Method and device for improving laser shock forming property of metal plate material

A metal sheet, laser shock technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve problems such as easy to break, achieve the effect of low manufacturing cost, flexible processing, and improve reasonable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

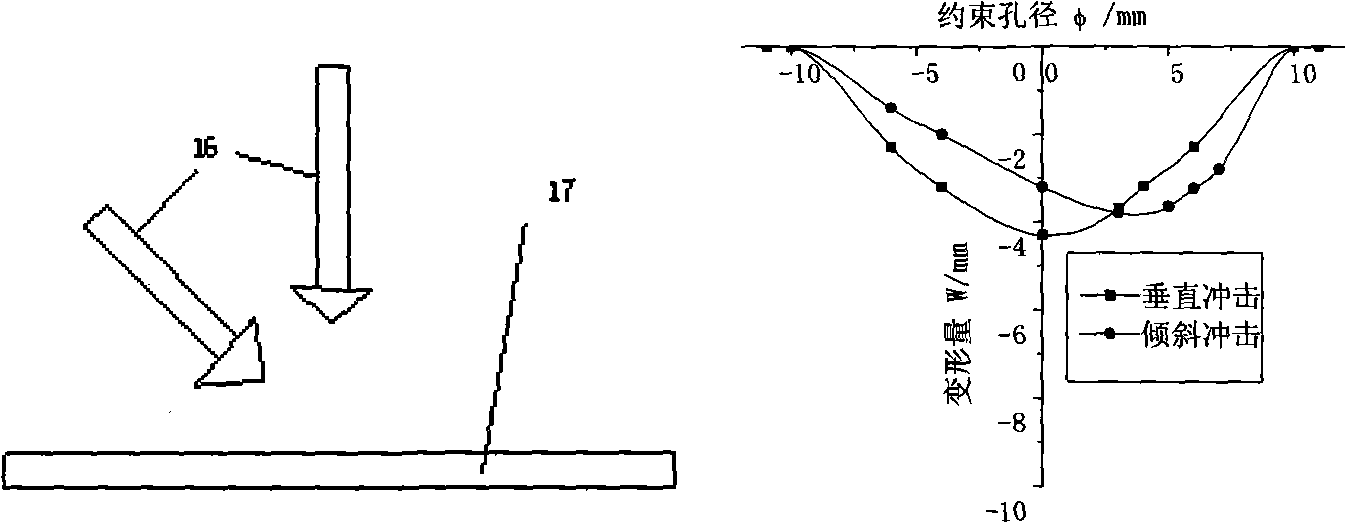

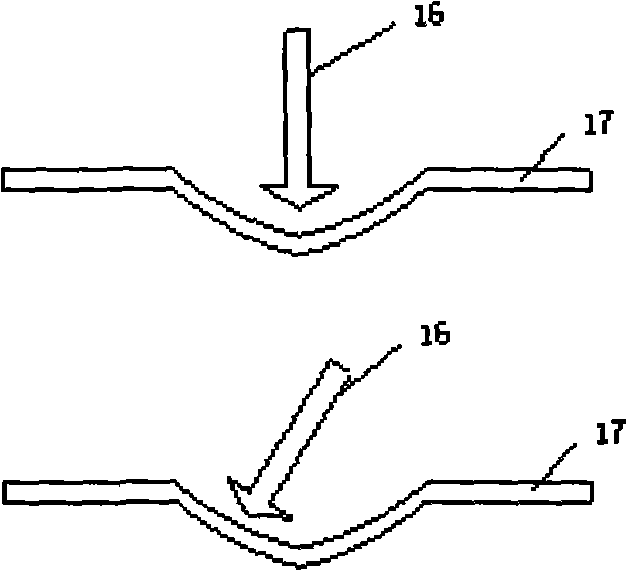

[0028] figure 2 Shown are the schematic diagrams when the laser is vertically and obliquely incident and the cross-sectional view when microcracks are generated after the impact of the sheet. With laser energy of 18J, spot diameter of 8mm, die aperture of 20mm, laser incident direction 16 was adjusted, and the size of 40mm×40mm×0.3mm aluminum alloy sample 17 was subjected to laser vertical impact and oblique impact respectively to generate microcracks. Through the measurement, it can be known that the forming limit depth of the sheet metal during laser vertical impact and oblique impact is 4.31mm and 3.75mm respectively, which means that the sheet metal can obtain a greater forming limit depth under the laser vertical impact. Therefore, in the process of laser impacting the sheet, the incident direction of the laser is always kept consistent with the normal direction in the area to be impacted, which can improve the forming performance of the sheet.

[0029] image 3 Shown ...

example 2

[0032] Figure 5Shown is the impact distribution diagram of two rows of light spots for laser impacting a 17 "V"-shaped piece of sheet material. Die 12 adopts " V " shape die. The forming of the metal laser shock "V" shape involves multi-point forming and curved surface forming. If the direction is not changed during the impact process, the forming effect of the sheet will be seriously affected. That is to say, if the energy is small, the deformation may be small, and the energy is large, which may cause the sheet to break. When the sheet material is impacted at multiple points, as the "V" shape rushes to the "n" point 20, to the "n+1" point 21, the sheet material has been deformed in the last stage. At this time, if it acts directly on the sheet, it must not be along the normal direction in the impact area, which is not conducive to the impact forming of the "V" shape. This method can be used at any impact point when the sheet is subjected to multi-point impact. , the spec...

example 3

[0034] Such as Figure 8 As shown, when the curved surface part 22 is impacted, for different impact areas of the curved surface part, the normal direction 18 of different impact areas is obtained through the ATOS scanner. The incident direction of the beam is consistent with the normal direction of the curved sheet, which improves the formability of the curved sheet. In the forming process, on the one hand, it can prevent the sheet from breaking in advance; on the other hand, it can reduce the number of impacts in the precise forming process of the sheet, and make full use of the force effect of the laser shock wave, so that the sheet is formed at a lower impact frequency. In less cases, better results can be obtained and costs can be reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| Beam diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com