Patents

Literature

95results about How to "Solve the long loading time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

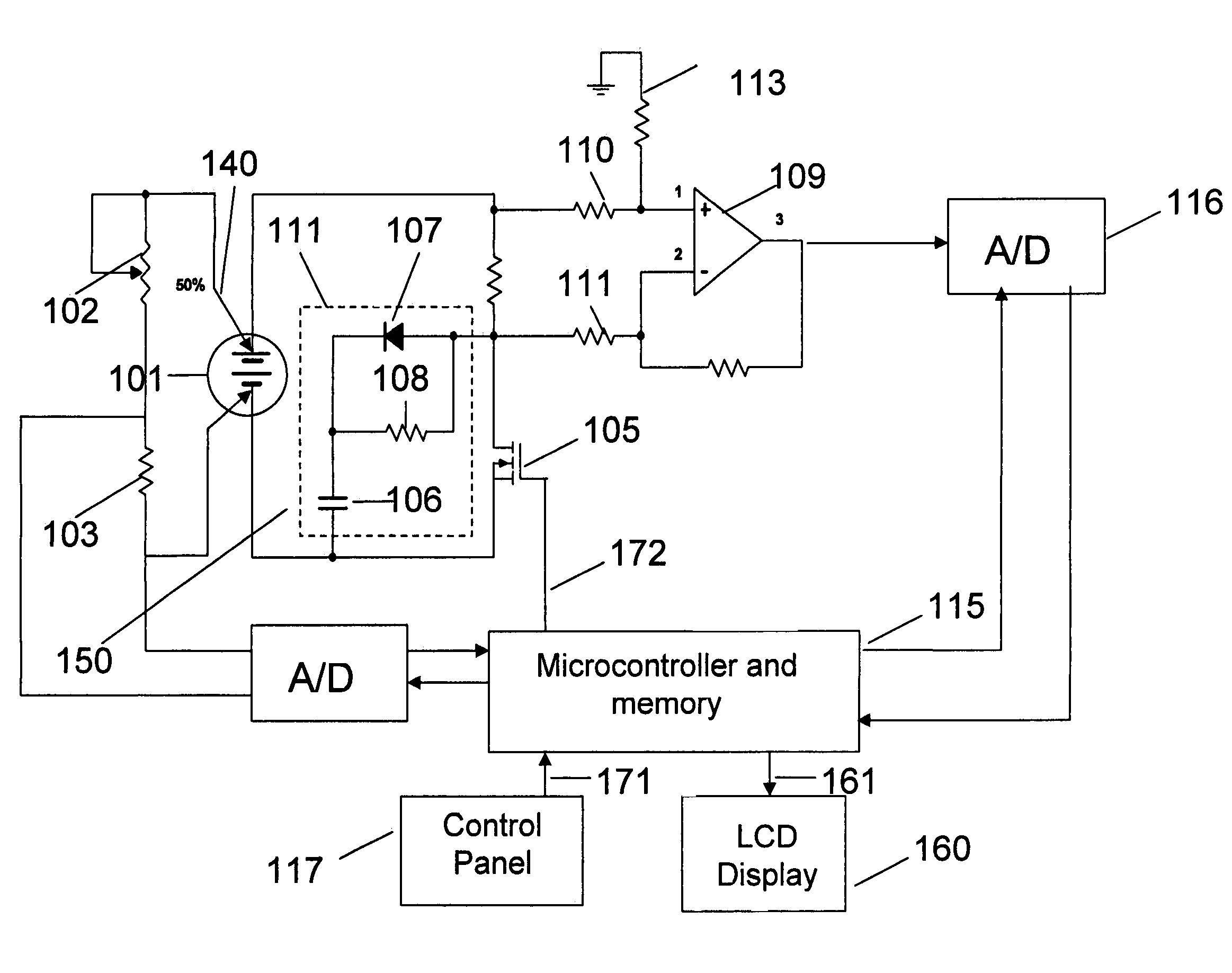

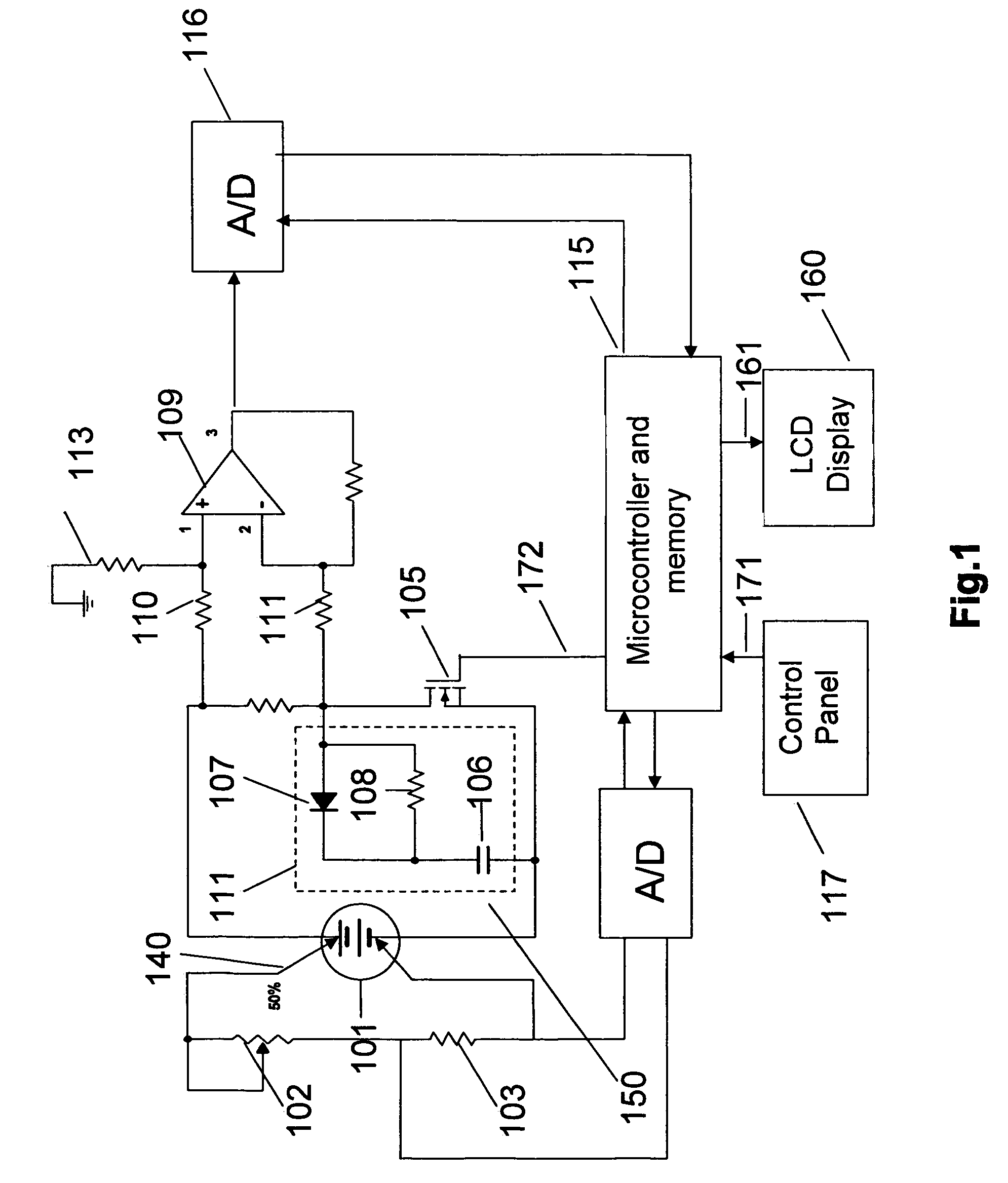

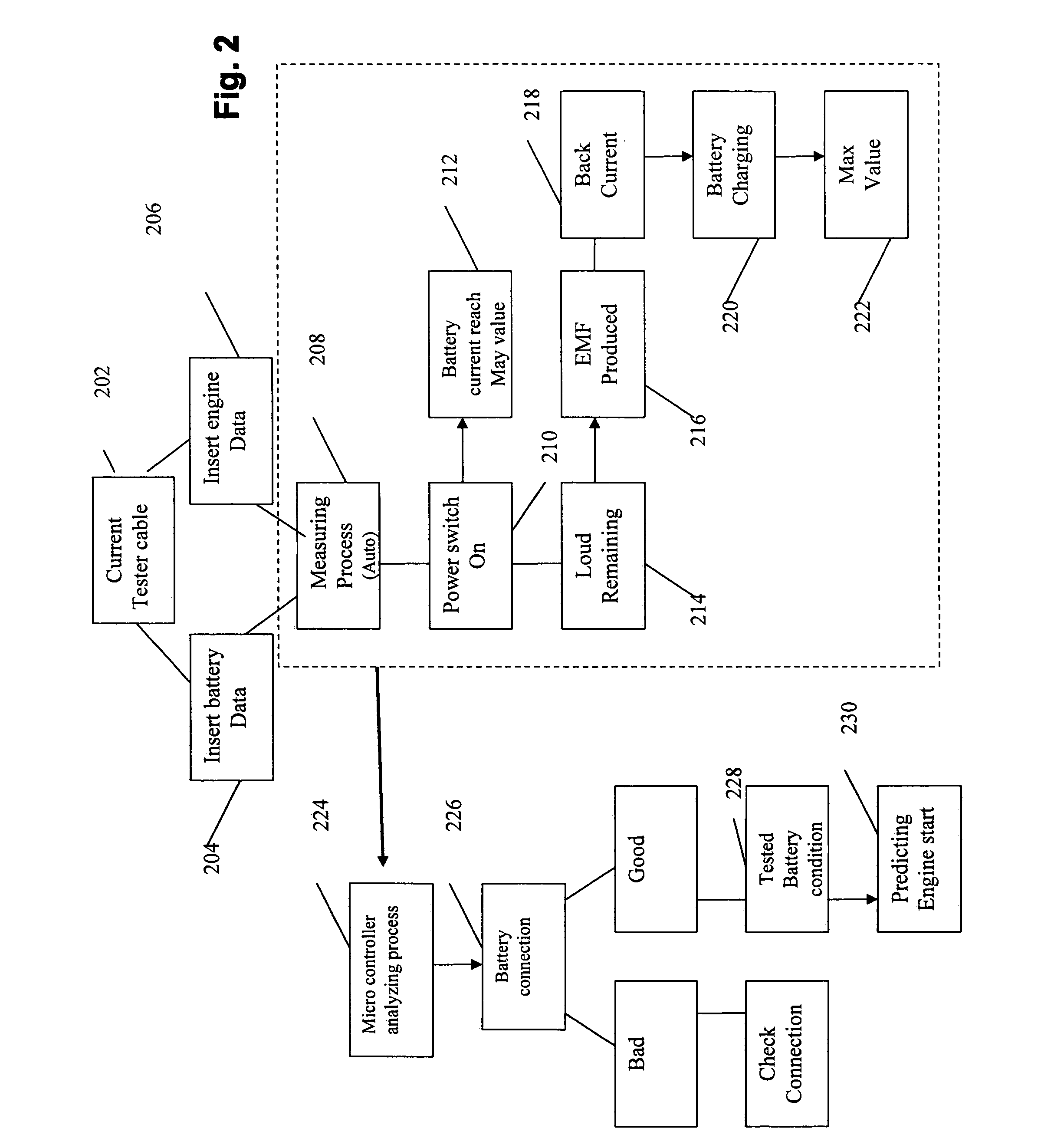

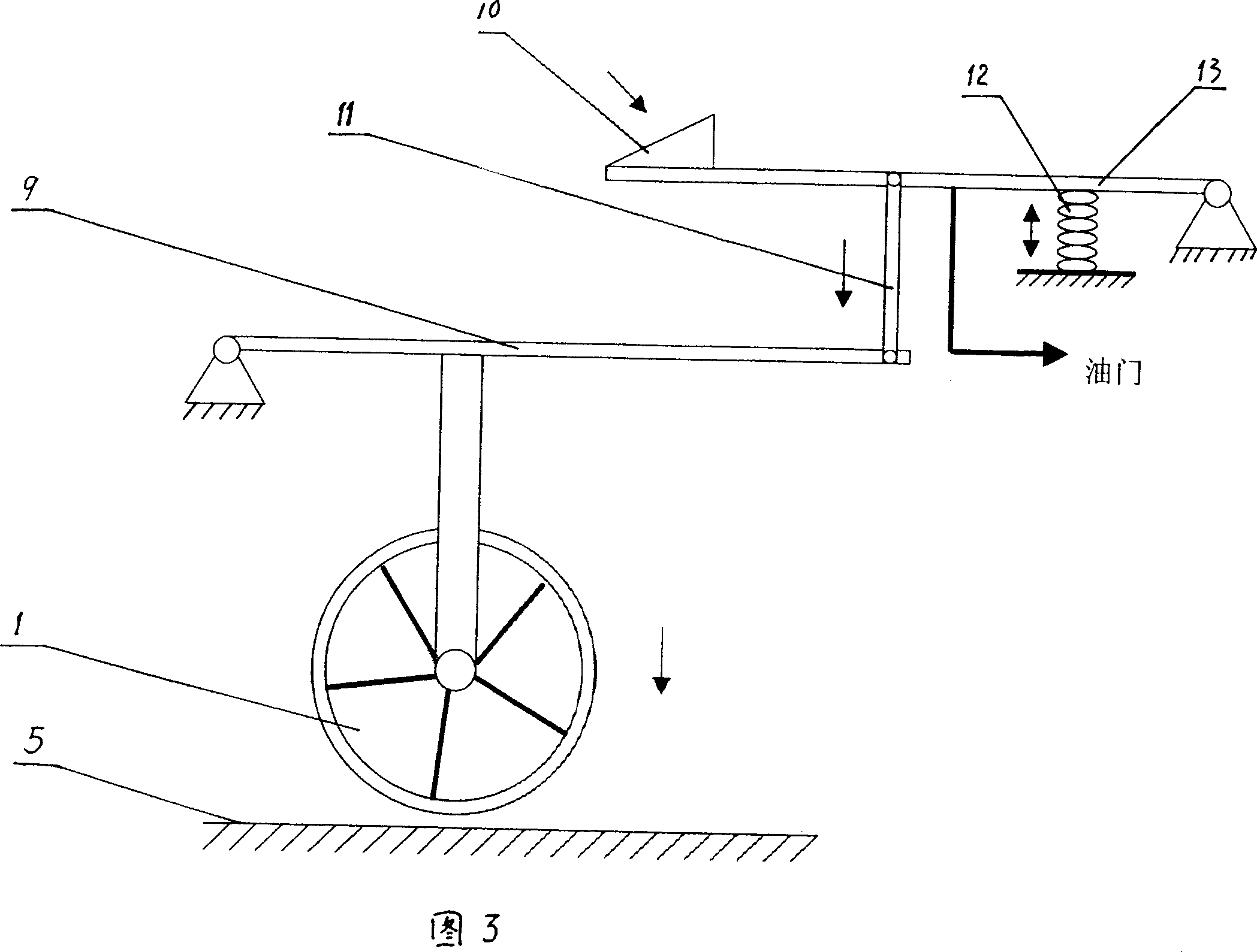

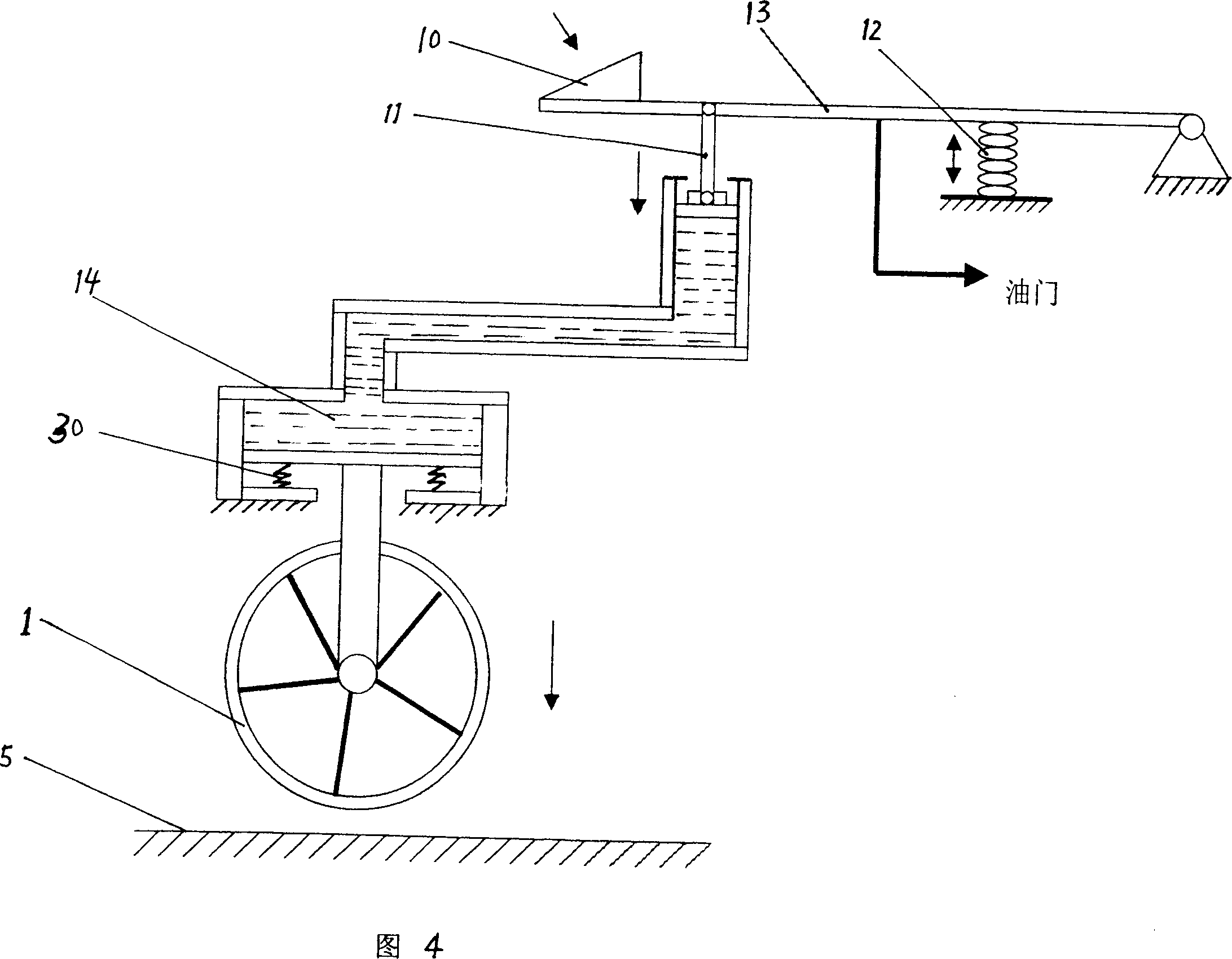

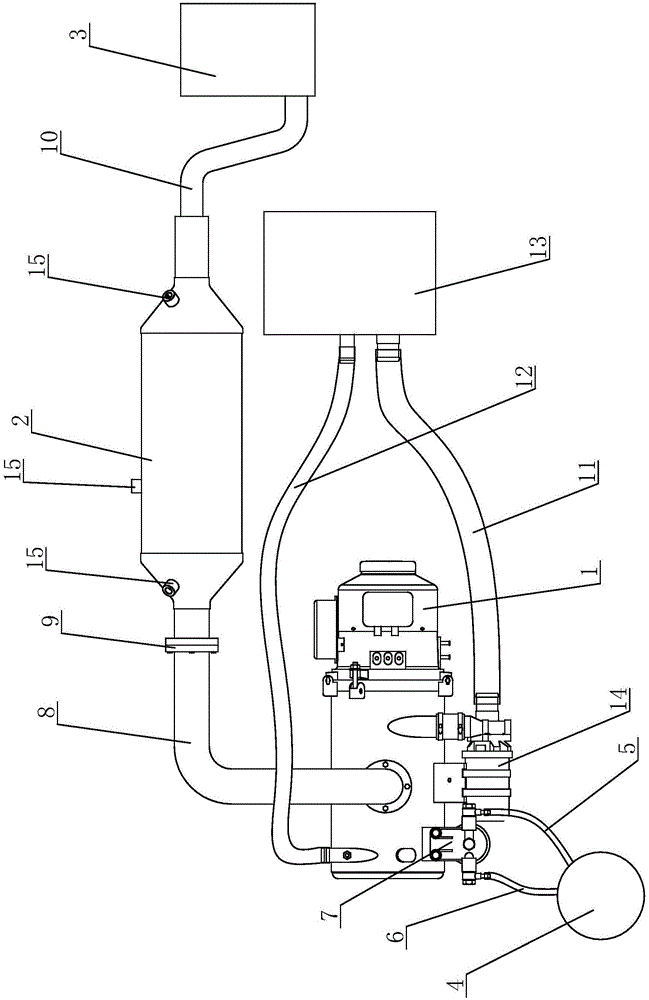

[method and apparatus for battery testing and measuring]

InactiveUS20050134282A1Minimize high voltage pickShorten the battery polesMaterial analysis by electric/magnetic meansElectrical testingEngineeringTest set

According to this invention a battery testing device is provided. Such device activates a shortening between the battery poles using a predefined electronic circuit (in order to maximize the battery's energy potential) for a time period of 10-50 μsec. In a subsequent time period of 100-200 μsec, the loading is slowly decreased until the voltage returns to an open circuit voltage UOC. During the testing process, the voltage and the battery current are measured. The measurements are stored at the device database, to be later used in an algorithm for checking battery conditions.

Owner:BATTERY CONTROL CORP

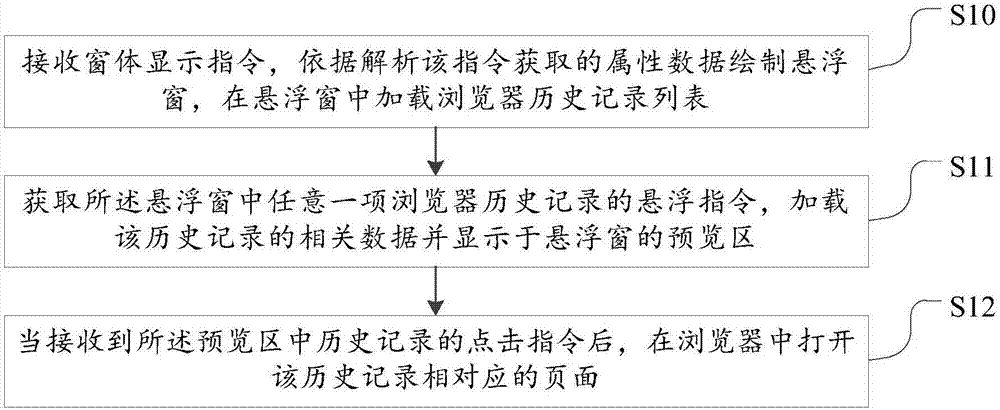

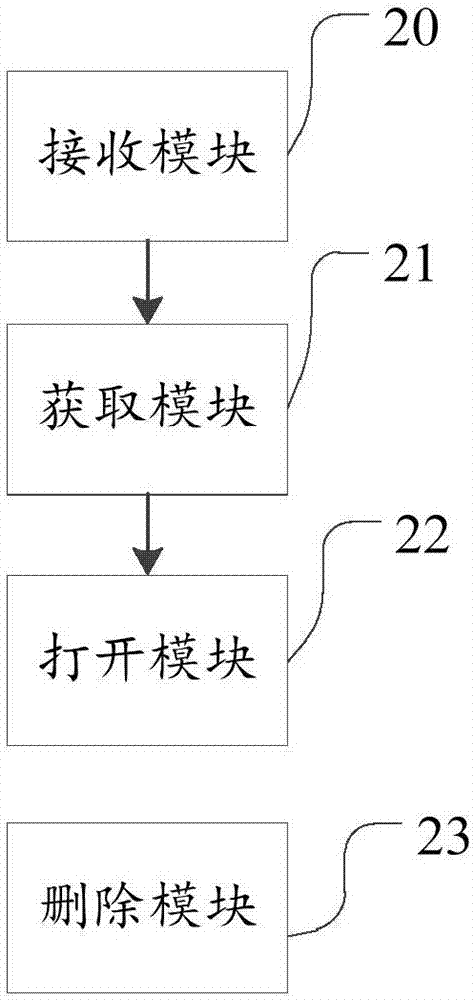

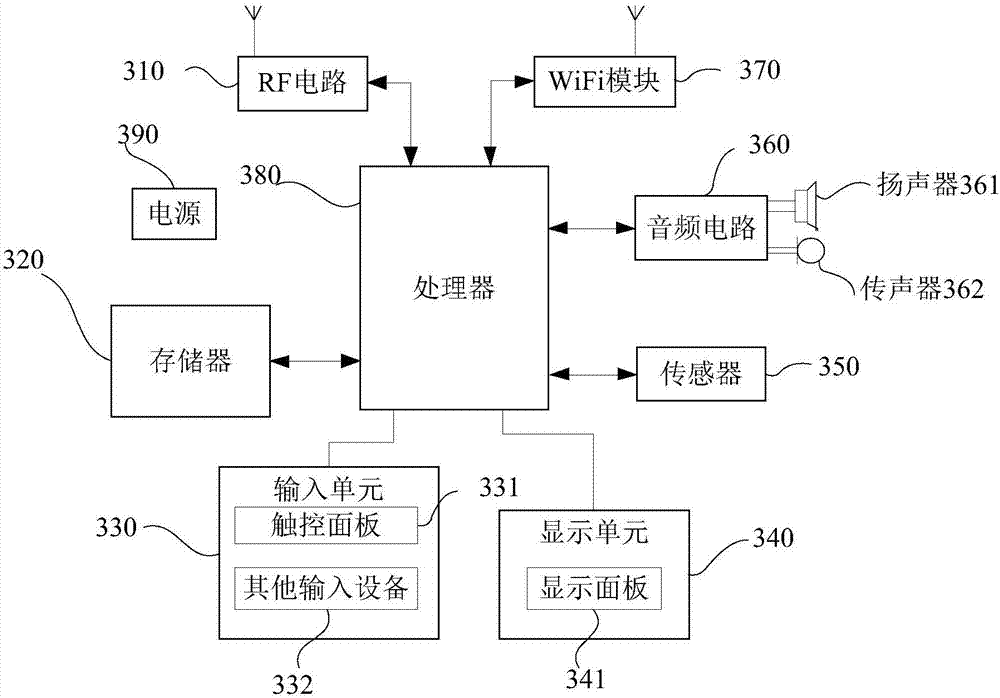

Method and terminal for viewing historical records of browser

ActiveCN106874390AEasy to openSolve the long loading timeWeb data indexingSpecial data processing applicationsOperating systemHistorical record

The invention discloses a method and a terminal for viewing historical records of a browser. The method comprises the following steps of receiving a window body display instruction, drawing a floating window according to attribute data obtained by analyzing the instruction and loading a historical record list of the browser to the floating window; obtaining a suspension instruction of any historical record of the browser in the floating window, loading related data of the historical record and displaying a preview area of the floating window; after receiving a click instruction of the historical record in the preview area, opening the page corresponding to the historical record in the browser. Through the method, the target of quickly and accurately viewing the historical records of the browser is achieved.

Owner:BEIJING ANYUNSHIJI TECH CO LTD

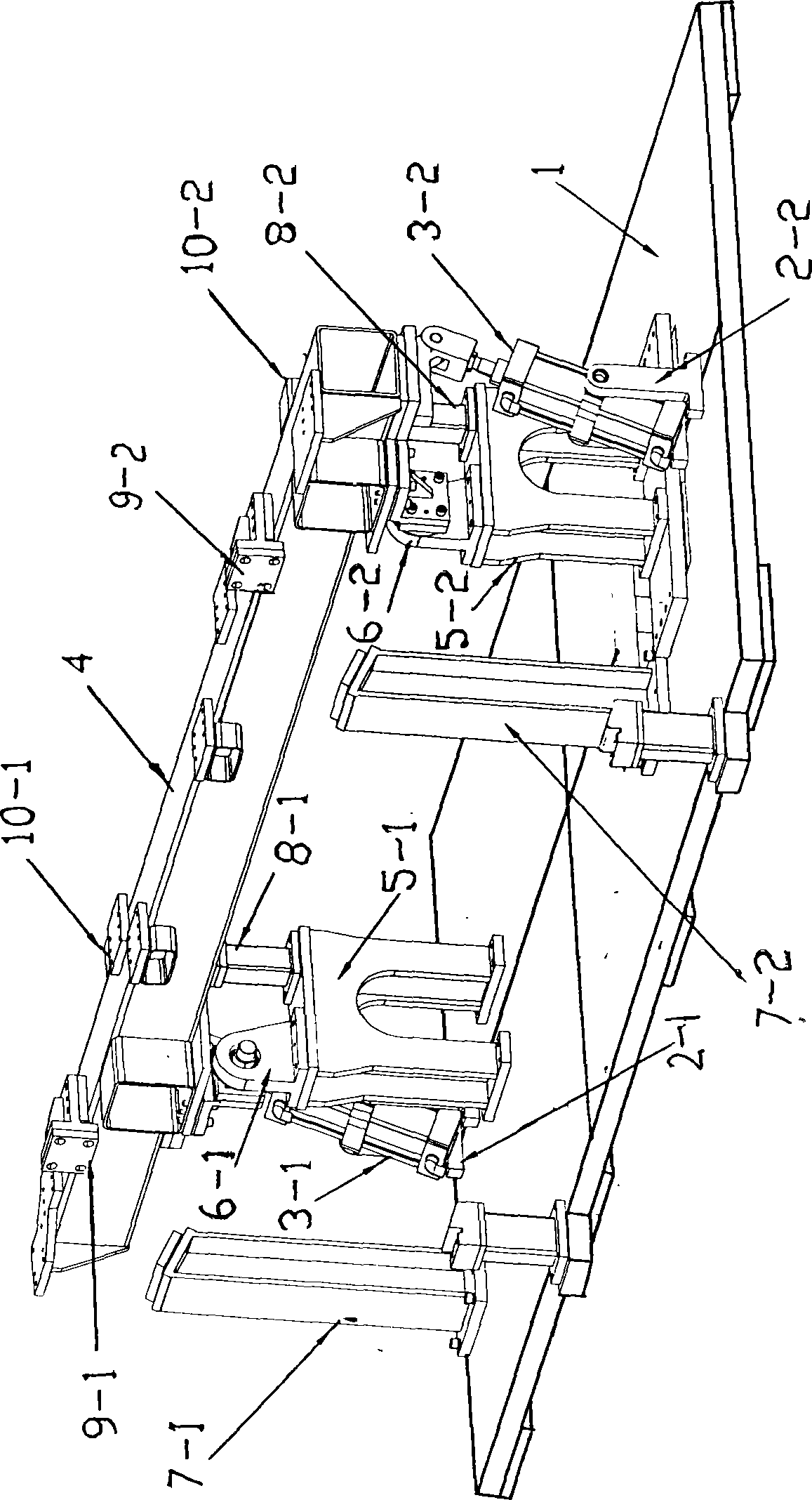

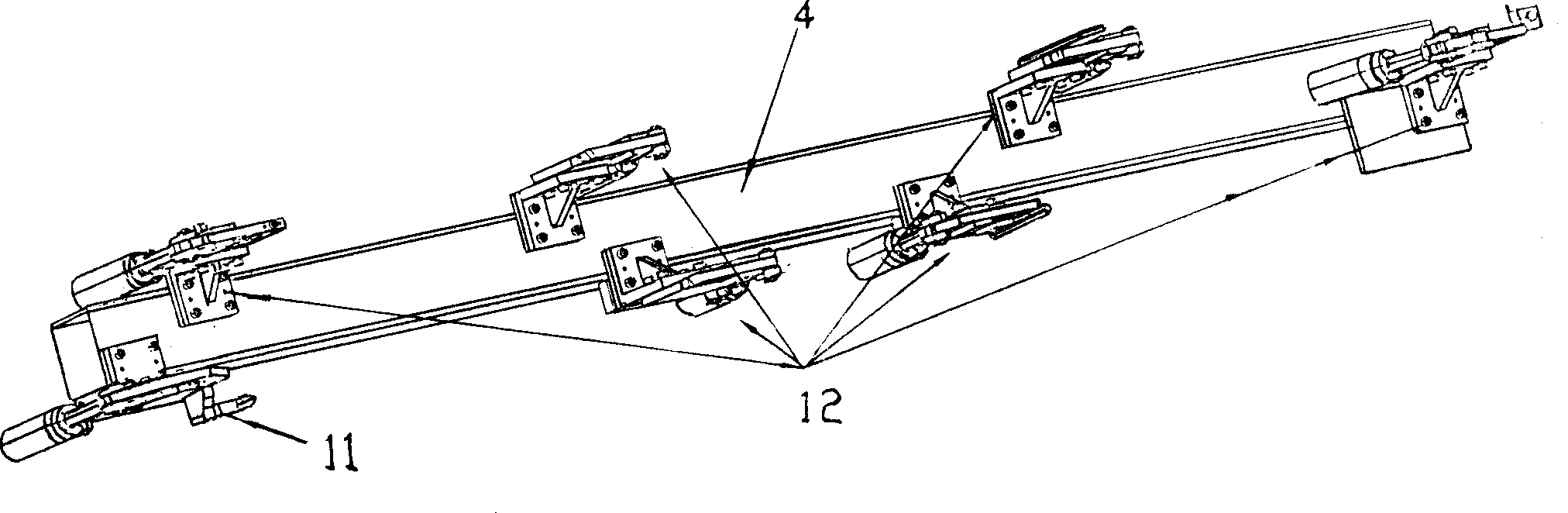

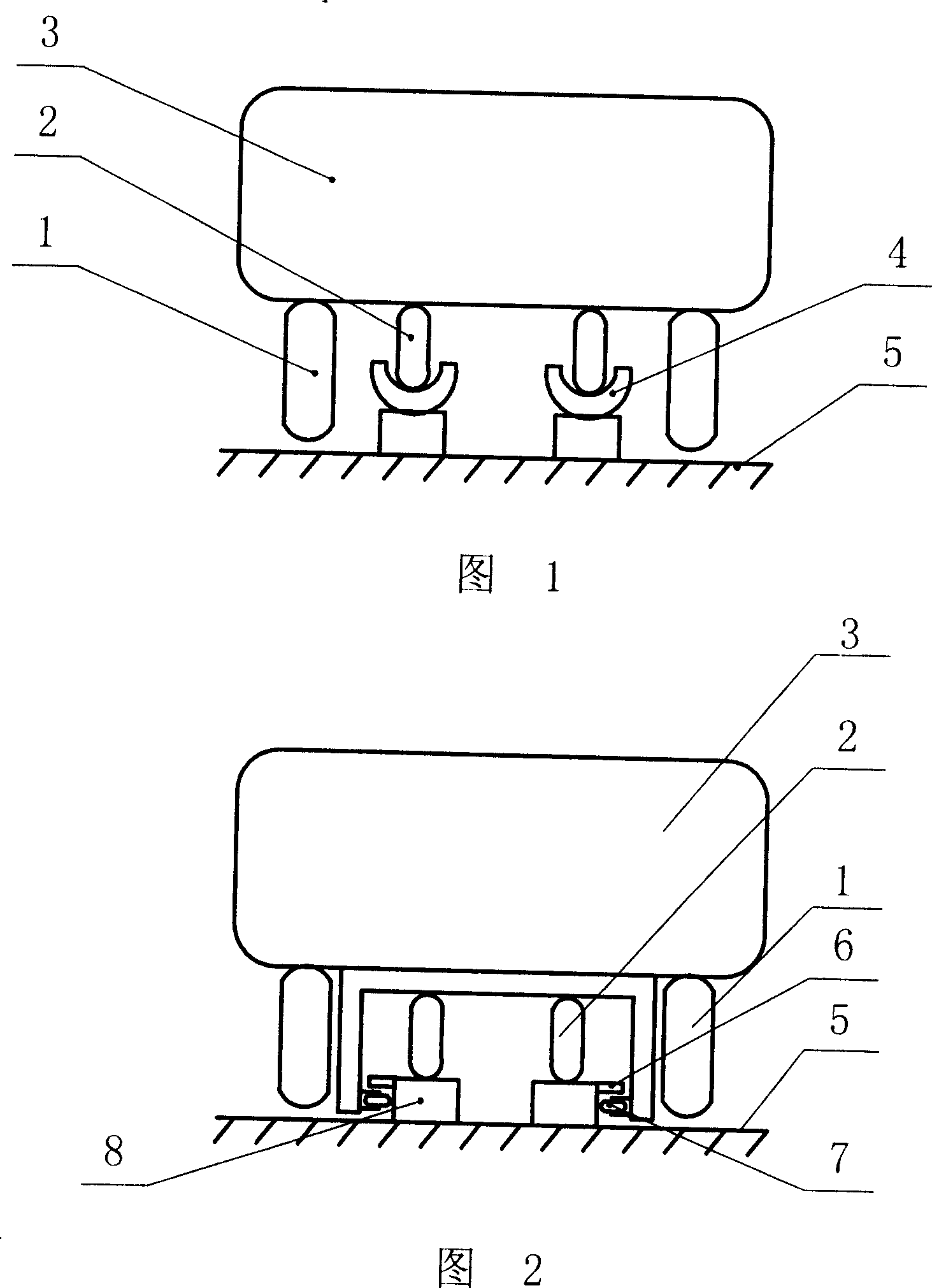

Turnover mechanism for installing vehicle side around external covering

InactiveCN101474731AMeet the needs of the beatAvoid safety hazardsWelding/cutting auxillary devicesAuxillary welding devicesManufacturing lineCoating

The invention relates to a turnover mechanism for installing the external coating of the side wall of a motorcar, comprising a base plate, a first main body supporting seat, a second main body supporting seat, a first turnover bearing, a second turnover bearing, a first low limited post, a second low limited post, a first high limited post, a second high limited post, a first air cylinder seat, a second air cylinder seat, a first air cylinder and a second air cylinder, wherein the first main body supporting seat and the second main body supporting seat are arranged on the base plate, the first turnover bearing and the second turnover bearing are respectively arranged on the left sides of the first main body supporting seat and the second main body supporting seat, the first low limited post and the second low limited post are respectively arranged on the right sides of the tops of the first main body supporting seat and the second main body supporting seat, the first high limited post and the second high limited post are respectively arranged on the base plate and are positioned on the left sides of the first main body supporting seat and the second main body supporting seat, and the first air cylinder seat and the second air cylinder seat are respectively arranged on the base plate. The turnover mechanism is characterized in that the front part and the rear part of a turnover body are respectively connected with the first turnover bearing and the second turnover bearing; and the first air cylinder and the second air cylinder are connected with the turnover body. The turnover mechanism has the advantages that single-side manual external coating installation is realized, the safety is ensured, the quality of external coating installation is improved, and the requirement of the production line rhythm is satisfied.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

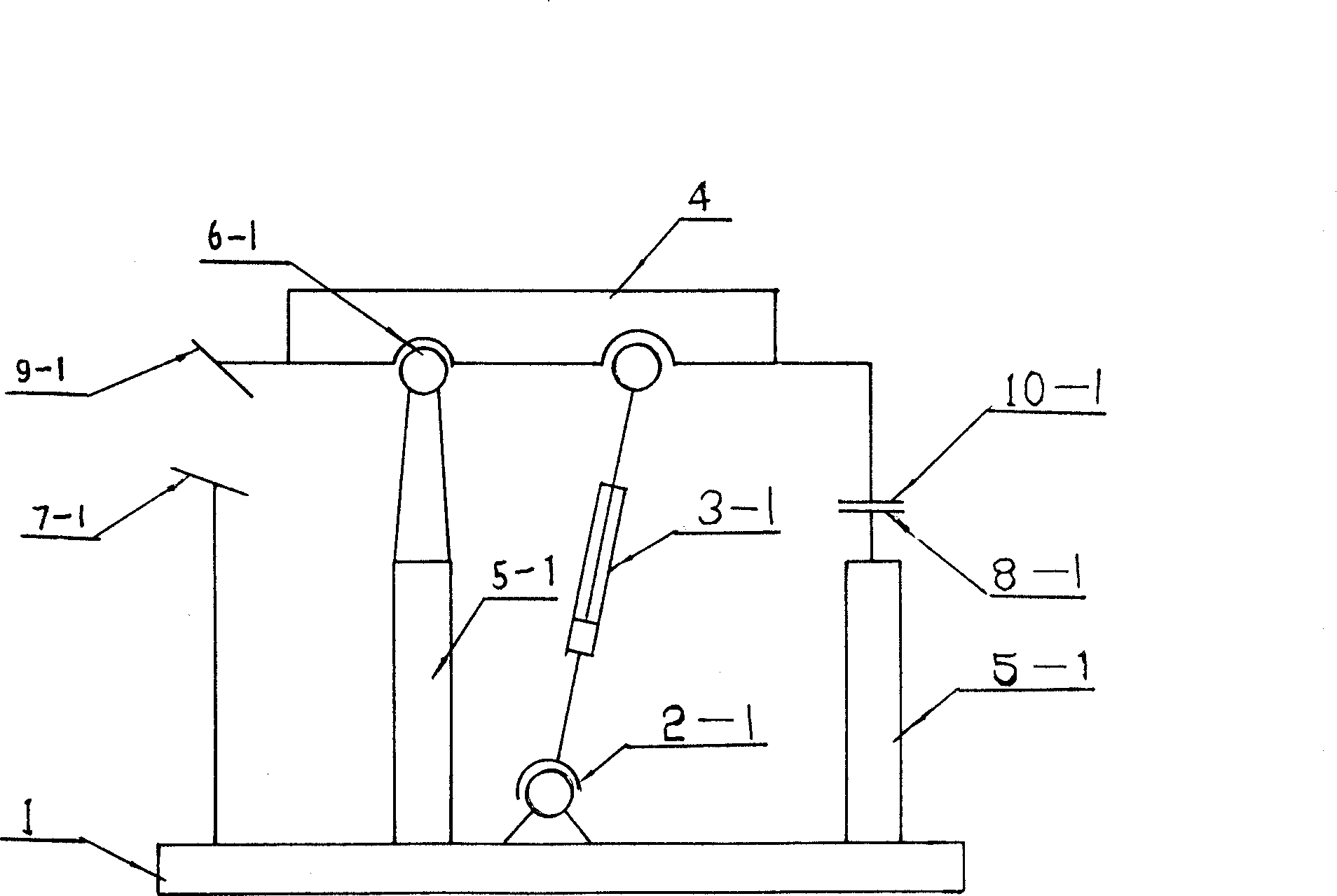

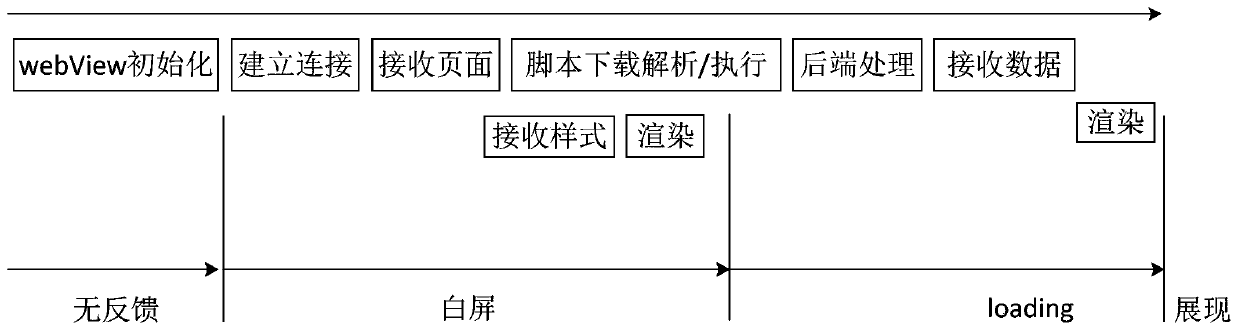

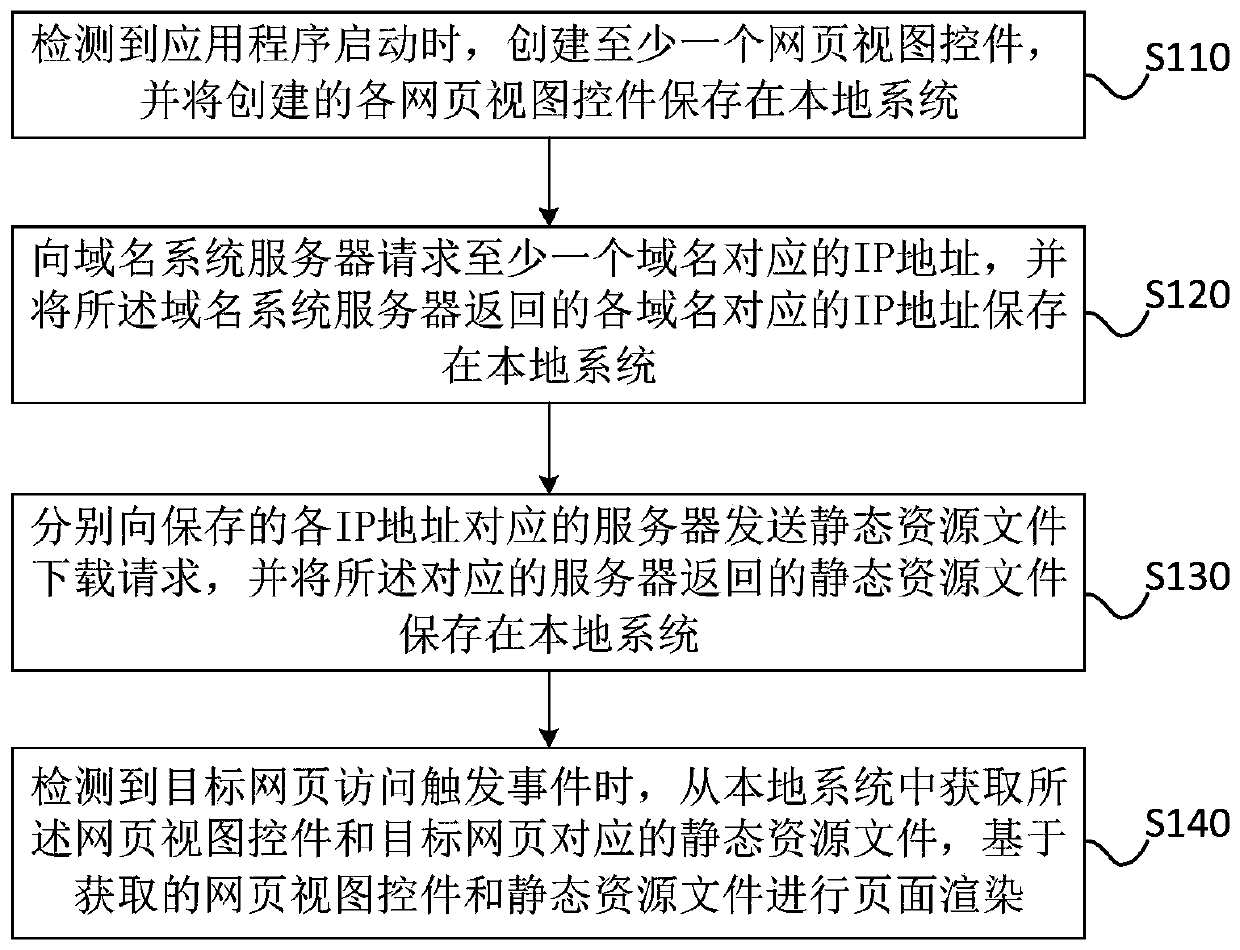

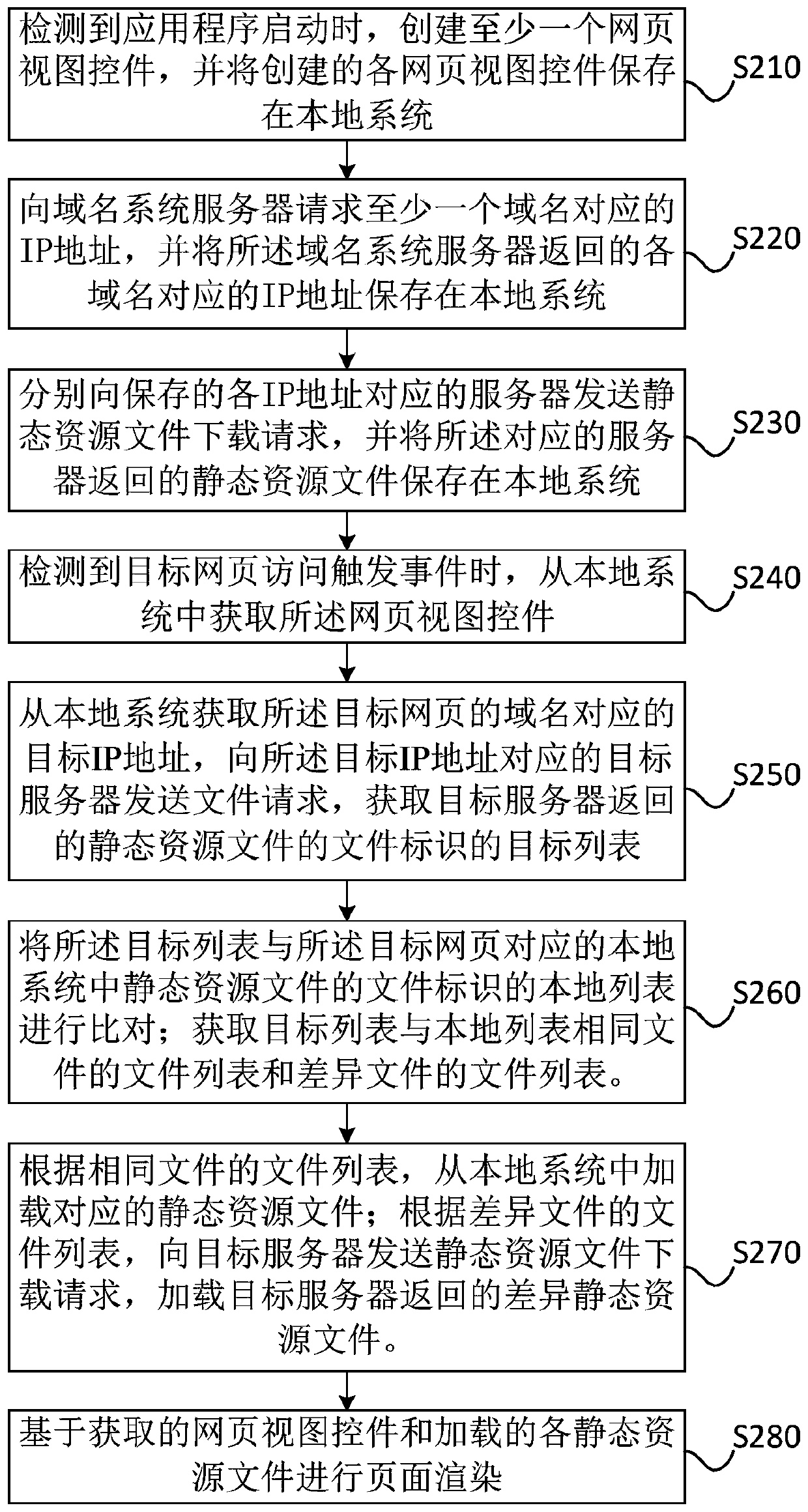

Webpage access method and device, mobile terminal and storage medium

ActiveCN110263275AQuick showSolve the long loading timeTransmissionSpecial data processing applicationsDomain nameAccess method

The embodiment of the invention discloses a webpage access method and device, a mobile terminal and a storage medium. The method comprises: when it is detected that an application program is started, creating at least one webpage view control, and storing the created webpage view controls in a local system; requesting an IP address corresponding to at least one domain name from a domain name system server, and storing the IP address corresponding to each domain name returned by the domain name system server in a local system; respectively sending a static resource file downloading request to a server corresponding to each stored IP address, and storing the static resource file returned by the corresponding server in a local system; and when a target webpage access trigger event is detected, obtaining the webpage view control and a static resource file corresponding to the target webpage from a local system, and performing page rendering based on the obtained webpage view control and the static resource file. According to the embodiment of the invention, the problem that the page loading time is too long in the webpage access process is solved.

Owner:深圳桔子数字技术有限公司

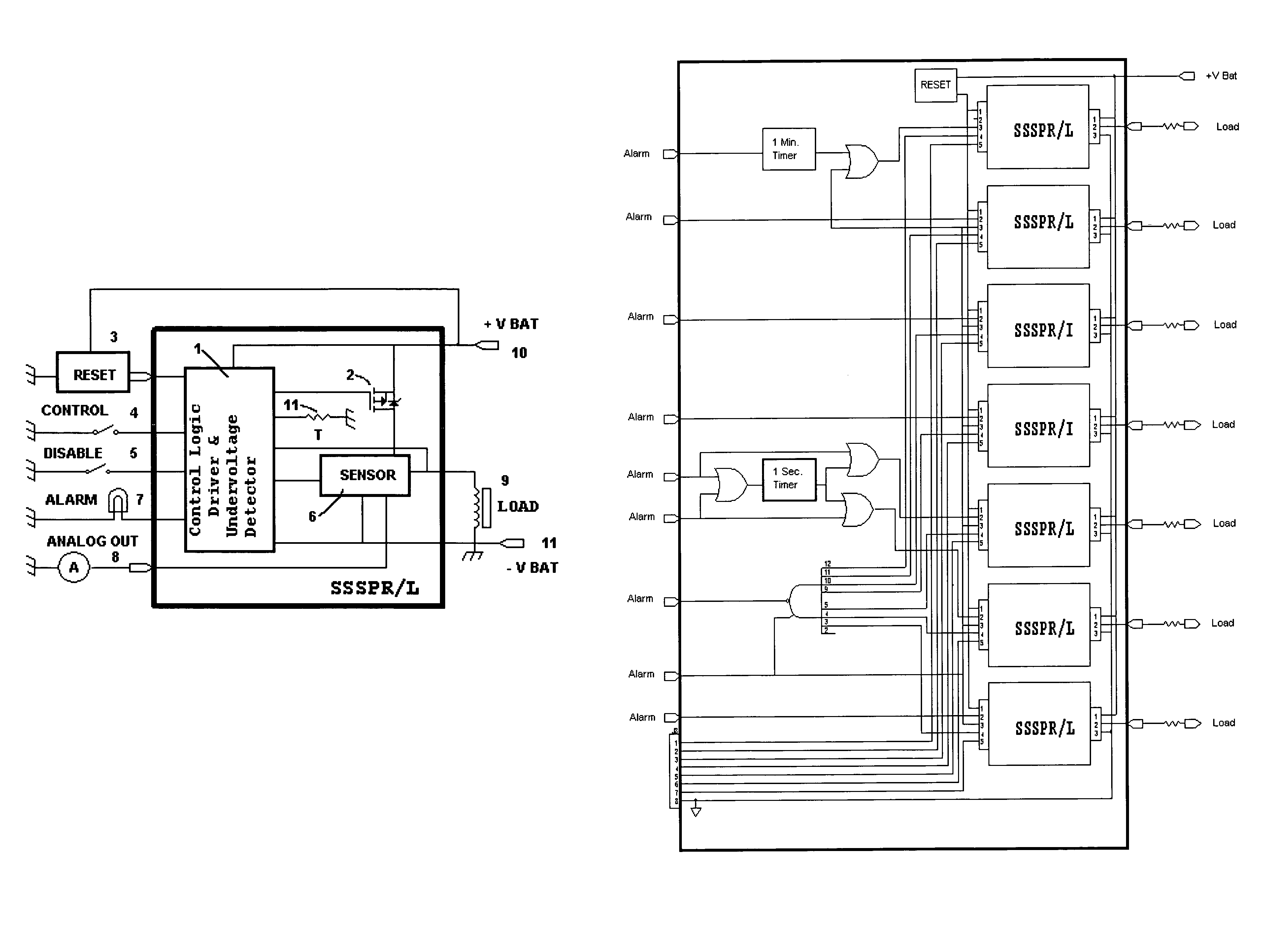

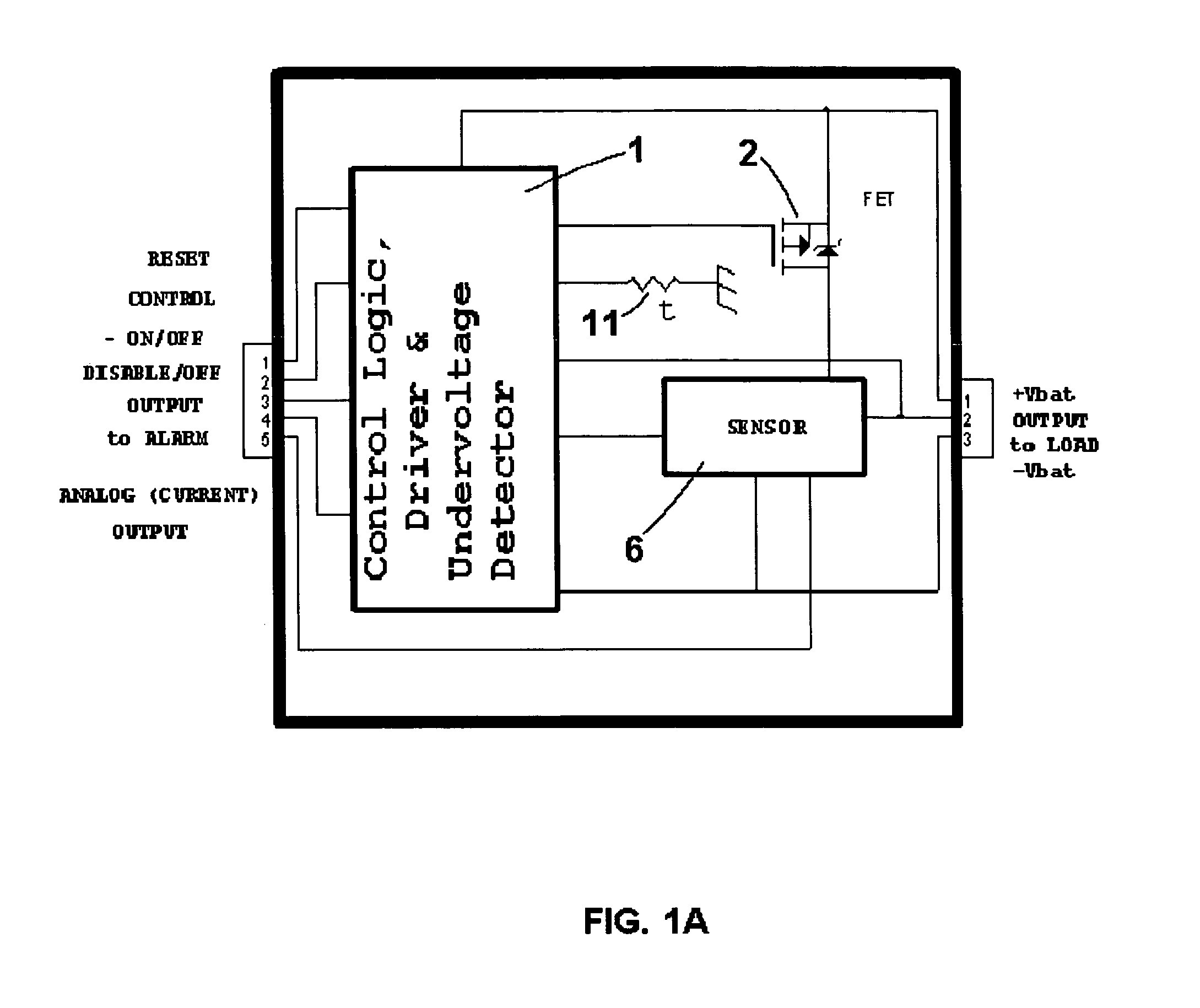

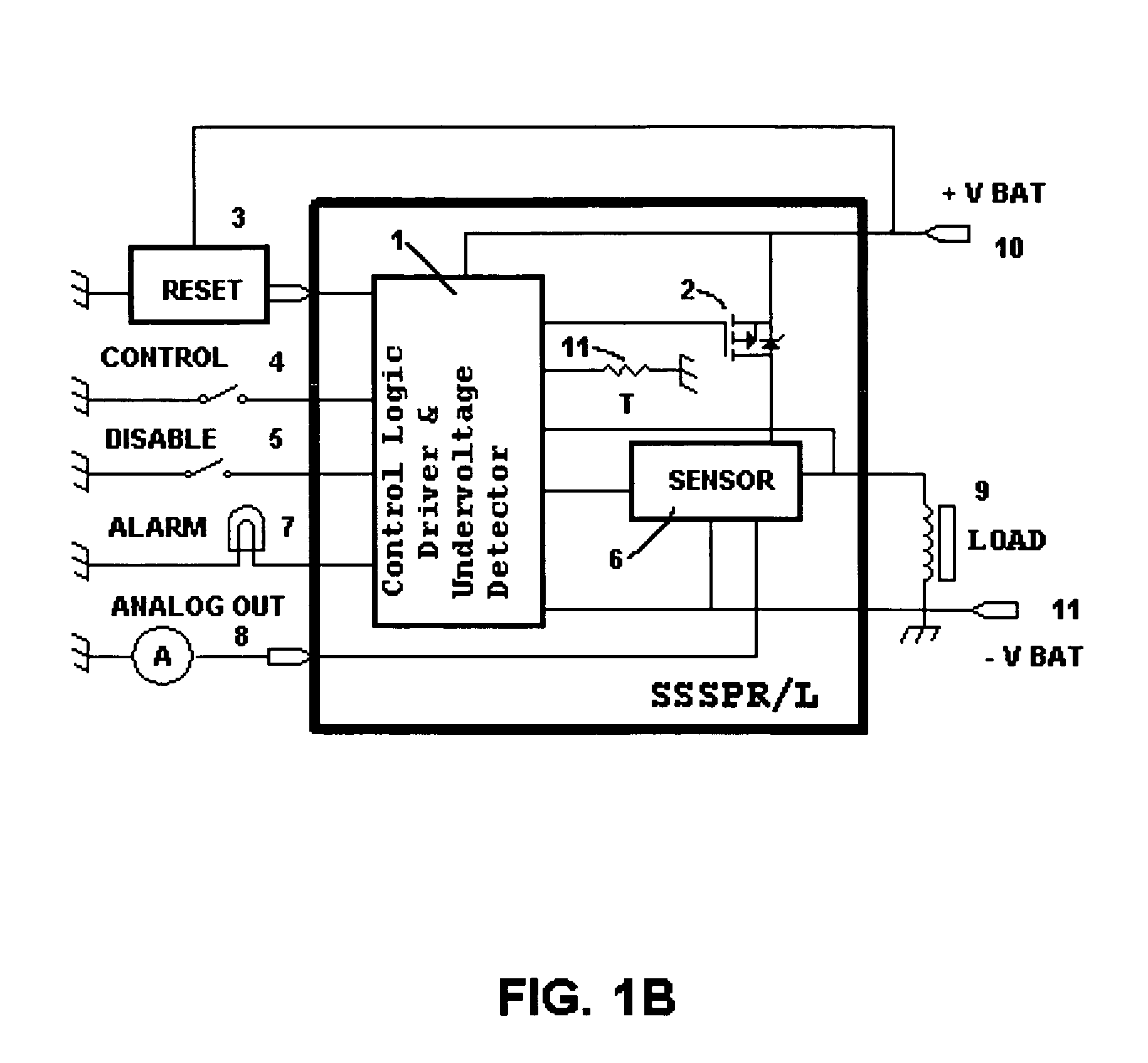

Self-protected, intelligent, power control module

InactiveUS7742273B1Lower resistanceSolve the long loading timeTransistorElectric devicesControl signalCurrent sensor

An intelligent, self-protected control module which is a fully protected and configured as a multi-terminal device controlling a number of power field-effect transistors for delivering power to loads. The device can contain a central processing unit or logic, precision Hall-Effect based current sensors for precise measuring of bypass currents, temperature sensors, and input / output circuitry as well as an optional RF receiver. The inputs can incorporate de-bouncing techniques to prevent false turn on / off. Inputs can provide command signals for the processor or logic with built-in watchdog circuitry to monitor the input power supply. The CPU or logic can provide communications with external devices, generate alarms, generate control signals to turn-on / turn-off power MOSFETs, and analyze currents and temperature of each channel. Unlike an electromechanical relay, the present invention is free from arcing and sparking, there are no contact materials to wear, and it is noiseless. The present invention provides over-current protection by shutting down a troubled channel if it is overloaded. It provides protection to the load by limiting the bypass current to the preset value, or shutting the channel off in a case of over-current. The present invention provides over-temperature protection by shutting down an appropriate channel if any of the MOSFET's temperature reaches a predetermined value. The present invention can generate an output signal that is capable of driving an external indicator lamp if a problem has occurred. An optional RF receiver designed to receive a coded signal from a key-chain transmitter can provide a method of enabling the module to accept a control signal from the input remotely.

Owner:SHVARTSMAN VLADIMIR

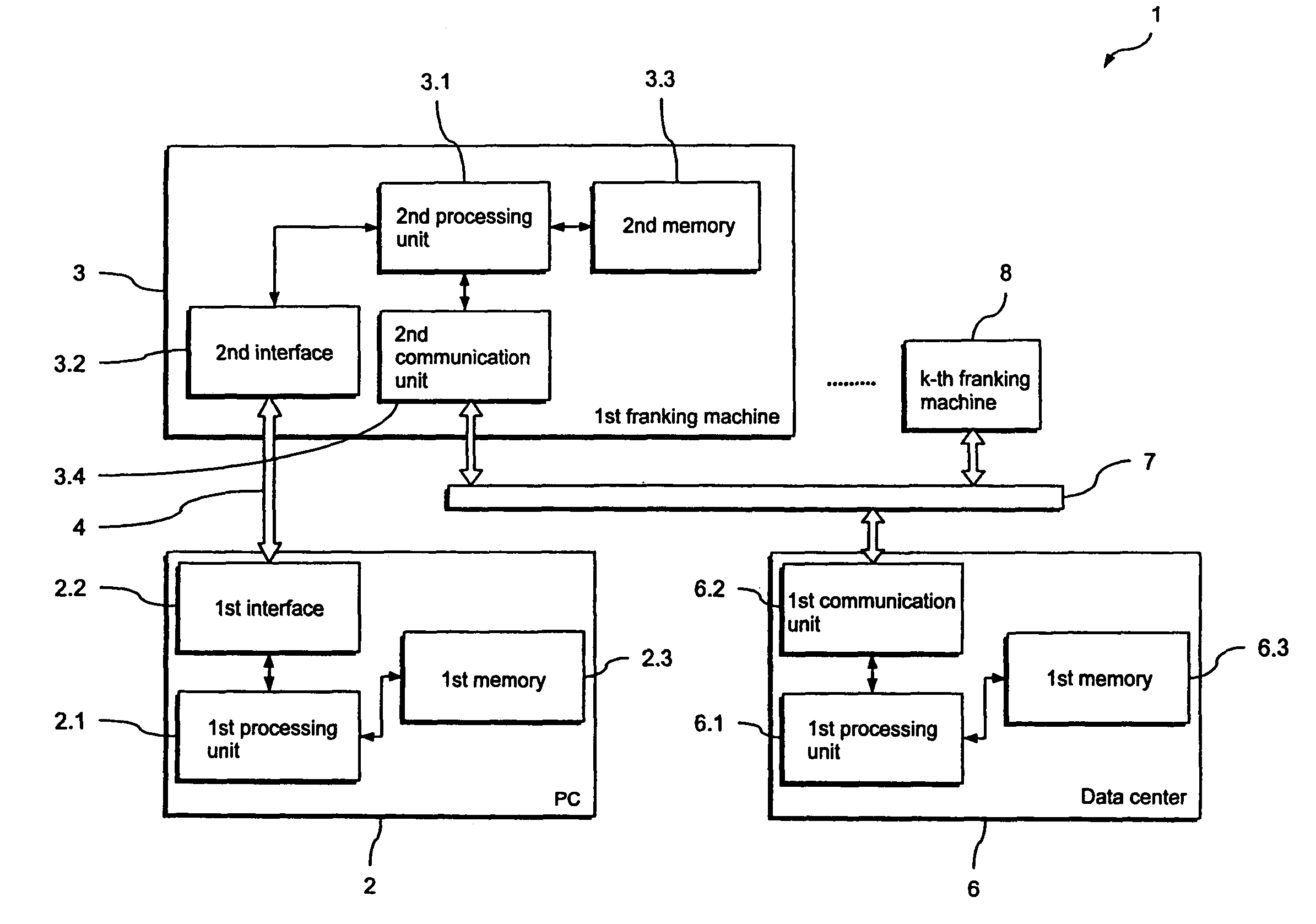

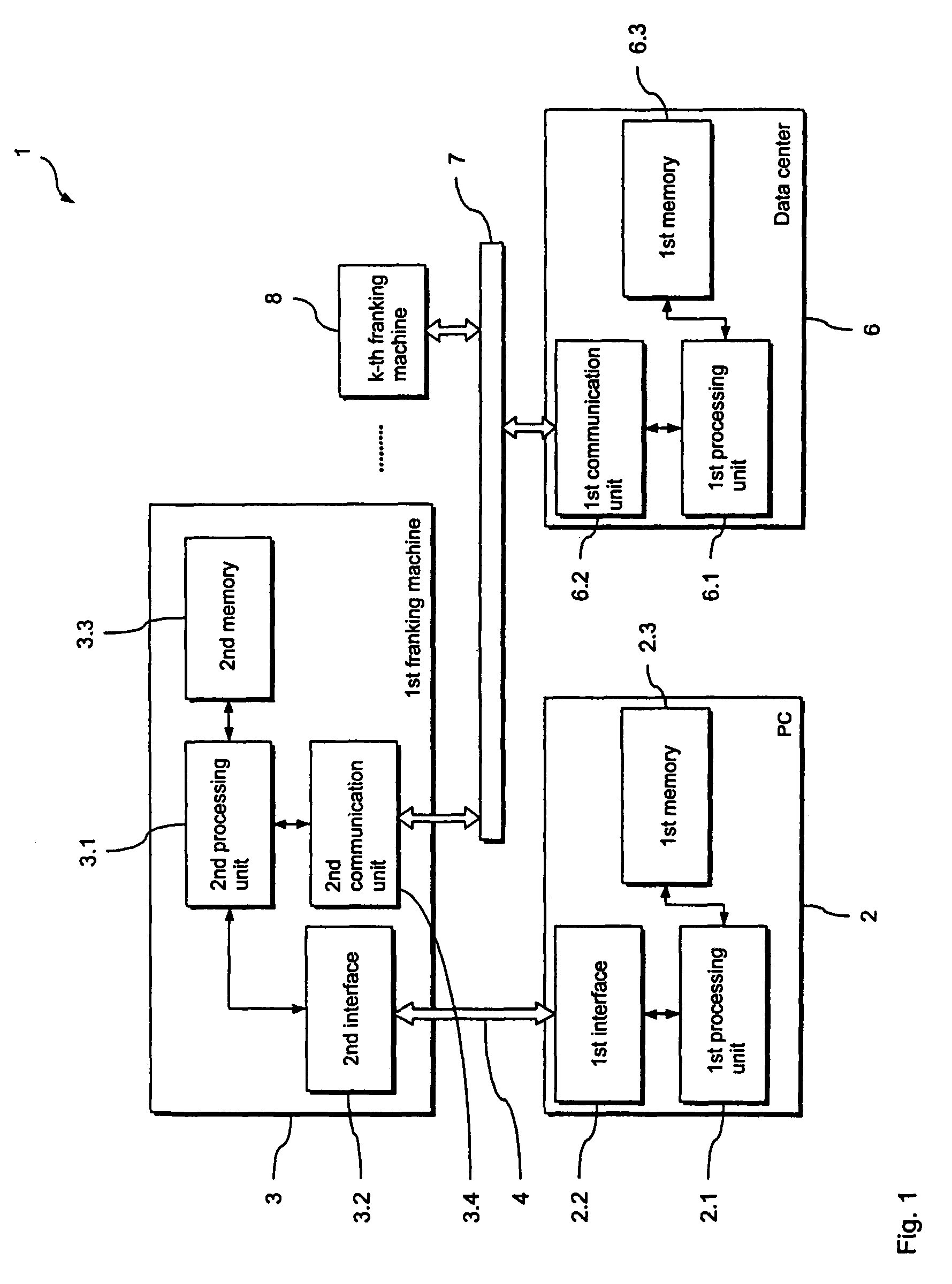

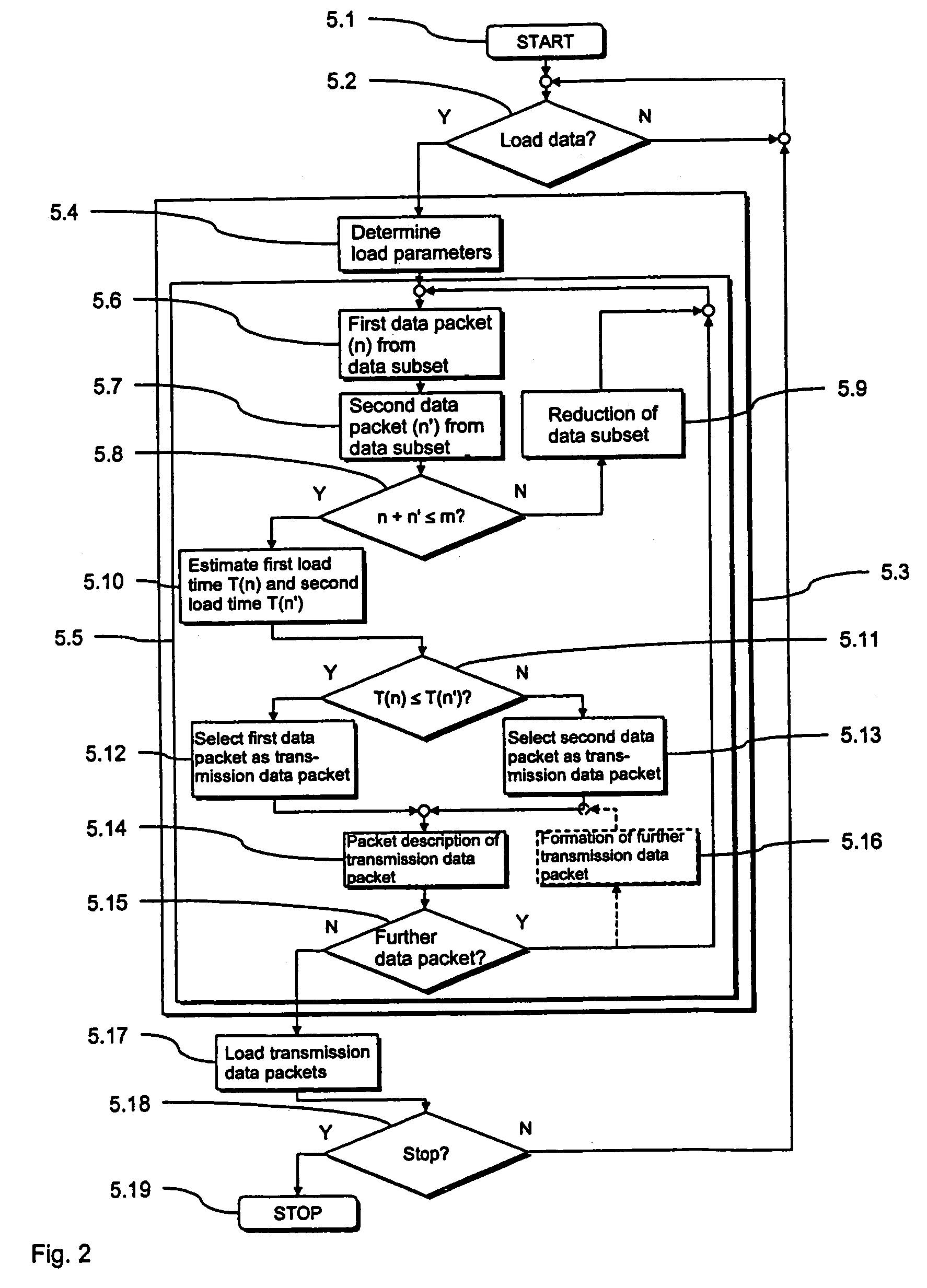

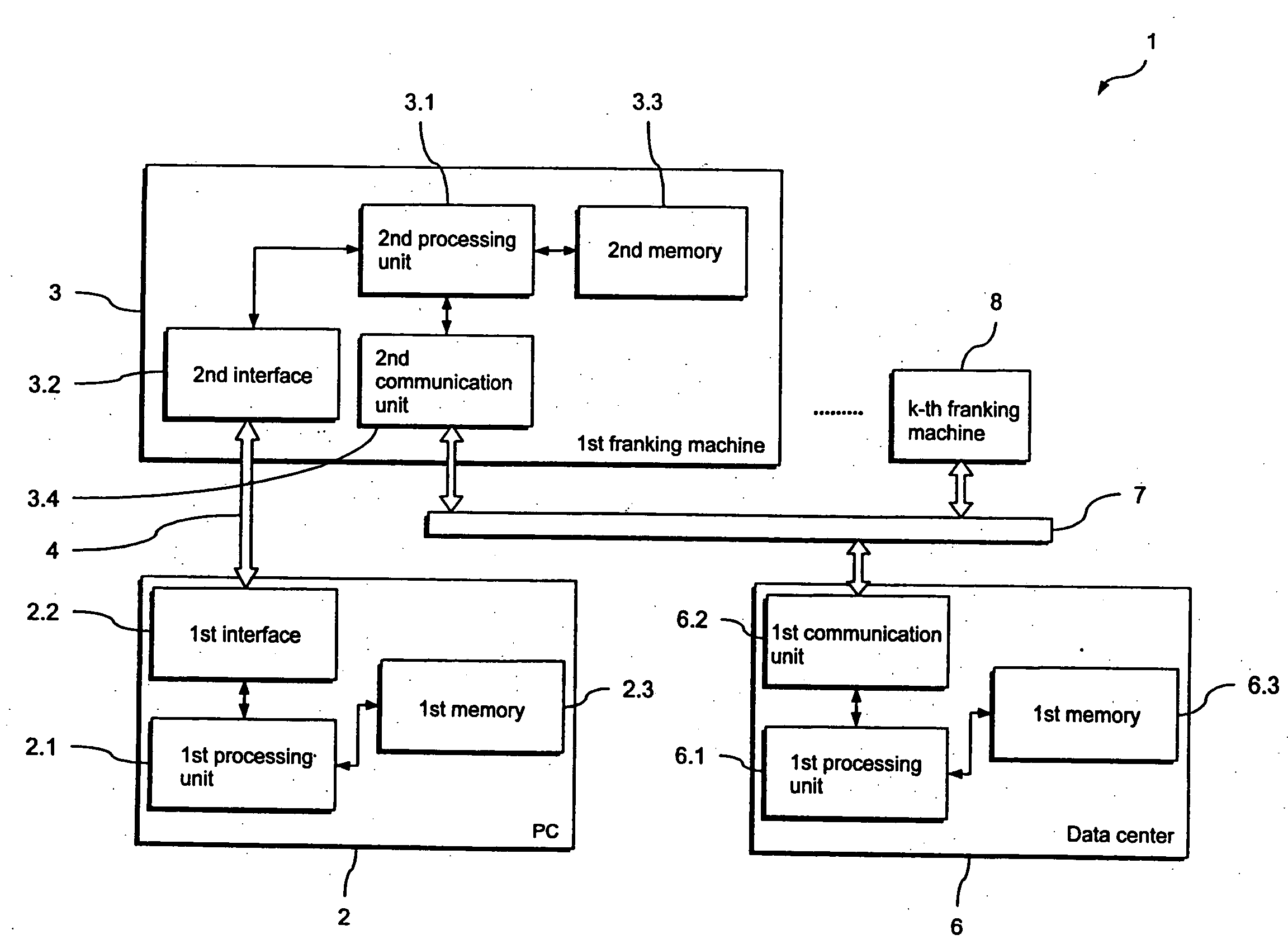

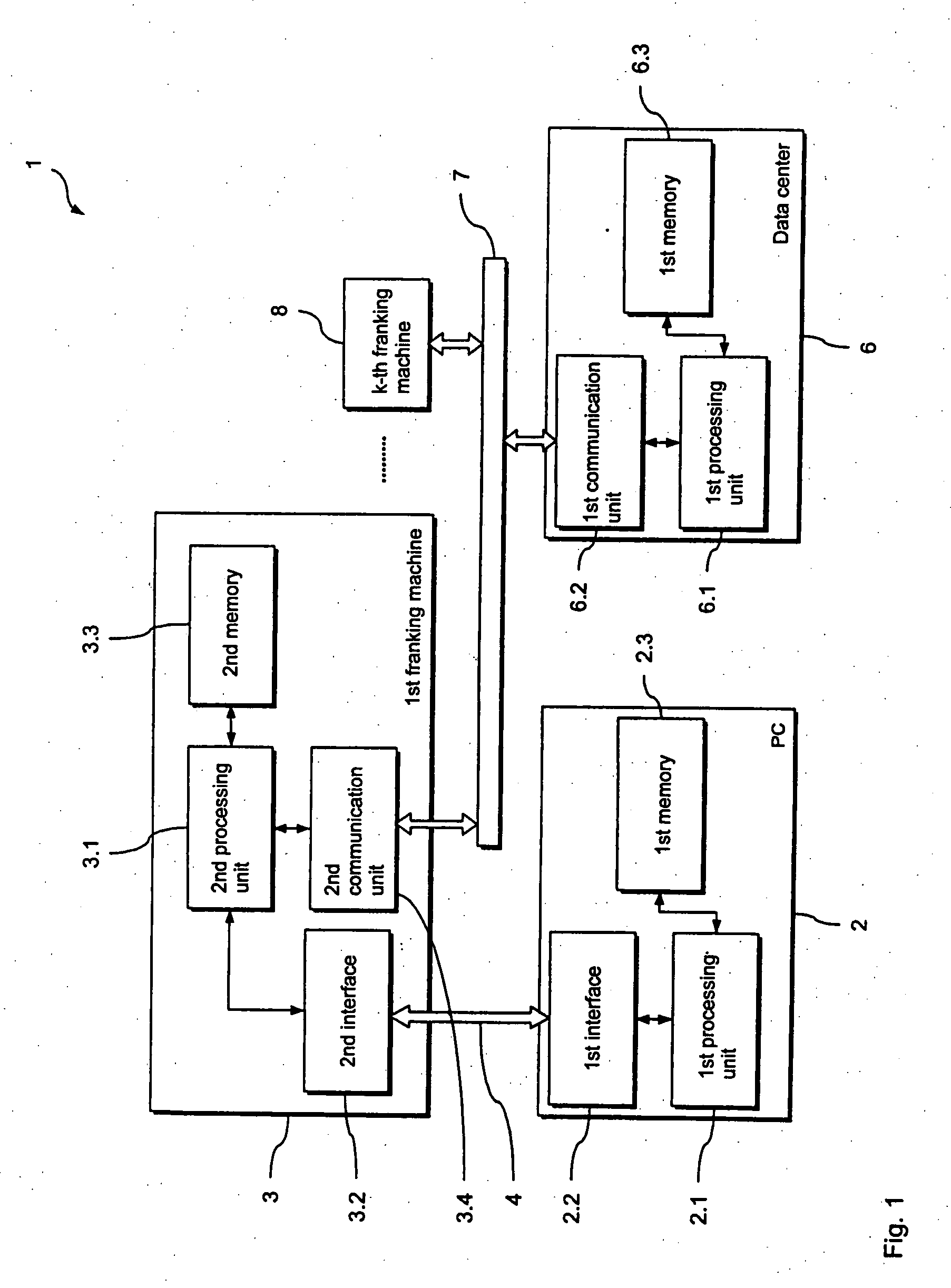

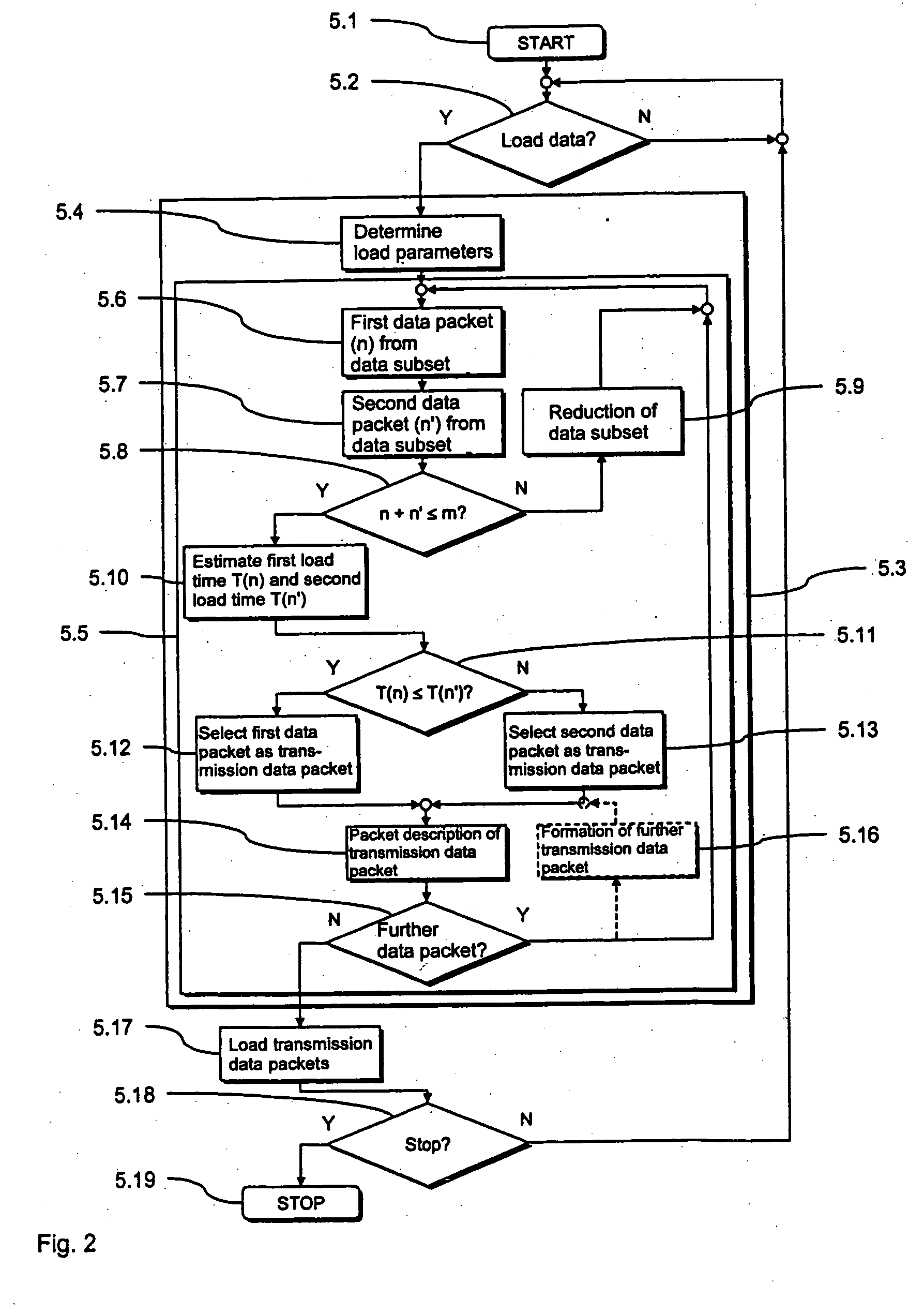

Method for preparation of data for loading into a data processing device

ActiveUS7793000B2Solve the long loading timeDigital data processing detailsTime-division multiplexData connectionLoad time

In a method and arrangement for preparation of data for loading from a first data processing device into a second data processing device via a first data connection, a number of transmission-ready transmission data packets are generated in at least one packetizing step from the data to be loaded into the second data processing device; and at least one load parameter influencing the total load time until a complete loading of the data into the second data processing device is determined in a determination step preceding the packetizing step. The generation of the transmission data packets ensues in the at least one packetizing step dependent on the first load parameter.

Owner:FRANCOTYP POSTALIA

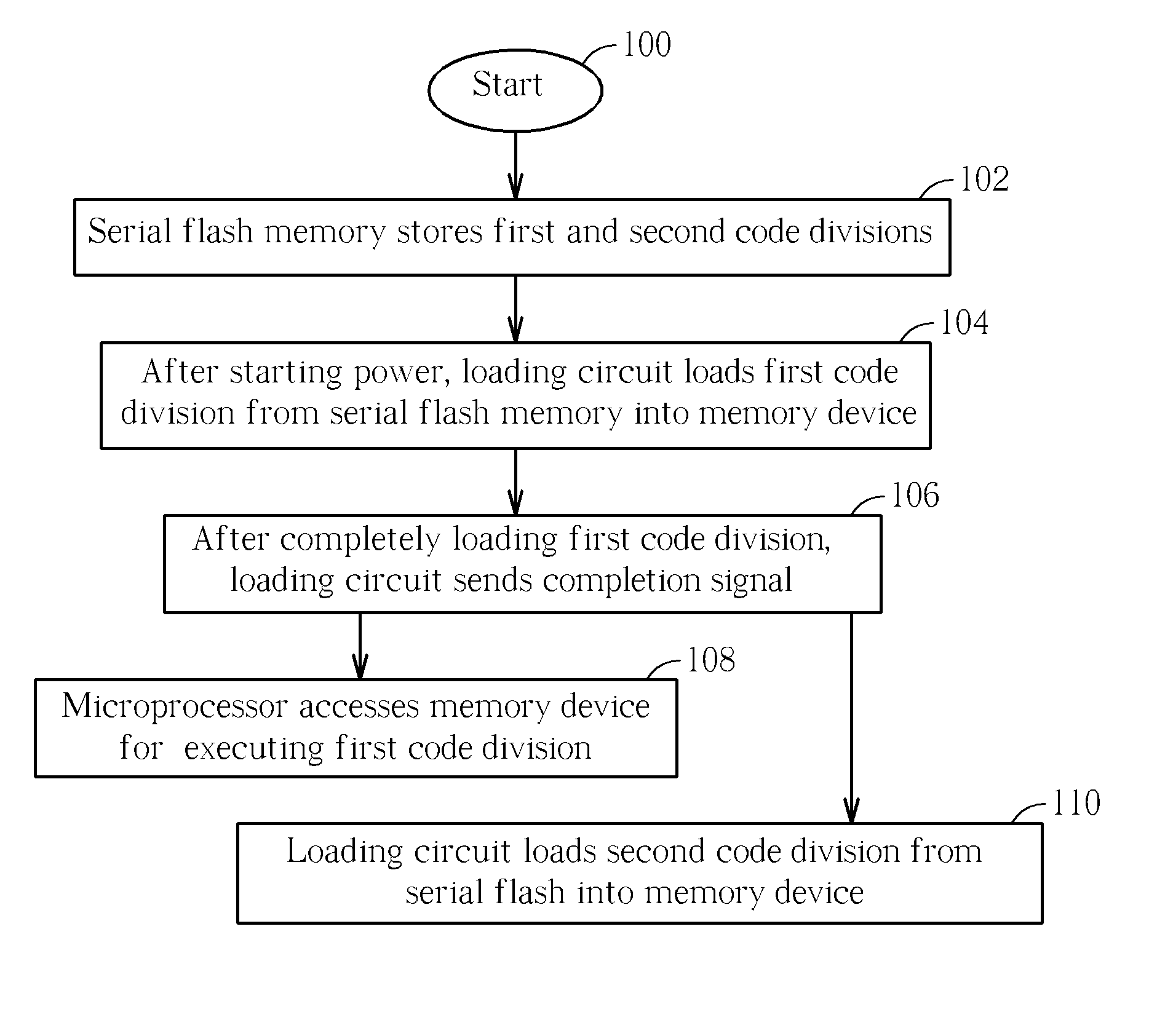

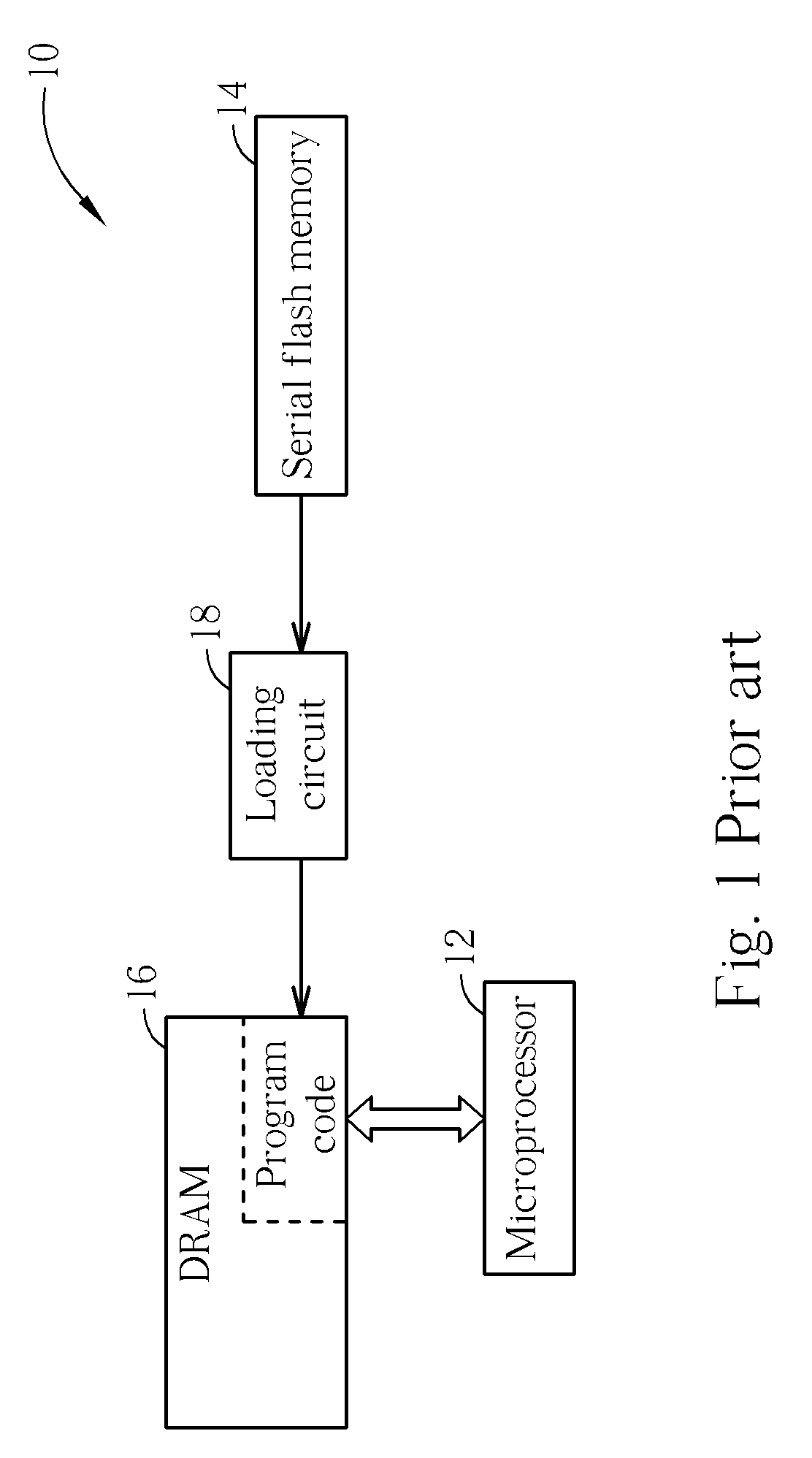

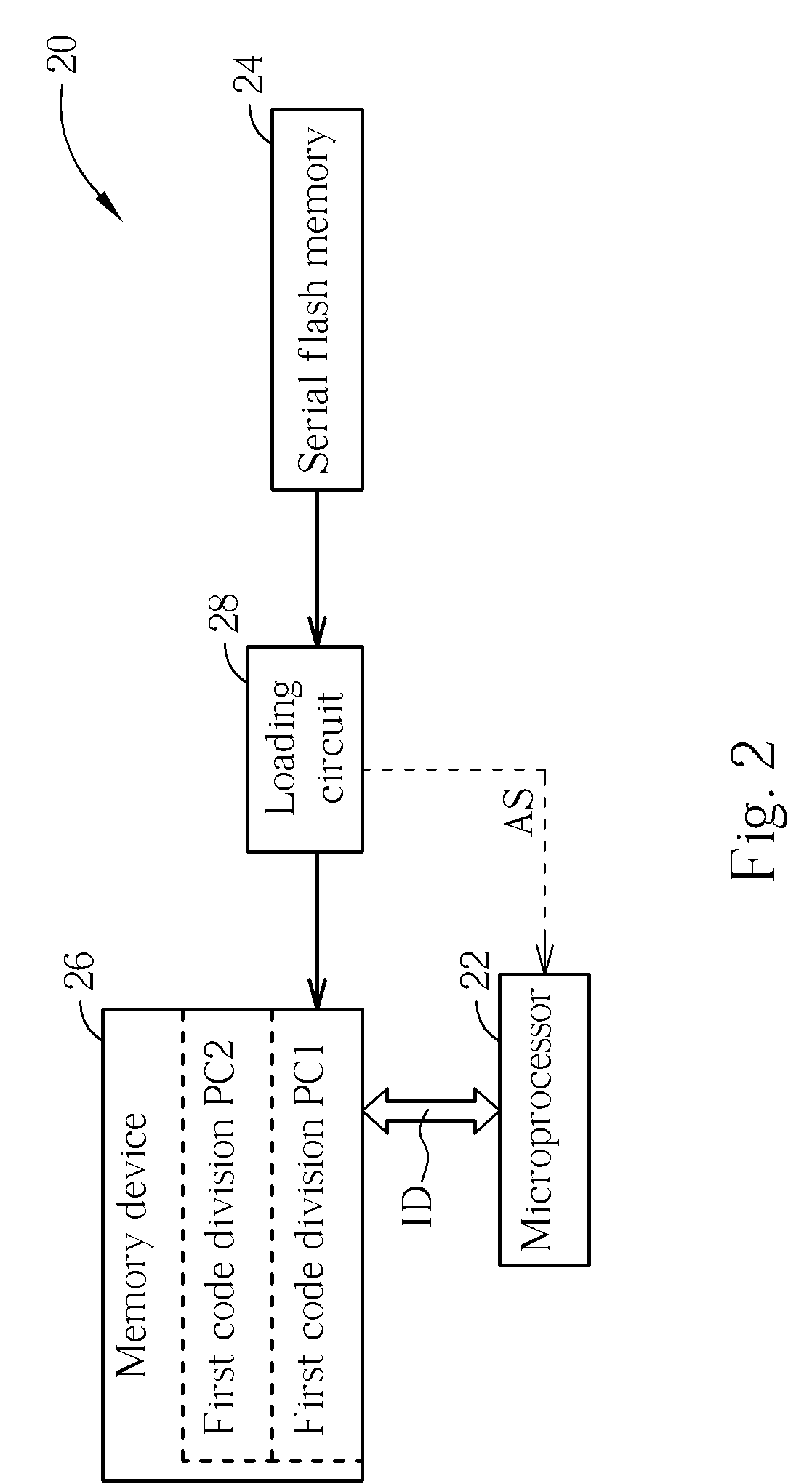

Memory management method for simultaneously loading and executing program codes

ActiveUS20050144364A1Avoid misuseQuick responseDigital computer detailsData resettingParallel computingProgram code

A method is provided for simultaneously loading and executing program code in a circuit system. The circuit system includes a plurality of memory devices, a microprocessor, and a loading circuit. The method includes dividing the program code into a plurality of code divisions and utilizing the microprocessor to execute at least a code division when the loading circuit loads any other code division into a memory device of the plurality of memory devices.

Owner:MEDIATEK INC

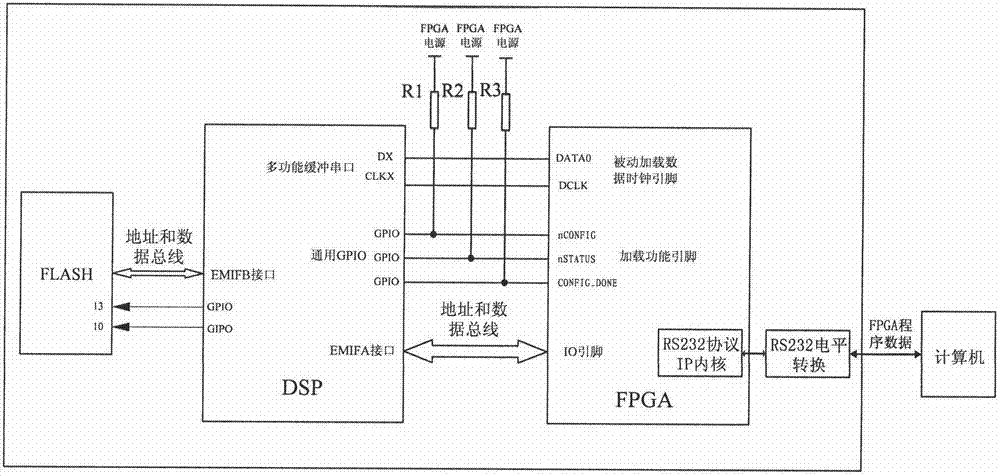

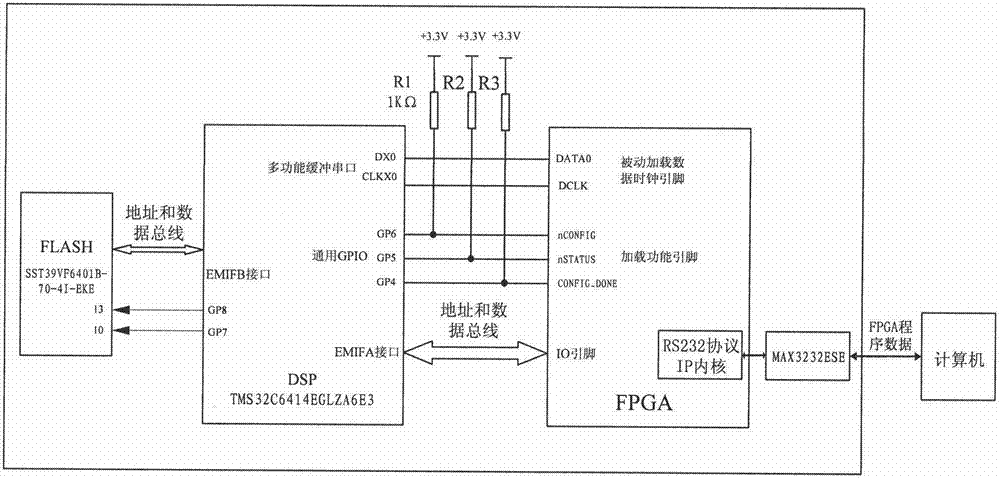

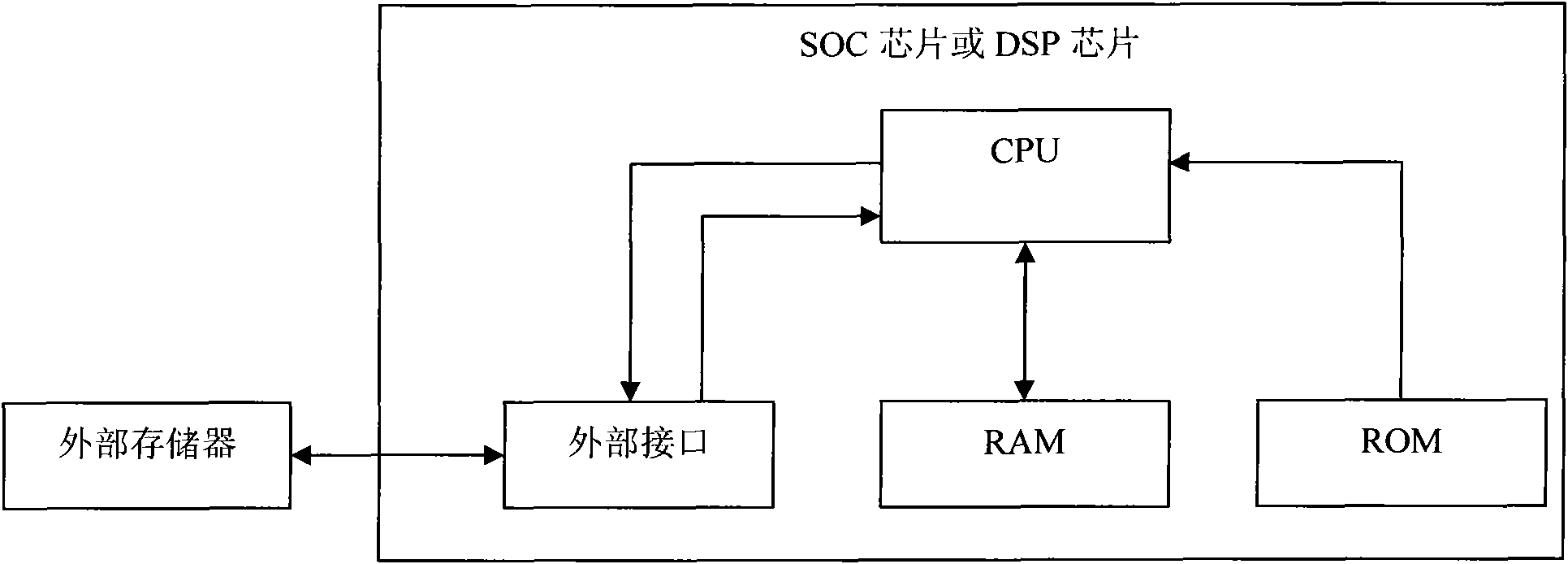

Satellite navigation receiver FPGA (Field Programmable Gate Array) rapid loading method

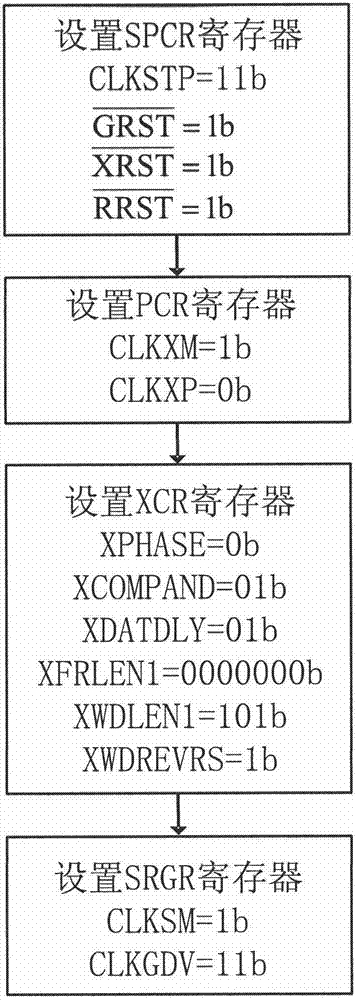

ActiveCN103034515AEasy to upgradeFast loadingSatellite radio beaconingProgram loading/initiatingElectromagnetic interferenceField-programmable gate array

The invention relates to a satellite navigation receiver FPGA (Field Programmable Gate Array) rapid loading method. According to the method, a multifutional buffer serial port of a DSP (Digital Signal Processor) chip is adopted as a special clock data line special for an FPGA during loading by virtue of a special use metod; the DXm of the multifunctional buffer serial port is used as a data line to be connected with an FPGA loading data input end DATA0; the CLKXm of the multifunctional buffer serial port is used as a clock line to be connected with an FPGA loading data input end DCLK; and the GPIO (General Purpose Input / Output) pin of the DSP is used as a loading functional line to be connected with three special deployment pins of the FPGA. According to the method, the DSP chip, a FLASH chip, an RS232 level conversion chip, resisters R1, R2 and R3, and the FPGA are firstly connected, then FPGA loading is performed, and remote upgrading is performed on a FLASH program according to needs; and the method has the advantages of short loading time, easiness for external program upgrading, large storage capacity, rapid loading speed, less possibility of electromagnetic interference and strong universality.

Owner:BEIJING RES INST OF TELEMETRY +1

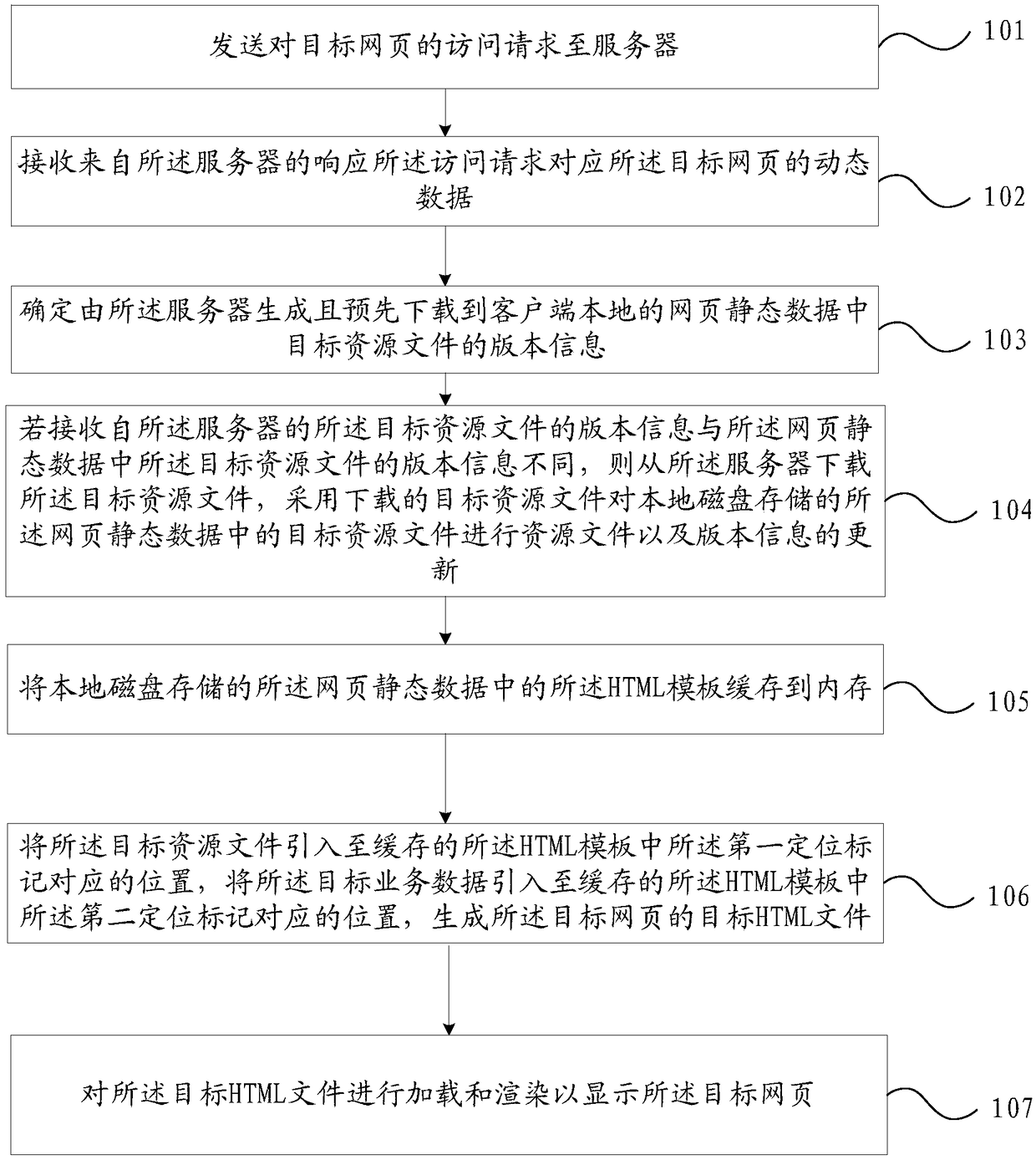

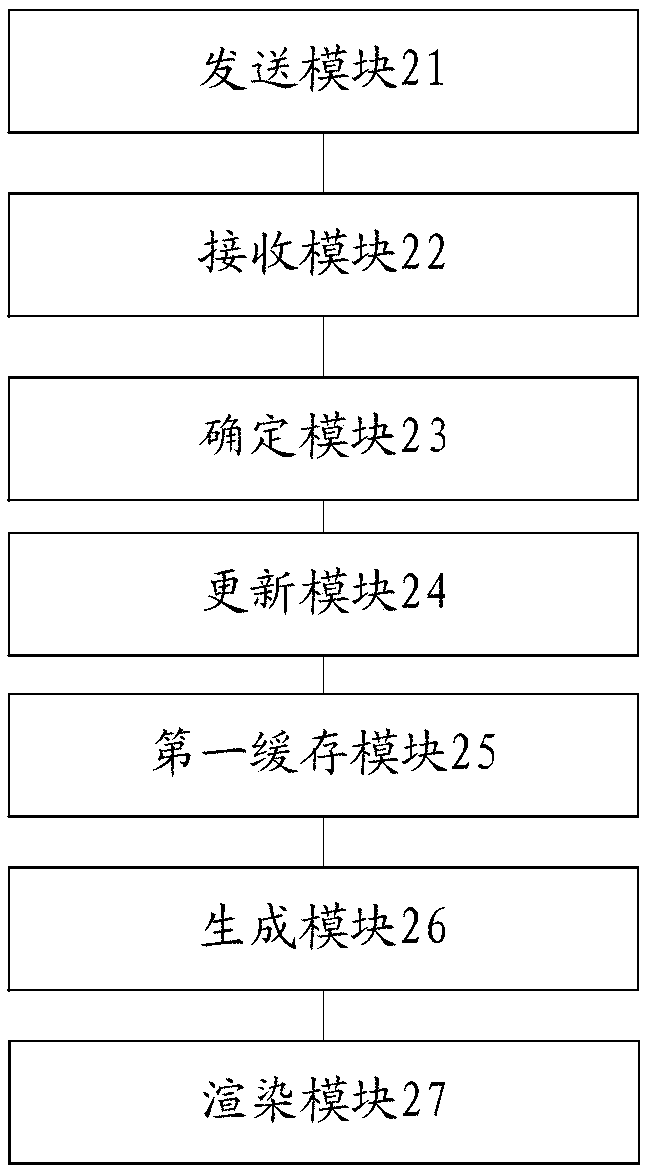

Web page display method and device

InactiveCN109165369AImprove loading speedReduce waiting timeWebsite content managementWeb data browsing optimisationClient-sideDynamic data

The invention provides a web page display method and device. The method comprises the following steps: sending an access request to a target web page to a server; receiving dynamic data from a targetweb page of the server; determining version information of a target resource file in static data of a web page generated by a server and downloaded to a client side in advance; if the version information of the target resource file received from the server is different from the version information of the target resource file in the static data of the web page, then downloading the target resourcefile from the server, updating the resource file and the version information of the target resource file in the static data of the web page stored on the local disk by using the downloaded target resource file; caching HTML templates in static data of web pages stored on the local disk into memory; introducing the target resource file into the position of the first positioning tag in the cached HTML template, and introducing the target service data into the position of the second positioning tag in the cached HTML template to generate the target HTML file of the target web page.

Owner:北京猫眼文化传媒有限公司

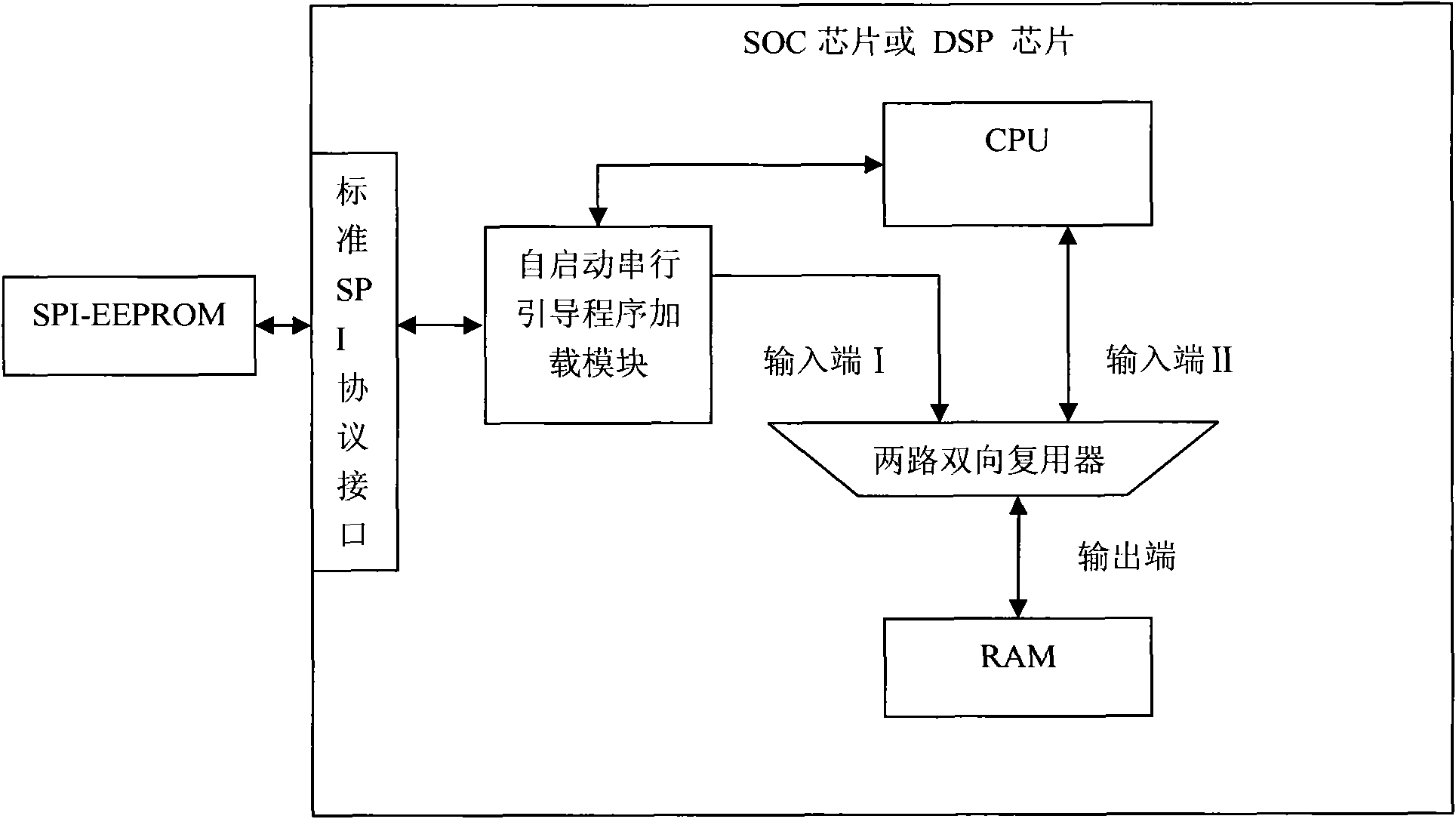

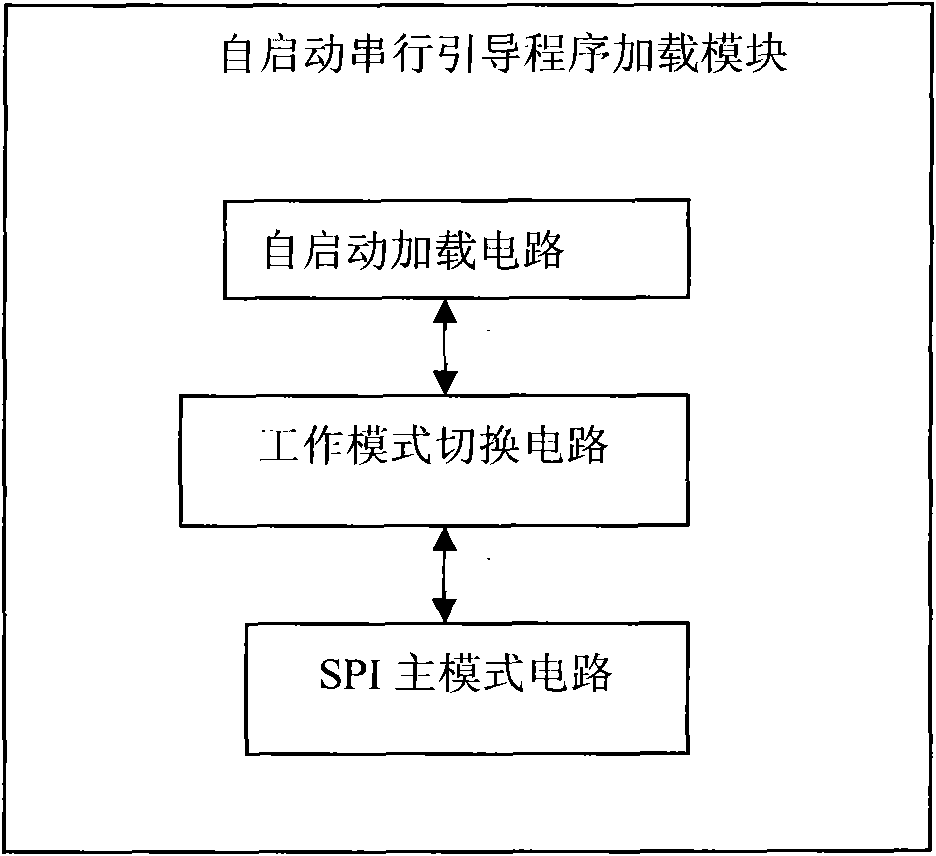

Self-starting serial boot program loading and reading system and method thereof

The invention provides a self-starting serial boot program loading and reading system and method thereof. The system comprises a system chip and an exterior SPI interface storage, wherein the system chip comprises a CPU, an inner program storage, a self-starting serial boot program loading module, a two-way multiplexer and a standard SPI protocol interface. The self-starting serial boot program loading module is respectively connected with an input end I of the two-way multiplexer and the CPU and is connected with the exterior SPI interface storage by the standard SPI protocol interface; the input end I of the two-way multiplexer is connected with the CPU while the output end thereof is connected with a RAM; and the self-starting serial boot program loading module comprises a self-starting loading circuit, a work mode switch circuit and an SPI major mode circuit. After being electrified, the self-starting serial boot program loading module directly reads an algorithm routine in the exterior storage and rapidly loads in the inner program storage. The program loading method is simple, the system starting time is short and the loading and reading operations can be performed for many times.

Owner:GRAND CHIPS MICROELECTRONICS

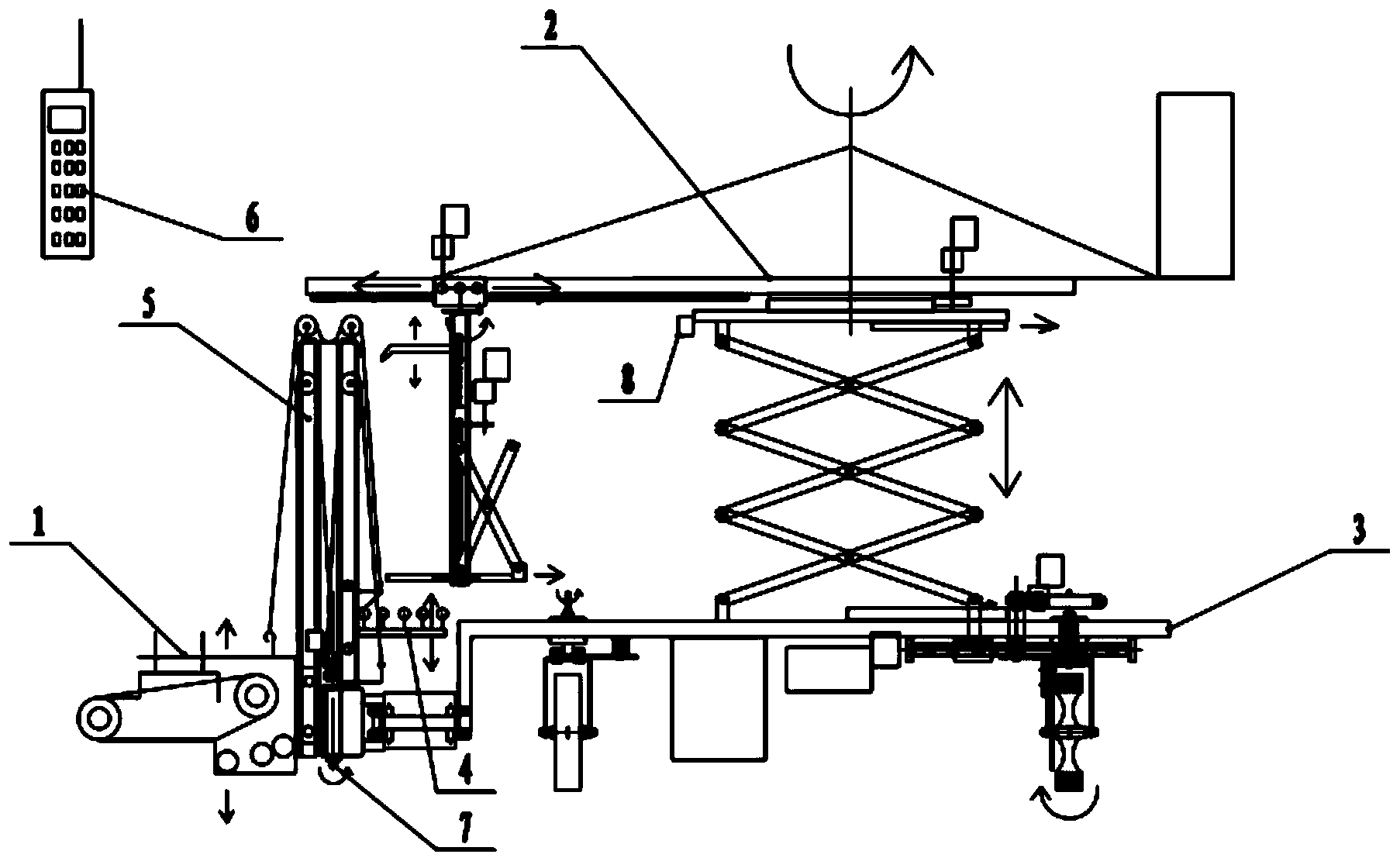

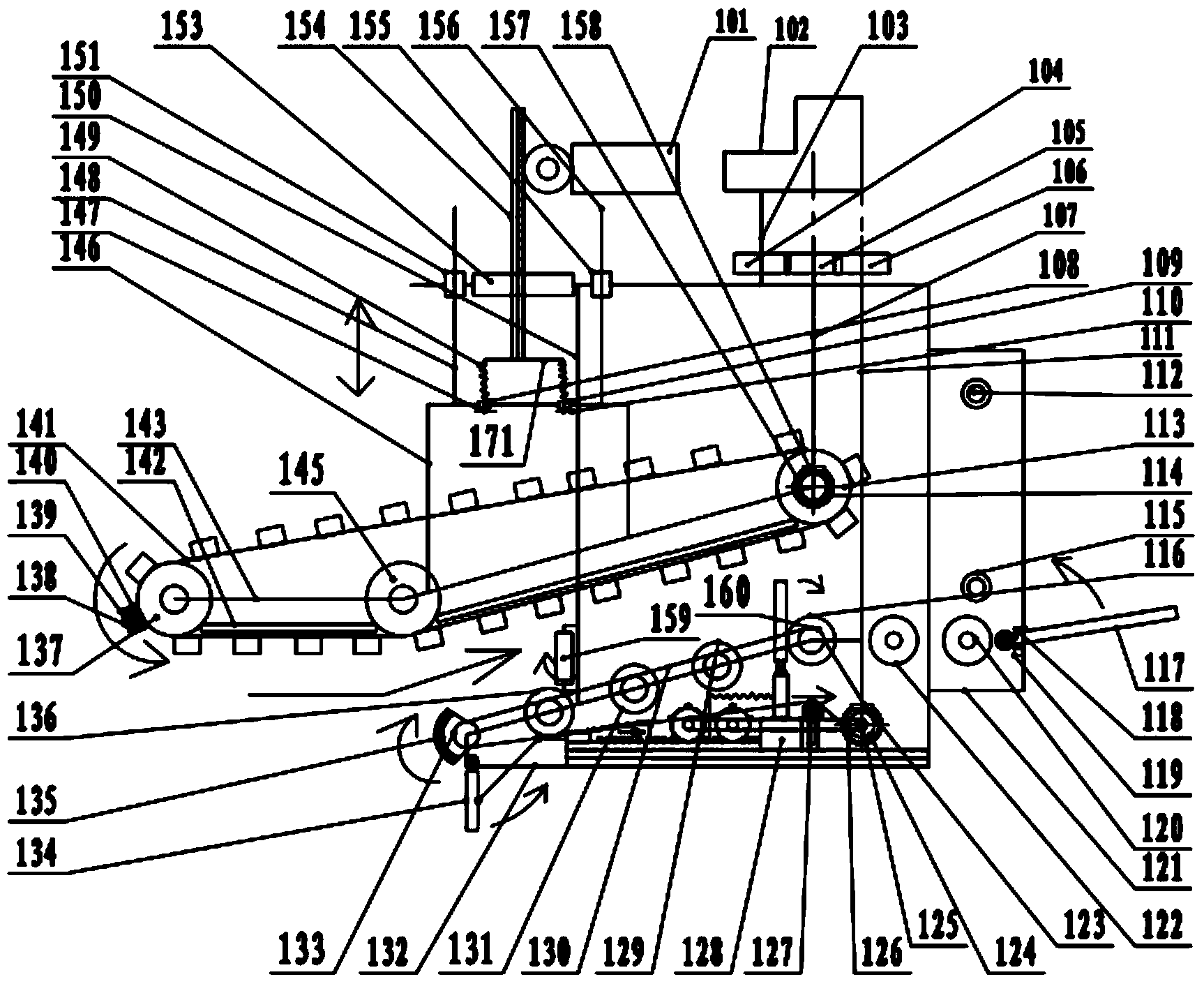

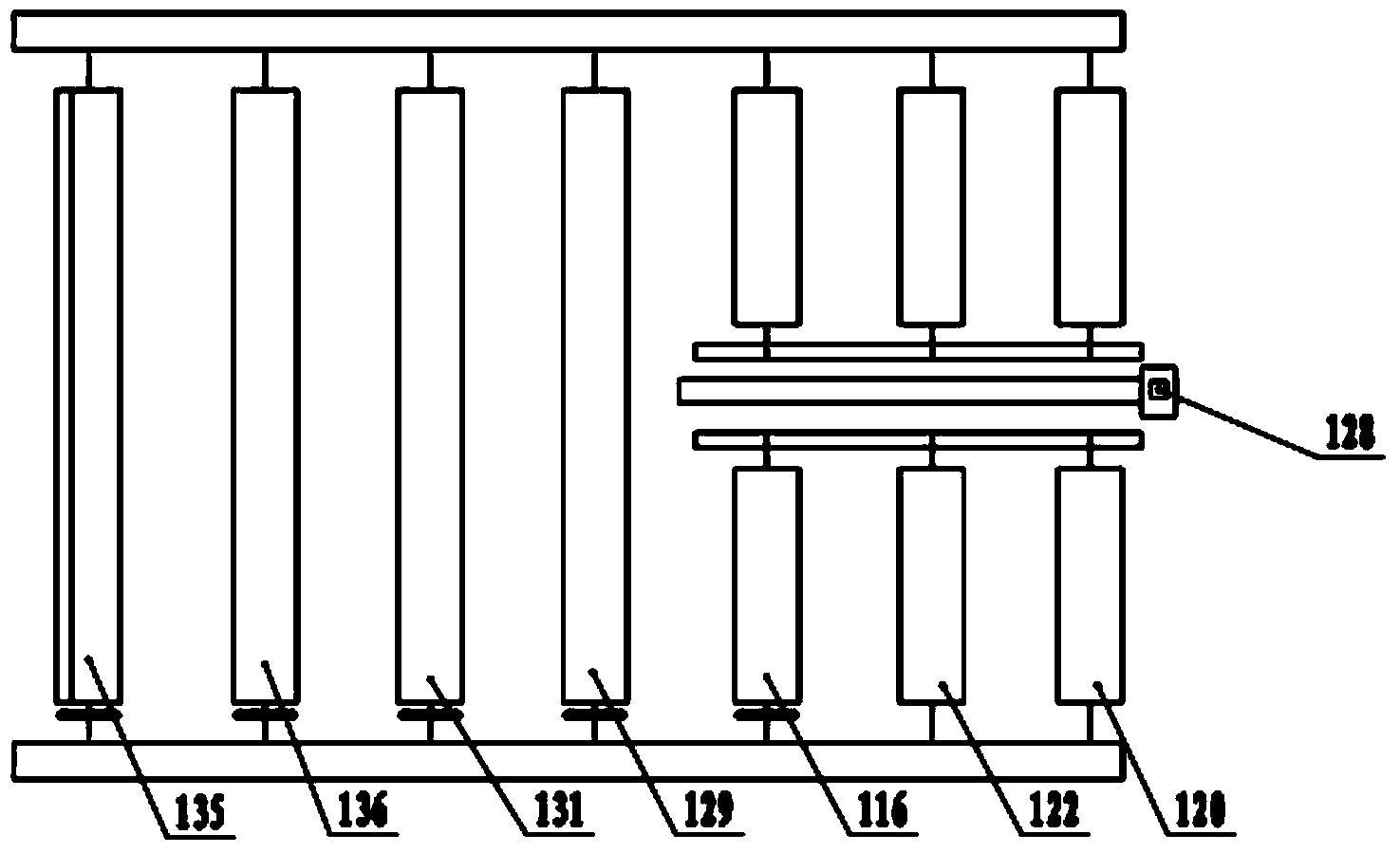

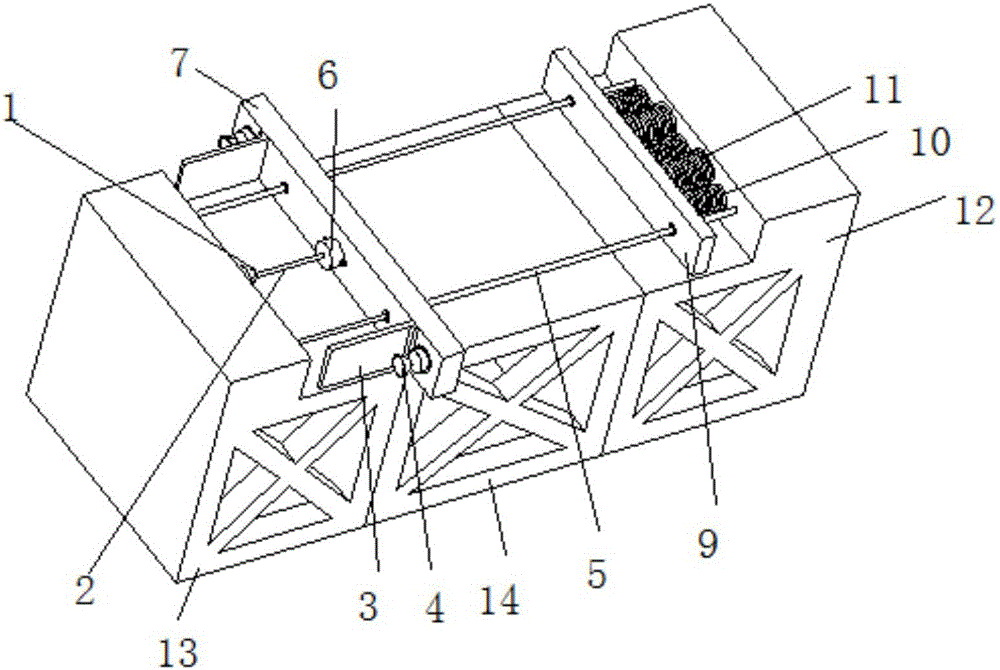

Self-propelled bagged cargo stacking and unstacking track loader

The invention relates to a self-propelled bagged cargo stacking and unstacking track loader, and belongs to bagged cargo stacking and unstacking truck loading equipment. The self-propelled bagged cargo stacking and unstacking track loader mainly solves the technical problems that according to existing stacking equipment, the stacking and truck loading speed is low, and carry workloads are large. According to the technical scheme, the self-propelled bagged cargo stacking and unstacking track loader comprises a remote controller, an encoder and an angle sensor, and further comprises a cargo delivery taking device, a cargo hoisting device, a walking mechanism, a stacking device and a rotary type door frame, wherein the cargo delivery taking device is arranged on the lower portion of a cargo delivery taking door frame in front of the rotary type door frame and can move up and down on the cargo delivery taking door frame, the stacking device is arranged on the lower portion of a stacking door frame at the back of the rotary type door frame and can move up and down on the stacking door frame, the rotary type door frame is connected with the front end of the walking mechanism through a rotating shaft, the cargo hoisting device is installed on the upper surface of the walking mechanism, the encoder is arranged at the bottom of the rotating shaft of the rotary type door frame, and the angle sensor is disposed on a swing mechanism of the cargo hoisting device.

Owner:张利军

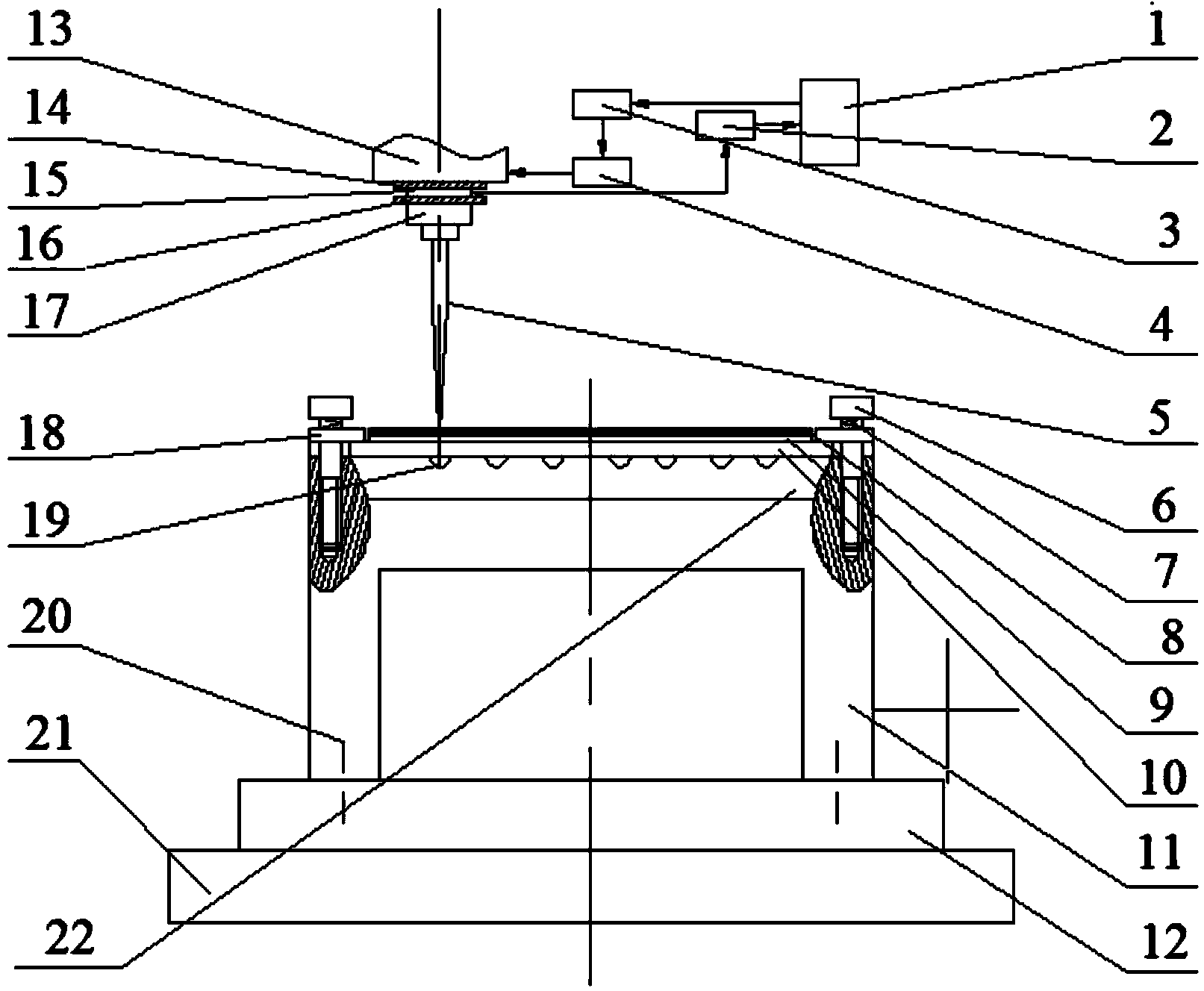

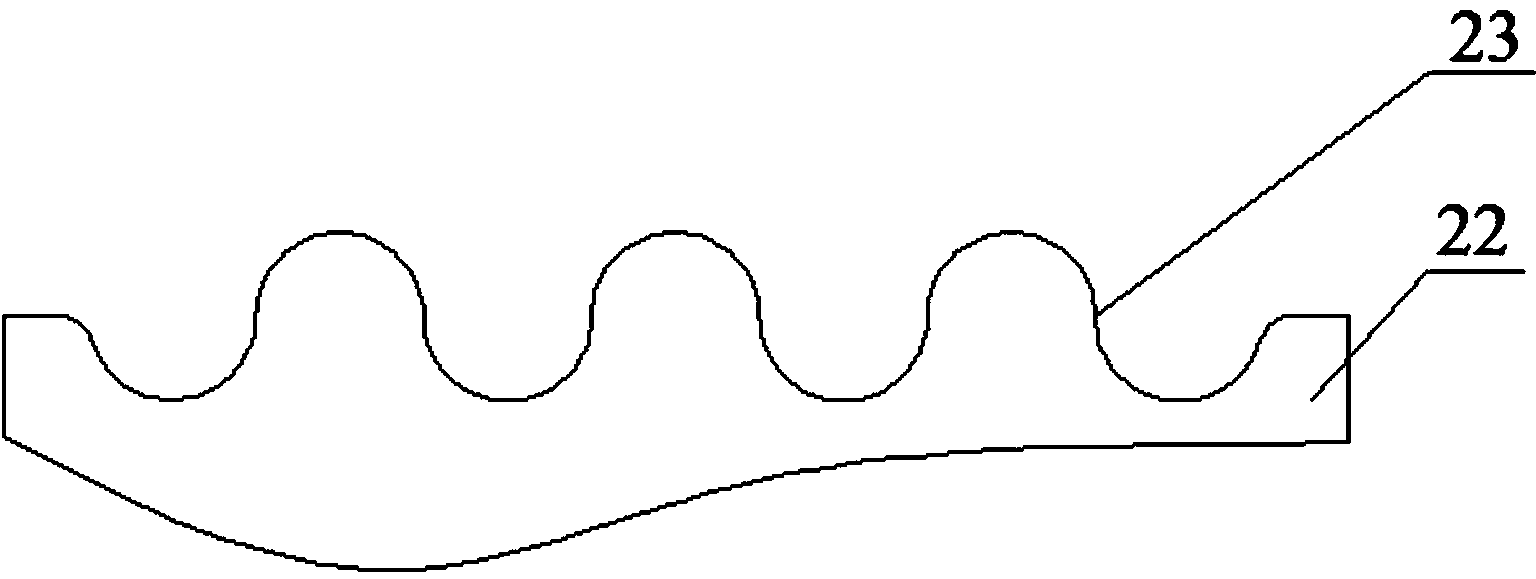

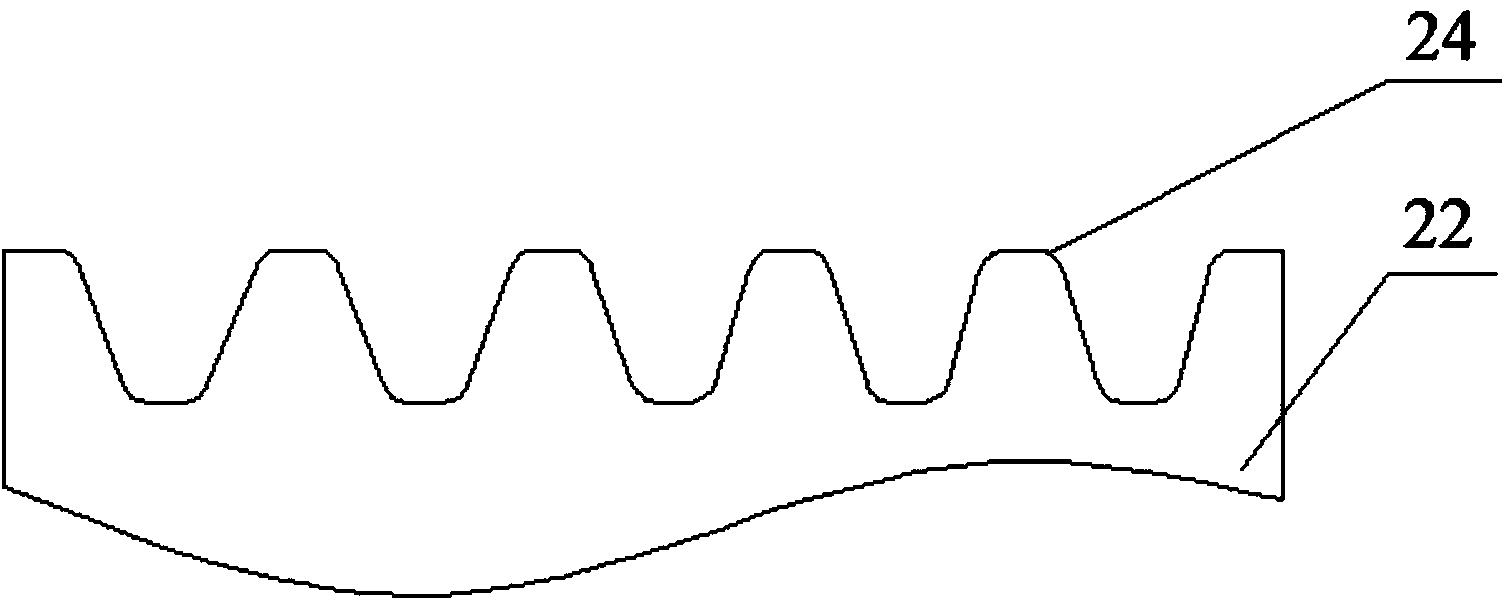

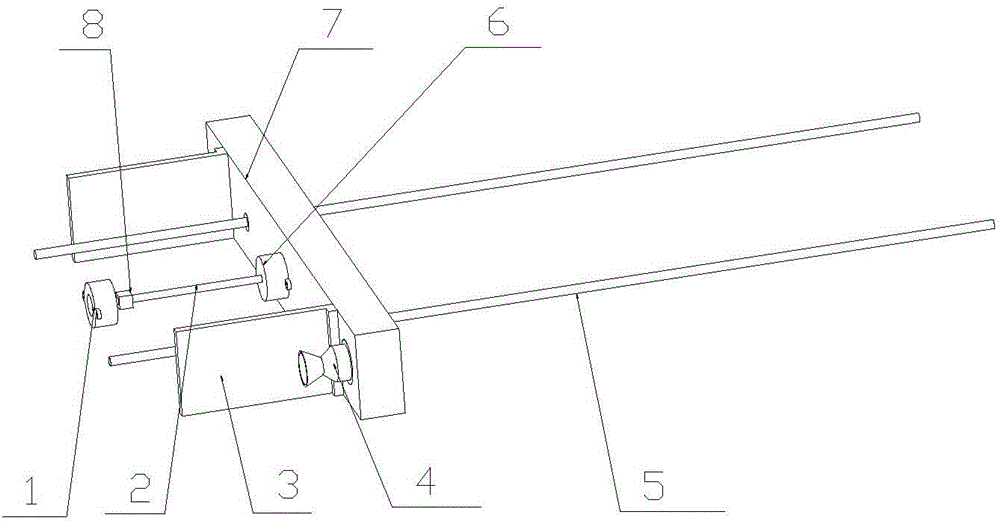

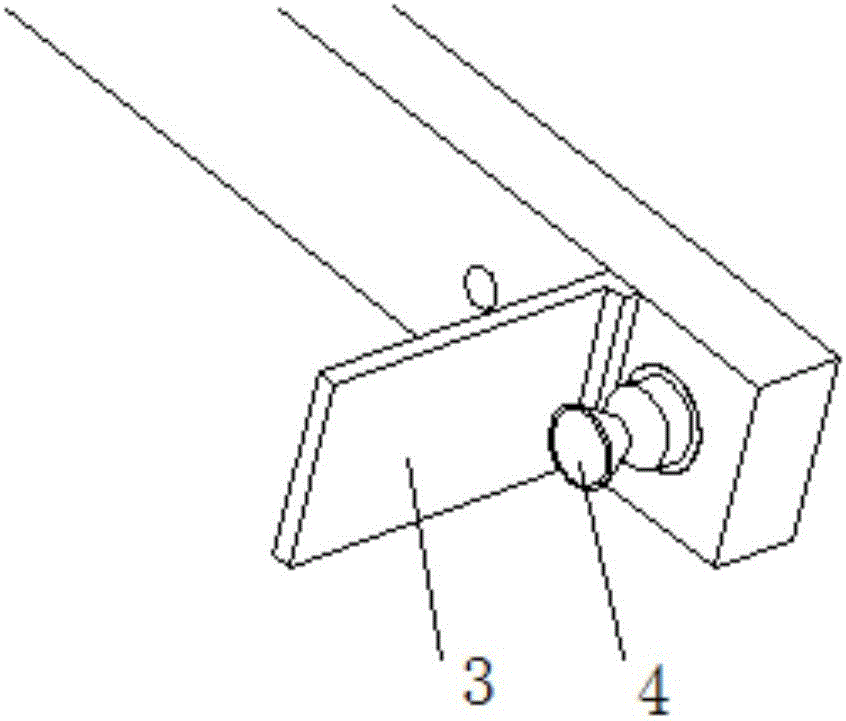

Method and device for forming half-mold of metal flow field plate of mini-type fuel cell in laser shock mode

InactiveCN103920988AImprove forming efficiencyHigh forming precisionCell electrodesLaser beam welding apparatusControl systemEngineering

The invention provides a method and device for forming a half-mold of a metal flow field plate of a mini-type fuel cell in a laser shock mode. The method comprises the steps that according to the designed shape and the designed size of a flow channel of the metal flow field plate, a template provided with a groove with the same shape and the same size is machined, and a motion path of laser beams is well planned according to the shape and the size of the flow channel; a control system controls the motion direction, the path and the machining speed of the laser beams according to a track and a whole flow field is formed through accumulation of plastic forming. The device for forming the half-mold comprises a workbench base, a blank pressing device, the control system and a forming system. According to the method and device, the snake-shaped metal flow field plate can be formed, machining is simple, accuracy and efficiency are high, cost is low, and popularization and application of the metal flow field plate of the fuel cell and a mini-type PEMFC are facilitated.

Owner:JIANGSU UNIV

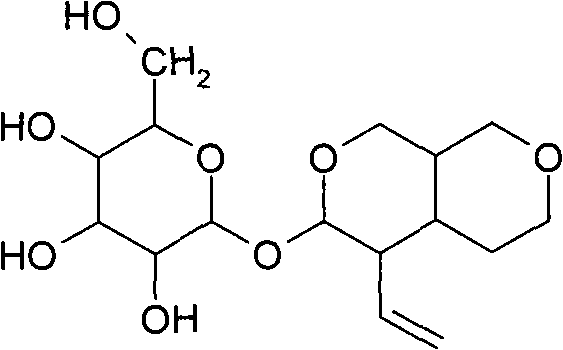

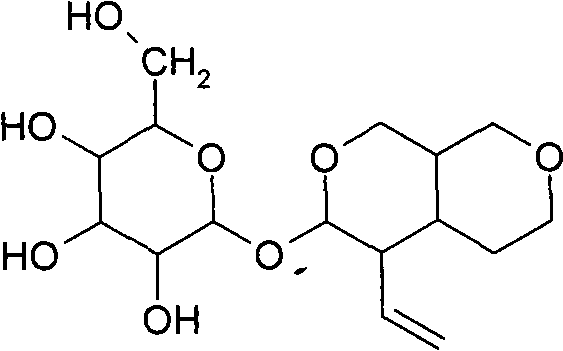

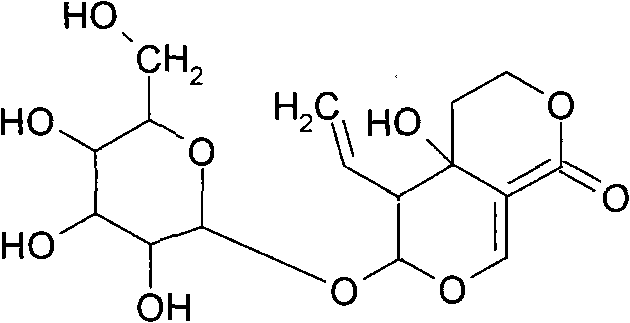

Method for separating glycoside chemical components from tibetan capillaris

ActiveCN101830892AShorten the timeLow costSugar derivativesSugar derivatives preparationChemistryColumn chromatography

Owner:CHONGQING ACAD OF CHINESE MATERIA MEDICA

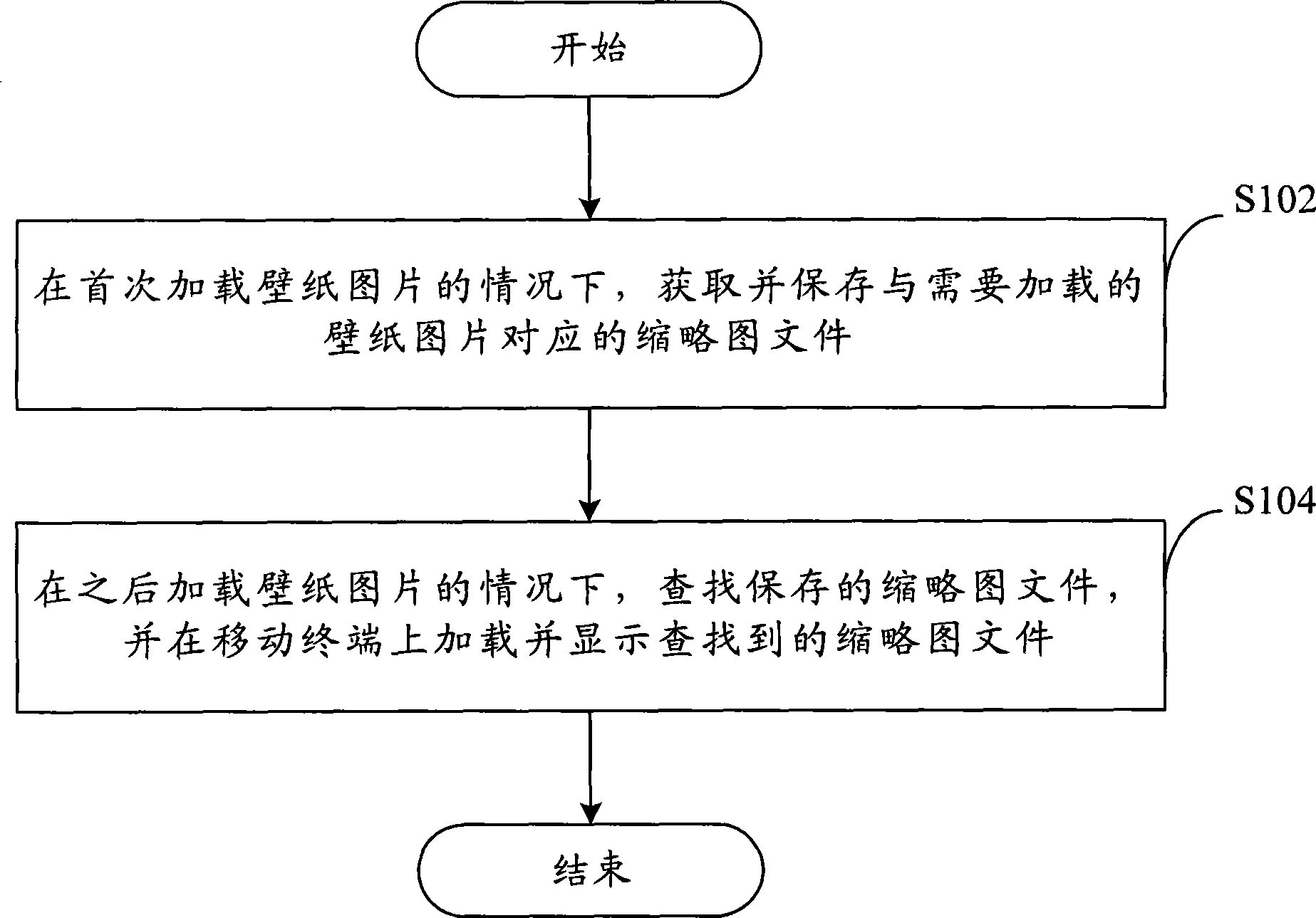

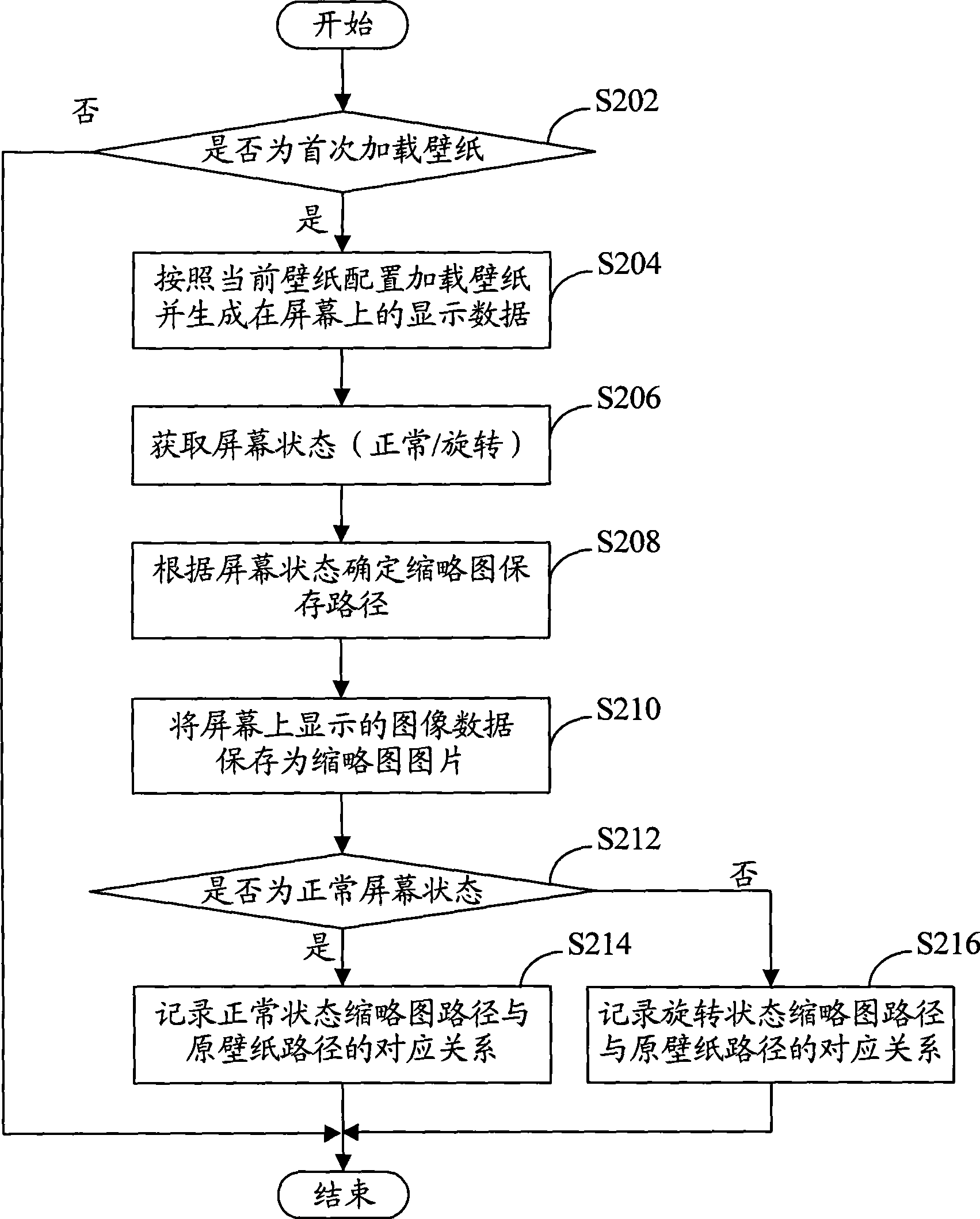

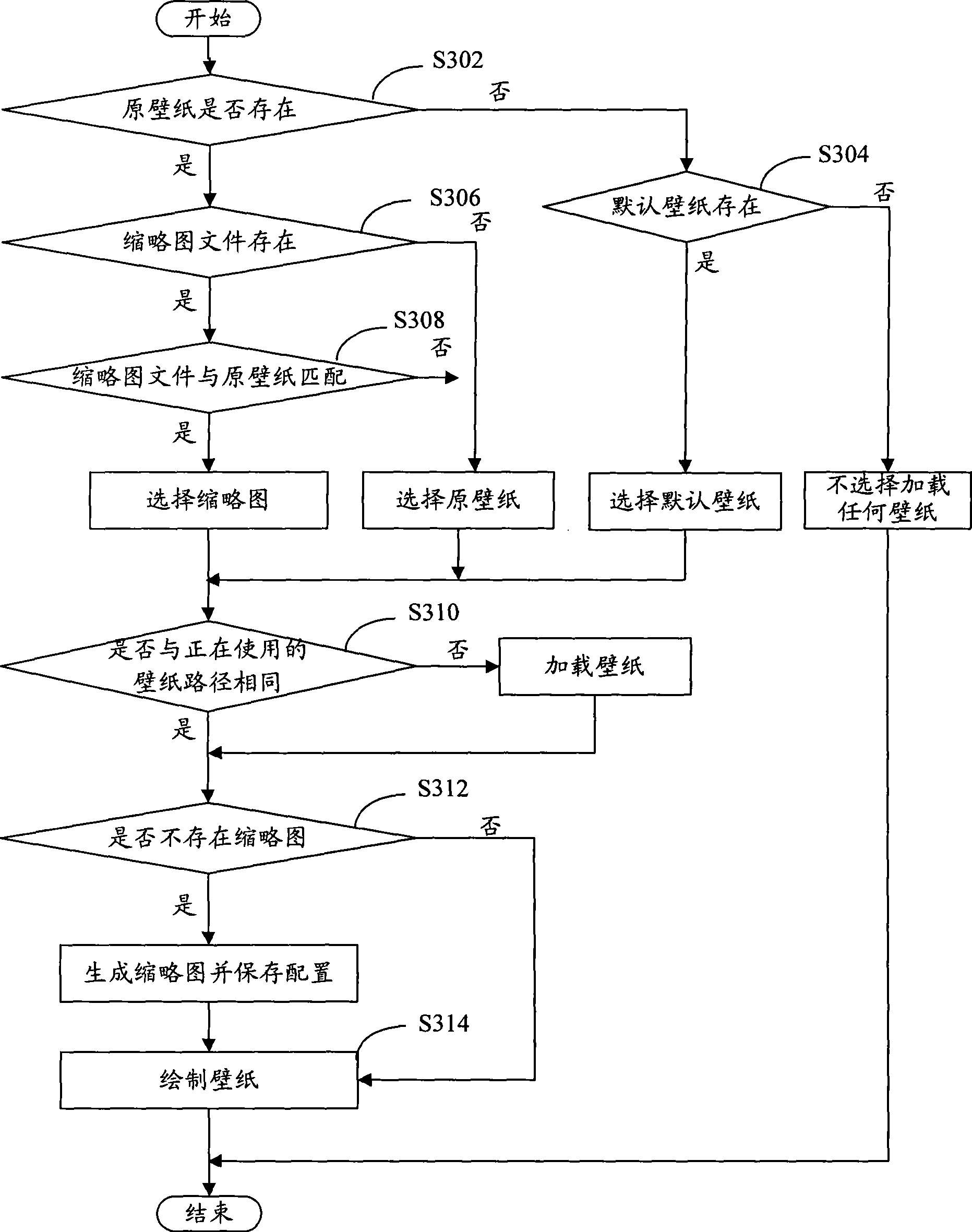

Wallpaper displaying method used for mobile terminal and mobile terminal

ActiveCN101420484AReduce time spentSolve the long loading timeSubstation equipmentInput/output processes for data processingMobile data terminalThumbnail

The invention discloses a wallpaper display method used for a mobile terminal and the mobile terminal. The method comprises the following steps: obtaining and storing a thumbnail file corresponding to a wallpaper picture which is required to be loaded when the wallpaper picture is loaded for the first time; searching the stored thumbnail file after the wallpaper picture is loaded, and loading and displaying the searched thumbnail file on the mobile terminal. By the method, the wallpaper loading time can be effectively reduced, and the user experience is improved.

Owner:ZTE CORP

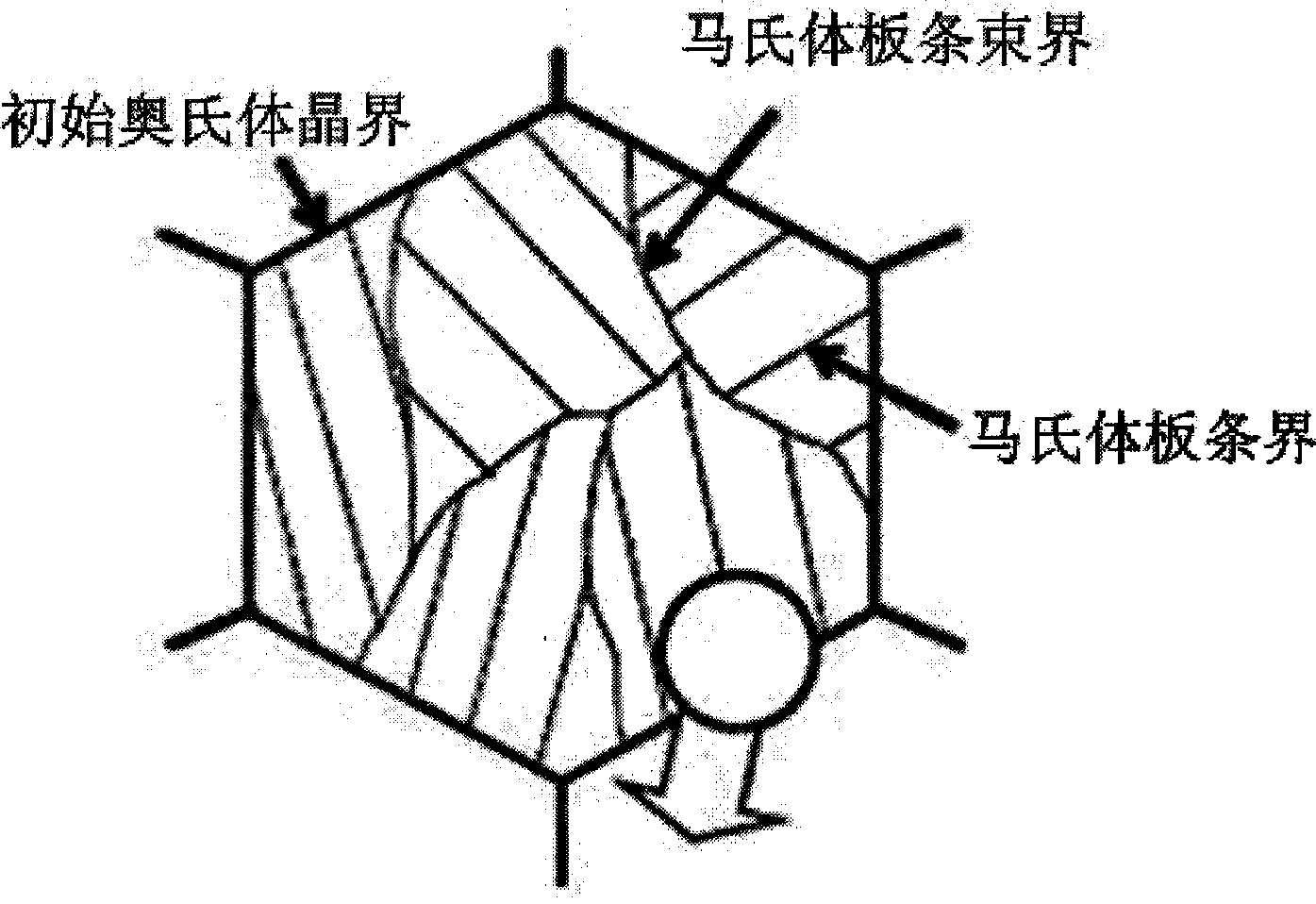

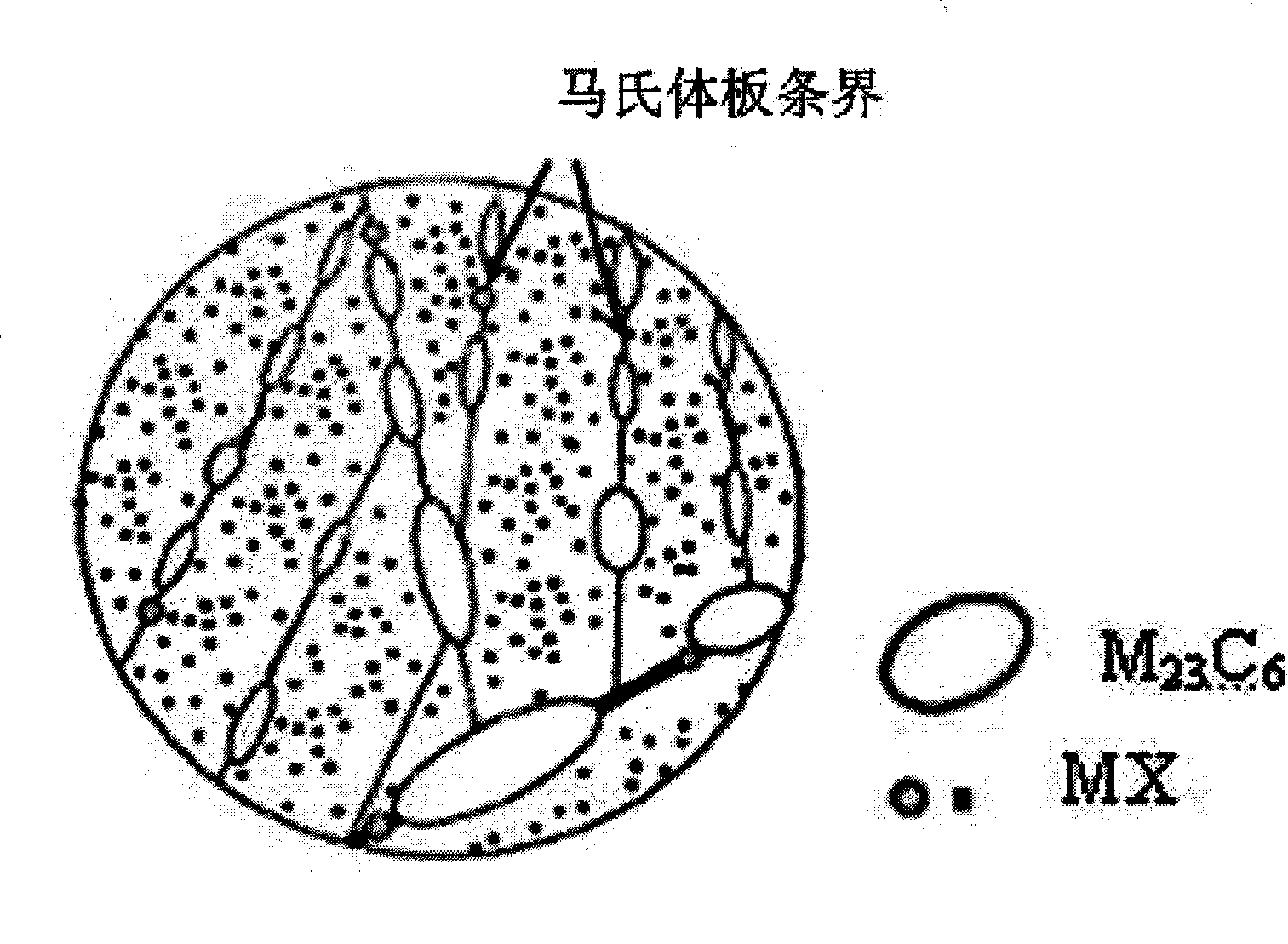

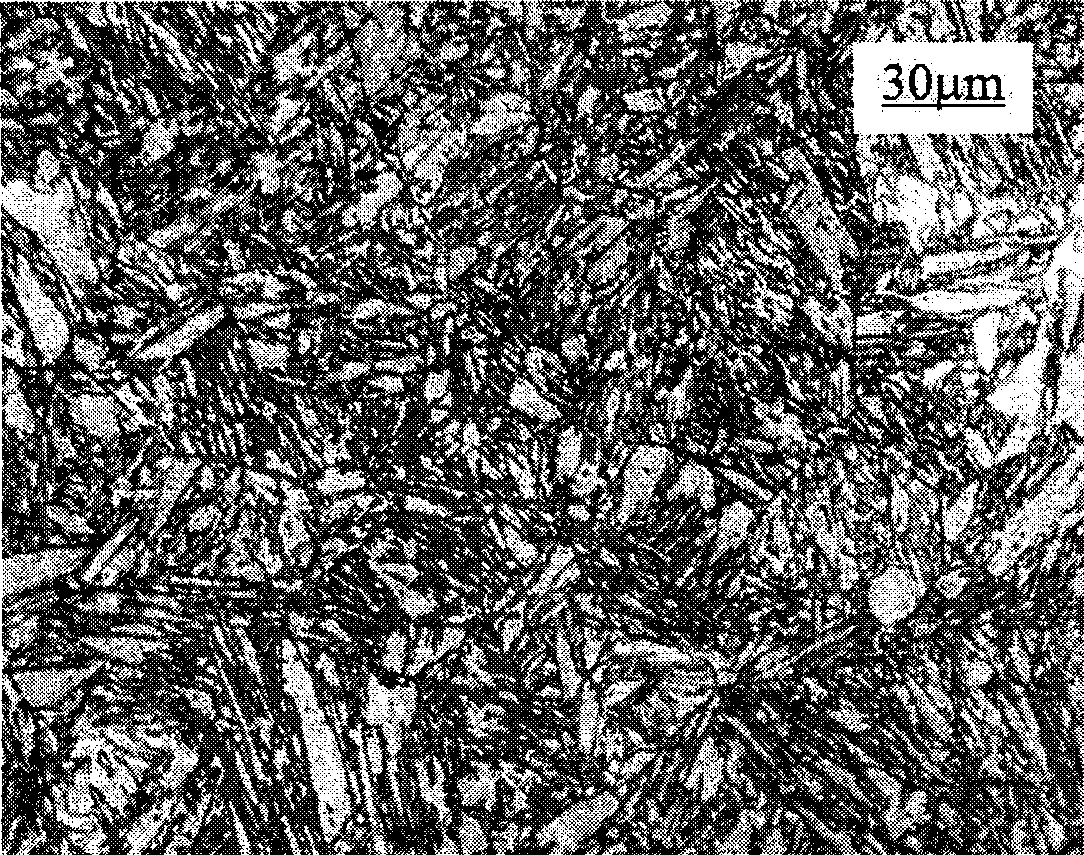

High-chromium ferrite heat-resistant steel fine-deformation martensite lath microstructure refinement method

InactiveCN101509058AImprove performanceLoading stress is smallIncreasing energy efficiencyAlloyHeat treated

The invention relates to a method for refining the micro-deformation martensitic lath microstructure of high-chromium (Cr) ferrite heat-resistant steel, comprising the following steps: the high-chromium (Cr) ferrite heat-resistant steel is hot-rolled into tubes or plates, and is generally produced into samples with the wall thickness being not larger than 6cm to be ensured to reach required heating and cooling rate; the method is characterized in that the samples are placed in a high-frequency induction heat-treating device for treatment, wherein, the procedures are set as follows: setting the heating rate as 30 to 80 K / min; preserving temperatrue for 5 to 15min after the temperature rises from room temperature to 1,223 to 1,323 K; further cooling to 1,023 to 1,073 K at a cooling rate equal to the heating rate; carrying out slight compressive stress deformation, loading for 3 to 10 s and then unloading immediately, wherein, the stress loaded is 10 to 40 MPa; and then, cooling to the room temperature at the rate equal to the cooling rate. Compared with the conventional method for refining the martensitic lath microstructure, which is characterized in that the deformation is formed by increasing the stress, the method of the invention for refining alloy grains has the advantages of small loaded stress and short loading time; the energy consumption is much lower than that of the conventional method; furthermore, the high-temperature performance of the alloy is much improved, therefore, the method is a potential and practical manufacturing method.

Owner:TIANJIN UNIV

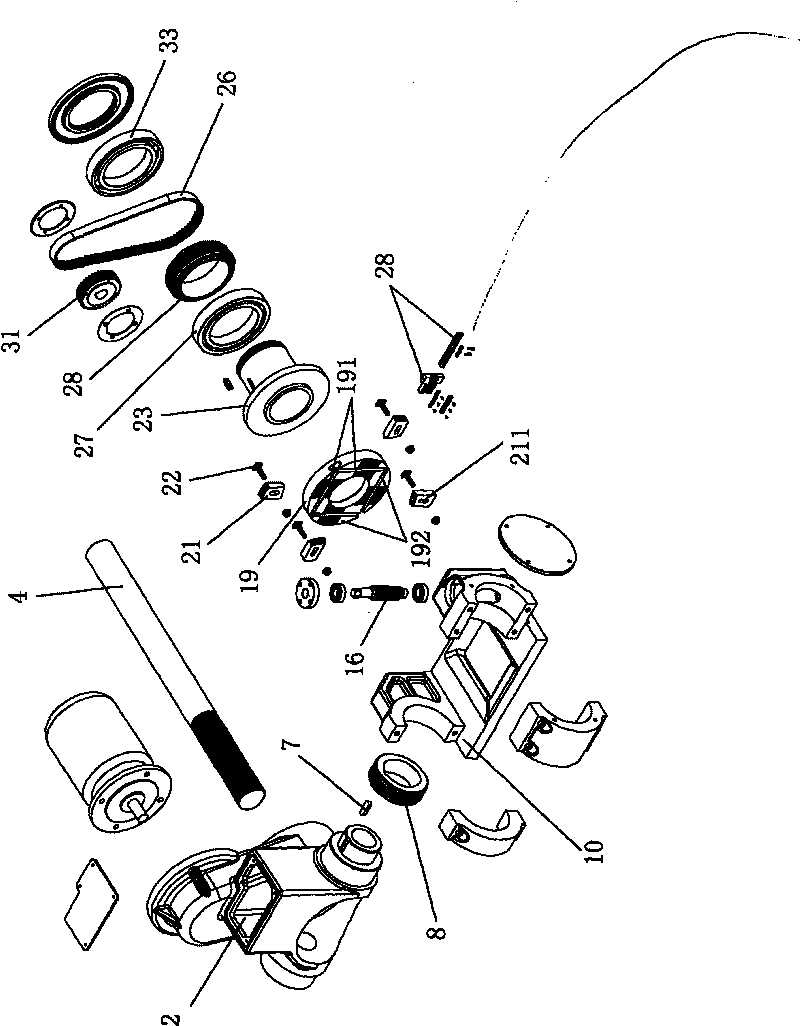

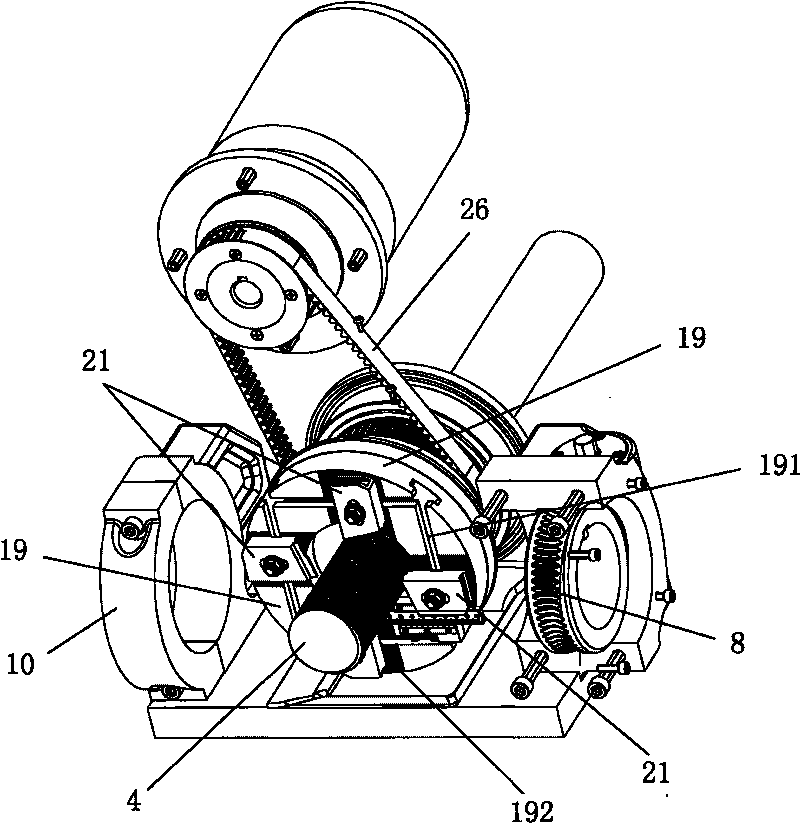

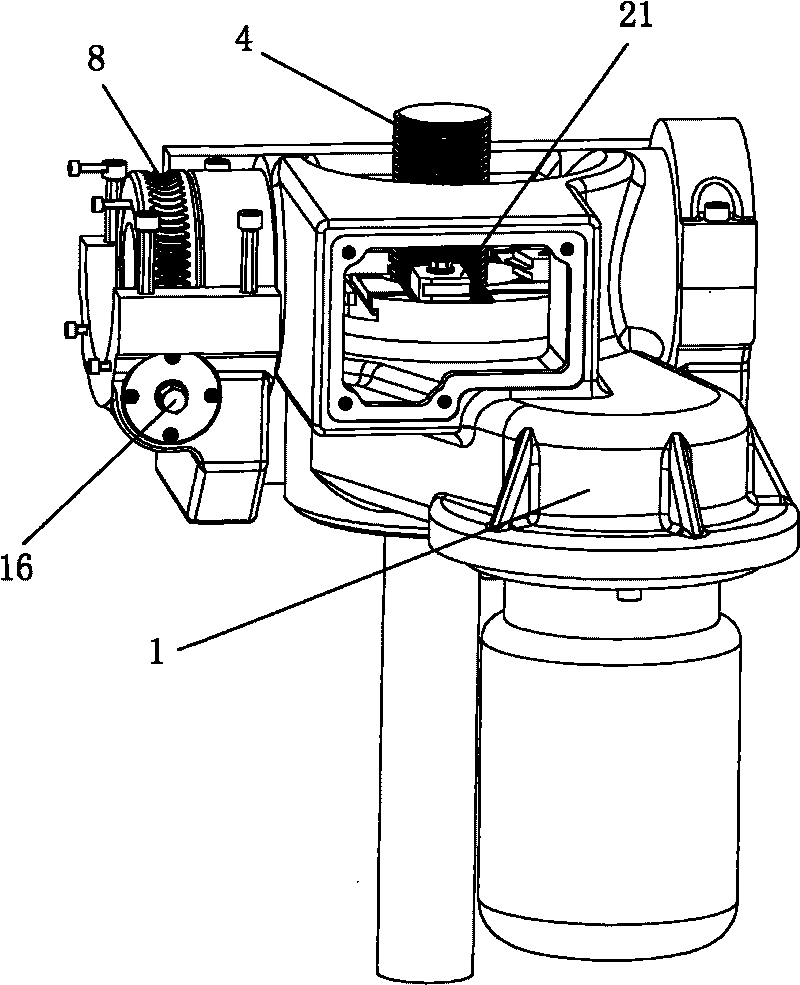

New high-efficiency whirling milling head

InactiveCN101745705AHigh precisionIncrease contact surfaceThread cutting toolsThread cutting machinesMilling cutterMouse Tooth

The invention discloses a new high-efficiency whirling milling head. Four cutter bars are fixedly arranged on four cutter installing grooves on a milling cutter disk, and the milling cutter disk is provided with mouse tooth-shaped gears meshed with the cutter bars, so that the cutter bars can be positioned more reliably and can be assembled and disassembled more conveniently. The positions of the cutter bars in the cutter installing grooves are adjusted by a vernier depth gauge to meet the condition that the center of the top edge of a cutter passes through the axle center of a workpiece. In the invention, the milling cutter disk and a pulley drive mechanism fixing cover are arranged in a whirling milling head cover body, and the lift angle of a milling head which is integrally connected with the whirling milling head cover body is adjusted through a set of screw bevel gear mechanism. After the cutter bars are worn, only the top surfaces of the obtuse parts of the cutter bars need to be ground, the tooth thickness and the cutting center line of the cutter bars can not be changed, the cutter bars can be reground for many times, and the dimensional accuracy and the positioning accuracy of the cutter bars can not be changed. The cutter which is ground by being vertically inclined for 13 degrees by the cutter bars is in a shortened tooth shape, still has very high strength and can be used for powerful high-speed milling.

Owner:南靖长青精密丝杆制造有限公司

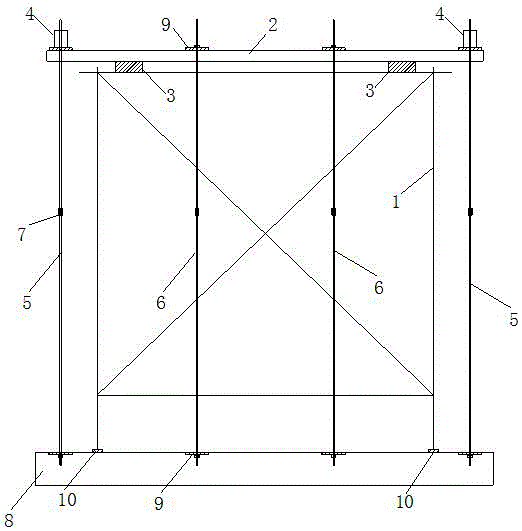

Loading device for static load test of steel structure frame body

ActiveCN106092545AAccurately measure the actual loading forceImprove test efficiencyMachine part testingForce sensorSteel structures

Owner:JIANGSU TESTING CENT FOR QUALITY OF CONSTR ENG +1

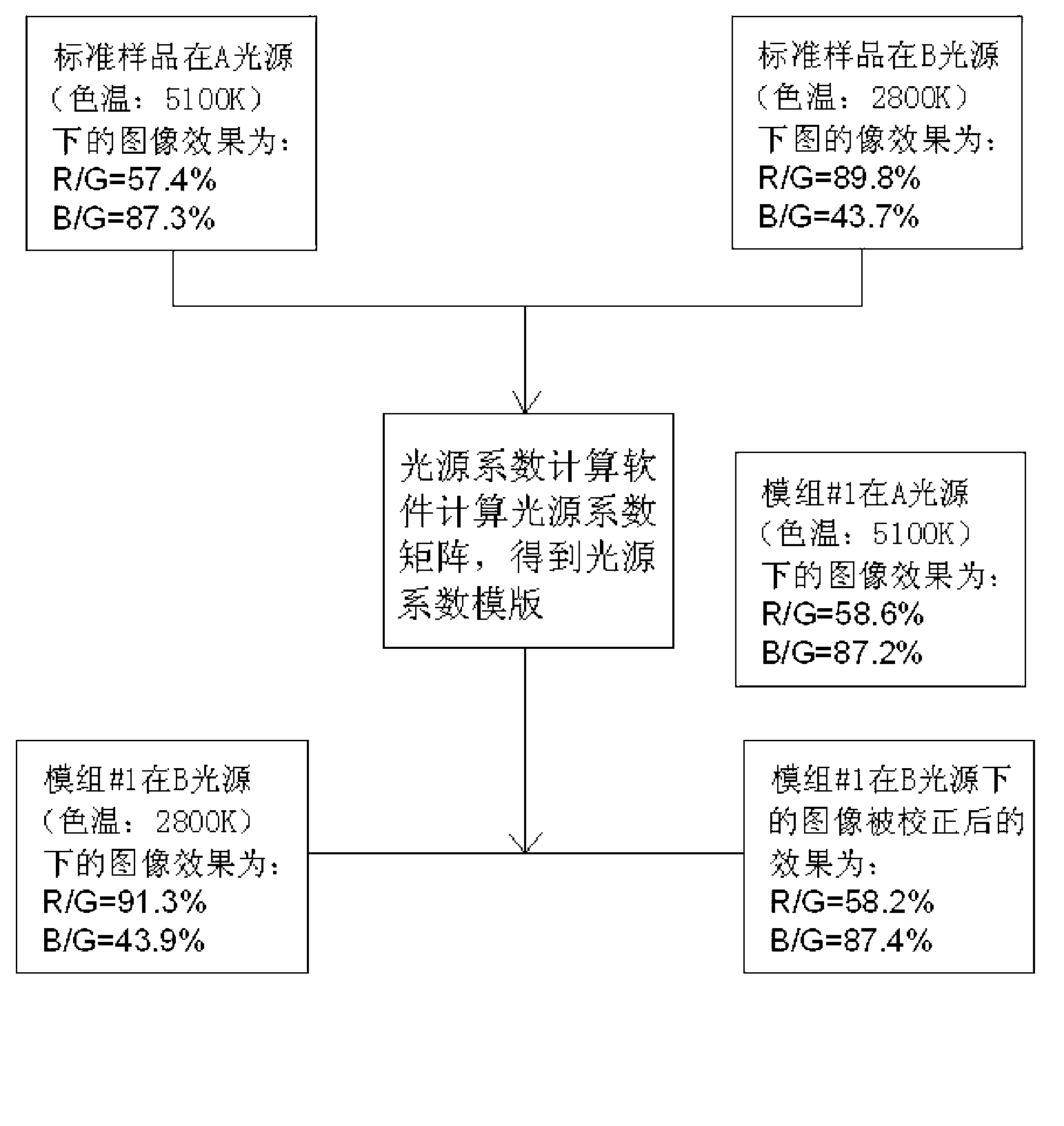

Camera module set one time programmable (OTP) burning photosource coefficient remedying and controlling method

ActiveCN103067739AOvercome the problem of poor consistencyImprove consistencyTelevision systemsCamera moduleOne time programmable

The invention discloses a camera module set one time programmable (OTP) burning photosource coefficient remedying and a controlling method which comprise steps as follows: a. a photosource image A of a standard sample can be gathered under an OTP burning standard environment; b. a photosource image B of the standard sample can be gathered under an OTP burning and being corrected environment; c. the photosource coefficient matrix of the image A in the step a and the image B in the step b can be calculated by a photosource coefficient calculation software to acquire a photosource coefficient template; d. when the camera module set is burned under the OTP burning to be corrected environment, the photosource coefficient template of the step c can be brought to do coefficient correction. After the coefficient is corrected, a photosource image C is obtained; e. when the camera module set OTP is burned, the camera module set can do data burning according to the corrected photosource image C in the step d. The camera module set OTP burning photosource coefficient remedying and the controlling method can achieve to unify photosources of different photosource equipments into an effect under an identical target photosource in the camera module set OTP burning station to solve the problem that photosources in different color temperatures are difficult to adjust to be consistent in the different burning stations.

Owner:KUNSHAN Q TECH CO LTD

Method for preparation of data for loading into a data processing device

ActiveUS20060179159A1Solve the long loading timeDigital data processing detailsTime-division multiplexData packData connection

In a method and arrangement for preparation of data for loading from a first data processing device into a second data processing device via a first data connection, a number of transmission-ready transmission data packets are generated in at least one packetizing step from the data to be loaded into the second data processing device; and at least one load parameter influencing the total load time until a complete loading of the data into the second data processing device is determined in a determination step preceding the packetizing step. The generation of the transmission data packets ensues in the at least one packetizing step dependent on the first load parameter.

Owner:FRANCOTYP POSTALIA

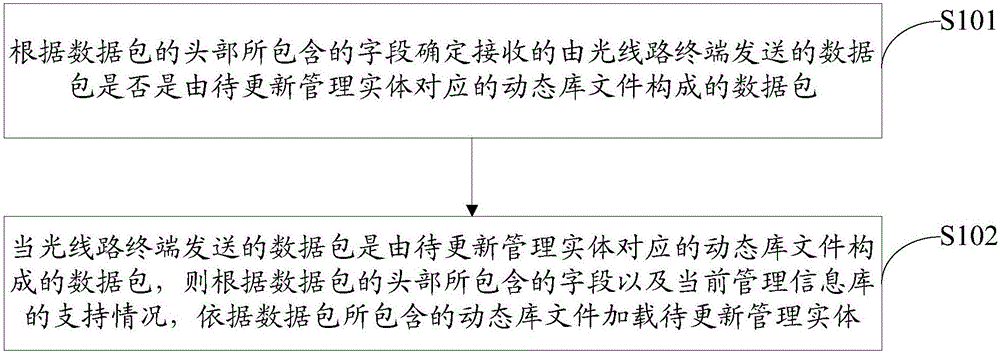

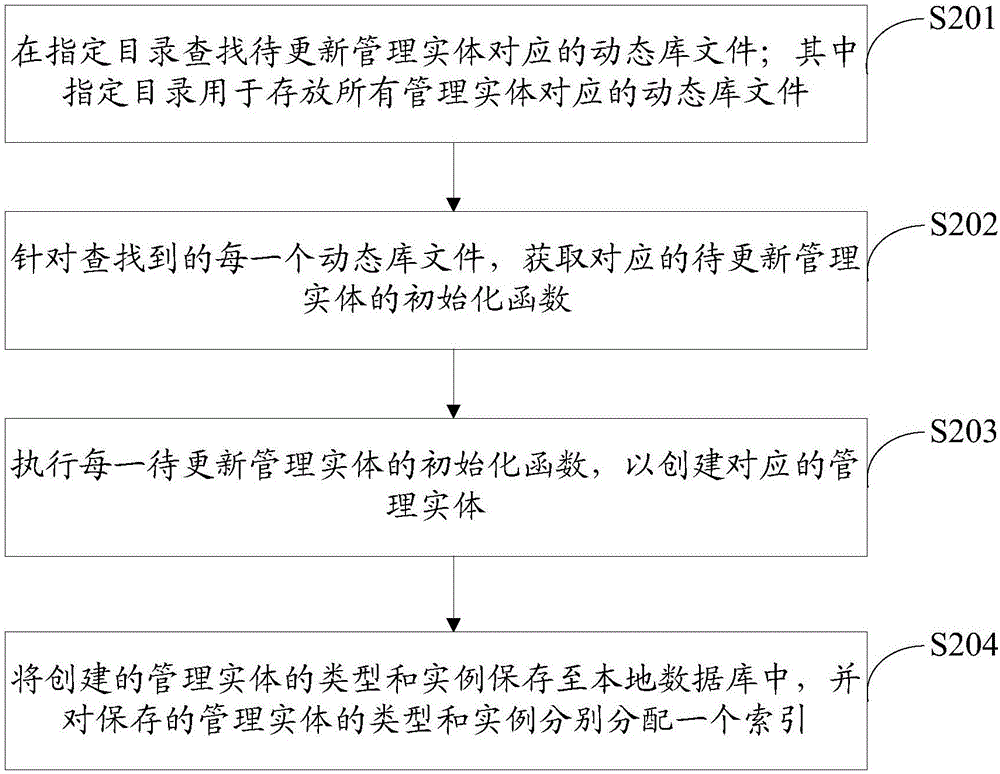

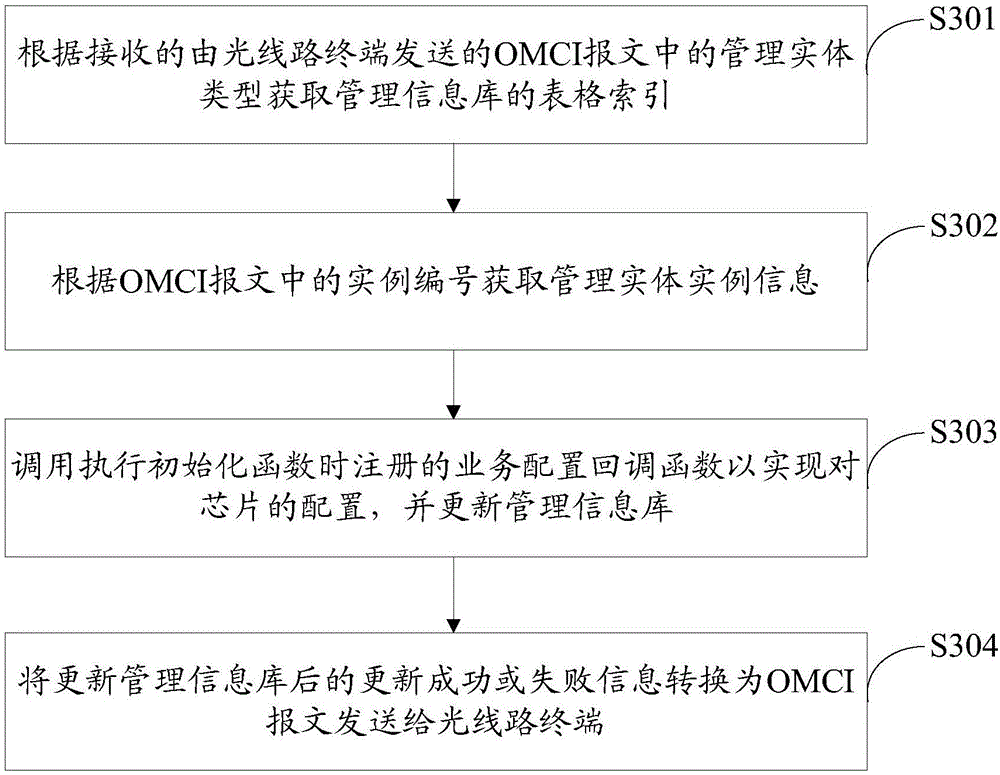

Optical network unit, method for dynamic extension management function thereof and GPON system

ActiveCN106506246ASmall load fileSolve the long loading timeMultiplex system selection arrangementsData switching networksDynamic ExtensionProtocol for Carrying Authentication for Network Access

The invention discloses an optical network unit, a network unit and a method for dynamic extension management function of the optical network unit and a GPON system. An optical line terminal sends a data packet formed by a dynamic depot file corresponding to a to-be-updated management entity to the optical network unit through a standard upgrading interface in an OMCI protocol; the optical network unit determines whether the received data packet is formed by the dynamic depot file corresponding to the to-be-updated management entity according to fields included in a head of the data packet; and if yes, loading the to-be-updated management entity according to the dynamic depot file included in the data packet. For the to-be-updated management entity, updating data corresponding to the to-be-updated management entity is sent in a form of the dynamic depot file, so that dynamic loading is carried out on the to-be-updated management entity, and other businesses of the ONU cannot be interrupted; and furthermore, the loaded file is small, the loading time is short and the whole process does not need Flash operation, so that a condition of damage to equipment due to the Flash operation can be avoided.

Owner:RAISECOM TECH

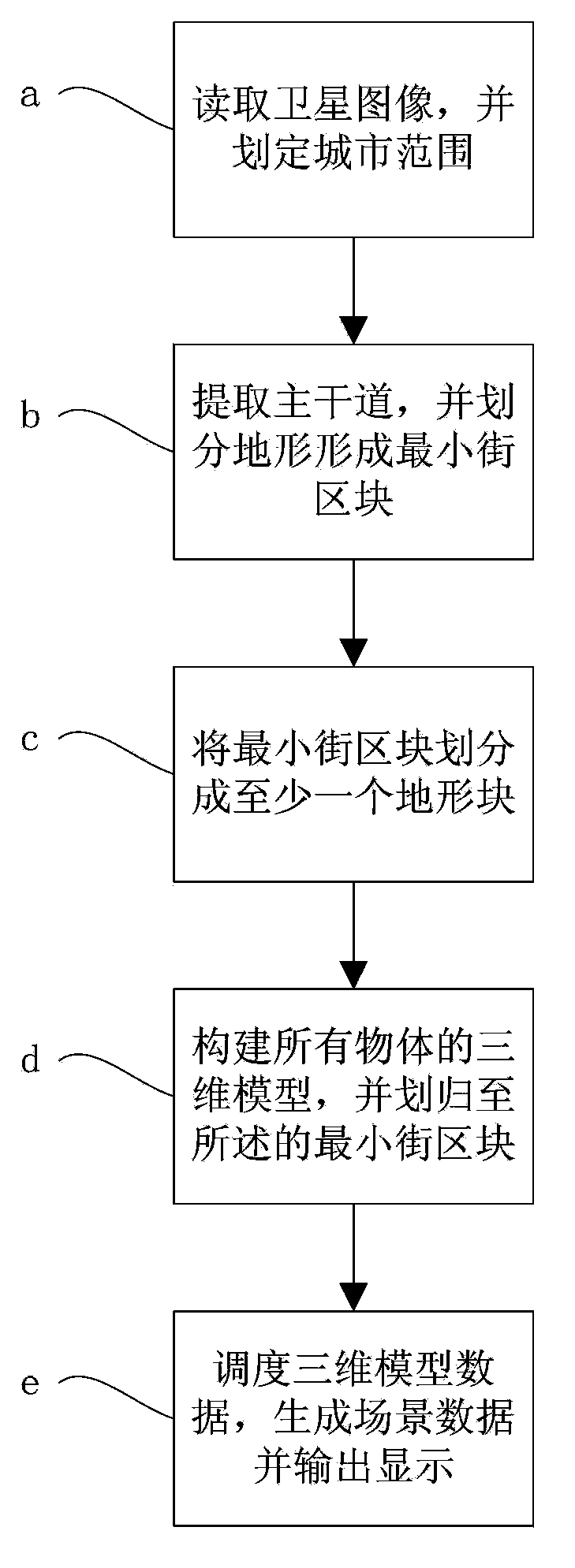

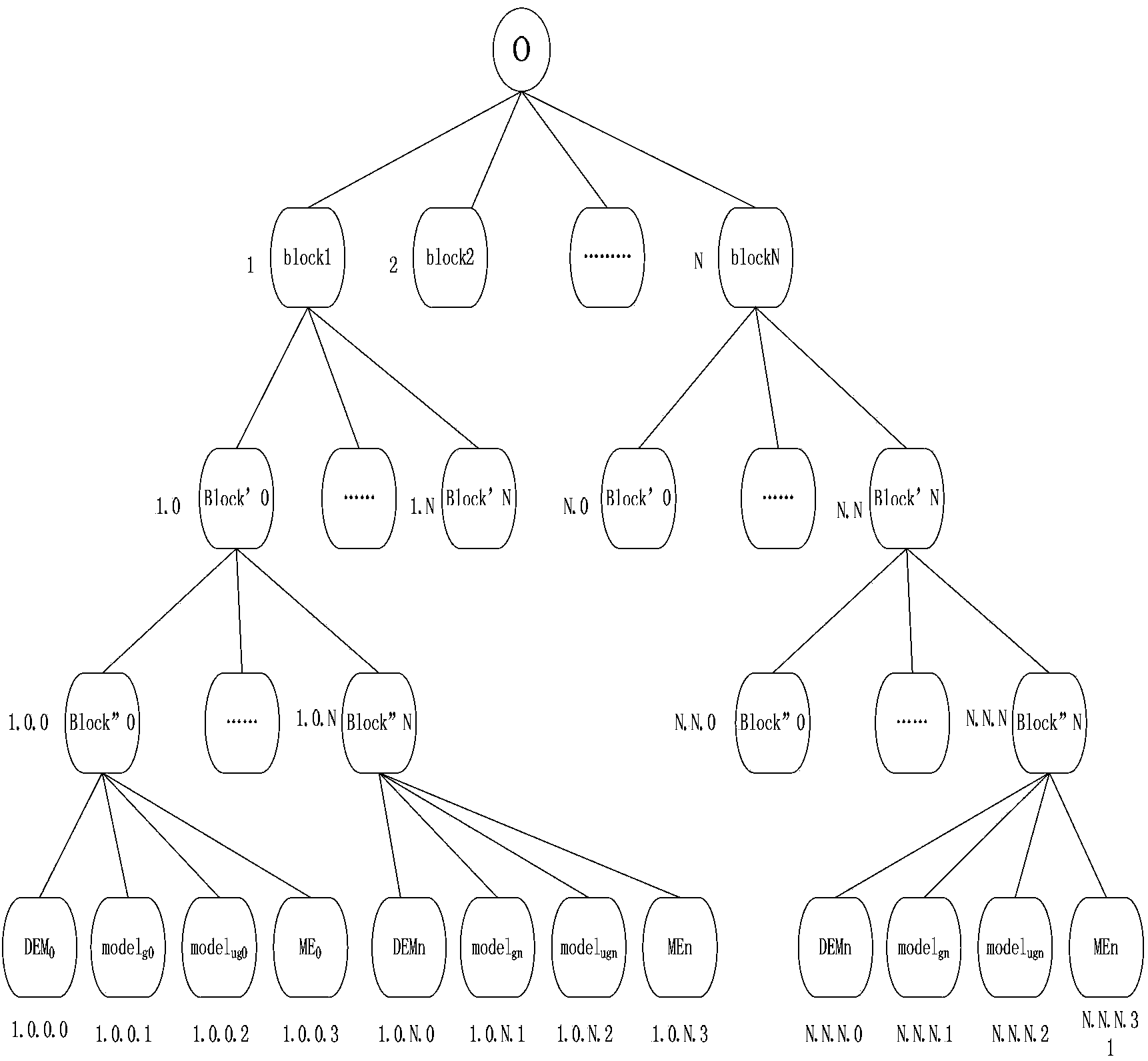

City stereoscopic dynamic scenario generation method based on BRLO-Tree mixed tree structure

InactiveCN103793935ANo blankSolve the long loading time3D-image rendering3D modellingState of artViewpoints

The invention relates to a city stereoscopic dynamic scenario generation method based on a BRLO-Tree mixed tree structure. The method includes the following steps: calculating and reading satellite images of a city and delimiting a city range in a two-dimension planar graph; extracting main roads in east-west and south-north directions in the city range and forming a plurality of minimum street blocks according to city-landform-dividing DEM data of the main roads; dividing each of the minimum street blocks into at least one landform block; constructing three-dimensional models for all objects on the ground and under the ground in adjacent landform blocks through a computer and dividing to the three-dimensional models to the minimum street blocks to which the three-dimensional models belong according to the positions of the landform blocks; adopting a BRLO-Tree mixed structure tree to schedule data of the three-dimensional models and calling scenario data with the three-dimensional models according to the viewpoint positions of scenarios and outputting and displaying the scenario data. Compared with the prior art, the city stereoscopic dynamic scene generation method based on the BRLO-Tree mixed tree structure is short in loading time, free from a blank-screen situation, small in data quantity, small in occupied storage space and smooth and fluent in scenario pictures.

Owner:TONGJI UNIV

Method for testing battery condition

InactiveUS7411400B2Minimize high voltage pickShorten the battery polesMaterial analysis by electric/magnetic meansElectrical testingTest batteryEngineering

According to this invention a battery testing device is provided. Such device activates a shortening between the battery poles using a predefined electronic circuit (in order to maximize the battery's energy potential) for a time period of 10-50 μsec. In a subsequent time period of ˜100-200 μsec, the loading is slowly decreased until the voltage returns to an open circuit voltage UOC. During the testing process, the voltage and the battery current are measured. The measurements are stored at the device database, to be later used in an algorithm for checking battery conditions.

Owner:BATTERY CONTROL CORP

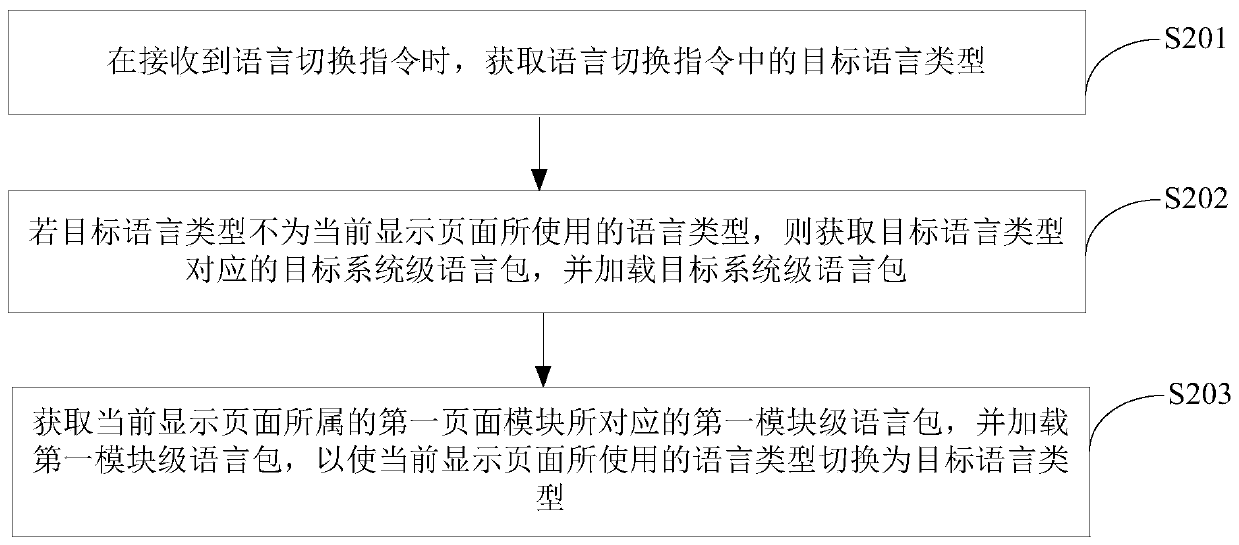

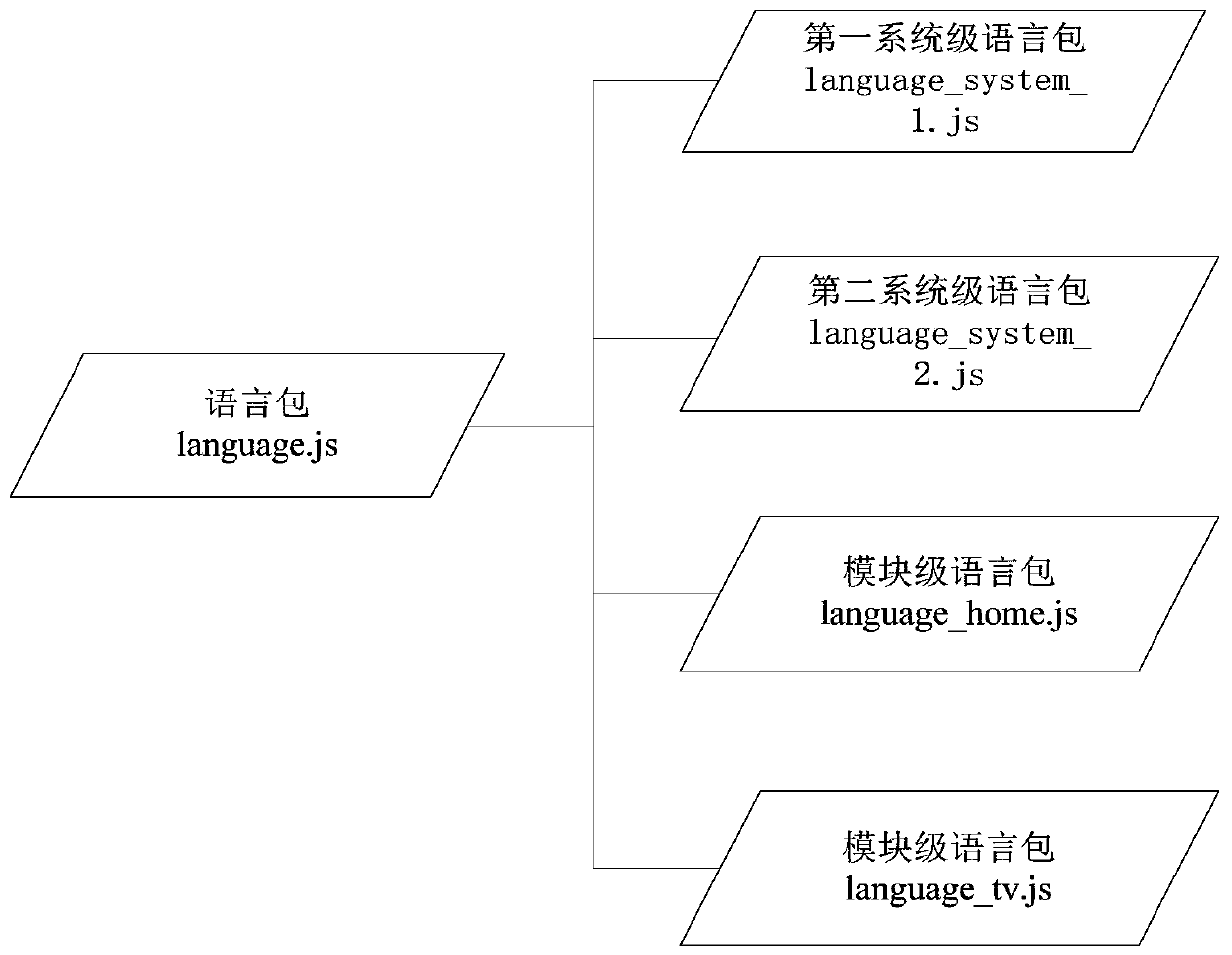

Language switching method and device and terminal equipment

ActiveCN110795192AShort switching latencyImprove experienceExecution for user interfacesEnergy efficient computingSoftware engineeringTerminal equipment

The embodiment of the invention provides a language switching method and device and terminal equipment. The language switching method comprises the following steps: when receiving a language switchinginstruction, obtaining a target language type in the language switching instruction; if the target language type is not the language type used by the current display page, obtaining a target system-level language package corresponding to the target language type, and loading a target system-level language package; obtaining a first module-level language package corresponding to a first page module to which the current display page belongs, and loading a first module-level language package; and switching the language type used by the current display page into the target language type, when language switching is carried out, only the system-level language package and the partial module-level language package need to be loaded, and the volume of a file needing to be loaded is small, so thatthe file loading time is short, and the time needed for language switching is short, and a user is prevented from experiencing long switching waiting time, and the user experience is improved.

Owner:VIDAA(荷兰)国际控股有限公司

Ultrahigh-speed tensile testing machine driven by rocket engines

ActiveCN106813983AIncrease the itineraryStrong pullMaterial strength using tensile/compressive forcesSlide plateEngineering

The invention discloses an ultrahigh-speed tensile testing machine driven by rocket engines. The ultrahigh-speed tensile testing machine comprises a workbench, a stretching device, a driving device, a reduction gear, and a guide slide rail, wherein the stretching device comprises a first clamp, a second clamp and a sliding plate; the driving device comprises the rocket engines; the guide slide rail is fixed at the upper end of the workbench; the first clamp is fixed at one end of the upper end of the workbench, and the reduction gear is fixed at the other end of the upper end of the workbench; the second clamp is fixed on the sliding plate and used for clamping the other end of a tested sample, and a connecting line between the first clamp and the second clamp is parallel to a length direction of the guide slide rail; the sliding plate slides linearly on the guide slide rail; and the rocket engines are symmetrically fixed at two ends of the sliding plate. The tensile testing machine provided by the invention can implement a short-time ultrahigh-speed tensile test for a material, can adjust the stretching stroke at the same time, and is suitable for performance analysis of short-time ultrahigh-speed loading of a material.

Owner:NANJING UNIV OF SCI & TECH

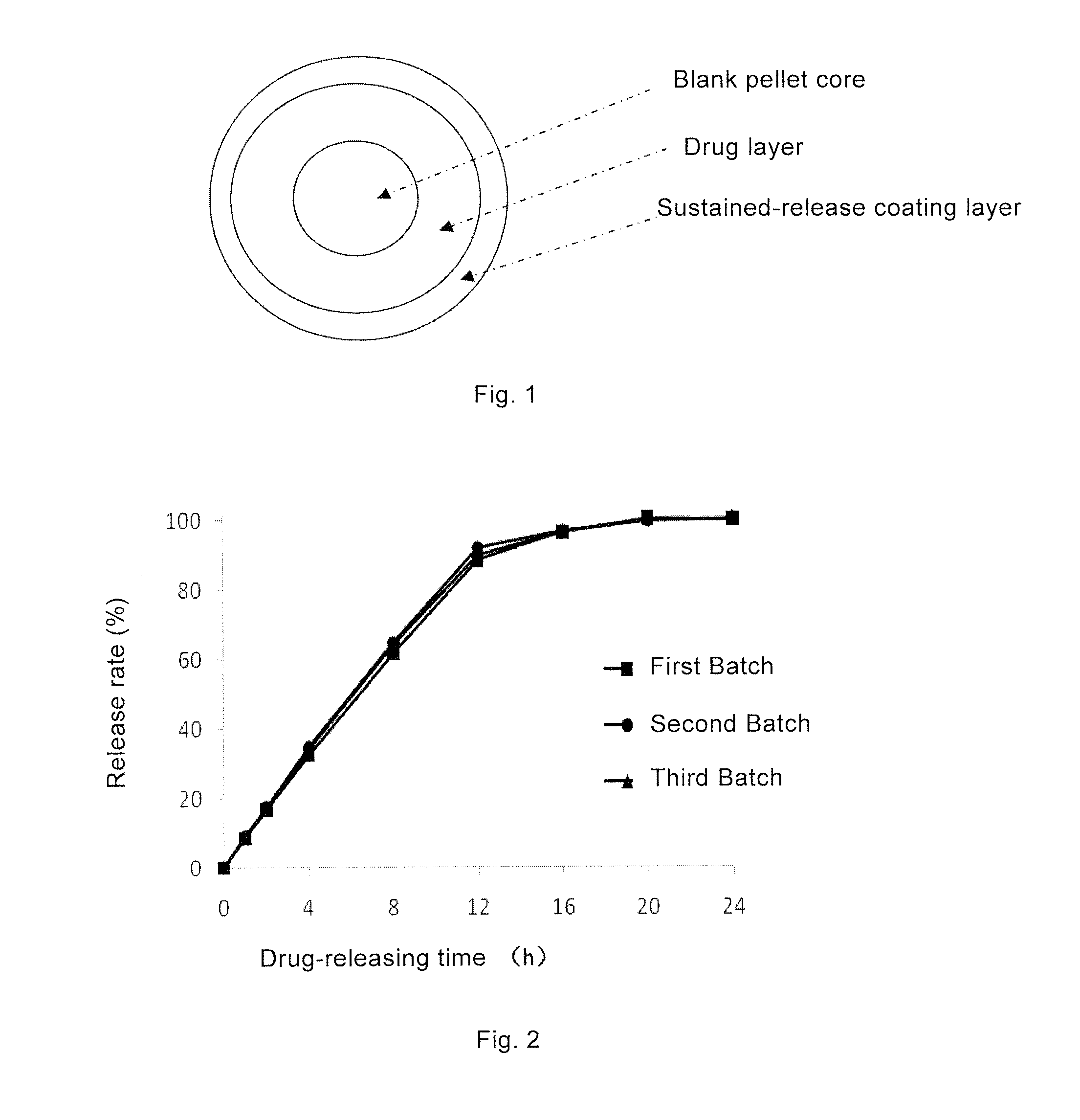

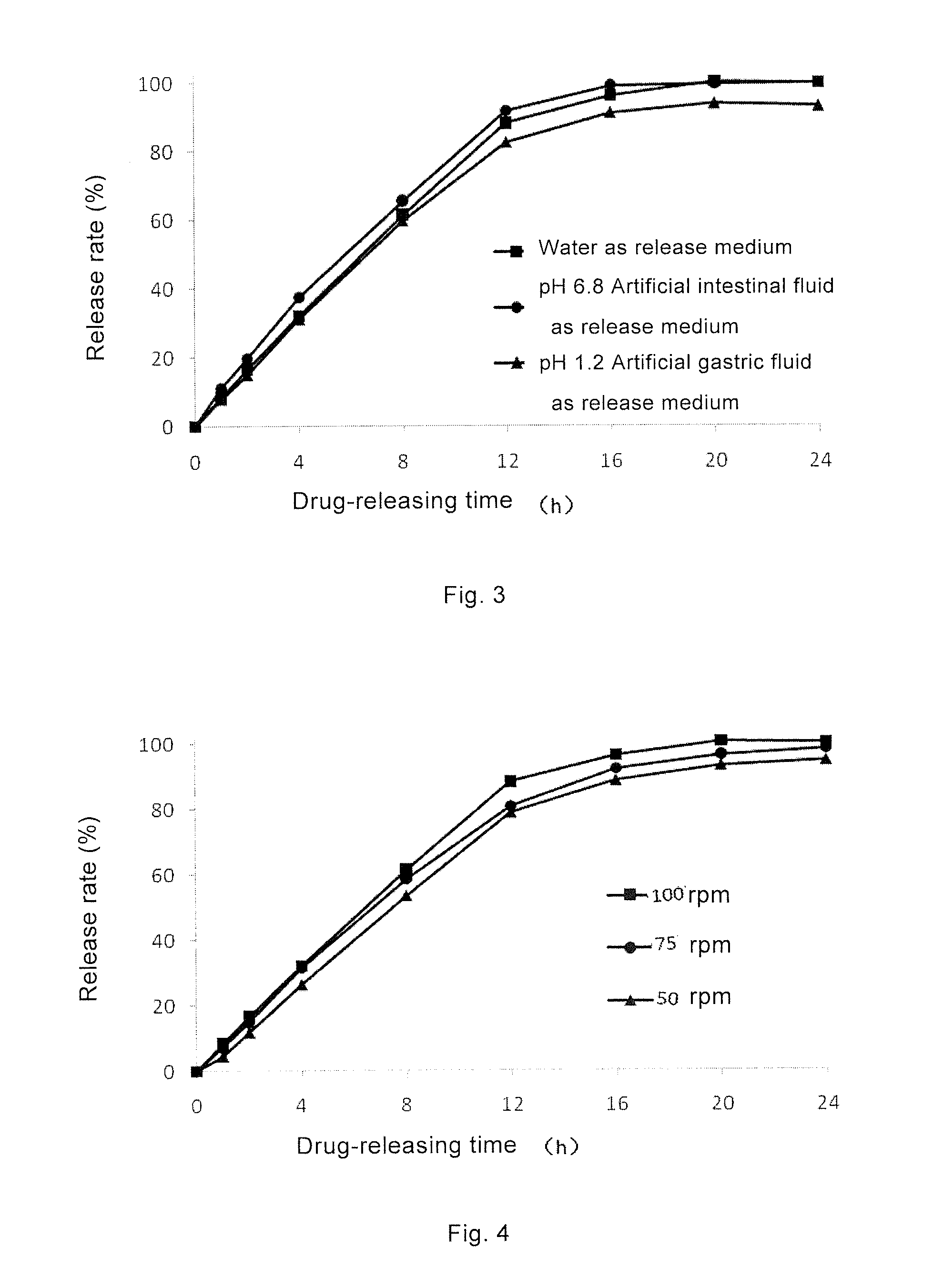

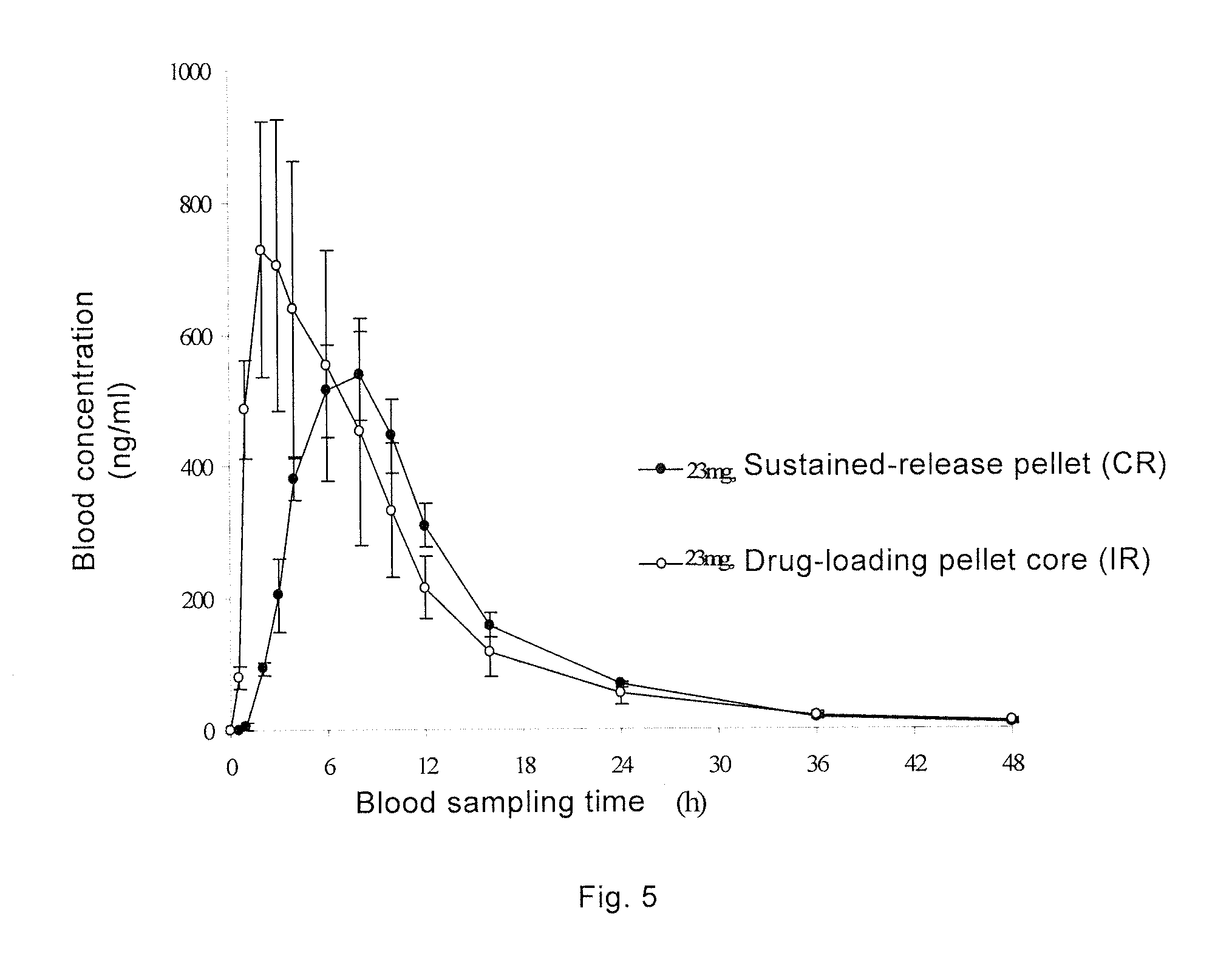

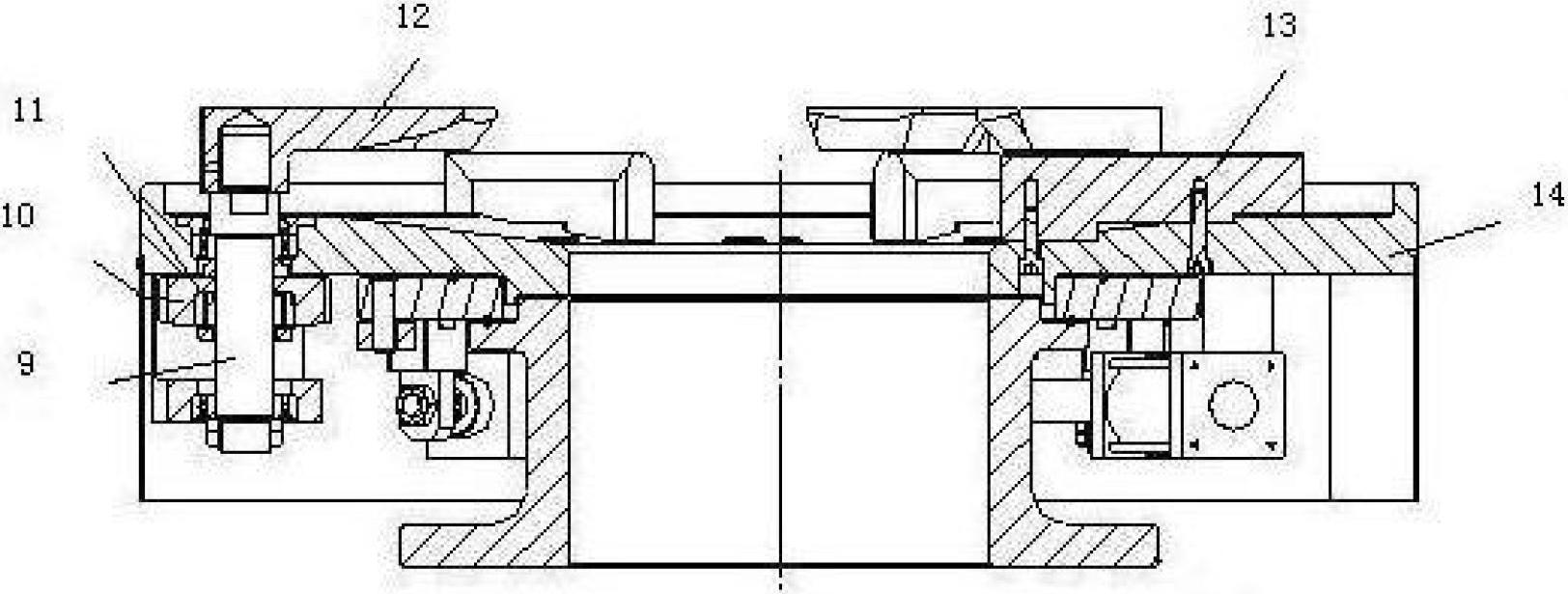

Topiramate Sustained-Release Pharmaceutical Composition, Method for Preparing Same, and Uses Thereof

InactiveUS20150099003A1Good effectImprove controllabilityBiocideNervous disorderSustained release pelletsMedicine

A sustained-release pharmaceutical composition of topiramate, which is free of binding agent. The sustained-release pharmaceutical composition of topiramate is a sustained-release pellet, comprising a blank pellet core, a drug layer, and a sustained-release coating layer.

Owner:INST OF PHARMACOLOGY & TOXICOLOGY ACAD OF MILITARY MEDICAL SCI P L A

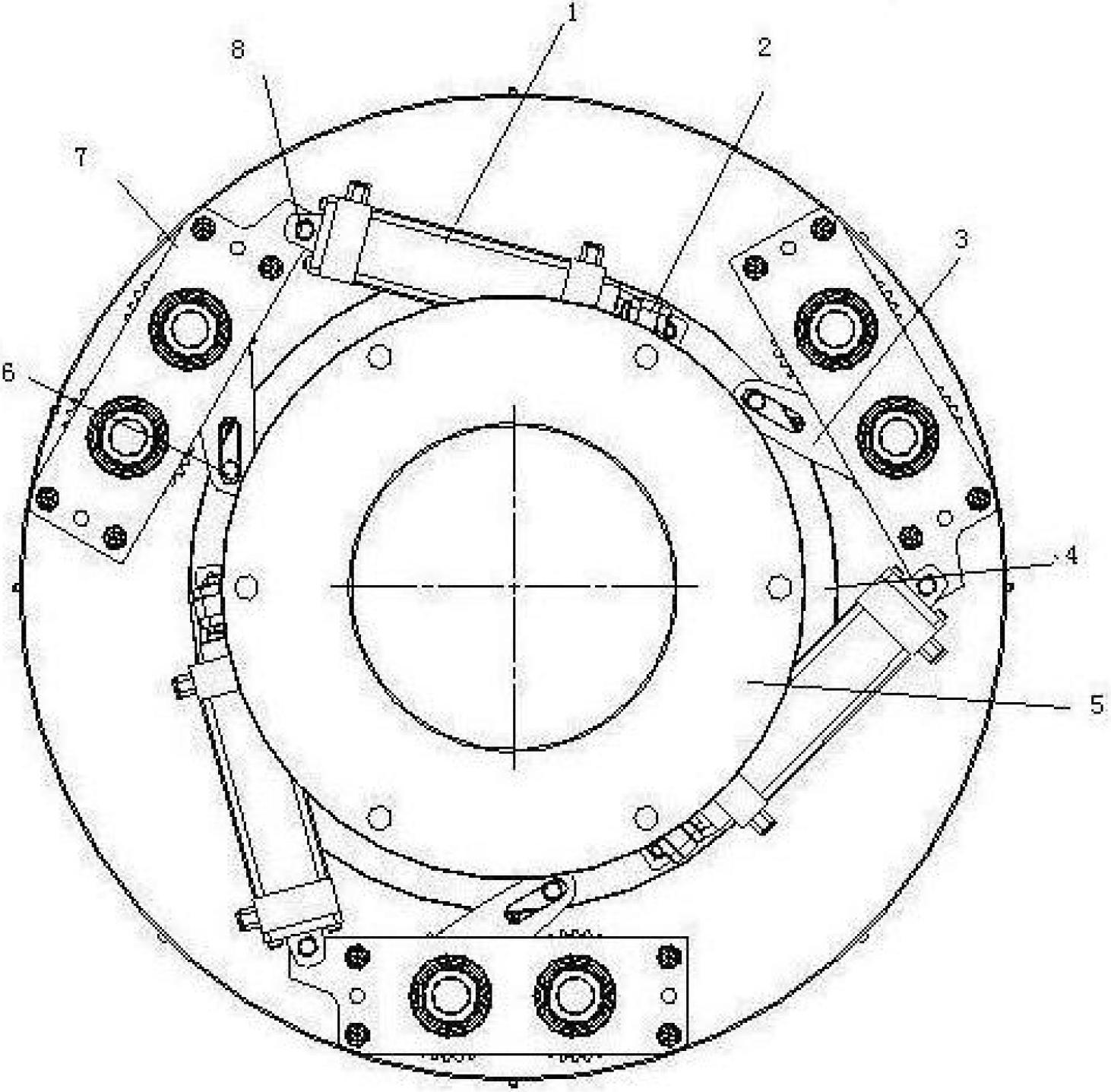

High-speed chuck for aluminum alloy wheel

ActiveCN102642035AVersatilityAction response is fastTurning machine accessoriesMachining processAluminium alloy

The invention discloses a high-speed chuck for an aluminum alloy wheel, belonging to the machining process equipment for the aluminum alloy wheel. The high-speed chuck is capable of realizing quick mounting (loosening) of the aluminum alloy wheel, and the mounting time taken is one quarter of that of the existing chuck; and the high-speed chuck is capable of mounting the aluminum alloy wheels of a series of diameters, and does not need to be frequently replaced and adjusted. Three driving cylinders 1, three pairs of synchronous gears 10, six jaw shafts 9, six jaws 12 and a synchronous turntable 4 are mounted on the chuck body 14; and a locking sleeve 11 is connected to the synchronous gears 10 and the jaw shafts 9. The driving cylinders 1 fixed to the chuck body 14 acts to drive the synchronous turntable 4 to rotate; the swinging of three synchronous gear oscillating arms 3 and the rotation engagement of three gear pairs 10 are realized through three lead pins 6 which are arranged on the synchronous turntable 4 and embedded in the lead grooves of the synchronous gear oscillating arms 3, so that the jaws 12 at the upper ends of the jaw shafts 9 are closed up; therefore, quick fastening of the aluminum alloy wheel is completed. The high-speed chunk is quick in mounting, accurate in centering, reliable in locking, and universal.

Owner:秦皇岛燕大现代集成制造技术开发有限公司

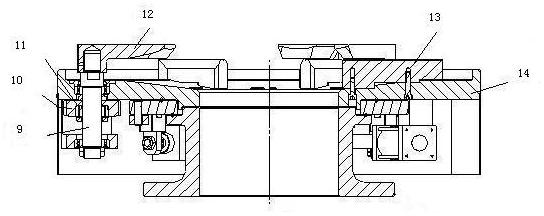

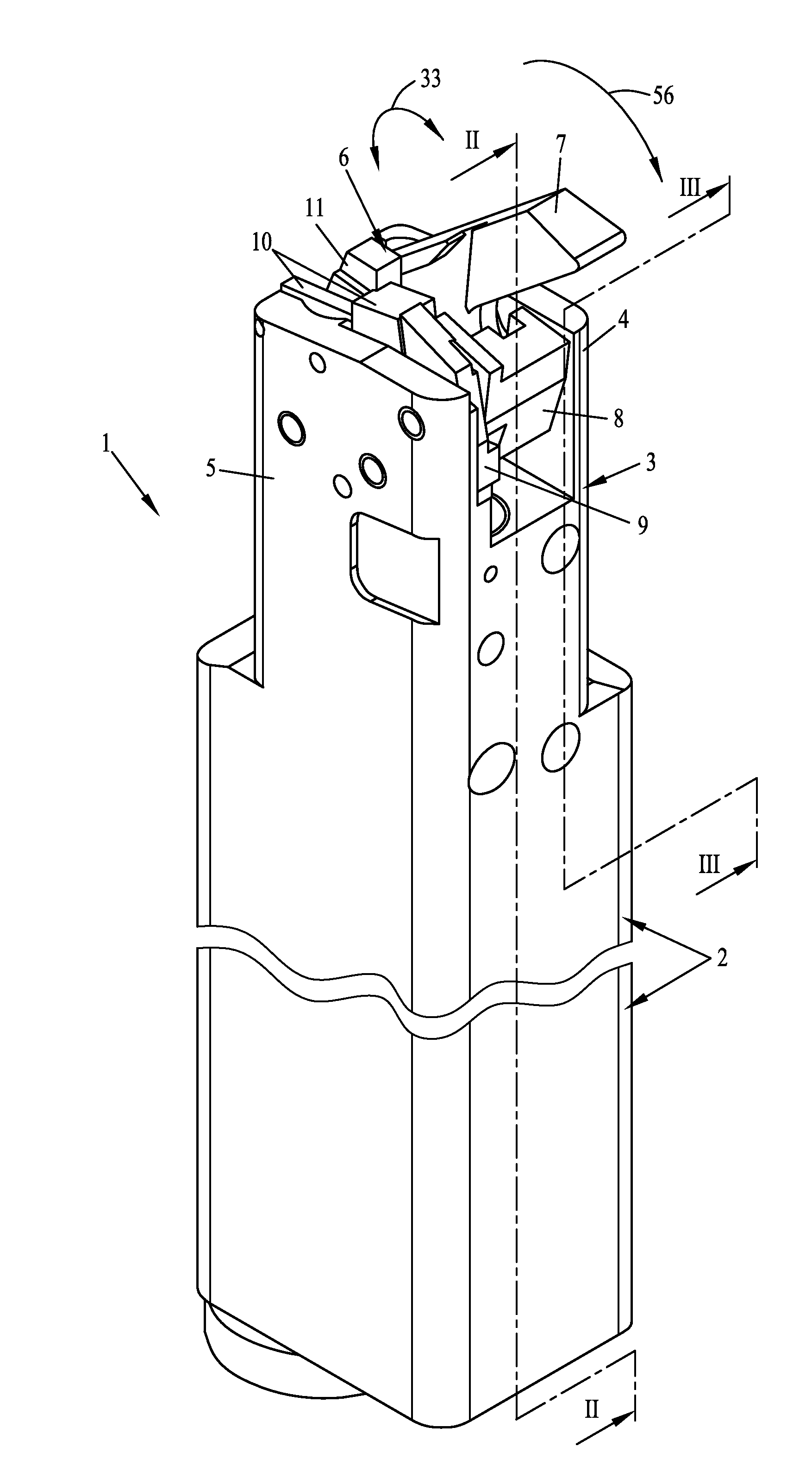

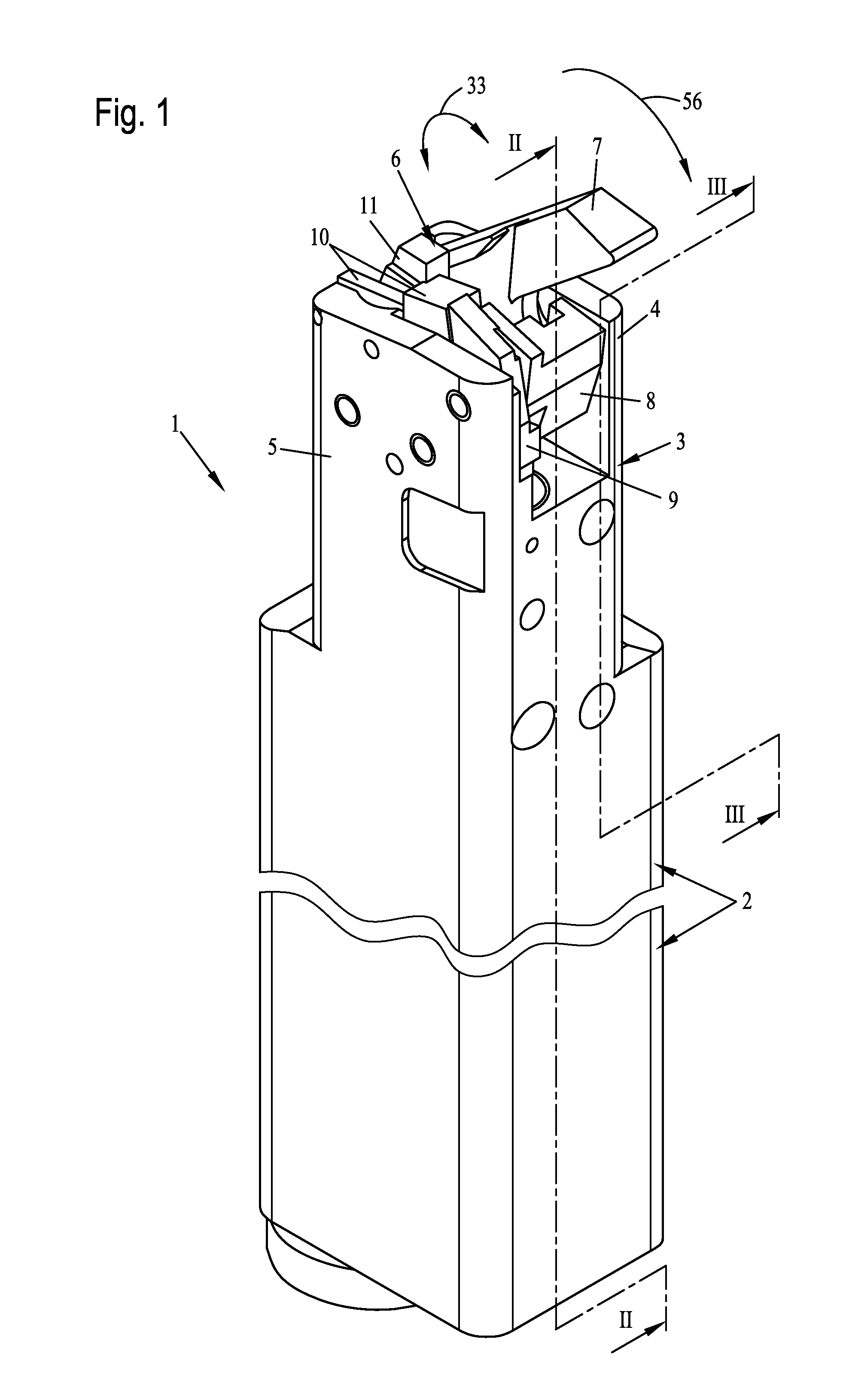

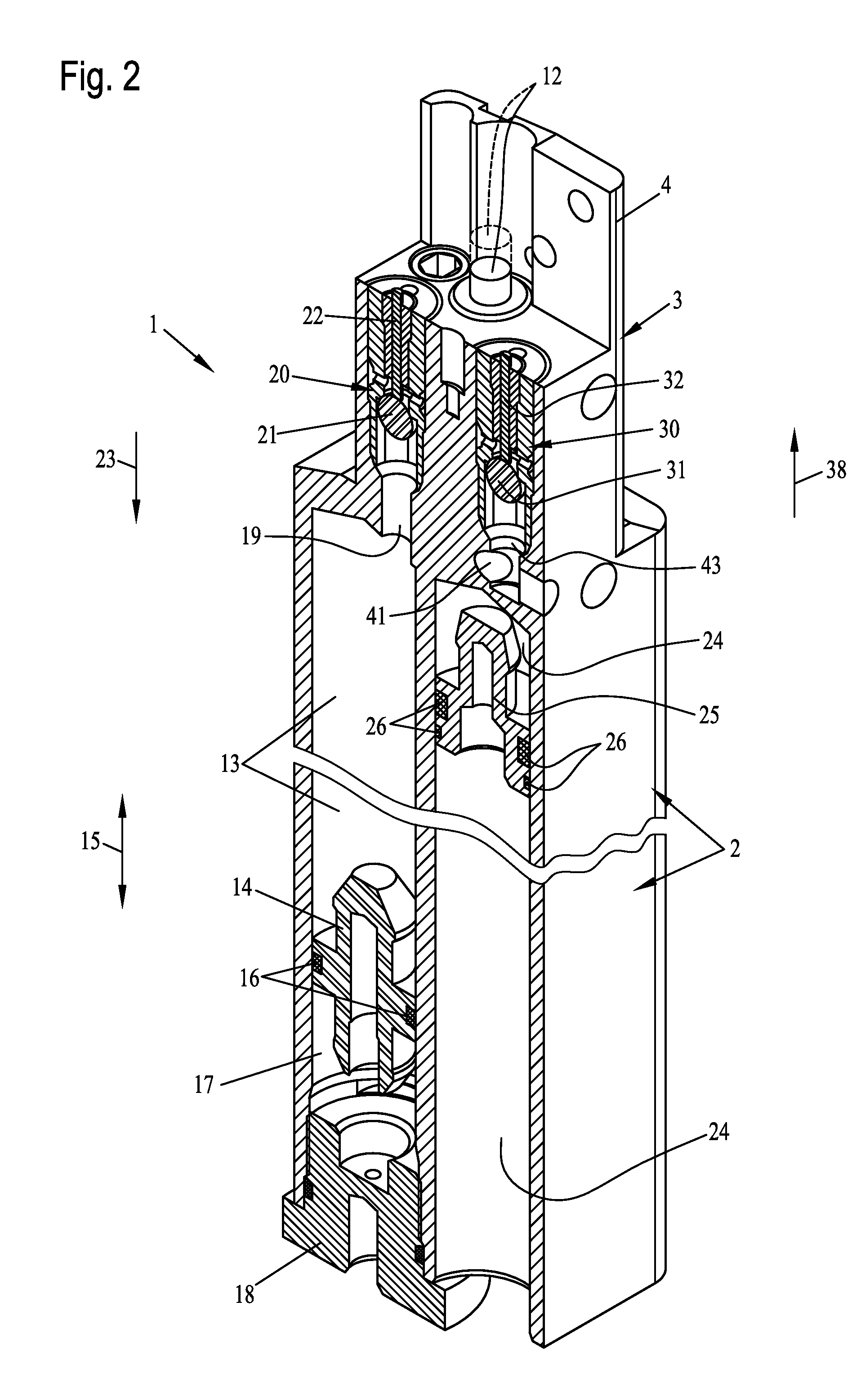

Recoil system for firearms

ActiveUS20110275036A1The equipment is reliableHigh simulationTraining adaptationEngineeringGas chamber

A device (1) simulates the recoil of a firearm and has a breechblock (60) with a knockover slide (63). To avoid freezing up and outward emissions, a control mechanism controls a hydraulic working piston in working connection with the breechblock (60). A valve pressure lever (11) is deflected by movement of the knockover slide (63) to open a pressure valve (20), as a result of which fluid is fed to the working piston. The valve (20) has a movable separating piston (14) separating a hydraulic chamber (13) tightly from a gas chamber (17) filled with compressed gas. The separating piston (14) is acted on by the compressed gas. The working piston at the end of an adjusting movement brings about the closing of the valve (20) and opening of a discharge valve. The hydraulic fluid is guided, with open discharge valve, from the working piston into a return chamber (24).

Owner:RAUSER WILLI

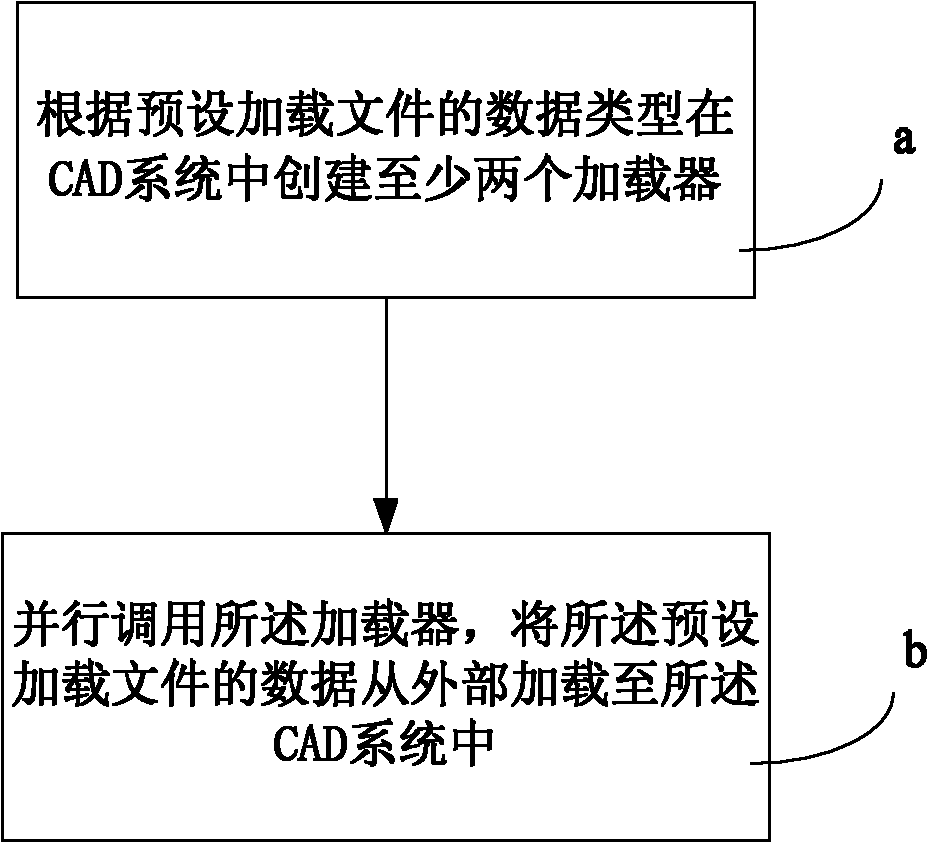

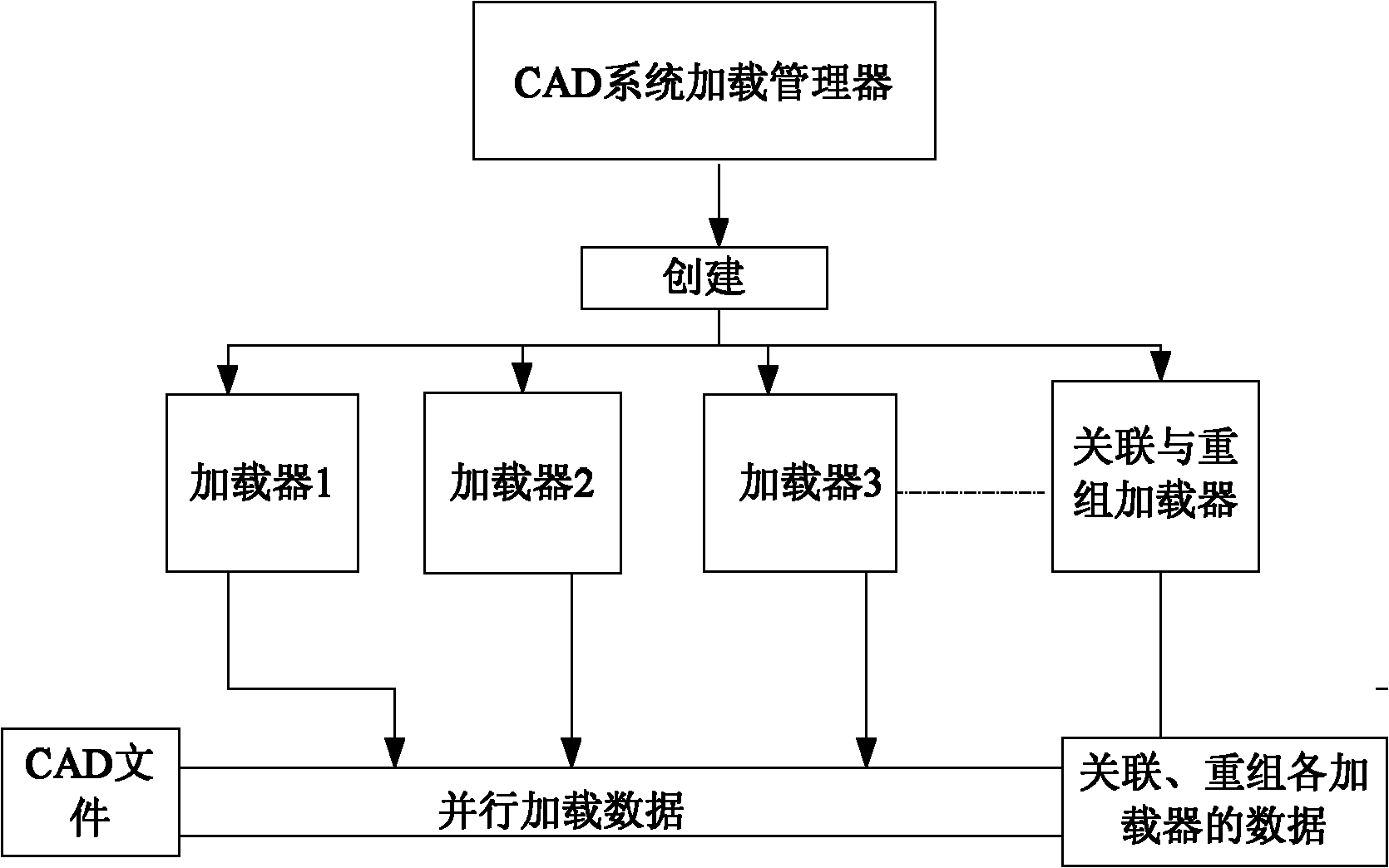

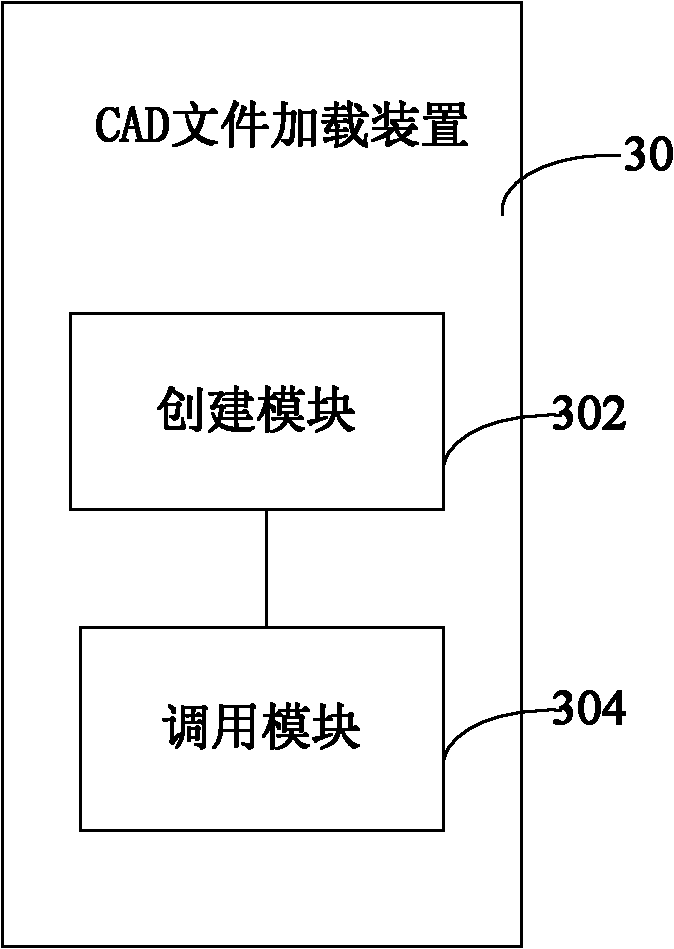

CAD (Computer Aided Design) document loading method and device

InactiveCN102156705ASolve the long loading timeImprove overall operational efficiencySpecial data processing applicationsCad systemComputer Aided Design

The invention provides a CAD (Computer Aided Design) document loading method and device. The method comprises the following steps of: establishing at least two loaders in a CAD system according to data type of a preset document to be loaded; and concurrently calling the loaders and loading the data of the preset document to be loaded from exterior to the CAD system. The CAD document loading device comprises an establishing module and a calling module, wherein the establishing module is used for establishing at least two loaders in the CAD system according to the data type of the preset document to be loaded; and the calling module is used for concurrently calling the loaders and loading the data of the preset document to be loaded from the exterior to the CAD system. Compared with the prior art, the method and the device have the advantages of increasing loading speed of the CAD document and overall efficiency of CAD software.

Owner:CAXA TECH

Novel traffic tool

InactiveCN101143550AReduce frictional resistanceReduce energy lossRail and road vehiclesLow noiseDrive wheel

The present invention relates to a novel transportation tool consisting of a novel motor vehicle and a rail for the motor vehicle. The present invention is characterized in that the novel motor vehicle at least consists of a vehicle body, an engine, a power transmission system, a brake device, bearing wheels, driving wheels, and a wheel height regulating device for controlling relative lifting of the bearing wheels and the driving wheels; the rail consists of a bearing wheel rail and a driving wheel rail or the road surface. The friction resistance of the novel transportation tool of the present invention and the rail or road surface the tool runs on is greatly reduced, and the present invention has the advantages of energy saving, high speed, easiness in driving, low cost, low pollution, low noise, etc.

Owner:刘全文

DPF carrier carbon loading amount test apparatus

InactiveCN105067496ASolve the long loading timeConsume less resourcesPermeability/surface area analysisGas-discharge lampCombustor

The present invention discloses a DPF carrier carbon loading amount test apparatus, which comprises an oil supply device, a burner, a DOC and DPF package carrier, a dust collector and a controller, wherein the oil supply device is connected with the burner so as to supply oil for the burner, the gas inlet end of the DOC and DPF package carrier is connected with the gas discharge end of the burner, the gas discharge end is connected with the dust collector, the DOC and DPF package carrier is provided with a plurality of sensors, and the controller forms communication connection with the burner, the dust collector and the sensors. According to the present invention, the DPF carrier carbon loading amount test apparatus has characteristics of short loading time, less resource consumption and cost savings; and the whole apparatus control is simple and practical, and the maintenance and detection operations are convenient.

Owner:KAILONG HIGH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[method and apparatus for battery testing and measuring] [method and apparatus for battery testing and measuring]](https://images-eureka.patsnap.com/patent_img/6820cd8c-11ba-4c3d-ad89-ee5a3e0380e5/US20050134282A1-20050623-D00001.png)

![[method and apparatus for battery testing and measuring] [method and apparatus for battery testing and measuring]](https://images-eureka.patsnap.com/patent_img/6820cd8c-11ba-4c3d-ad89-ee5a3e0380e5/US20050134282A1-20050623-D00002.png)

![[method and apparatus for battery testing and measuring] [method and apparatus for battery testing and measuring]](https://images-eureka.patsnap.com/patent_img/6820cd8c-11ba-4c3d-ad89-ee5a3e0380e5/US20050134282A1-20050623-D00003.png)