Die-casting die and interior drawing sliding block device and die casting method thereof

A technology for die-casting molds and sliders, which is applied in the field of die-casting molds, the die-casting of the above-mentioned die-casting molds, and the field of inner-drawing slider devices, which can solve problems such as excessive assembly gaps, affecting product appearance, and poor production environments for die-casting processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

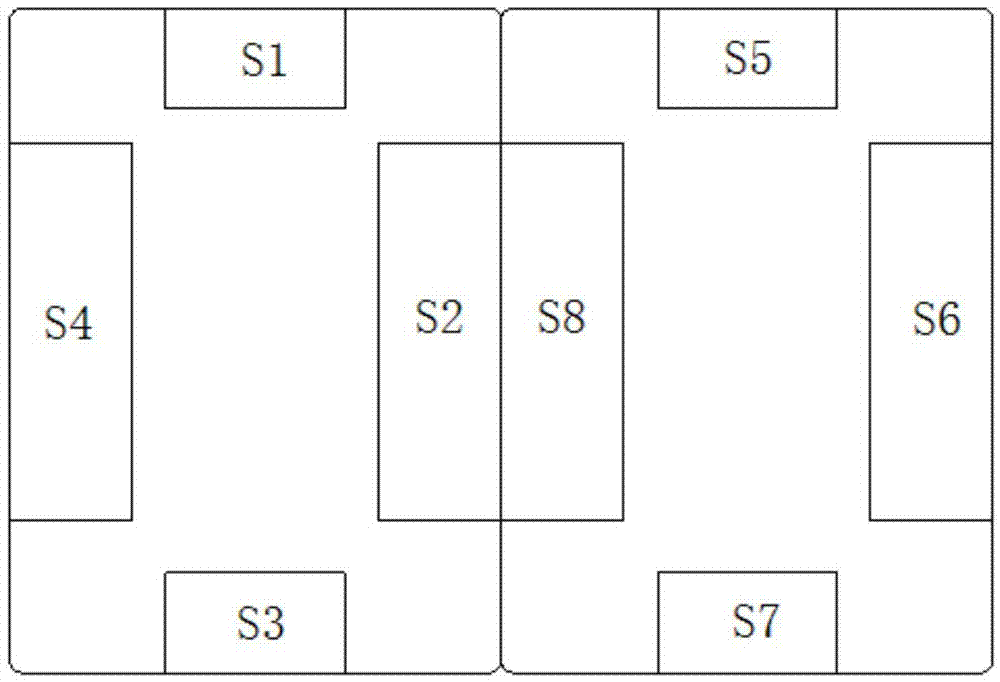

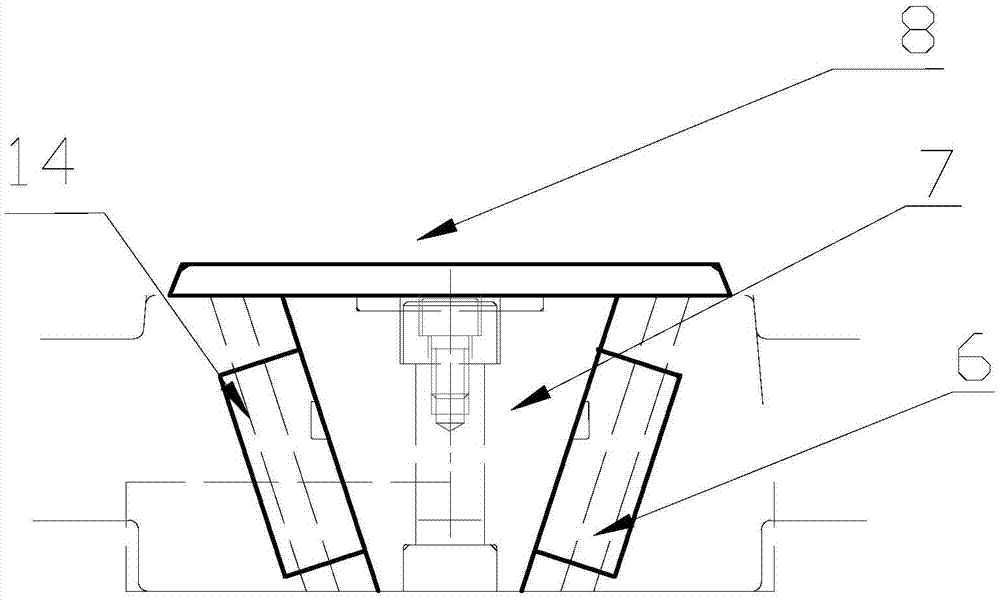

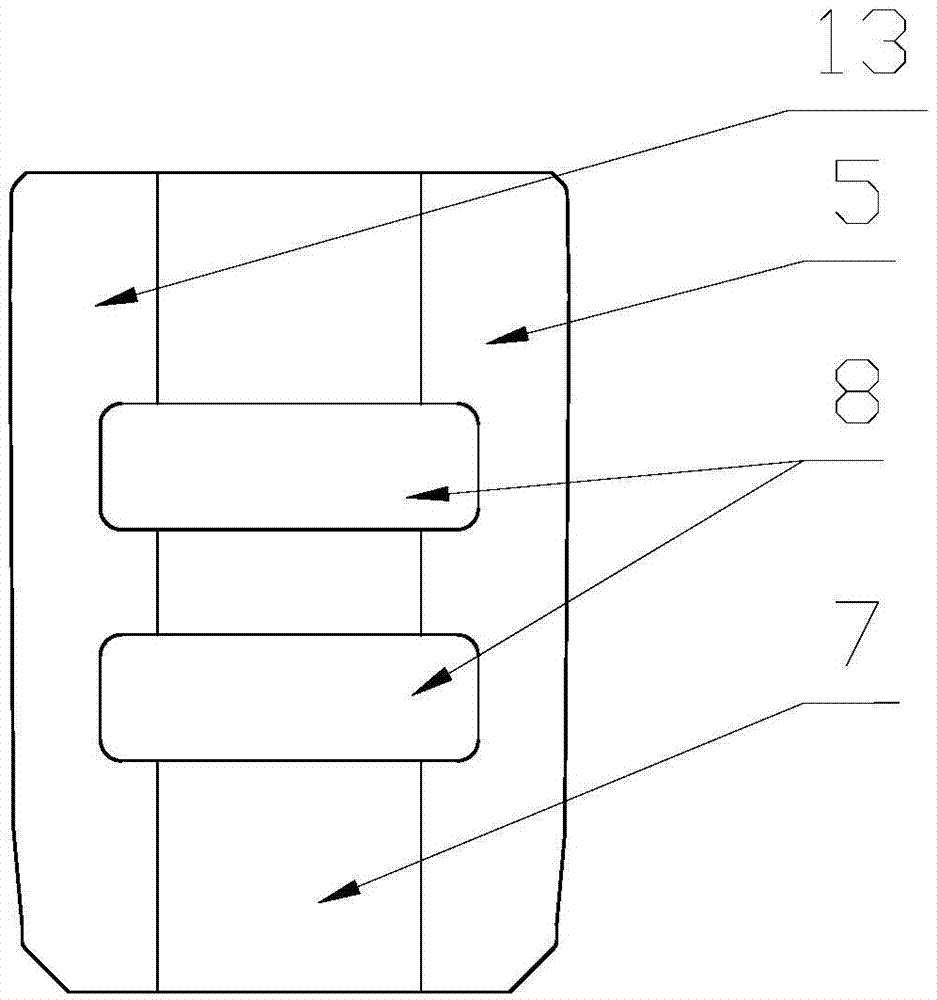

[0069] see figure 2 , image 3 , the invention discloses a die-casting mold and an inner drawing slider device thereof. The inner sliding block device includes a wedge-shaped part 7 , a first dovetail groove slide rail part 6 , a second dovetail groove slide rail part 14 , a first slide block 5 and a second slide block 13 .

[0070] Wherein, the side of the first dovetail groove slide rail part 6 and the second dovetail groove slide rail part 14 away from the slide rail is fastened to the wedge part 7 by bolts, and the side with the slide rail is slidably connected to the first dovetail groove slide rail part 14 respectively. The "I"-shaped slide table on the slide block 5 and the second slide block 13 is connected so that the slide block and the dovetail groove slide rail parts can slide relative to each other without breaking away from each other. Arranged so that when the wedge-shaped member is displaced in the longitudinal direction, the first dovetail slide rail member...

Embodiment 2

[0083] The invention discloses an inner drawing slider device of a die-casting mold, and the slider device includes: a pressing part, at least two follower parts and at least two sliding mechanisms; the sliding mechanisms are respectively connected by the follower parts to the pressing member; the follower can convert the displacement of the pressing member in the first direction to the displacement of the sliding mechanism in the second direction. The first direction and the second direction may be perpendicular (of course, a predetermined included angle may also be formed).

[0084] The present invention also discloses a die-casting mold. The die-casting mold includes the above-mentioned inner drawing slider device, a driving mechanism, a mold core group, and a mold frame; the inner drawing slider device is arranged in the mold core group, and the driving mechanism is connected to the inner drawing block device.

[0085] The die-casting method of the above-mentioned die-cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com