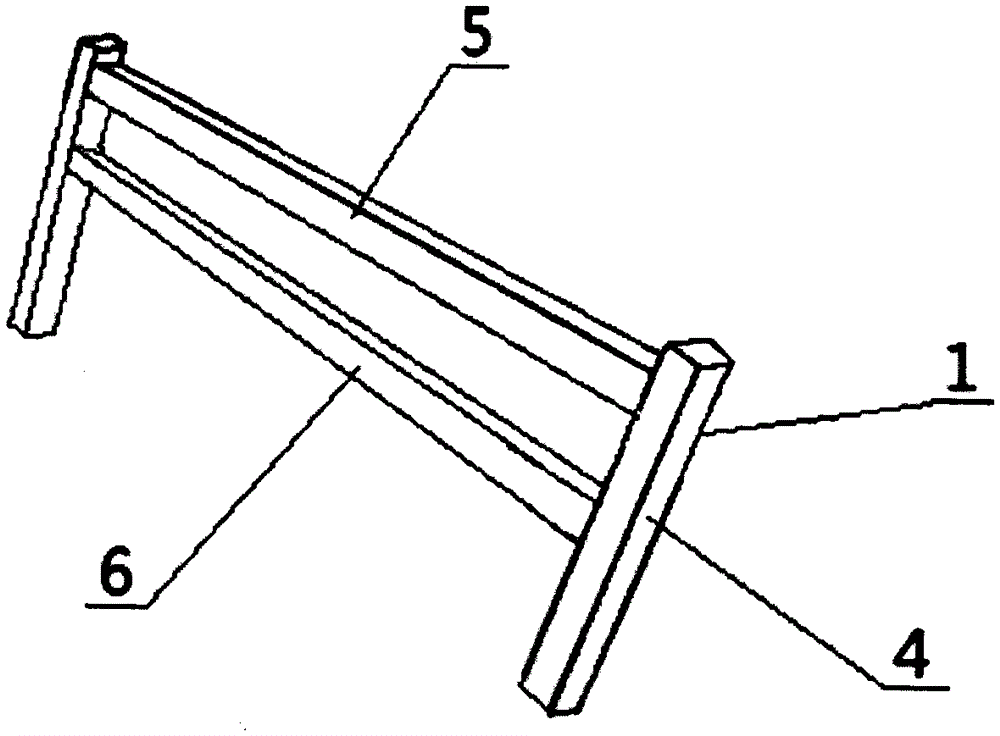

[0031] figure 2 Shown is a schematic structural view of the frame (1) in the present invention. The frame body (1) is made up of a frame foot (4), an upper fixed frame (5), and a lower fixed frame (6), and there are three frame bodies (1).

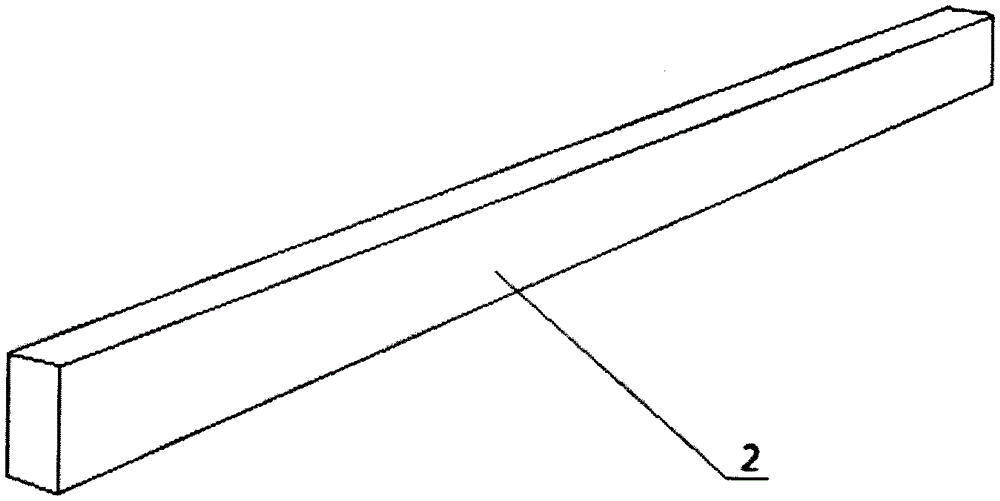

[0032] image 3 Shown is a structural schematic diagram of the plate limiting pipe frame (2) in the present invention. The plate limit pipe frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com