Laser impact tiny bulk forming method and apparatus for tiny apparatus

A laser shock, micro-volume technology, used in laser welding equipment, welding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

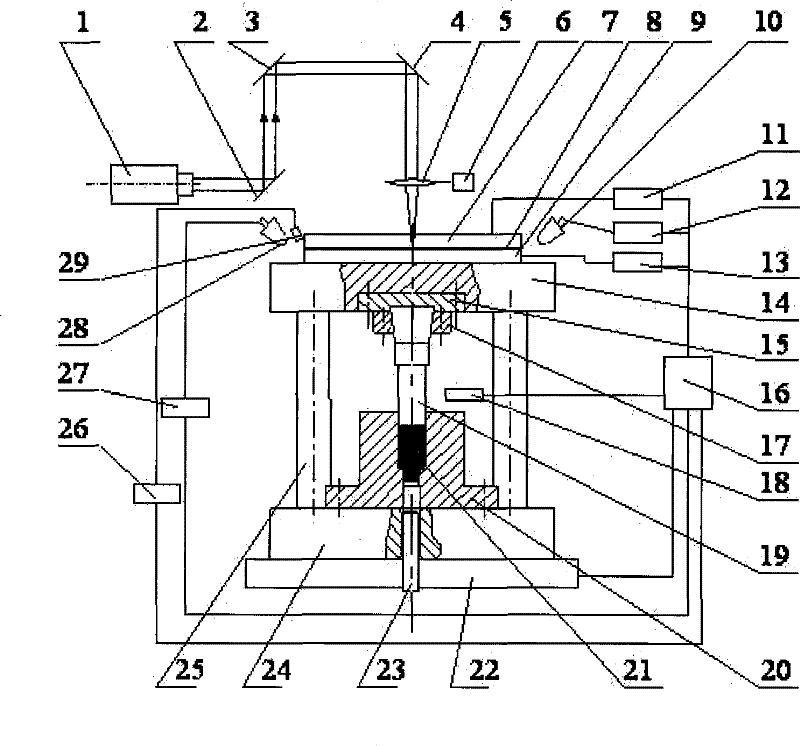

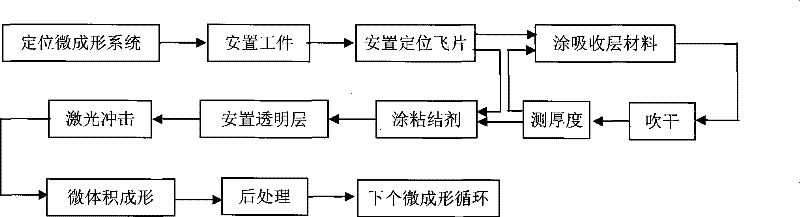

[0043] Combine figure 1 , figure 2 with Figure 4 The laser shock micro-volume forming method of micro devices is as follows:

[0044] According to the shape, size and precision of the micro-devices that need to be micro-formed, the punch 19 and the concave mold 20 are designed and processed. The backing plate 15 is installed in the upper mold base 14, and then the punch 34 is placed on the upper mold base 14. In the mold base 14, the concave mold 20 is placed on the lower mold base 24, and the lower mold base 24 is placed on the workbench 22. The guide mechanism is respectively connected with the upper mold base 14 and the lower mold base 24; the computer 16 is used to control the workbench 22 X, Y, and Z-direction movement, adjust the relative position of the male mold 19 and the female mold 20 and the centering of the male mold 19 and the female mold 20 in the micro plastic forming system, if the male mold 19 and the female mold 20 have passed a period of time After forming, ...

specific Embodiment approach 2

[0045] Combine figure 1 , figure 2 , Figure 4 , Figure 5 with Image 6 The laser shock micro-volume forming method of micro devices is as follows:

[0046] According to the shape, size and precision of the micro-devices to be micro-shaped, the convex mold 34 and the concave mold 36 with the periodic repeating array structure are designed and processed. The convex mold 34 is distributed with the convex mold array 37 of the repeated structure and the concave mold 36 Distributed with an array of concave mold cavities 35 in the form of repeated structures, install the micro-forming system according to the first embodiment; use the computer 16 to control the movement of the worktable 22 in X, Y and Z directions, and adjust the male mold 34 and the female mold 36 in the micro-plastic forming system The relative position of the male mold 34 and the female mold 36, if the male mold 34 and the female mold 36 are formed after a period of time due to the wear of the mold, they need to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com