Self-propelled bagged cargo stacking and unstacking track loader

A self-propelled, truck-loading machine technology, applied in the direction of lifting devices, etc., can solve problems such as high labor intensity, long loading hours, and small handling workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

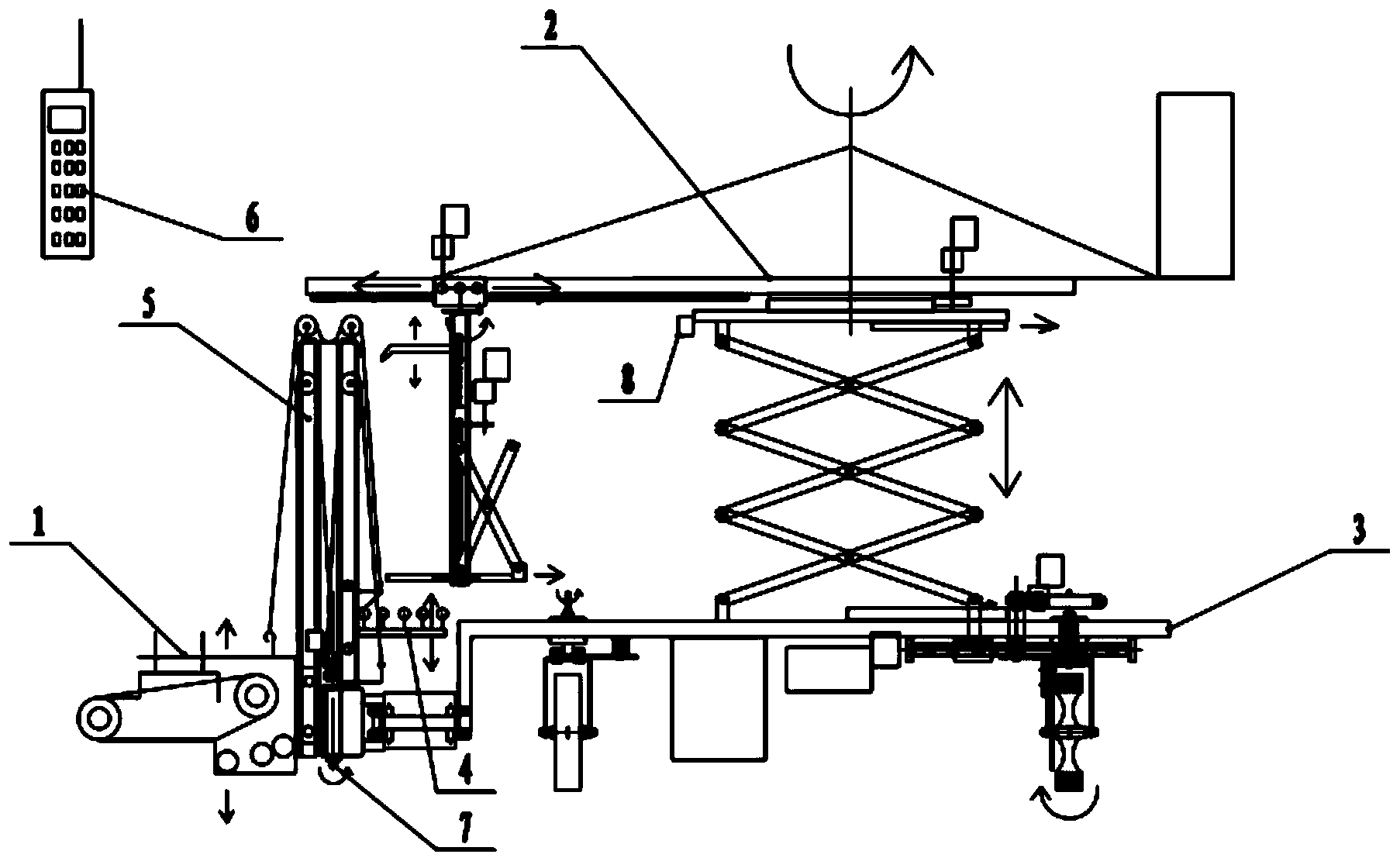

[0023] like figure 1 As shown, the self-propelled bagged goods palletizing, unstacking and loading machine in this embodiment includes a remote controller 6, an encoder 7 and an angle sensor 8, wherein: it also includes a picking device 1, a cargo lifting device 2, Walking mechanism 3, stacking device 4 and rotary gantry 5, pick-up device 1 is installed in the lower part of the pick-up gantry in front of the rotary gantry 5 and can move up and down in the pick-up gantry, stacking device 4 is set The lower part of the palletizing gantry behind the rotary gantry 5 can move up and down in the palletizing gantry. The rotary gantry 5 is connected to the front end of the running mechanism 3 through the rotating shaft, and the cargo hoisting device 2 is installed on the running mechanism 3. Above, the encoder 7 is located at the bottom of the rotating shaft of the rotary gantry 5, and the angle sensor 8 is located on the slewing mechanism of the cargo hoisting device 2.

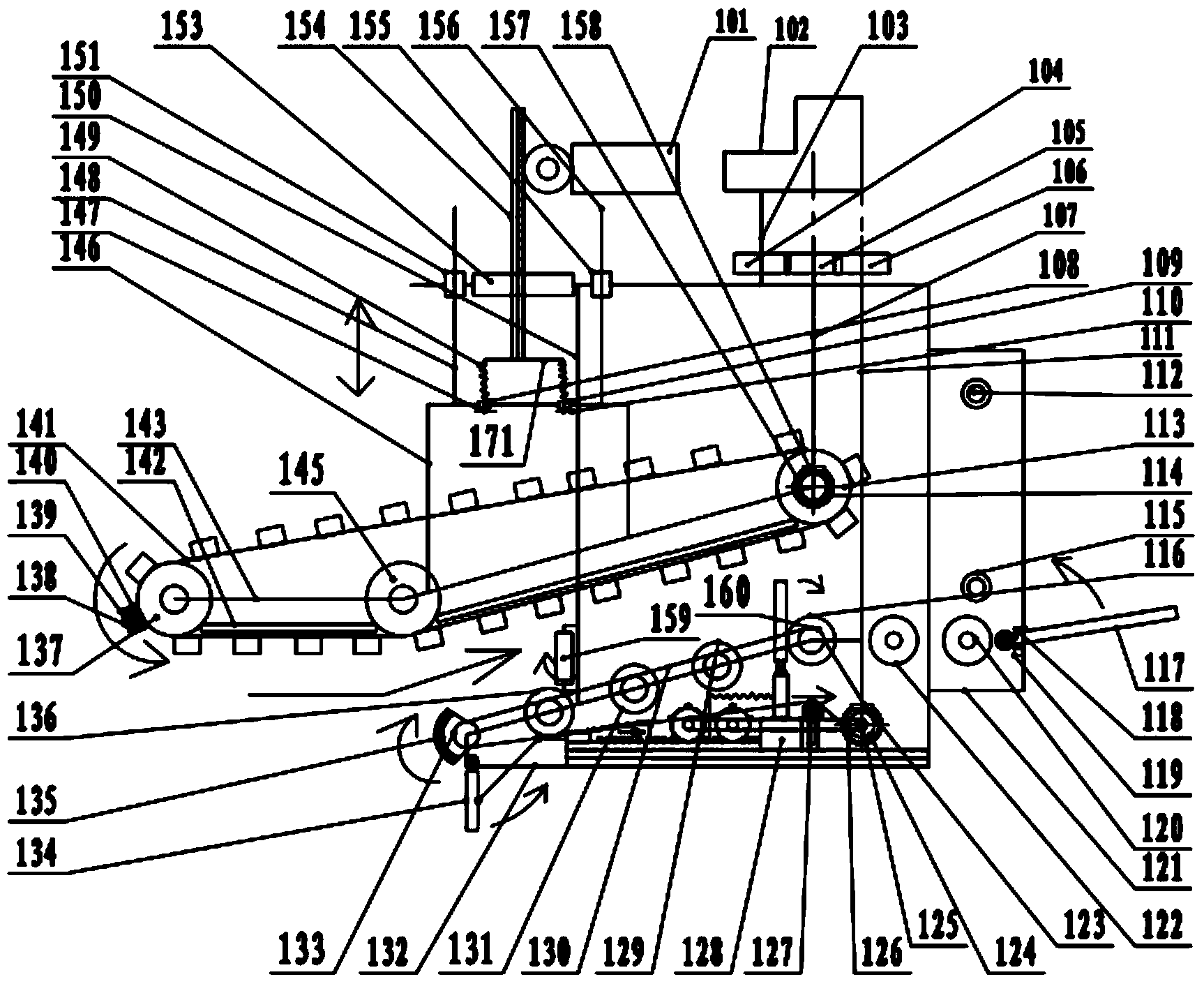

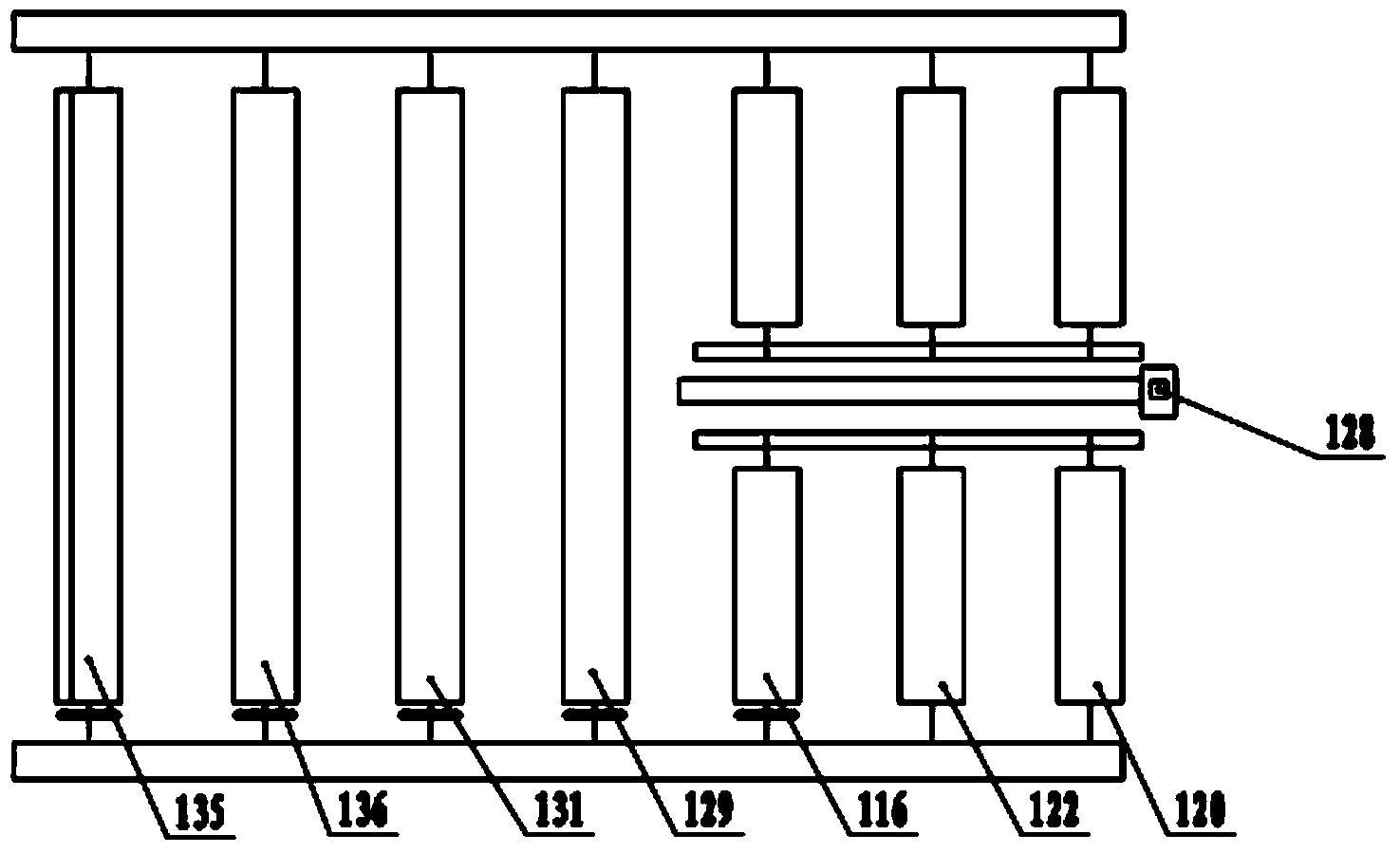

[0024] lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com