Auxiliary heating micro-device bending forming method and device based on laser

A bending forming, laser-assisted technology, applied in the direction of microstructure devices, chemical instruments and methods, optical components, etc., can solve the problems of small application range, uneven material flow, complex mold structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

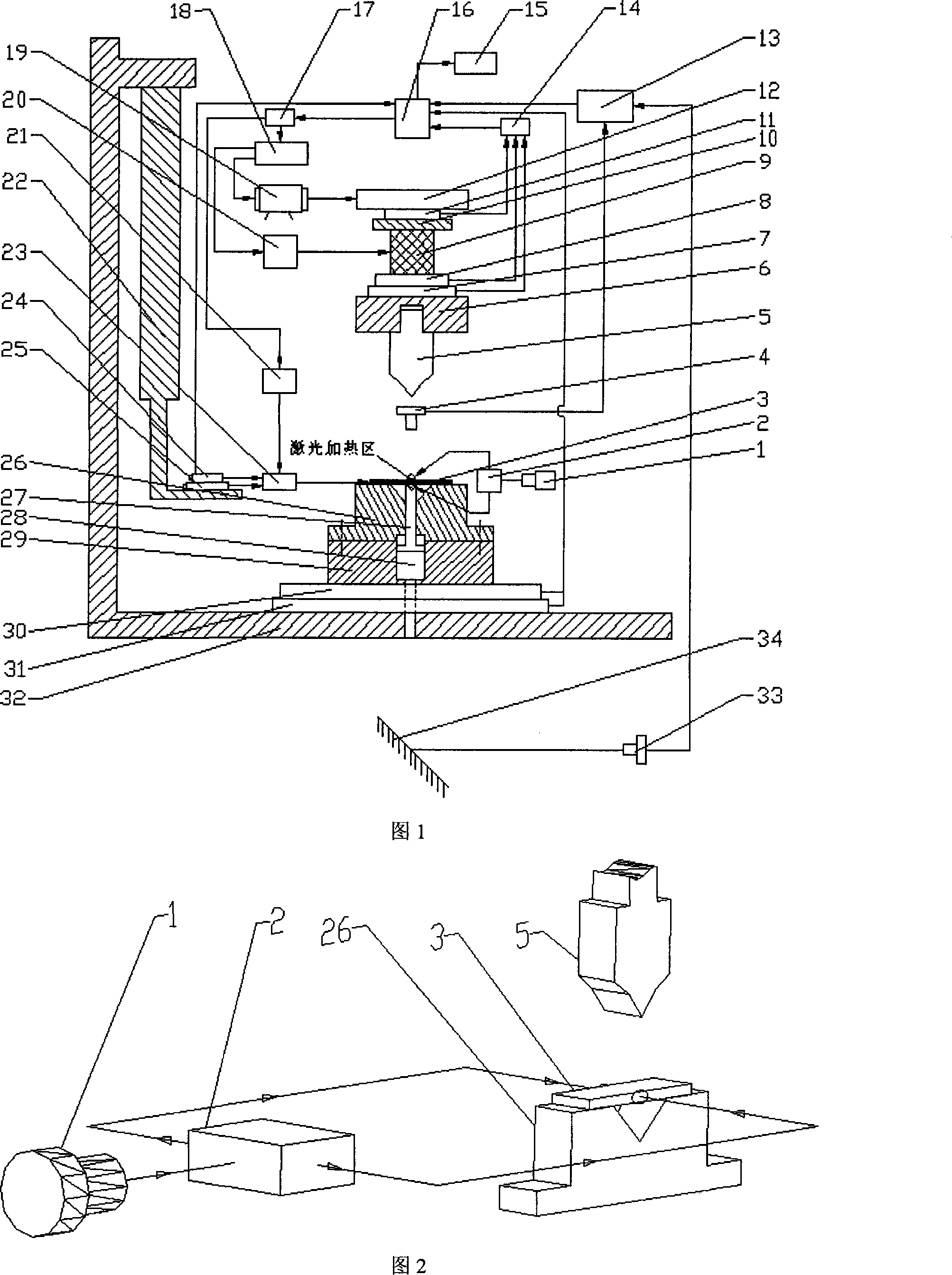

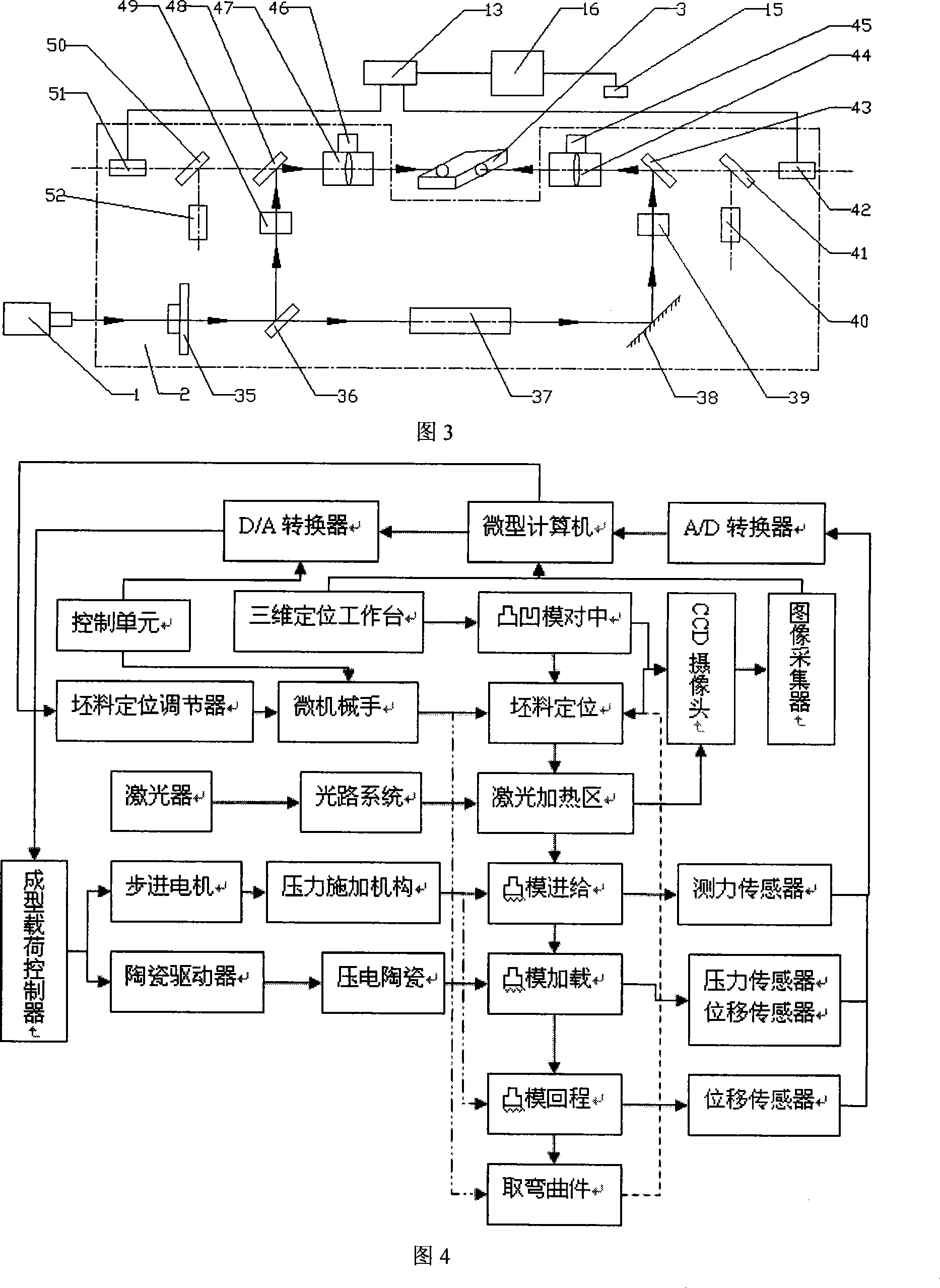

[0035] Taking the micro-bending forming of V-shaped parts as an example, the details and working conditions of the specific device proposed by the present invention will be described in detail in conjunction with Fig. 1 , Fig. 2 , Fig. 3 and Fig. 4 .

[0036] The micro-device bending forming device based on laser-assisted heating proposed by the present invention includes a mounting platform, a punch and a die centering component, a micro-bending component, a feeding mechanism, a loading mechanism, a workpiece positioning component, a laser heating system and a control system eight parts. The installation platform is composed of a support frame 22 installed under the left arm of the base 32; the centering assembly of the punch and die is composed of a mirror 34, a CCDII 33, a three-dimensional coarse adjustment positioning worktable 31, and a three-dimensional fine adjustment positioning workbench 30 to realize the punch 5 and the centering of the die 26; the micro-bending for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com