Turnover mechanism for installing vehicle side around external covering

A technology of flipping mechanism and outer skin, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to adapt to the production rhythm, difficulty in loading parts, and the quality of workpieces and the safety of workers cannot be effectively guaranteed. Achieve the effect of improving the quality of the loading, short loading time, and less time-consuming turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

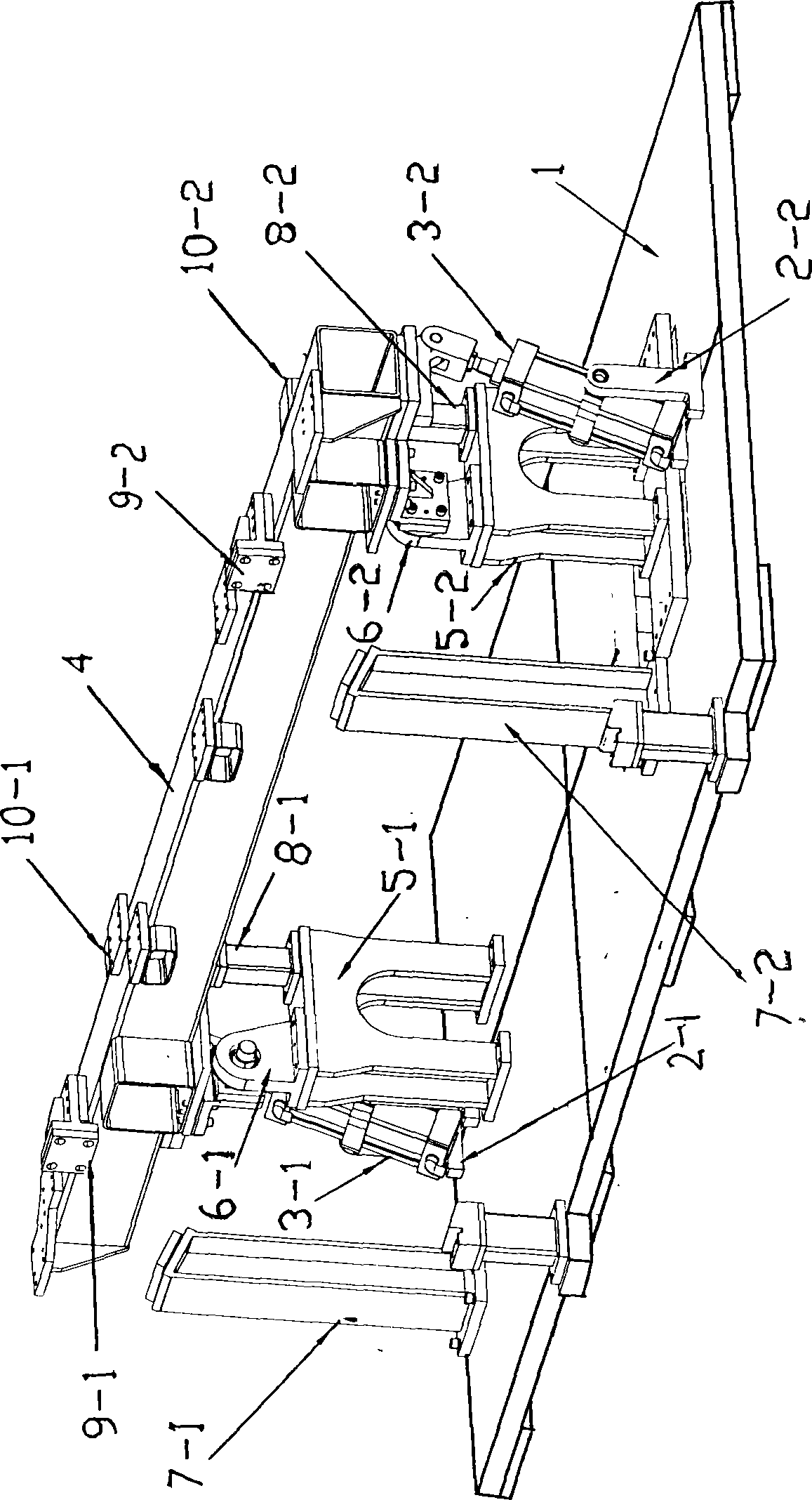

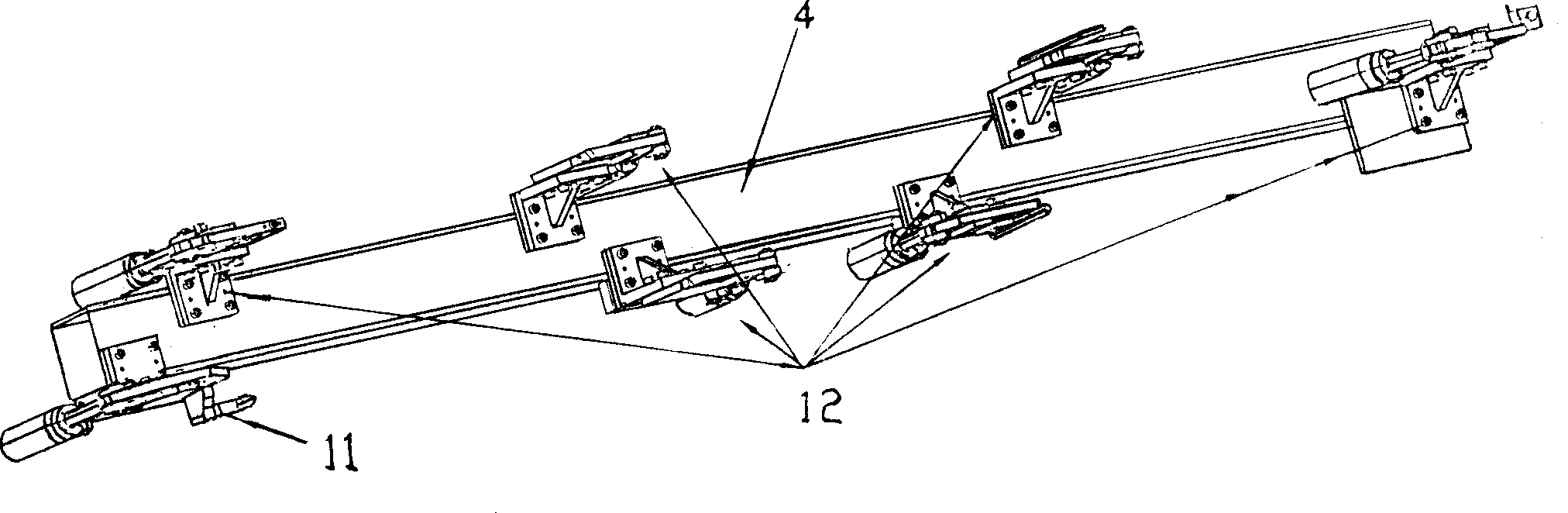

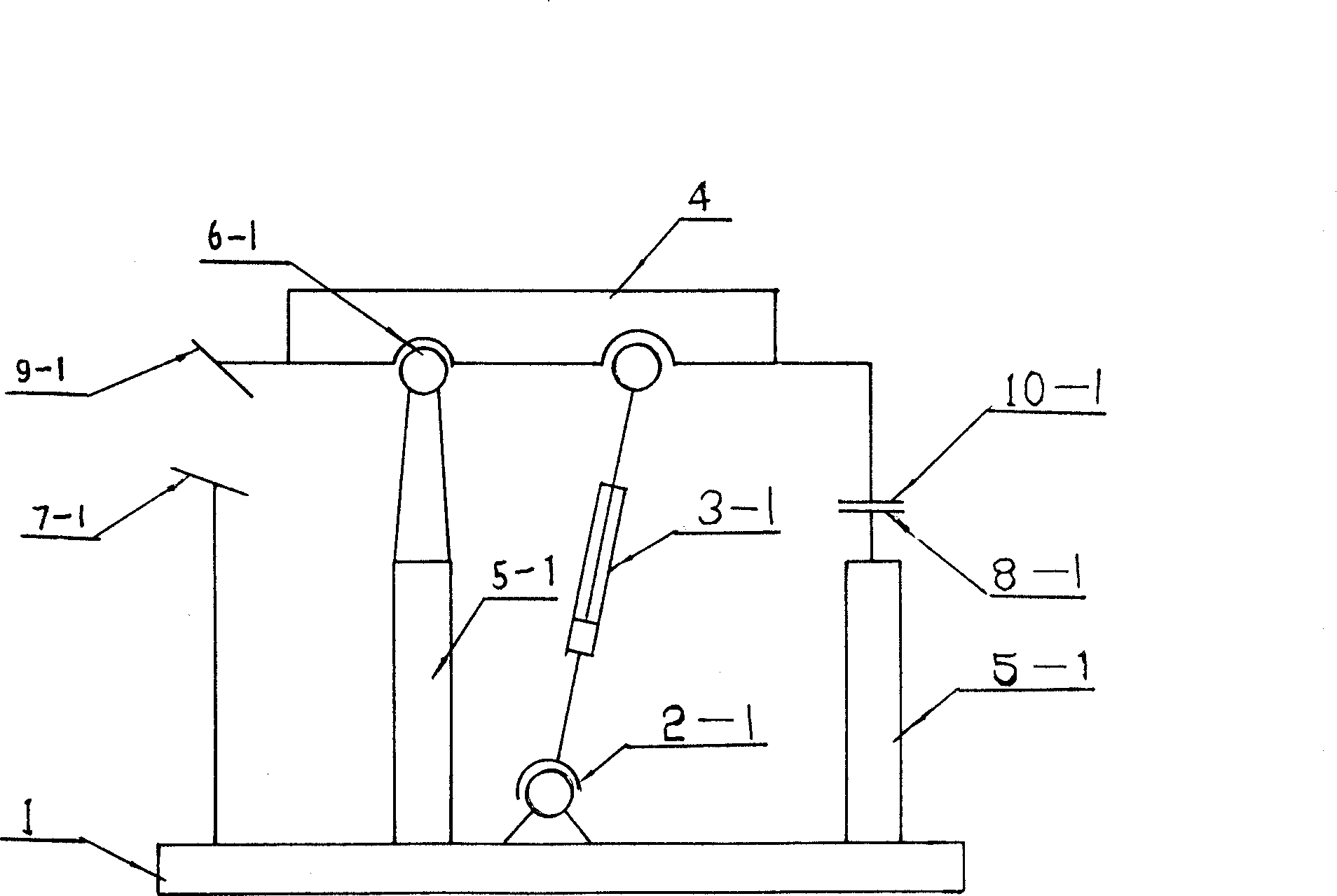

[0015] see figure 1 and figure 2 , the first body support 5-1 and the second body support 5-2 are symmetrically arranged on the base plate 1, and the first turning bearing 6-1 and the second turning bearing 6-2 are arranged on the first turning bearing 6-2 respectively. On the left side of the top of the body support and the second body support, the first low limit column 8-1 and the second low limit column 8-2 are respectively arranged on the right side of the first body support and the top of the second body support, and the The first high limit column 7-1 and the second high limit column 7-2 are respectively arranged on the base plate 1 and are positioned at the left side of the first body support and the second body support, and the first cylinder block 2-1 and the second cylinder seat 2-2 are respectively arranged on the base plate 1, and are respectively locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com