Multi-probiotic solid beverage and preparation method thereof

A technology of solid beverages and probiotics, applied in the direction of bacteria, lactobacilli, bifidobacteria, etc. used in food preparation, can solve the problems of single strains, lower intestinal fixed rate and survival rate of probiotics, and low number of viable bacteria And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

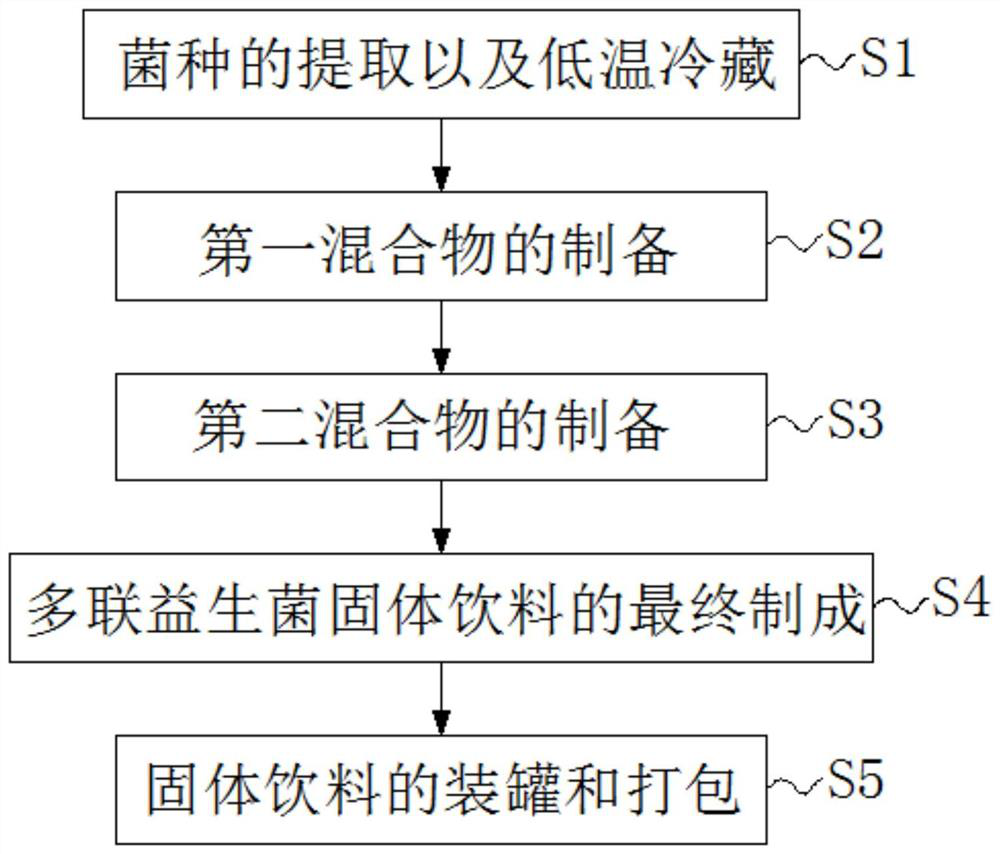

[0028] S1. Extraction of strains and low-temperature storage: select 12 parts of Lactobacillus casei, 10 parts of Lactobacillus acidophilus, 15 parts of Lactobacillus rhamnosus and 10 parts of single strains of Bifidobacterium longum frozen in glycerol tubes, and purify Afterwards, expand cultivation, high-density culture in the fermenter and centrifugation to obtain strains, place the strains in the refrigerator for low-temperature refrigeration, and then dry them to 18°C in a sterile environment, waiting for standby;

[0029] S2. Preparation of the first mixture: 15 parts of water-soluble dietary fiber, 2 parts of flavor enhancer, 10 parts of fructooligosaccharide and 8 parts of stachyose were stirred with a mixer for 15 minutes. After mixing evenly, filter through a 60-mesh sieve. and drying in an oven until the moisture content drops to 0.15% to obtain the first mixture, waiting for use;

[0030] S3. Preparation of the second mixture: 20 parts of skimmed milk powder and ...

Embodiment 2

[0034] S1. Extraction of strains and low-temperature storage: 13 parts of Lactobacillus casei, 11 parts of Lactobacillus acidophilus, 16 parts of Lactobacillus rhamnosus and 11 parts of Bifidobacterium longum were selected and purified respectively. Afterwards, expand cultivation, high-density culture in the fermenter and centrifugation to obtain strains, place the strains in the refrigerator for low-temperature refrigeration, and then dry them to 20°C in a sterile environment, waiting for standby;

[0035] S2, preparation of the first mixture: 18 parts of water-soluble dietary fiber, 3 parts of flavor enhancers, 12 parts of fructooligosaccharides and stachyose were stirred with a mixer for 18 minutes, after mixing evenly, filtered through a 70-mesh sieve, and Drying in an oven until the moisture drops to 0.18% to obtain the first mixture, waiting for standby;

[0036] S3. Preparation of the second mixture: 22 parts of skimmed milk powder and 11 parts of soybean protein powder...

Embodiment 3

[0040] S1. Extraction of strains and low-temperature storage: 14 parts of Lactobacillus casei, 12 parts of Lactobacillus acidophilus, 17 parts of Lactobacillus rhamnosus and 12 parts of Bifidobacterium longum were selected and purified respectively. Afterwards, expand cultivation, high-density culture in the fermenter and centrifugation to obtain strains, place the strains in the refrigerator for low-temperature refrigeration, and then dry them to 21°C in a sterile environment, waiting for standby;

[0041] S2. Preparation of the first mixture: 20 parts of water-soluble dietary fiber, 4 parts of flavor enhancer, 15 parts of fructooligosaccharide and 10 parts of stachyose were stirred with a mixer for 20 minutes, and after being mixed evenly, filtered through an 80-mesh sieve, and drying in an oven until the moisture content drops to 0.2% to obtain the first mixture, waiting for use;

[0042] S3. Preparation of the second mixture: 25 parts of skimmed milk powder and 12 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com