Method and device for forming half-mold of metal flow field plate of mini-type fuel cell in laser shock mode

A micro fuel cell, laser shock technology, applied in battery electrodes, laser welding equipment, metal processing equipment, etc., can solve the problems of low flow channel processing efficiency, difficult to control process parameters, and inability to exceed the strain rate, and achieve laser focusing. and regional selectivity, the method is simple and practical, and the effect of ensuring sustainability and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

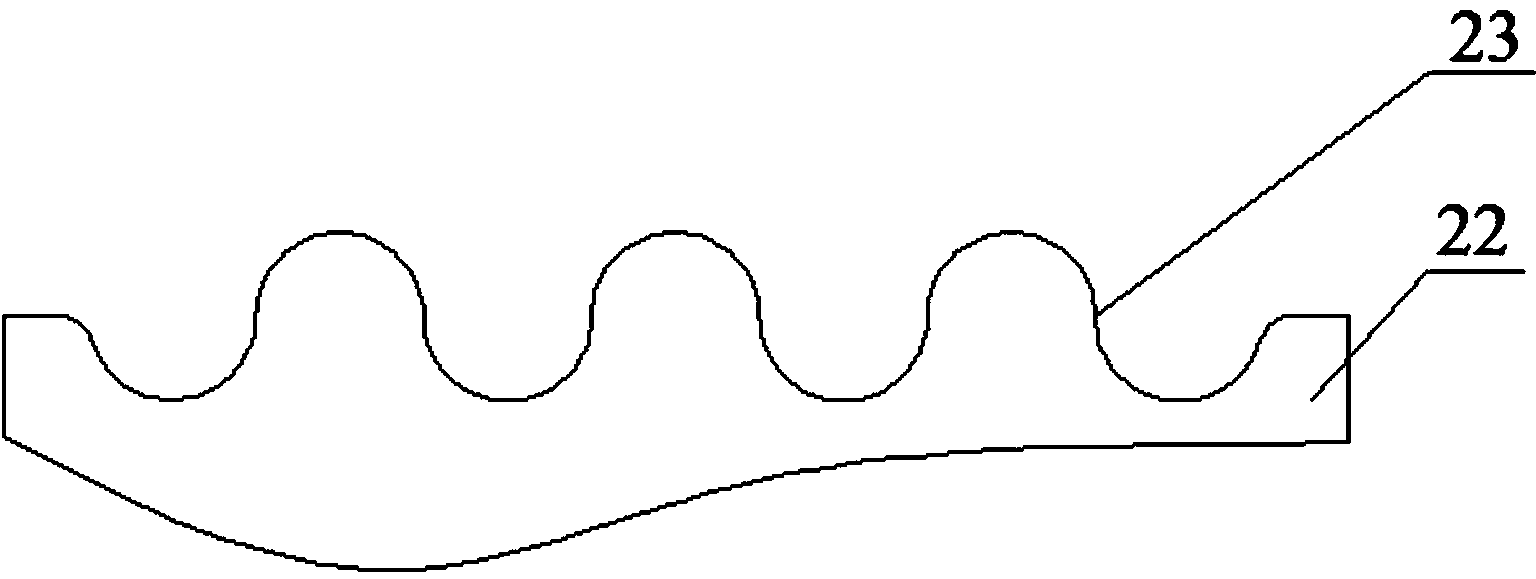

[0040] The flow channel of the target metal flow field plate 28 is a serpentine flow channel 30 with a semicircular cross section.

[0041] First, according to the pre-designed cross-sectional shape of the flow channel of the metal flow field plate 28, the template 22 is processed by LIGA; a semicircular track with the same shape and size as the serpentine flow channel 30 on the metal flow field plate 28 is processed on the template 22 23, such as figure 2 shown.

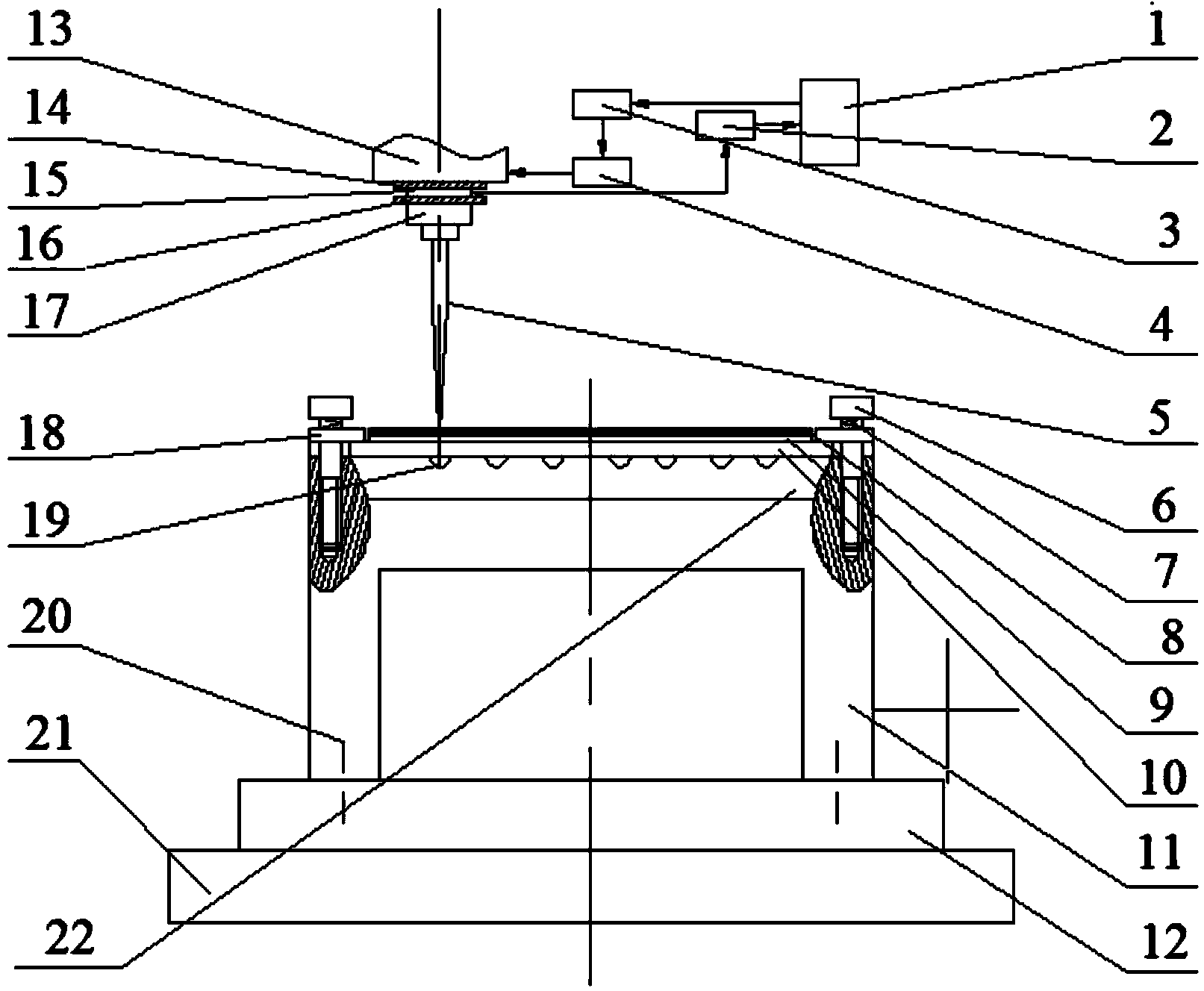

[0042] Secondly, stainless steel with a thickness of 1.2 cm×1.2 cm and a thickness of 100 μm is selected as the base material 10 for manufacturing the metal flow field plate 28 . The workbench 12 for adjustable positioning is placed on the base 21; the support seat 11 is fixed on the workbench 12 for adjustable positioning with connecting screws 20, and the template 22, the base material 10, the constraining layer 9, and the energy absorbing layer 8 are Place it on the supporting base 11 in turn from bottom to to...

Embodiment 2

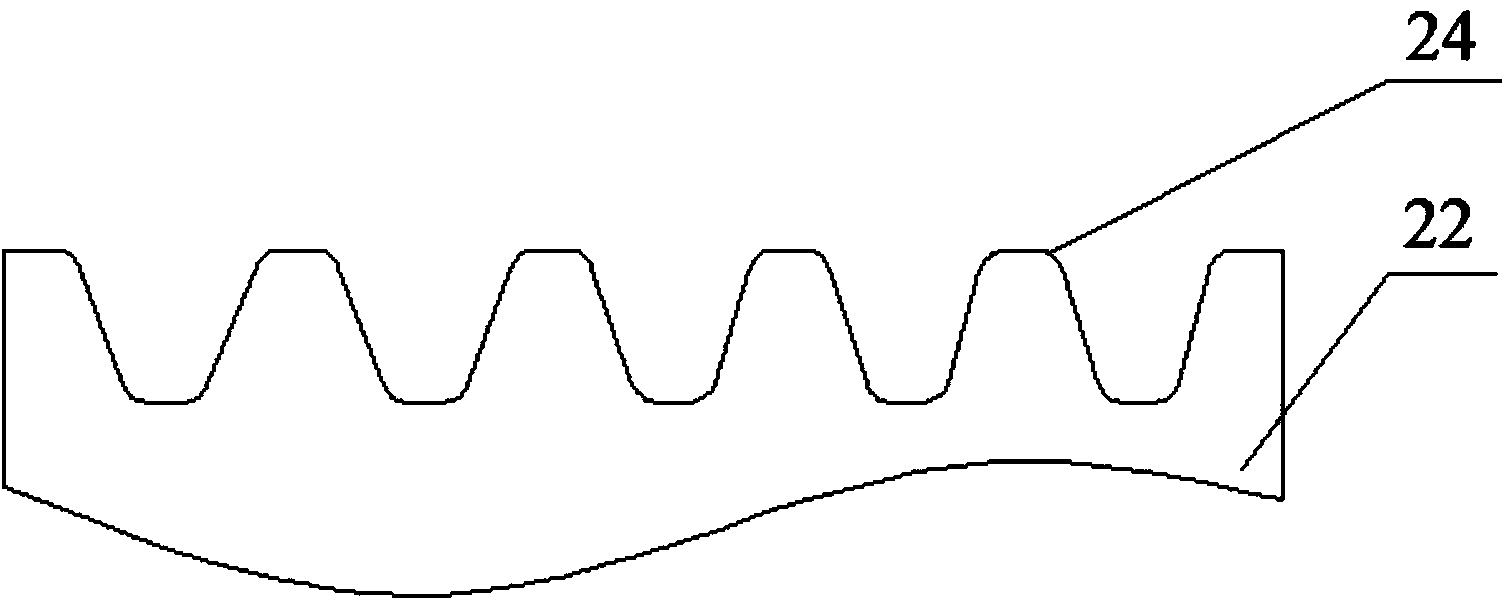

[0045] The flow channel of the target metal flow field plate 28 is a serpentine flow channel 30 , and the cross section of the flow channel is trapezoidal.

[0046] First, according to the pre-designed cross-sectional shape of the flow channel of the metal flow field plate 28, the template 22 is processed by etching; ,Such as image 3 shown. Stainless steel with a thickness of 1.2 cm×1.2 cm and a thickness of 100 μm is selected as the base material 10 for manufacturing the metal flow field plate 28 . The processing process is the same as that of Example 1, and finally a metal flow field plate 28 with a serpentine flow channel 30 and a trapezoidal cross section is obtained.

[0047] It should be noted that the base material 10 can also be a plate with a thickness in the range of 40-1200 μm and made of stainless steel, titanium alloy, or aluminum alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com