High-performance graphene concrete and preparation method thereof

A graphene and concrete technology, applied in the field of materials, can solve the problems of limited improvement of mechanical properties and frost resistance, compatibility affects material stability and durability, and research and industrial production need to be further deepened to achieve production technology Low requirements, inhibit crack formation and growth, and ensure the effect of large-scale projects and infrastructure construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

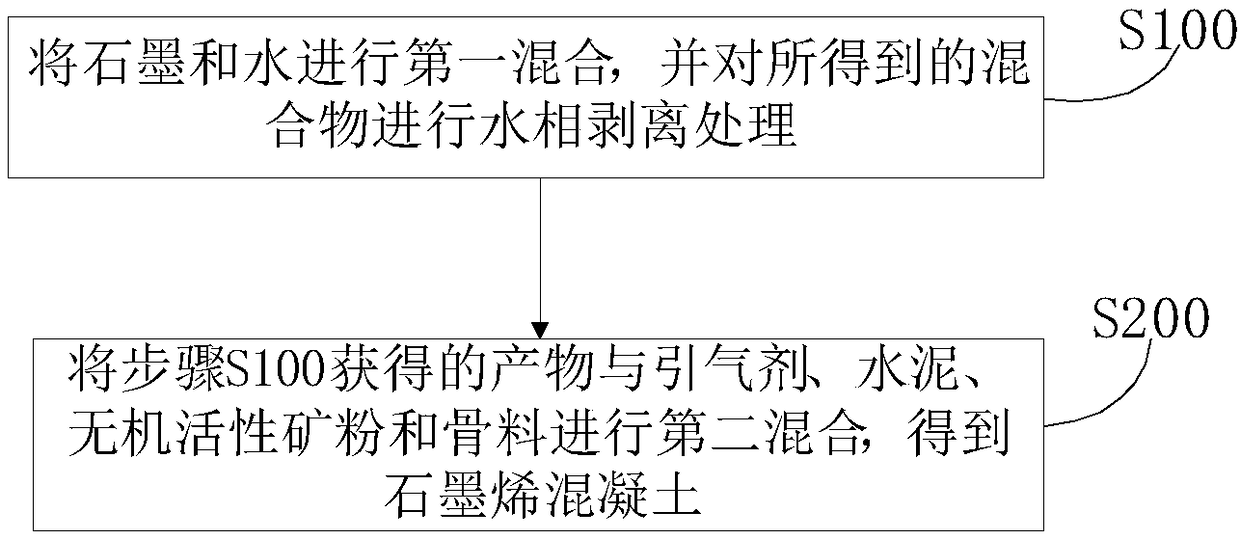

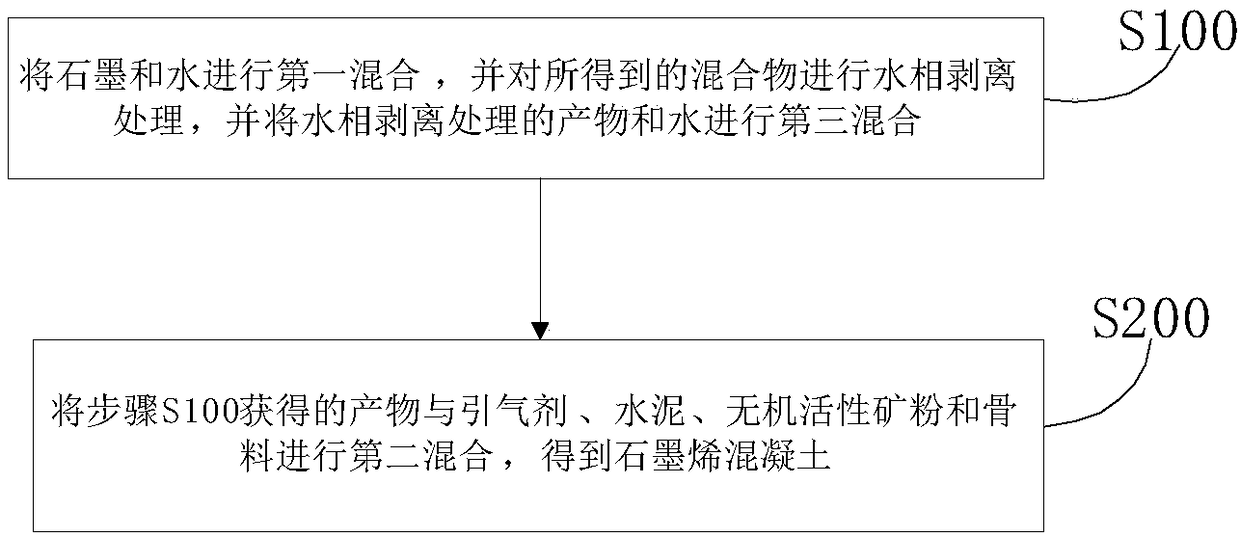

[0055] The steps of preparing graphene concrete include:

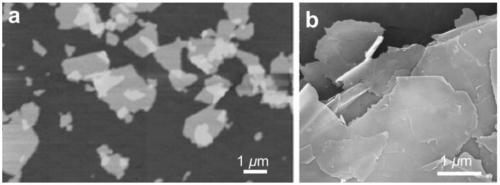

[0056] 1. Preparation of graphene dispersion liquid: using expanded graphite (fixed carbon content 99% and maximum radial dimension 84 radial) produced by Aoyu Group as raw material, after ultrasonic stirring in hot water at 60°C for 2 hours, through high pressure The homogenizer was mixed and dispersed for 30 minutes, then ground and peeled off by a pin-type sand mill for 4 hours (the grinding medium was a zirconia bead of 0.8mm to 1.0mm), to obtain a graphene content of 10wt% graphene dispersion, wherein graphite Microstructural characterization of graphene in olefin dispersion figure 1 ;

[0057] 2, the preparation of graphene concrete: according to the formula shown in table 1, get 4 mass parts of graphene dispersion liquid and stir in 40.4 mass parts water (that is, the total mass parts of water is 44), add MICRO-AIR company while stirring 0.01 parts by mass of 202 concrete air-entraining agent produced, 60 part...

Embodiment 2

[0059] Same as the step of preparing graphene concrete in embodiment 1, difference is: the addition of graphene dispersion liquid and water is respectively 20 and 26 mass parts, to guarantee the consistency of water and cement ratio (44:60), graphene is in graphite The content of ethylene concrete is 0.68%.

Embodiment 3

[0061] Same as the step of preparing graphene concrete in embodiment 1, difference is: the content of graphene in the graphene dispersion liquid is 20wt%; In step 2, the mass parts of graphene dispersion liquid and water are respectively 20 mass parts and 28 Parts by mass, to ensure that the water and cement ratio (44:60) are consistent, the content of graphene in graphene concrete is 1.35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com