Two-way fine stamping die and two-way fine stamping part processing method

A technology of fine blanking and dies, which is applied in the field of two-way fine blanking dies and two-way fine blanking parts processing, can solve the problems of increasing processing procedures and process difficulties, increasing costs and quality risks, and burrs on the cross-section, so as to achieve convenient promotion and implementation, structure Simple, good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

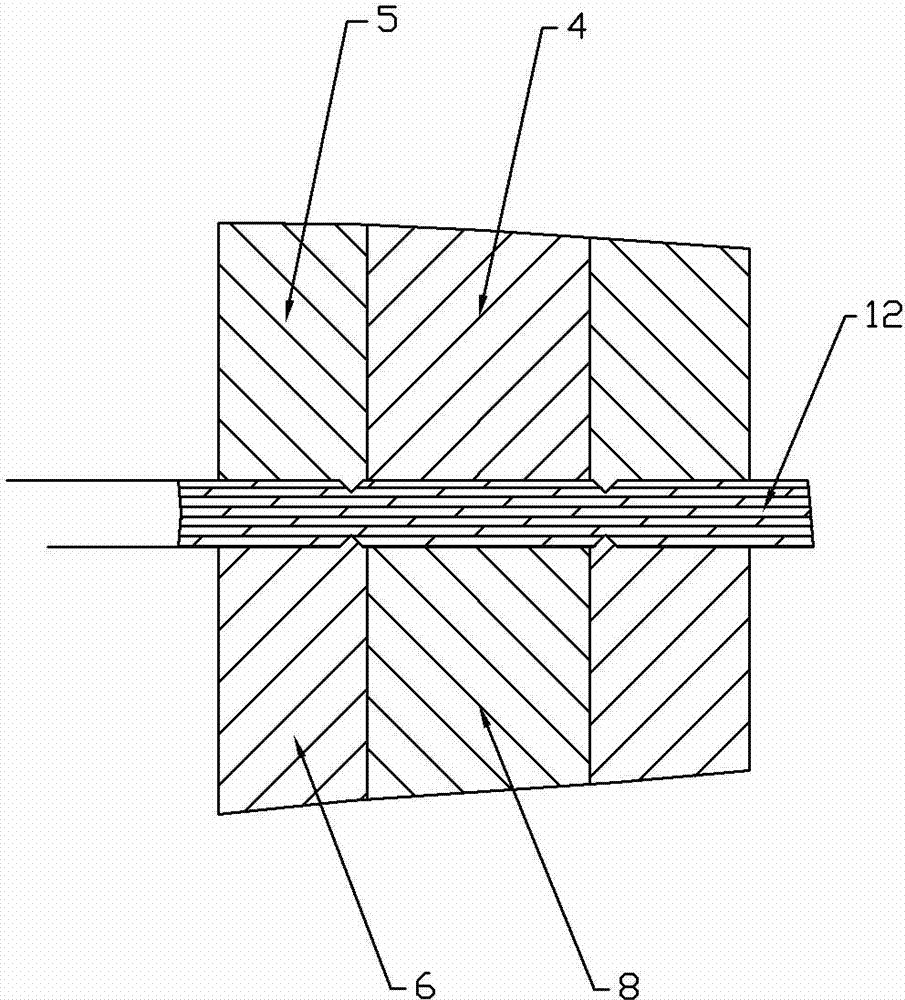

[0020] Embodiment one: see figure 1 , Figure 5 . The two-way fine blanking die of the present invention comprises a patrix and a lower die, and the upper and lower dies all adopt a structure in which the die includes a punch, the patrix includes an upper punch 4, an upper die 5, and the lower die includes a lower punch 8. The lower die 6; the upper die 4 is installed in the upper die cavity, the upper die is installed on the upper die base 3, the lower die 8 is installed in the lower die cavity, and the lower die 6 passes through the die The fixed plate 7 is fixed on the lower mold base 10, and the upper punch and the lower punch rely on the pressure transmitted by the fine blanking press to slide in the die. The upper die 5 is connected with the fine blanking press through the upper die ejector pin 2 .

Embodiment 2

[0021] Embodiment two: see figure 1 , Figure 5 . In the two-way fine-blanking die described in this embodiment, the upper punch 4 is connected to the fine-blanking press through the upper punch ejector 1; the lower punch 8 is connected to the fine-blanking press through the lower punch ejector 11, and the lower punch A top block 9 is arranged between the push rod 11 and the fine blanking press.

[0022] For the two-way fine blanking dies of the foregoing embodiments, ring gears are provided on the stamping end faces of the upper die and the lower die.

Embodiment 3

[0023] Embodiment three: see Figure 1 ~ Figure 4 , Figure 5 . This embodiment is a two-way fine-blanking part processing method using the aforementioned two-way fine-blanking die. The process of blanking the material to complete the part production is as follows:

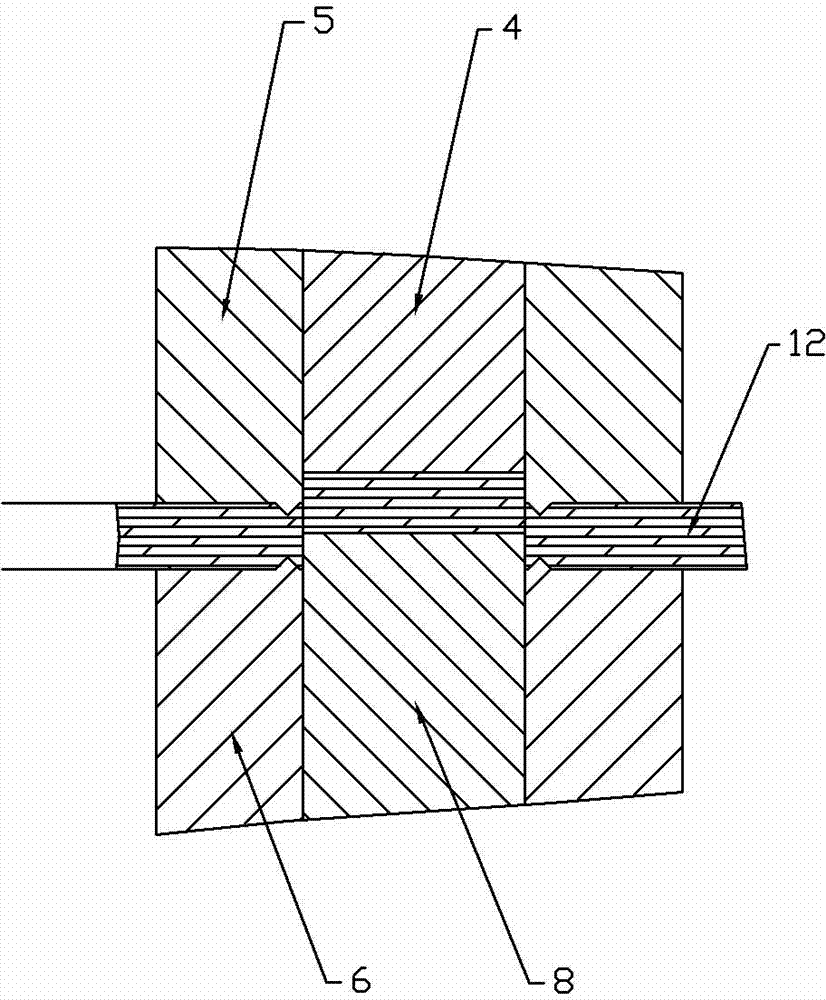

[0024] The first step: the lower die goes up, and the upper die, the lower die, the upper punch and the lower punch with the ring gear compress the material;

[0025] Step 2: When the material is in a compacted state, the fine blanking press acts on the lower punch through the ejector pin of the lower punch,

[0026] The lower punch continues to go up to 1 / 3~1 / 2 thickness of the material;

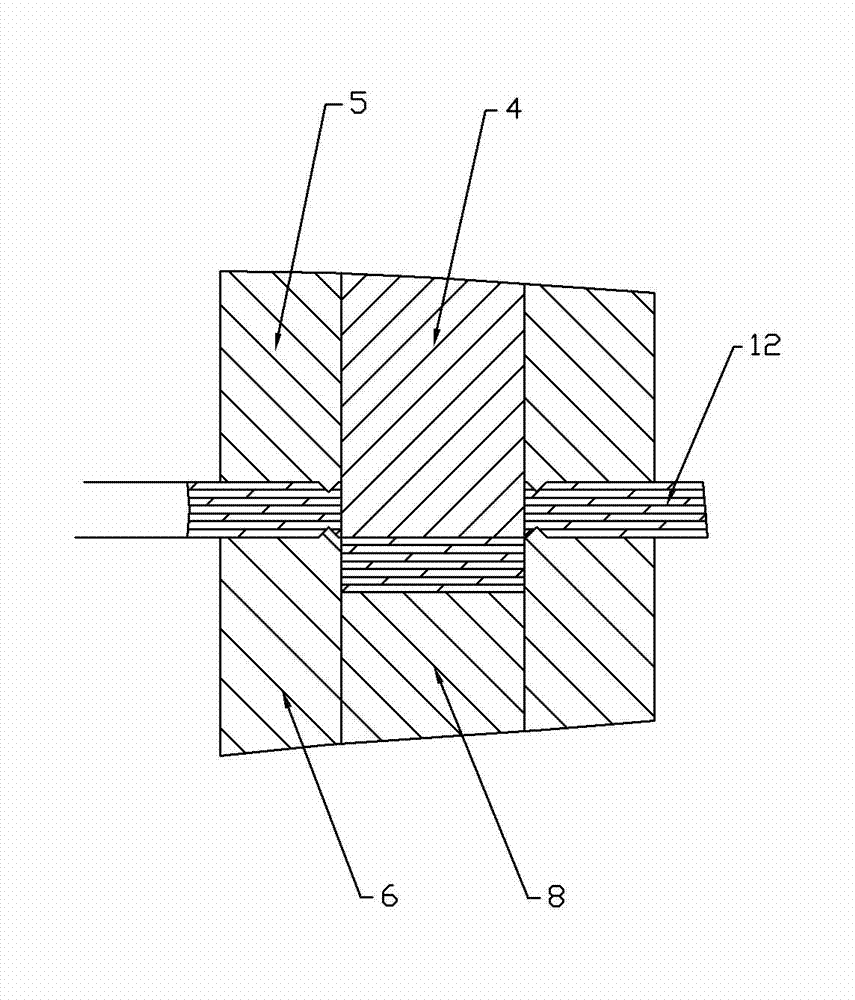

[0027] Step 3: The fine blanking press acts on the upper punch through the ejector pin of the upper punch, and the upper punch goes down, and the material is punched under the action of the pressing force, blanking force and counter pressure until the material is separated, realizing two Second blanking, complete two-way fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com